Abstract

The repair of tendon to bone junction (TBJ) remains a tremendous challenge in tissue engineering due to the complicated structure, components, mechanical properties, and cell types. In order to reconstruct the tissue and restore its functionality, biomedical scaffolds with hierarchical and gradient structures have been fabricated by various strategies. In recent decades, electrospinning has become one of the most popular methods in fabricating TBJ scaffolds due to easy fabrication, high porosity, and ECM-like nano-scale structure. However, mechanical properties are the pain point of electrospun biomedical scaffolds. Traditional textile technology can be exploited to compensate for this weakness, which will be deeply discussed here. This review will start with a brief introduction to the structure and function of the native TBJ tissue and a short overview of electrospinning technology. Then, different electrospun biomedical scaffolds for TBJ repair will be summarized and compared. Furthermore, some advanced technologies and modification methods in fabricating functionalized electrospun TBJ scaffolds are discussed. In the end, current challenges and solutions are being proposed, which would provide instruction for the research of electrospun textile TBJ scaffolds.

Graphical Abstract

Similar content being viewed by others

References

Lim WL, Liau LL, Ng MH, Chowdhury SR, Law JX. Current progress in tendon and ligament tissue engineering. Tissue Eng Regen Med 2019;16:549.

Stannard J, Fortington L. Musculoskeletal injury in military special operations forces: a systematic review. BMJ Mil Health 2021;167:255.

Derwin KA, Galatz LM, Ratcliffe A, Thomopoulos S. Enthesis repair: challenges and opportunities for effective tendon-to-bone healing. J Bone Joint Surg Am 2018;100:e109.

McCarron JA, Derwin KA, Bey MJ, Polster JM, Schils JP, Ricchetti ET, Iannotti JP. Failure with continuity in rotator cuff repair “healing.” Am J Sports Med 2013;41:134.

Thomopoulos S. The role of mechanobiology in the attachment of tendon to bone. IBMS BoneKey 2011;8:271.

Agarwal S, Wendorff JH, Greiner A. Use of electrospinning technique for biomedical applications. Polymer 2008;49:5603.

Huang Y, Du Z, Li K, Jing W, Wei P, Zhao B, Yu Y, Cai Q, Yang X. ROS-scavenging electroactive polyphosphazene-based core-shell nanofibers for bone regeneration. Adv Fiber Mater 2022;4:894.

Xue Y, Kim HJ, Lee J, Liu Y, Hoffman T, Chen Y, Zhou X, Sun W, Zhang S, Cho HJ, Lee J, Kang H, Ryu W, Lee CM, Ahadian S, Dokmeci MR, Lei B, Lee K, Khademhosseini A. Co-electrospun silk fibroin and gelatin methacryloyl sheet seeded with mesenchymal stem cells for tendon regeneration. Small 2022;18:e2107714.

Yu C, Wang T, Diao H, Liu N, Zhang Y, Jiang H, Zhao P, Shan Z, Sun Z, Wu T, Mo X, Yu T. Photothermal-triggered structural change of nanofiber scaffold integrating with graded mineralization to promote tendon-bone healing. Adv Fiber Mater 2022;2022:5.

Cai J, Wang J, Ye K, Li D, Ai C, Sheng D, Jin W, Liu X, Zhi Y, Jiang J, Chen J, Mo X, Chen S. Dual-layer aligned-random nanofibrous scaffolds for improving gradient microstructure of tendon-to-bone healing in a rabbit extra-articular model. Int J Nanomed 2018;13:3481.

Li X, Xie J, Lipner J, Yuan X, Thomopoulos S, Xia Y. Nanofiber scaffolds with gradations in mineral content for mimicking the tendon-to-bone insertion site. Nano Lett 2009;9:7.

Chen Y, Dong X, Shafiq M, Myles G, Radacsi N, Mo X. Recent advancements on three-dimensional electrospun nanofiber scaffolds for tissue engineering. Adv Fiber Mater 2022;2022:55.

Jiao Y, Li C, Liu L, Wang F, Liu X, Mao J, Wang L. Construction and application of textile-based tissue engineering scaffolds: a review. Biomater Sci 2020;8:3574.

Saveh-Shemshaki N, Nair LS, Laurencin CT. Nanofiber-based matrices for rotator cuff regenerative engineering. Acta Biomater 2019;94:64.

Stace ET, Nagra NS, Tiberwel S, Khan W, Carr AJ. The Use of Electrospun Scaffolds in Musculoskeletal Tissue Engineering: A Focus on Tendon and the Rotator Cuff. Curr Stem Cell Res T 2018;13:619.

Font Tellado S, Balmayor ER, Van Griensven M. Strategies to engineer tendon/ligament-to-bone interface: Biomaterials, cells and growth factors. Adv Drug Deliver Rev 2015;94:126.

Lei T, Zhang T, Ju W, Chen X, Heng BC, Shen W, Yin Z. Biomimetic strategies for tendon/ligament-to-bone interface regeneration. Bioact Mater 2021;6:2491.

Wang D, Zhang X, Huang S, Liu Y, Fu BS, Mak KK, Blocki AM, Yung PS, Tuan RS, Ker DFE. Engineering multi-tissue units for regenerative medicine: bone-tendon-muscle units of the rotator cuff. Biomaterials 2021;272:120789.

Baldino L, Maffulli N, Reverchon E. Regenerative enginnering of musculoskeletal tissue and interfaces. London: Woodhead Publishing; 2015. p. 345–61.

Baldino L, Cardea S, Maffulli N, Reverchon E. Regeneration techniques for bone-to-tendon and muscle-to-tendon interfaces reconstruction. Brit Med Bull 2016;117:25.

Barnes CP, Sell SA, Boland ED, Simpson DG, Bowlin GL. Nanofiber technology: designing the next generation of tissue engineering scaffolds. Adv Drug Deliver Rev 2007;59:1413.

Peng S, Jin G, Li L, Li K, Srinivasan M, Ramakrishna S, Chen J. Multi-functional electrospun nanofibres for advances in tissue regeneration, energy conversion & storage, and water treatment. Chem Soc Rev 2016;45:1225.

Jiang C, Wang K, Liu Y, Zhang C, Wang B. Application of textile technology in tissue engineering: a review. Acta Biomater 2021;128:60.

Furtado M, Chen L, Chen Z, Chen A, Cui W. Development of fish collagen in tissue regeneration and drug delivery. Eng Regener 2022;3:217.

Li C, Cui W. 3D bioprinting of cell-laden constructs for regenerative medicine. Eng Regener 2021;2:195.

Liu C, Xu X, Cui W, Zhang H. Metal-organic framework (MOF)-based biomaterials in bone tissue engineering. Eng Regener 2021;2:105.

Tang Y, Chen C, Liu F, Xie S, Qu J, Li M, Li Z, Li X, Shi Q, Li S, Li X, Hu J, Lu H. Structure and ingredient-based biomimetic scaffolds combining with autologous bone marrow-derived mesenchymal stem cell sheets for bone-tendon healing. Biomaterials 2020;241:119837.

Kirillova A, Yeazel TR, Asheghali D, Petersen SR, Dort S, Gall K, Becker ML. Fabrication of biomedical Scaffolds using biodegradable polymers. Chem Rev 2021;121:11238.

Place ES, George JH, Williams CK, Stevens MM. Synthetic polymer scaffolds for tissue engineering. Chem Soc Rev 2009;38:1139.

Akbari M, Tamayol A, Bagherifard S, Serex L, Mostafalu P, Faramarzi N, Mohammadi MH, Khademhosseini A. Textile technologies and tissue engineering: a path toward organ weaving. Adv Healthc Mater 2016;5:751.

Echave MC, Domingues RMA, Gomez-Florit M, Pedraz JL, Reis RL, Orive G, Gomes ME. Biphasic hydrogels integrating mineralized and anisotropic features for interfacial tissue engineering. ACS Appl Mater Inter 2019;11:47771.

Huang K, Du J, Xu J, Wu C, Chen C, Chen S, Zhu T, Jiang J, Zhao J. Tendon-bone junction healing by injectable bioactive thermo-sensitive hydrogel based on inspiration of tendon-derived stem cells. Mater Today Chem 2022;23:100720.

Font Tellado S, Bonani W, Balmayor ER, Foehr P, Motta A, Migliaresi C, van Griensven M. Fabrication and characterization of biphasic silk fibroin scaffolds for tendon/ligament-to-bone tissue engineering. Tissue Eng PT A 2017;23:859.

Caliari SR, Weisgerber DW, Grier WK, Mahmassani Z, Boppart MD, Harley BA. Collagen scaffolds incorporating coincident gradations of instructive structural and biochemical cues for osteotendinous junction engineering. Adv Healthc Mater 2015;4:831.

Ramakrishna H, Li T, He T, Temple J, King MW, Spagnoli A. Tissue engineering a tendon-bone junction with biodegradable braided Scaffolds. Biomater Res 2019;23:11.

Li H, Fan J, Sun L, Liu X, Cheng P, Fan H. Functional regeneration of ligament-bone interface using a triphasic silk-based graft. Biomaterials 2016;106:180.

Calejo I, Costa-Almeida R, Reis RL, Gomes ME. A textile platform using continuous aligned and textured composite microfibers to engineer tendon-to-bone interface gradient Scaffolds. Adv Healthc Mater 2019;8:e1900200.

Zhu C, Pongkitwitoon S, Qiu J, Thomopoulos S, Xia Y. Design and fabrication of a hierarchically structured scaffold for tendon-to-bone repair. Adv Mater 2018;30:e1707306.

Brennan DA, Conte AA, Kanski G, Turkula S, Hu X, Kleiner MT, Beachley V. Mechanical considerations for electrospun nanofibers in tendon and ligament repair. Adv Healthc Mater 2018;7:e1701277.

Lim TK, Dorthe E, Williams A, D’Lima DD. Nanofiber Scaffolds by electrospinning for rotator cuff tissue engineering. Chonnam Med J 2021;57:13.

Xu Y, Zhang WX, Wang LN, Ming YQ, Li YL, Ni GX. Stem cell therapies in tendon-bone healing. World J Stem Cells 2021;13:753.

Kenry LCT. Nanofiber technology: current status and emerging developments. Prog Polym Sci 2017;70:1.

Shi S, Si Y, Han Y, Wu T, Iqbal MI, Fei B, Li RKY, Hu J, Qu J. Recent progress in protective membranes fabricated via electrospinning: advanced materials, biomimetic structures, and functional applications. Adv Mater 2022;34:e2107938.

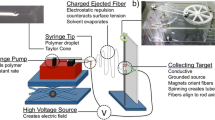

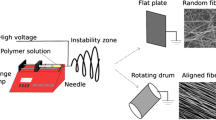

Xue J, Wu T, Dai Y, Xia Y. Electrospinning and electrospun nanofibers: methods, materials, and applications. Chem Rev 2019;119:5298.

Park J-S. Electrospinning and its applications. Adv Nat Sci-Nanosci 2011;1:043002.

Zhang X, Xie L, Wang X, Shao Z, Kong B. Electrospinning super-assembly of ultrathin fibers from single- to multi-Taylor cone sites. Appl Mater Today 2022;26:101272.

SalehHudin HS, Mohamad EN, Mahadi WNL, Muhammad AA. Multiple-jet electrospinning methods for nanofiber processing: a review. Mater Manuf Process 2017;33:479.

Li Y, Zhu J, Cheng H, Li G, Cho H, Jiang M, Gao Q, Zhang X. Developments of advanced electrospinning techniques: a critical review. Adv Mater Technol 2021;6:2100410.

Huang C, Thomas NL. Fabrication of porous fibers via electrospinning: strategies and applications. Polym Rev 2019;60:595.

Hou L, Wang N, Wu J, Cui Z, Jiang L, Zhao Y. Bioinspired superwettability electrospun micro/nanofibers and their applications. Adv Funct Mater 2018;28:1801114.

Wen X, Xiong J, Lei S, Wang L, Qin X. Diameter refinement of electrospun nanofibers: from mechanism, strategies to applications. Adv Fiber Mater 2021;4:145.

Bhardwaj N, Kundu SC. Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv 2010;28:325.

Kchaou M, Alquraish M, Abuhasel K, Abdullah A, Ali AA. Electrospun nanofibrous Scaffolds: review of current progress in the properties and manufacturing process, and possible applications for COVID-19. Polymers (Basel) 2021;2021:13.

Ogueri KS, Laurencin CT. Nanofiber technology for regenerative engineering. ACS Nano 2020;14:9347.

Nie G, Zhang Z, Wang T, Wang C, Kou Z. Electrospun one-dimensional electrocatalysts for oxygen reduction reaction: insights into structure-activity relationship. ACS Appl Mater Inter 2021;13:37961.

Yoon J, Yang HS, Lee BS, Yu WR. Recent progress in coaxial electrospinning: new parameters, various structures, and wide applications. Adv Mater 2018;30:e1704765.

Bi F, Dong X, Wang J, Liu G. Flexible Janus nanofiber to acquire tuned and enhanced simultaneous magnetism-luminescence bifunctionality. J Mater Sci 2014;49:7244.

Zhan L, Deng J, Ke Q, Li X, Ouyang Y, Huang C, Liu X, Qian Y. Grooved fibers: preparation principles through electrospinning and potential applications. Adv Fiber Mater 2021;4:203.

Forward KM, Rutledge GC. Free surface electrospinning from a wire electrode. Chem Eng J 2012;183:492.

Vass P, Szabo E, Domokos A, Hirsch E, Galata D, Farkas B, Demuth B, Andersen SK, Vigh T, Verreck G, Marosi G, Nagy ZK. Scale-up of electrospinning technology: Applications in the pharmaceutical industry. Wires Nanomed Nanobi 2020;12:e1611.

Wang Z, Tian Y, Zhang C, Wang Y, Deng W. Massively multiplexed electrohydrodynamic tip streaming from a thin disc. Phys Rev Lett 2021;126:064502.

Liu SL, Huang YY, Zhang HD, Sun B, Zhang JC, Long YZ. Needleless electrospinning for large scale production of ultrathin polymer fibres. Mater Res Innov 2014;18:S4.

Zhang CL, Yu SH. Nanoparticles meet electrospinning: recent advances and future prospects. Chem Soc Rev 2014;43:4423.

Juncos Bombin AD, Dunne NJ, McCarthy HO. Electrospinning of natural polymers for the production of nanofibres for wound healing applications. Mat Sci Eng C-Mater 2020;114:110994.

Dziemidowicz K, Sang Q, Wu J, Zhang Z, Zhou F, Lagaron JM, Mo X, Parker GJM, Yu DG, Zhu LM, Williams GR. Electrospinning for healthcare: recent advancements. J Mater Chem B 2021;9:939.

Zhang X, Li L, Ouyang J, Zhang L, Xue J, Zhang H, Tao W. Electroactive electrospun nanofibers for tissue engineering. Nano Today 2021;39:101196.

Zare M, Davoodi P, Ramakrishna S. Electrospun shape memory polymer micro-/nanofibers and tailoring their roles for biomedical applications. Nanomater (Basel) 2021;2021:11.

Dou Y, Zhang W, Kaiser A. Electrospinning of metal-organic frameworks for energy and environmental applications. Adv Sci 2020;7:1902590.

Tebyetekerwa M, Ramakrishna S. What is next for electrospinning? Matter 2020;2:279.

Hao Y, Hu F, Chen Y, Wang Y, Xue J, Yang S, Peng S. Recent progress of electrospun nanofibers for zinc-air batteries. Adv Fiber Mater 2021;4:185.

Agarwal S, Greiner A, Wendorff JH. Functional materials by electrospinning of polymers. Prog Polym Sci 2013;38:963.

Suja PS, Reshmi CR, Sagitha P, Sujith A. Electrospun nanofibrous membranes for water purification. Polym Rev 2017;57:467.

Zhang F, Chen J, Yang J. Fiber materials for electrocatalysis applications. Adv Fiber Mater. 2022;2022:558.

Zhao J, Zhu W, Wang X, Liu L, Yu J, Ding B. Fluorine-free waterborne coating for environmentally friendly, robustly water-resistant, and highly breathable fibrous textiles. ACS Nano 2019;14:1045.

Zhou W, Yu X, Cao L, Yang M, Li Y, Si Y, Yu J, Ding B. Green and ethanol-resistant polyurethane nanofibrous membranes based on an ethanol solvent for waterproof and breathable textiles. Adv Sustain Syst 2020;4:2000105.

Zhou W, Yu X, Li Y, Jiao W, Si Y, Yu J, Ding B. Green-solvent-processed fibrous membranes with water/oil/dust-resistant and breathable performances for protective textiles. ACS Appl Mater Inter 2021;13:2081.

Zhou W, Gong X, Li Y, Si Y, Zhang S, Yu J, Ding B. Environmentally friendly waterborne polyurethane nanofibrous membranes by emulsion electrospinning for waterproof and breathable textiles. Chem Eng J 2022;427:130925.

Peng Y, Cui Y. Advanced textiles for personal thermal management and energy. Joule 2020;4:724.

Li D, Liu X, Li W, Lin Z, Zhu B, Li Z, Li J, Li B, Fan S, Xie J, Zhu J. Scalable and hierarchically designed polymer film as a selective thermal emitter for high-performance all-day radiative cooling. Nat Nanotechnol 2021;16:153.

Zhong H, Li Y, Zhang P, Gao S, Liu B, Wang Y, Meng T, Zhou Y, Hou H, Xue C, Zhao Y, Wang Z. Hierarchically hollow microfibers as a scalable and effective thermal insulating cooler for buildings. ACS Nano 2021;15:10076.

Liu L, Xu W, Ding Y, Agarwal S, Greiner A, Duan G. A review of smart electrospun fibers toward textiles. Compos Commun 2020;2020:22.

Iqbal MI, Shi S, Kumar GMS, Hu JL. Evaporative/radiative electrospun membrane for personal cooling. Nano Res 2020;2020:698.

Gao C, Zhang L, Wang J, Jin M, Tang Q, Chen Z, Cheng Y, Yang R, Zhao G. Electrospun nanofibers promote wound healing: theories, techniques, and perspectives. J Mater Chem B 2021;9:3106.

Zhang X, Lv R, Chen L, Sun R, Zhang Y, Sheng R, Du T, Li Y, Qi Y. A multifunctional Janus electrospun nanofiber dressing with biofluid draining, monitoring, and antibacterial properties for wound healing. ACS Appl Mater Inter 2022;14:12984.

Dong R, Li Y, Chen M, Xiao P, Wu Y, Zhou K, Zhao Z, Tang BZ. In situ electrospinning of aggregation-induced emission nanofibrous dressing for wound healing. Small Methods 2022;6:e2101247.

Celebioglu A, Uyar T. Electrospun formulation of acyclovir/cyclodextrin nanofibers for fast-dissolving antiviral drug delivery. Mat Sci Eng C-Mater 2021;118:111514.

Luraghi A, Peri F, Moroni L. Electrospinning for drug delivery applications: a review. J Control Release 2021;334:463.

Parın FN, Aydemir Çİ, Taner G, Yıldırım K. Co-electrospun-electrosprayed PVA/folic acid nanofibers for transdermal drug delivery: Preparation, characterization, and in vitro cytocompatibility. J Ind Text 2021;2021:1528.

Ahmed J. Electrospinning for the manufacture of biosensor components: a mini-review. Med Dev Sensors. 2020;2020:4.

Liu Y, Hao M, Chen Z, Liu L, Liu Y, Yang W, Ramakrishna S. A review on recent advances in application of electrospun nanofiber materials as biosensors. Curr Opin Biomed Eng 2020;13:174.

Crapnell RD, Street RJ, Ferreira-Silva V, Down MP, Peeters M, Banks CE. Electrospun nylon fibers with integrated polypyrrole molecularly imprinted polymers for the detection of glucose. Anal Chem 2021;93:13235.

Frias IAM, Vega-Gonzales-Gil LH, Cordeiro MT, Oliveira MDL, Andrade CAS. Self-enriching electrospun biosensors for impedimetric sensing of zika virus. ACS Appl Mater Inter 2022;14:41.

Wang Z, Wang Y, Yan J, Zhang K, Lin F, Xiang L, Deng L, Guan Z, Cui W, Zhang H. Pharmaceutical electrospinning and 3D printing scaffold design for bone regeneration. Adv Drug Deliver Rev 2021;174:504.

Rahmati M, Mills DK, Urbanska AM, Saeb MR, Venugopal JR, Ramakrishna S, Mozafari M. Electrospinning for tissue engineering applications. Prog Mater Sci 2021;117:100721.

Si Y, Guo C, Xu X, Zhang K, Tan R, Lau K-T, Hu J. Bioinspired Janus all-natural electrospinning membranes with directional water transport as ecofriendly dry facial masks. ACS Sustain Chem Eng 2022;2022:3659.

Robinson AJ, Pérez-Nava A, Ali SC, González-Campos JB, Holloway JL, Cosgriff-Hernandez EM. Comparative analysis of fiber alignment methods in electrospinning. Matter 2021;4:821.

Zhao S, Zhao X, Dong S, Yu J, Pan G, Zhang Y, Zhao J, Cui W. A hierarchical, stretchable and stiff fibrous biotemplate engineered using stagger-electrospinning for augmentation of rotator cuff tendon-healing. J Mater Chem B 2015;3:990.

Kolluru PV, Lipner J, Liu W, Xia Y, Thomopoulos S, Genin GM, Chasiotis I. Strong and tough mineralized PLGA nanofibers for tendon-to-bone scaffolds. Acta Biomater 2013;9:9442.

Wang L, Zhu T, Kang Y, Zhang J, Du J, Gao H, Chen S, Jiang J, Zhao J. Crimped nanofiber scaffold mimicking tendon-to-bone interface for fatty-infiltrated massive rotator cuff repair. Bioact Mater 2022;16:149.

Zhu Q, Ma Z, Li H, Wang H, He Y. Enhancement of rotator cuff tendon-bone healing using combined aligned electrospun fibrous membranes and kartogenin. RSC Adv 2019;9:15582.

Yang R, Zheng Y, Zhang Y, Li G, Xu Y, Zhang Y, Xu Y, Zhuang C, Yu P, Deng L, Cui W, Chen Y, Wang L. Bipolar metal flexible electrospun fibrous membrane based on metal-organic framework for gradient healing of tendon-to-bone interface regeneration. Adv. Healthc. Mater. 2022;2022:e2200072.

Cong S, Sun Y, Lin J, Liu S, Chen J. A synthetic graft with multilayered co-electrospinning nanoscaffolds for bridging massive rotator cuff tear in a rat model. Am J Sports Med 1826;2020:48.

Li X, Cheng R, Sun Z, Su W, Pan G, Zhao S, Zhao J, Cui W. Flexible bipolar nanofibrous membranes for improving gradient microstructure in tendon-to-bone healing. Acta Biomater 2017;61:204.

Hakimi O, Mouthuy PA, Zargar N, Lostis E, Morrey M, Carr A. A layered electrospun and woven surgical scaffold to enhance endogenous tendon repair. Acta Biomater 2015;26:124.

Guan X, Xia H, Ni QQ. Shape memory polyurethane-based electrospun yarns for thermo-responsive actuation. J Appl Polym Sci 2021;2021:138.

Zhou Y, Fang J, Wang X, Lin T. Strip twisted electrospun nanofiber yarns: Structural effects on tensile properties. J Mater Res 2011;27:537.

Jiang C, Wang K, Liu Y, Zhang C, Wang B. Using wet electrospun PCL/Gelatin/CNT yarns to fabricate textile-based scaffolds for vascular tissue engineering. ACS Biomater Sci Eng 2021;7:2627.

Jiang C, Wang K, Liu Y, Zhang C, Wang B. Textile-based sandwich scaffold using wet electrospun yarns for skin tissue engineering. J Mech Behav Biomed Mater 2021;119:104499.

Smit E, Bűttner U, Sanderson RD. Continuous yarns from electrospun fibers. Polymer 2005;46:2419.

Wei L, Qin X. Nanofiber bundles and nanofiber yarn device and their mechanical properties: a review. Text Res J 1885;2016:86.

Tian L, Yan T, Pan Z. Fabrication of continuous electrospun nanofiber yarns with direct 3D processability by plying and twisting. J Mater Sci 2015;50:7137.

Chen S, Wang J, Chen Y, Mo X, Fan C. Tenogenic adipose-derived stem cell sheets with nanoyarn scaffolds for tendon regeneration. Mat Sci Eng C-Mater 2021;119:111506.

Li X, Yao C, Sun F, Song T, Li Y, Pu Y. Conjugate electrospinning of continuous nanofiber yarn of poly(L-lactide)/nanotricalcium phosphate nanocomposite. J Appl Polym Sci 2008;107:3756.

Yao C, Li X, Song T. Preparation and characterization of zein and zein/poly-L-lactide nanofiber yarns. J Appl Polym Sci 2009;114:2079.

Wu S, Zhou R, Zhou F, Streubel PN, Chen S, Duan B. Electrospun thymosin Beta-4 loaded PLGA/PLA nanofiber/ microfiber hybrid yarns for tendon tissue engineering application. Mat Sci Eng C-Mater 2020;106:110268.

Learn GD, McClellan PE, Knapik DM, Cumsky JL, Webster-Wood V, Anderson JM, Gillespie RJ, Akkus O. Woven collagen biotextiles enable mechanically functional rotator cuff tendon regeneration during repair of segmental tendon defects in vivo. J Biomed Mater Res B Appl Biomater 2019;107:1864.

Moutos FT, Freed LE, Guilak F. A biomimetic three-dimensional woven composite scaffold for functional tissue engineering of cartilage. Nat Mater 2007;6:162.

Krishnan AG, Joseph J, Chandra RR, Nair SV, Nair M, Menon D. Silk-based bilayered small diameter woven vascular conduits for improved mechanical and cellular characteristics. Int J Polym Mater 2021;2021:1.

Padmakumar S, Paul-Prasanth B, Pavithran K, Vijaykumar DK, Rajanbabu A, Sivanarayanan TB, Kadakia E, Amiji MM, Nair SV, Menon D. Long-term drug delivery using implantable electrospun woven polymeric nanotextiles. Nanomedicine 2019;15:274.

Xie X, Cai J, Yao Y, Chen Y, Khan AR, Wu J, Mo X. A woven scaffold with continuous mineral gradients for tendon-to-bone tissue engineering. Compos Part B-Eng 2021;2021:212.

Deacon F, Crow M, Rajah S, Kester R. Comparison of the thrombogenicity of four types of knitted Dacron arterial graft in an artificial circulation. Biomaterials 1985;6:64–7.

Guo D, Wang S, Yin Y, Luo J, Meng C, Liu Q, Ni H, Feng J. Preparation of three-dimensional multilayer ECM-simulated woven/knitted fabric composite scaffolds for potential tissue engineering applications. Text Res J 2019;90:925.

Ouyang HW, Goh JCH, Thambyah A, Teoh SH, Lee EH. Knitted poly-lactide-co-glycolide scaffold loaded with bone marrow stromal cells in repair and regeneration of rabbit achilles tendon. Tissue Eng 2003;9:431.

Ruan D, Zhu T, Huang J, Le H, Hu Y, Zheng Z, Tang C, Chen Y, Ran J, Chen X, Yin Z, Qian S, Pioletti D, Heng BC, Chen W, Shen W, Ouyang HW. Knitted silk-collagen scaffold incorporated with ligament stem/progenitor cells sheet for anterior cruciate ligament reconstruction and osteoarthritis prevention. ACS Biomater Sci Eng 2019;5:5412.

Chen X, Qi YY, Wang LL, Yin Z, Yin GL, Zou XH, Ouyang HW. Ligament regeneration using a knitted silk scaffold combined with collagen matrix. Biomaterials 2008;29:3683.

Cai J, Xie X, Li D, Wang L, Jiang J, Mo X, Zhao J. A novel knitted scaffold made of microfiber/nanofiber core-sheath yarns for tendon tissue engineering. Biomater Sci 2020;8:4413.

Nowotny J, Aibibu D, Farack J, Nimtschke U, Hild M, Gelinsky M, Kasten P, Cherif C. Novel fiber-based pure chitosan scaffold for tendon augmentation: biomechanical and cell biological evaluation. J Biomat Sci-Polym E 2016;27:917.

Czaplewski SK, Tsai TL, Duenwald-Kuehl SE, Vanderby R Jr, Li WJ. Tenogenic differentiation of human induced pluripotent stem cell-derived mesenchymal stem cells dictated by properties of braided submicron fibrous scaffolds. Biomaterials 2014;35:6907.

Laranjeira M, Domingues RMA, Costa-Almeida R, Reis RL, Gomes ME. A 3D mimicry of native-tissue-fiber architecture guides tendon-derived cells and adipose stem cells into artificial tendon constructs. Small 2017;2017:13.

Rothrauff BB, Lauro BB, Yang G, Debski RE, Musahl V, Tuan RS. Braided and stacked electrospun nanofibrous Scaffolds for tendon and ligament tissue engineering. Tissue Eng Pt A 2017;23:378.

Silva M, Ferreira FN, Alves NM, Paiva MC. Biodegradable polymer nanocomposites for ligament/tendon tissue engineering. J Nanobiotechnol 2020;18:23.

Akbari N, Khorshidi S, Karkhaneh A. Effect of piezoelectricity of nanocomposite electrospun scaffold on cell behavior in bone tissue engineering Iran. Polym J 2022;31:919–30.

Fernandez-Yague MA, Trotier A, Demir S, Abbah SA, Larranaga A, Thirumaran A, Stapleton A, Tofail SAM, Palma M, Kilcoyne M, Pandit A, Biggs MJ. A self-powered piezo-bioelectric device regulates tendon repair-associated signaling pathways through modulation of mechanosensitive ion channels. Adv Mater 2021;33:e2008788.

Wang L, Zhang F, Liu Y, Leng J. Shape memory polymer fibers: materials, structures, and applications. Adv Fiber Mater 2021;4:5.

Jacob J, More N, Kalia K, Kapusetti G. Piezoelectric smart biomaterials for bone and cartilage tissue engineering. Inflamm Regen 2018;38:2.

Barbosa F, Ferreira FC, Silva JC. Piezoelectric electrospun fibrous Scaffolds for bone, articular cartilage and osteochondral tissue engineering. Int J Mol Sci 2022;23:1.

Khare D, Basu B, Dubey AK. Electrical stimulation and piezoelectric biomaterials for bone tissue engineering applications. Biomaterials 2020;258:120280.

More N, Kapusetti G. Piezoelectric material—a promising approach for bone and cartilage regeneration. Med Hypotheses 2017;108:10.

Azimi B, Milazzo M, Lazzeri A, Berrettini S, Uddin MJ, Qin Z, Buehler MJ, Danti S. Electrospinning piezoelectric fibers for biocompatible devices. Adv Healthc Mater 2020;9:e1901287.

Gritsch L, Maqbool M, Mourino V, Ciraldo FE, Cresswell M, Jackson PR, Lovell C, Boccaccini AR. Chitosan/hydroxyapatite composite bone tissue engineering scaffolds with dual and decoupled therapeutic ion delivery: copper and strontium. J Mater Chem B 2019;7:6109.

Zhang X, Li Z, Yang P, Duan G, Liu X, Gu Z, Li Y. Polyphenol scaffolds in tissue engineering. Mater Horiz 2021;8:145.

Chen W, Zheng D, Chen Y, Ruan H, Zhang Y, Chen X, Shen H, Deng L, Cui W, Chen H. Electrospun fibers improving cellular respiration via mitochondrial protection. Small 2021;17:2104012.

Wang Y, Zhang W, Yao Q. Copper-based biomaterials for bone and cartilage tissue engineering. J Orthop Translat 2021;29:60.

Dong Y, Zhang T, Lin X, Feng J, Luo F, Gao H, Wu Y, Deng R, He Q. Graphene/aptamer probes for small molecule detection: from in vitro test to in situ imaging. Mikrochim Acta 2020;187:179.

Lu H, Chen C, Wang Z, Qu J, Xu D, Wu T, Cao Y, Zhou J, Zheng C, Hu J. Characterization of calcium and zinc spatial distributions at the fibrocartilage zone of bone–tendon junction by synchrotron radiation-based micro X-ray fluorescence analysis combined with backscattered electron imaging. Spectrochim Acta B 2015;111:15.

Lake SP, Liu Q, Xing M, Iannucci LE, Wang Z, Zhao C. Tendon and ligament tissue engineering. Principl Tissue Eng 2020;2020:989–1005.

Xie X, Chen Y, Wang X, Xu X, Shen Y, Khan AR, Aldalbahi A, Fetz AE, Bowlin GL, El-Newehy M, Mo X. Electrospinning nanofiber scaffolds for soft and hard tissue regeneration. J Mater Sci Technol 2020;59:243.

Zhong H, Huang J, Wu J, Du J. Electrospinning nanofibers to 1D, 2D, and 3D scaffolds and their biomedical applications. Nano Res 2021;15:787.

Mertz D, Harlepp S, Goetz J, Bégin D, Schlatter G, Bégin-Colin S, Hébraud A. Nanocomposite polymer scaffolds responding under external stimuli for drug delivery and tissue engineering applications. Adv Therapeut 2019;3:1900143.

Reina G, González-Domínguez JM, Criado A, Vázquez E, Bianco A, Prato M. Promises, facts and challenges for graphene in biomedical applications. Chem Soc Rev 2017;46:4400.

Kuo WS, Chang CN, Chang YT, Yang MH, Chien YH, Chen SJ, Yeh CS. Gold nanorods in photodynamic therapy, as hyperthermia agents, and in near-infrared optical imaging. Angew Chem Int Edit 2010;49:2711.

Tindell RK, Busselle L, Holloway J. Magnetic fields enable precise spatial control of electrospun fiber alignment for fabricating complex gradient materials. Polym Sci 2022;2022:55.

Xing C, Chen S, Liang X, Liu Q, Qu M, Zou Q, Li J, Tan H, Liu L, Fan D, Zhang H. Two-dimensional MXene (Ti3C2)-integrated cellulose hydrogels: toward smart three-dimensional network nanoplatforms exhibiting light-induced Swelling and bimodal photothermal/chemotherapy anticancer activity. ACS Appl Mater Inter 2018;10:27631.

Xie Z, Peng M, Lu R, Meng X, Liang W, Li Z, Qiu M, Zhang B, Nie G, Xie N, Zhang H, Prasad PN. Black phosphorus-based photothermal therapy with aCD47-mediated immune checkpoint blockade for enhanced cancer immunotherapy. Light Sci Appl 2020;9:161.

Yin F, Hu K, Chen S, Wang D, Zhang J, Xie M, Yang D, Qiu M, Zhang H, Li ZG. Black phosphorus quantum dot based novel siRNA delivery systems in human pluripotent teratoma PA-1 cells. J Mater Chem B 2017;5:5433.

Xie Z, Chen S, Duo Y, Zhu Y, Fan T, Zou Q, Qu M, Lin Z, Zhao J, Li Y, Liu L, Bao S, Chen H, Fan D, Zhang H. Biocompatible two-dimensional titanium nanosheets for multimodal imaging-guided cancer theranostics. ACS Appl Mater Inter 2019;11:22129.

Chen S, Xing C, Huang D, Zhou C, Ding B, Guo Z, Cao Y, et al. Eradication of tumor growth by delivering novel photothermal selenium-coated tellurium nanoheterojunctions. Sci Adv 2020;6:15.

Lee WC, Maul TM, Vorp DA, Rubin JP, Marra KG. Effects of uniaxial cyclic strain on adipose-derived stem cell morphology, proliferation, and differentiation. Biomech Model Mechan 2007;6:265.

Altman GH, Horan RL, Martin I, Farhadi J, Stark PRH, Volloch V, Richmond JC, Vunjak-Novakovic G, Kaplan DL. Cell differentiation by mechanical stress. FASEB J 2001;16:2.

Wu S, Wang Y, Streubel PN, Duan B. Living nanofiber yarn-based woven biotextiles for tendon tissue engineering using cell tri-culture and mechanical stimulation. Acta Biomater 2017;62:102.

Sensini A, Cristofolini L, Zucchelli A, Focarete ML, Gualandi C, Dem A, Kao AP, Roldo M, Blunn G, Tozzi G. Hierarchical electrospun tendon-ligament bioinspired scaffolds induce changes in fibroblasts morphology under static and dynamic conditions. J Microsc 2020;277:3.

Tseng LF, Mather PT, Henderson JH. Shape-memory-actuated change in scaffold fiber alignment directs stem cell morphology. Acta Biomater 2013;9:8790.

Reifenrath J, Wellmann M, Kempfert M, Angrisani N, Welke B, Gniesmer S, Kampmann A, Menzel H, Willbold E. TGF-beta3 loaded electrospun polycaprolacton fibre scaffolds for rotator cuff tear repair: an in vivo study in rats. Int J Mol Sci 2020;2020:21.

Majidinia M, Reiter RJ, Shakouri SK, Mohebbi I, Rastegar M, Kaviani M, Darband SG, Jahanban-Esfahlan R, Nabavi SM, Yousefi B. The multiple functions of melatonin in regenerative medicine. Ageing Res Rev 2018;45:33.

Gao W, Lin M, Liang A, Zhang L, Chen C, Liang G, Xu C, Peng Y, Chen C, Huang D, Su P. Melatonin enhances chondrogenic differentiation of human mesenchymal stem cells. J Pineal Res 2014;56:62.

Song W, Ma Z, Wang C, Li H, He Y. Pro-chondrogenic and immunomodulatory melatonin-loaded electrospun membranes for tendon-to-bone healing. J Mater Chem B 2019;7:6564.

Acknowledgements

The authors gratefully acknowledge the financial support from the Startup Grant of CityU (“Laboratory of Wearable Materials for Healthcare”, Grant 9380116), National Natural Science Foundation of China (“Study of high performance fiber to be achieved by mimicking the hierarchical structure of spider-silk”, Grant 52073241; “Study of Multi-Responsive Shape Memory Polyurethane Nanocomposites Inspired by Natural Fibers”, Grant 51673162; “Developing Spider-Silk-Model Artificial Fibers by A Chemical Synthetic Approach”, Grant 15201719), and the Contract Research (“Development of Breathable Fabrics with Nano-Electrospun Membrane”, CityU ref.: 9231419).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, X., Si, Y., Zhao, Y. et al. Electrospun Textile Strategies in Tendon to Bone Junction Reconstruction. Adv. Fiber Mater. 5, 764–790 (2023). https://doi.org/10.1007/s42765-022-00233-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-022-00233-9