Abstract

In the present study, the response surface methodology based on a rotatable central composite design was applied to optimize the production of the carotenoid pigment using a strain of Cellulosimicrobium that has not been reported so far for this genus. The microbial biomass and pigment production of strain AZ were investigated in the presence of tricarboxylic acid cycle intermediates (citrate, malate, succinate), and glutamate. Besides, the influence of the pH of the fermentation medium was also evaluated. The design consisted of a total of 32 experiments at five levels for each factor. Optimum carotenoid production (28.86 mg/L) was observed in the fermentation medium (pH 8.04) containing citrate (11.18 mM), glutamate (12.48 mM), malate (14.19 mM), and succinate (13.38 mM). It was 1.65-fold more than that of the OFAT method (17.5 mg/L) and 12-fold more than the unoptimized conditions (2.4 mg/L). The results were fitted with a quadratic model that could predict the responses to new observations significantly (pred-R2 = 0.9686). Optimum microbial biomass (10.61 g/L) was observed in the presence of citrate (10.27 mM), glutamate (14.03 mM), malate (13.1 mM), and succinate (10.39 mM) as well as pH 8.36. In contrast to the results of one-factor-at-a-time, the carotenoid production had not a direct relationship with bacterial biomass. The established model could describe the variability of above 99.85% in the response based on the determination coefficient (R2).

Similar content being viewed by others

1 Introduction

Carotenoids are tetraterpenoid organic pigments that contain yellow, orange, and red colors. Lowering the risk of cancer, cataract, and cardiovascular diseases, as well as improvement of immune system function, are some of the benefits of carotenoids in human health attributed to their antioxidant potential [1]. In addition, carotenoids have vast applications in cosmetics, foods, and animal feeds industries [2].

Carotenoids are produced chemically or naturally by different organisms. However, the production of natural carotenoids by microbial fermentation has attracted more attention in recent years [3]. Various carotenogenic microbes and recombinant non-carotenogenic microbes have been reported for large-scale production of carotenoids [4]. The major advantage of microbial pigments is their cost-effective production [5]. The reason can be attributed to the rapid growth of microorganisms in the low-cost fermentation media that are not affected by climatic conditions. Besides, the microbial pigments have advantages such as the significant antioxidant and antibacterial activity [6]. The efforts to find microbial strains producing new carotenoids are ongoing.

In addition to the type of microbial strains, fermentation condition optimization is critical for carotenoid production. Each microorganism or even each strain has its own unique nutritional need such as carbon and nitrogen sources for maximum production of carotenoids [7, 8]. Besides, carotenoid production is strongly affected by different physicochemical factors such as pH, temperature, the time of incubation, light intensity, inoculum size, etc. [9]. Traditionally, costly and time-consuming optimization procedures such as the one-factor-at-a time (OFAT) method is used for the enhancement of the carotenoid synthesis by microorganisms [10, 11]. However, the OFAT method doesn’t consider the interaction between variables [12]. In contrast, response surface methodology (RSM) has the benefits of investigating the influences of multiple factors and their interactions on one and even more response variables [11].

Among carbon and nitrogen sources, the effect of tricarboxylic acid cycle (TCA) intermediates or derivatives such as citrate, glutamate, malate, and succinate have investigated scarcely in the previous literature. To explain how these carbon and nitrogen sources can influence the carotenoid production in microorganisms, the pathways and substrates of carotenoids must be considered. Carotenoids are synthesized through two pathways including the mevalonate (MVA) or isoprenoid pathway as well as the 2-C-methyl-D-erythritol-4-phosphate (MEP) or non-mevalonate pathway. The MEP pathway is mainly present in most bacteria, while the MVA pathway is typically found in eukaryotes and archaea. The substrates of the carotenoid pathways are acetyl-CoA, glyceraldehyde-3-phosphate (G3P), and pyruvate that all of them are synthesized by the central carbon pathway [13, 14]. In addition, the central carbon pathway as well as TCA or the Krebs cycle provide the cofactors of carotenoid biosynthesis, i.e., ATP and NADPH [15, 16]. Therefore, providing the TCA intermediates can be resulted in a decrease in the consumption of the carotenoid substrates to generate the TCA cycle intermediates. Therefore, it can increase more flux into the carotenoid biosynthesis pathway [17, 18]. Accordingly, the influence of Krebs cycle intermediates on the carotenoid production was investigated in the present study. The bacterial strain studied in this study was phylogenetically close to the genus Cellulosimicrobium that has not been reported so far. This bacterium is a non-pathogenic strain and has a strong power of carotenoid production.

2 Materials and methods

2.1 Isolation, identification, and culture conditions of microorganism

Tryptone, glucose, yeast extract, agar–agar, and agarose were purchased from Merck Company (Germany). The studied bacterium, strain AZ was isolated from oil-contaminated soils using the TGY agar medium (pH = 7.2) containing tryptone (5 g/L), glucose (1 g/L), yeast extract (5 g/L), and 1.5% w/v agar [19]. The soil samples are serially diluted in a tenfold order and 1 mL of each dilution was inoculated in TGY agar plates (37 °C, 4–5 days). The pure colony was obtained after two subcultures.

The molecular identification of the strain was done by amplification of 16S rDNA through the PCR technique using the universal primer 27F (5′-AGAGTTTGATYMTGGCTCA-3′) and 1492R (5′-CGGTTACCTTGTTACGACTT-3′). The PCR mixture in the final volume of 25 µl was used as follows: PCR Master Mix (2 ×, CinnaGen, Iran), 10 p mole of each primer (0.5 µL), and extracted DNA (1 µL). The PCR conditions were the initial denaturation at 94 °C (5 min), 30 cycles of denaturing at 94 °C (45 s), annealing at 55 °C (1 min), and extension at 72 °C (1 min), and then a final extension at 72 °C (5 min). PCR product was electrophoresed on a 1% w/v agarose gel [20, 21]. The gene sequence was determined (Korean Macrogen Company) and compared to the previously reported bacterial sequences available in the Gene Bank database (www.ncbi.nlm.nih.gov/Blast.cgi, NCBI).

The inoculum (OD 600 nm = 0.1) was prepared into 5 ml sterile TGY broth medium (37 °C, 120 rpm, 4 h), and inoculated in the fermentation medium as much as 1% v/v.

The 60% w/v whey medium was used as the initial culture medium for the carotenoid production by strain AZ. The whey was used in powder (Pegah Company, Iran). The sterilization of whey medium was performed in three steps. First, the medium was autoclaved at 110 °C (15 min) as the heat treatment for deproteinization. After cooling, the culture medium was filtered with Whatman no. 40 paper and the resulting solution was centrifuged at 4000 rpm (3584×g) for 20 min for removing the precipitates. The final sterilization step was performed by autoclaving at 110 °C (15 min). Various concentrations of citrate, glutamate, malate, and succinate were added to the initial fermentation medium after the filtration of whey medium. The strain AZ was inoculated (1% v/v) into the fermentation medium and incubated at 30 °C for 5 days (120 rpm). The used whey contained 4.5% lactose and 0.8% casein protein. Since there is about 2.7 g lactose as the carbon source and about 0.48 g casein as the nitrogen source in a 60% w/v medium.

2.2 Response surface methodology (RSM)

The effective independent variables were selected based on the OFAT results and used to optimization through the RSM approach involving a rotatable central composite design (RCCD). For this purpose, different carbon sources (glucose, raffinose, starch, xylose, sorbitol, sucrose, citrate, malate, and succinate), nitrogen sources (yeast extract, tryptone, peptone, casein, ammonium sulfate, calcium nitrate, potassium nitrate, glutamate, and ammonium nitrate), and cultural conditions (pH, and temperature) were tested. Various fermentation media (whey medium at the concentrations of 40%, 50%, and 60% w/v as well as TGY broth medium) were also tested in the OFAT experiments to determine the best initial fermentation medium. In each OFAT experiment, only one factor was changed and other factors were kept constant. Among the effective factors, five factors including pH, glutamate, citrate, malate, and succinate were selected. Five levels of each factor, including axial point (+ α, − α), factorial point (+ 1, − 1), and center point (0), were studied in a set of 32 experiments (Table 1).

In each experiment, the microbial biomass and carotenoid production were measured after 5 days of incubation (30 °C, 120 rpm). The following quadratic equation was used to explain the relationship between the response (dependent) and the independent variables.

The constant (b0), the linear coefficients (b1, b2, b3, b4, and b5), the cross-product coefficients (b12, b13, b14, b15, b23, b24, b25, b34, b35, and b45), and the quadratic coefficients (b11, b22, b33, b44, and b55) are presented in this equation. The results were reported as the means of experiments performed in triplicate.

2.3 Biomass and total carotenoid assay

To evaluate the microbial biomass in the whey medium, the culture medium (100 mL) inoculated by 1% v/v of strain AZ, and also the whey medium without any inoculation (control) were centrifuged (4000 rpm or 3584×g for 5 min). Then, the resulting pellets were dried at 70 °C for 72 h. The pellets were then weighed, and the biomass in the whey medium was calculated by subtracting the weight of two pellets according to Eq. 1.

in which DWF was the dry weight of bacterial pellet in fermentation medium and DWC was the dry weight of pellet in control medium, i.e., the medium without any bacterial inoculation.

The amount of the produced pigment in 10 mL of culture medium was calculated according to the formula provided by Eq. 2 [22].

In this equation, A474, Vs, and \( A_{{1 \;{\text{cm}}}}^{1\% } \) are the total carotenoid maximum absorbance in the solvent, the sample solution volume, and the total carotenoid specific absorption coefficient in a 1 cm cell for a 1% solution, respectively.

2.4 Statistical analysis

The Design Expert 7.0 software (Stat-Ease, Minneapolis, USA) was used for all the statistical analysis, including the design of experiments, analysis of data, calculation of regression coefficients, and drawings of response surface graph. Besides, the Analysis of Variance (ANOVA) with a 95% confidence interval was performed to test the statistical significance of the RSM experiment results.

3 Results and discussion

In this study, the carotenoid pigment production by a strain of Cellulosimicrobium named strain AZ was optimized. The Gene Bank accession number of this strain is MG602070. The studied strain is a gram-positive, facultative anaerobe, catalase-positive, and non-spore-forming bacterium. It has yellow colonies in the TGY agar medium. Because there was no report of carotenoid pigment production in this genus previously, strain AZ was selected among other isolated strains from oil-contaminated soils for further analysis. Besides, the strain showed the good ability of carotenoid production even in the unoptimized condition (2.4 mg/L) i.e., in TGY broth medium without any change in the pH, carbon source, and nitrogen source of the medium. In addition, the carotenoid pigment of strain AZ showed significant antioxidant activity based on the half-maximal effective concentration (EC50) values were obtained in the free radical scavenging (10.97 mg/mL) and ferric reducing antioxidant power (6.02 μg/mL) assays.

In the present study, a rotatable central composite design (RCCD) with five factors, including 32 experiments in triplicate, was performed for optimization of the strain AZ biomass and carotenoid production, and the results are represented in Supplementary Table 1. The independent factors are tricarboxylic acid cycle intermediates and derivatives such as citrate, malate, succinate, and glutamate as well as pH of the fermentation medium. The selection of these factors was based on the results of the OFAT approach (data not shown). Due to some disadvantages of OFAT methodology such as the requirement of more experimental data sets (time-consuming) and missing the interactions among independent factors, this approach was only used as a simple screening method for selecting the effective parameters. This two-step strategy i.e., screening by OFAT and optimization by using RSM methods was successfully used by previous studies [11, 23]. According to the OFAT results, strain AZ produced 17.5 mg/L carotenoid in the 60% w/v whey medium without any change in the pH, carbon source, and nitrogen source of the fermentation medium.

The experimental results were analyzed by ANOVA, and the significant terms were selected (Table 2). The biomass production of strain AZ was affected using all studied factors except for citrate based on the values of “Prob > F” less than 0.05. However, only citrate and glutamate increased the carotenoid production of this strain. Besides, the interactions between citrate and malate, citrate and glutamate, malate and glutamate, malate and pH, and succinate and pH were statistically significant on the biomass production, as shown by the interaction terms p value (Table 2). The carotenoid production was affected by the interactions between all studied factors which was not concluded from the results of the OFAT method (data not shown). Therefore, the cultural conditions in increasing the biomass and carotenoid production of strain AZ were not similar. Glutamate was the only effective factor in increasing both biomass and carotenoid production of strain AZ. In other words, more biomass production is not always equal to more carotenoid production, and the type of carbon source is significantly effective in increasing carotenoid expression.

The determination of optimum values of the independent variables for maximizing strain AZ biomass and carotenoid production predicted by Design-Expert software. The optimum carotenoid production (28.86 mg/L) was observed in the fermentation medium (pH 8.04) containing citrate (11.18 mM), glutamate (12.48 mM), malate (14.19 mM), and succinate (13.38 mM). Besides, the optimum microbial biomass (10.61 g/L) was observed in the presence of citrate (10.27 mM), glutamate (14.03 mM), malate (13.1 mM), and succinate (10.39 mM) as well as at pH 8.36.

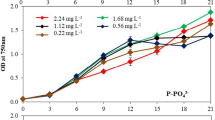

The contour plots were also depicted for the carotenoid production of strain AZ to show a better description of interactions between variables (Fig. 1). Figure 1a–d illustrated the effect of interaction between citrate and other factors on the pigment production of strain AZ. As shown in these figures, carotenoid synthesis improved in the presence of 10–11 mM and decreased with increasing the concentration of citrate. A similar result was observed in the study of Nasri Nasrabadi and Razavi [24]. They reported that the highest value of carotenoid production was achieved using the minimal level of both the citrate and malate concentrations. Besides, a lower concentration of glutamate had a more positive effect on carotenoid production (Fig. 1c, f, h, j). Figure 1d, g, i, j represent the interaction effect of pH and other factors on the production of the strain AZ pigment. As shown in these figures, the maximum synthesis of the pigment was achieved when the pH of the fermentation medium was between 8 and 8.5 (Fig. 1a, e, f, g).

Contour plots of carotenoid production of strain AZ. The effect of interaction between a citrate and malate, b citrate and succinate, c citrate and glutamate, d citrate and pH, e malate and succinate, f malate and glutamate, g malate and pH, h succinate and glutamate, i succinate and pH, j glutamate and pH

The intermediates of Krebs or TCA cycle can stimulate carotenoid production because they provide a carbon skeleton for the carotenoid molecules biosynthesis, affect the key enzymes participate in the carotenoid biosynthesis pathway, and increase acetyl CoA pool as the origin of isoprene units in microbial carotenogenic strains. Our results revealed that citrate and succinate were more effective in the carotenoid production of strain AZ. However, the result of another study showed that succinate, α-ketoglutarate, and oxaloacetate had more stimulatory effects on the carotenoid production of D. natronolimnaea HS-1 [24]. Therefore, the effect of TCA intermediates on increasing carotenoid production is different among various bacterial strains.

The polynomial models for the strain AZ biomass and pigment production yield were regressed by using only the significant terms and expressed as follows:

in which X1, X2, X3, X4, and X5 are citrate, malate, succinate, glutamate, and pH, respectively.

The significance of the regression models of biomass and pigment production was confirmed by F value (6.37 and 359.75, respectively) and the probability value (0.0015 and < 0.0001, respectively). Therefore, the pigment production model was more statistically significant. Besides, the non-significant lack of fit for biomass and pigment production models also revealed an appropriate fitness of the established models (Table 2).

The fit of the models was also confirmed by R2 (the determination coefficient) as well as Adj R2, i.e. adjusted determination coefficient (Table 3). These coefficients explain the correlations between experimental results and predicted data [25].

The obtained biomass and pigment production regression models in the present study can describe 92.06% and 99.85% of the variability in the response, respectively. Therefore, the carotenoid pigment production model was strong because the R2 value of this model was close to one [11]. In other words, there was only 0.015% of the total variation that could not be explained by the carotenoid model. Also, the Adj R2 value of the pigment production model (0.9957) confirmed the significance of the model. The difference between R2 and Adj R2 is the Adj R2 describes the percent of variation by the independent factors that really affect the dependent variable. In contrast, R2 represents the percent of variation by all the independent factors. The Adj R2 of the pigment production model was slightly less than the value of R2, which confirmed an appropriate correlation between the response and model [11].

The carotenoid production regression model also could predict the responses to new observations significantly (pred-R2 = 0.9686). The benefit of the Pred-R2 coefficient is the prevention of the model overfitting. In other words, the Pred-R2 explains whether the established model can predict logical responses for new experiments or not. Therefore, the carotenoid production regression model in the present study could predict as much as 96.86% of new observations that are not used in the model estimation. Besides, the adequate precision value of the carotenoid production regression model was 78.59 that indicates this model can navigate the design space appropriately.

Finally, the carotenoid production model was validated for all five factors used in this study (Table 4). Validation run with replications should present how close the actual value when compared to the predicted best condition by Design Expert simulation. The statistically predicted value in this experiment were in close agreement with the experimentally determined values of carotenoid production, confirming the model’s authenticity.

4 Conclusion

A two-step strategy method i.e., OFAT as the screening method and RSM with CCD as the optimization method was applied in the present study to achieved the maximum production of biomass and carotenoid by using Cellulosimicrobium Strain AZ. Five factors were selected for the optimization step including pH of fermentation medium and four intermediates of Krebs or TCA cycle (citrate, malate, succinate, and glutamate).

The tested intermediates TCA cycle in the present study increased the carotenoid and biomass production of Cellulosimicrobium Strain AZ. The reason attributed to the fact that they provide a carbon skeleton for the carotenoid molecules biosynthesis as well as the cofactors needed for it. Among TCA cycle intermediates, citrate and succinate were the most effective factors in increasing strain AZ carotenoid and biomass production, respectively. Besides, glutamate was the only effective factor in increasing both biomass and carotenoid production of strain AZ. The optimum pH of the fermentation medium for carotenoid and biomass production of this strain was between 8 and 8.5. The optimum carotenoid production (28.86 mg/L) was observed in the fermentation medium containing citrate (11.18 mM), glutamate (12.48 mM), malate (14.19 mM), and succinate (13.38 mM). Besides, the optimum microbial biomass (10.61 g/L) was observed in the presence of citrate (10.27 mM), glutamate (14.03 mM), malate (13.1 mM), and succinate (10.39 mM). Two regression models (biomass and carotenoid production) were formulated to correlate the experimental variables to the responses. The carotenoid production model well fitted the experimental data based on the Adj R2 results (0.9957), and had a great ability to predict responses for new observations based on the Pred R2 (0.9686). Overall, a significant improvement (1.65-fold) in the carotenoid production of strain AZ was achieved in the presence of the studied TCA cycle intermediates by using CCD.

Availability of data and material

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Kirti K, Amita S, Priti S, Mukesh Kumar A, Jyoti S (2014) Colorful world of microbes: carotenoids and their applications. J Adv Biol. https://doi.org/10.1155/2014/837891

Sandmann G (2001) Carotenoid biosynthesis and biotechnological application. Arch Biochem Biophys 385(1):4–12. https://doi.org/10.1006/abbi.2000.2170

Vachali P, Bhosale P, Bernstein PS (2012) Microbial carotenoids. In: Microbial carotenoids from fungi. Springer, pp 41–59. http://doi.org/10.1007/978-1-61779-918-1

Das A, Yoon SH, Lee SH, Kim JY, Oh DK, Kim SW (2007) An update on microbial carotenoid production: application of recent metabolic engineering tools. Appl Microbiol Biotechnol 77(3):505. https://doi.org/10.1007/s00253-007-1206-3

Malik K, Tokkas J, Goyal S (2012) Microbial pigments: a review. Int J Microbiol Res Technol 1(4):361–365

Venil CK, Zakaria ZA, Ahmad WA (2013) Bacterial pigments and their applications. Process Biochem 48(7):1065–1079. https://doi.org/10.1016/j.procbio.2013.06.006

Zhao JH, Bai FY, Guo LD, Jia JH (2002) Rhodotorula pinicola sp. nov., a basidiomycetous yeast species isolated from xylem of pine twigs. FEMS Yeast Res 2(2):159–163. https://doi.org/10.1111/j.1567-1364.2002.tb00080.x

El-Banna AA, El-Razek AMA, El-Mahdy AR (2012) Some factors affecting the production of carotenoids by Rhodotorula glutinis var. glutinis. Food Nutr Sci 3(1):64. https://doi.org/10.4236/fns.2012.31011

Chen D, Han Y, Gu Z (2006) Application of statistical methodology to the optimization of fermentative medium for carotenoids production by Rhodobacter sphaeroides. Process Biochem 41(8):1773–1778. https://doi.org/10.1016/j.procbio.2006.03.023

Tinoi J, Rakariyatham N, Deming R (2005) Simplex optimization of carotenoid production by Rhodotorula glutinis using hydrolyzed mung bean waste flour as substrate. Process Biochem 40(7):2551–2557. https://doi.org/10.1016/j.procbio.2004.11.005

Singh SK, Singh SK, Tripathi VR, Khare SK, Garg SK (2011) Comparative one-factor-at-a-time, response surface (statistical) and bench-scale bioreactor level optimization of thermoalkaline protease production from a psychrotrophic Pseudomonas putida SKG-1 isolate. Microb Cell Factories 10(1):114. https://doi.org/10.1186/1475-2859-10-114

Panda BP, Ali M, Javed S (2007) Fermentation process optimization. Res J Microbiol 2(3):201–208. https://doi.org/10.3923/jm.2007.201.208

Schmidt-Dannert C, Umeno D, Arnold FH (2000) Molecular breeding of carotenoid biosynthetic pathways. Nat Biotechnol 18(7):750–753. https://doi.org/10.1038/77319

Paniagua-Michel J, Olmos-Soto J, Ruiz MA (2012) Pathways of carotenoid biosynthesis in bacteria and microalgae. In: Microbial carotenoids from bacteria and microalgae. Springer, pp 1–12. https://doi.org/10.1007/978-1-61779-879-5_1

Armstrong GA, Alberti M, Hearst JE (1990) Conserved enzymes mediate the early reactions of carotenoid biosynthesis in nonphotosynthetic and photosynthetic prokaryotes. Proc Natl Acad Sci 87(24):9975–9979. https://doi.org/10.1073/pnas.87.24.9975

Li C, Swofford CA, Sinskey AJ (2020) Modular engineering for microbial production of carotenoids. Metab Eng Commun 10:e00118. https://doi.org/10.1016/j.mec.2019.e00118

Bhosale P (2004) Environmental and cultural stimulants in the production of carotenoids from microorganisms. Appl Microbiol Biotechnol 63(4):351–361. https://doi.org/10.1007/s00253-003-1441-1

Lee JJL, Chen L, Shi J, Trzcinski A, Chen WN (2014) Metabolomic profiling of Rhodosporidium toruloides grown on glycerol for carotenoid production during different growth phases. J Agric Food Chem 62(41):10203–10209. https://doi.org/10.1021/jf502987q

Basha NS, Rekha R, Komala M, Ruby S (2009) Production of extracellular anti-leukaemic enzyme lasparaginase from marine actinomycetes by solidstate and submerged fermentation: Purification and characterisation. Trop J Pharm Res. https://doi.org/10.4314/tjpr.v8i4.45230

Etemadifar Z, Gholami M, Derikvand P (2016) UV-resistant bacteria with multiple-stress tolerance isolated from desert areas in Iran. Geomicrobiol J 33(7):1–7. https://doi.org/10.1080/01490451.2015.1063025

Gholami M, Etemadifar Z, Bouzari M (2015) Isolation a new strain of Kocuria rosea capable of tolerating extreme conditions. J Environ Radioact 144:113–119. https://doi.org/10.1016/j.jenvrad.2015.03.010

Nasri Nasrabadi MR, Razavi SH (2010) Enhancement of canthaxanthin production from Dietzia natronolimnaea HS-1 in a fed-batch process using trace elements and statistical methods. Braz J Chem Eng 27(4):517–529. https://doi.org/10.4172/1948-5948.1000158

Vaishnav D, Suthar J, Oza T, Dave G, Sheth N, Sanghvi G (2014) A statistical approach for the enhanced production of thermostable alkaline protease showing detergent compatibility activity from Bacillus circulans. Biocatal Biotransformation 32:151–160. https://doi.org/10.3109/10242422.2014.913579

Nasri Nasrabadi MR, Razavi SH (2010) Use of response surface methodology in a fed-batch process for optimization of tricarboxylic acid intermediate to achieve high levels of canthaxanthin from Dietzia natronolimnaea HS-1. J Biosci Bioeng 109(4):361–368. https://doi.org/10.1016/j.jbiosc.2009.10.013

Adinarayana K, Ellaiah P (2002) Response surface optimization of the critical medium components for the production of alkaline protease by a newly isolated Bacillus sp. J Pharm Pharm Sci 5(3):272–278

Acknowledgements

This research was supported by the University of Isfahan.

Author information

Authors and Affiliations

Contributions

In order to recognize the authors’ participation, we highlight each individual contribution: ASB (author initials) contributed in experimental work and writing the manuscript, ZE designed the study and supervised the experiments and edited the manuscript, MSB made contributions in statistical analysis of the results and writing the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Salehi Bakhtiyari, A., Etemadifar, Z. & Borhani, M.S. Use of response surface methodology to enhance carotenoid pigment production from Cellulosimicrobium strain AZ. SN Appl. Sci. 2, 2096 (2020). https://doi.org/10.1007/s42452-020-03549-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03549-6