Abstract

Lithium-rich materials (LRMs) are among the most promising cathode materials toward next-generation Li-ion batteries due to their extraordinary specific capacity of over 250 mAh g−1 and high energy density of over 1 000 Wh kg−1. The superior capacity of LRMs originates from the activation process of the key active component Li2MnO3. This process can trigger reversible oxygen redox, providing extra charge for more Li-ion extraction. However, such an activation process is kinetically slow with complex phase transformations. To address these issues, tremendous effort has been made to explore the mechanism and origin of activation, yet there are still many controversies. Despite considerable strategies that have been proposed to improve the performance of LRMs, in-depth understanding of the relationship between the LRMs’ preparation and their activation process is limited. To inspire further research on LRMs, this article firstly systematically reviews the progress in mechanism studies and performance improving attempts. Then, guidelines for activation controlling strategies, including composition adjustment, elemental substitution and chemical treatment, are provided for the future design of Li-rich cathode materials. Based on these investigations, recommendations on Li-rich materials with precisely controlled Mn/Ni/Co composition, multi-elemental substitution and oxygen vacancy engineering are proposed for designing high-performance Li-rich cathode materials with fast and stable activation processes.

Graphical abstract

The “Troika” of composition adjustment, elemental substitution, and chemical treatment can drive the Li-rich cathode towards stabilized and accelerated activation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent decades, concerns over the energy crisis and the related environmental issues have dramatically increased the demand on electric vehicles (EVs) and hybrid electric vehicles (HEVs). The performance of EVs and HEVs is mainly determined by the high-energy-density Li-ion batteries (LIBs) [1]. The energy density of a LIB depends on its specific capacity and operational voltage, which are currently mainly limited by the cathode materials. However, the state-of-the-art commercialized LIBs cathodes such as LiMn2O4 (140 mAh g−1) [2], LiFePO4 (170 mAh g−1) [3], LiCoO2 (150 mAh g− 1) [4] and LiNixMnyCozO2 (NMC, where N, M, C represent Ni, Mn and Co, respectively, and x + y + z = 1) (around 200 mAh g− 1 depending on components) [2] working in the 3.0–4.0 V (vs. Li + /Li) potential range can hardly satisfy the demand. Although researchers are developing alternative new LIB systems, they are still far from practical applications [5,6,7,8,9,10,11,12]. Among LIB cathode materials, lithium-rich materials (LRMs) are promising candidates for EVs due to their superior specific capacity (over 280 mAh g− 1) [13], low cost, and excellent energy density (over 1 000 Wh kg− 1) [14]. As a unique phenomenon of LRMs during the initial charge of over 4.5 V [15], the activation process provides extra capacity compared to conventional layered cathode materials. Activation of the LRMs involves an oxygen anion redox reaction and Li extraction from the Li2MnO3 phase. These reactions determine the electrochemical performance such as specific capacity, cycling stability and rate capability of LRMs. However, the activation process is thermodynamically slow with severe structural degradation, which drastically hinders the commercialization of LRMs. To understand the process of activation, great efforts have been made to reveal the structure and electrochemical change during activation, but there are still many debates [16,17,18]. At the same time, various methods are proposed to eliminate the major obstacles against practical application of the materials, namely low Coulombic efficiency, poor cycling stability, voltage decay, and voltage hysteresis. These strategies can also influence the rate, extent, and stability of activation; unfortunately, they are rarely noticed. There are excellent review articles focusing on the various aspects of LRMs including the activation mechanism, the methods to suppress the irreversible oxygen loss, or the strategies to improve the stability [19,20,21,22,23,24]. However, to our knowledge, there is a lack of reviews that specifically highlight the strategies to control the activation process of LRMs, which plays an important role in determining the specific capacity, Coulombic efficiency, cycling performance, voltage retention, and voltage hysteresis.

This review aims to provide new insights on the understanding of the activation process and discuss the strategies that can effectively accelerate and stabilize the activation, in terms of compositional control, elemental substitution, and chemical treatment. We further propose guidelines of activation-tuning strategies, future perspectives, and research directions for Li-rich cathode materials. Rational selection/combination of chemical composition control, multi-elemental substitution and oxygen vacancy engineering are promising strategies toward LRMs with high capacity, fast activation, and stable cycling performance.

2 Structures, Activation Mechanism and Challenges of LRMs

2.1 Crystal Structure of LRMs

Lithium-rich cathodes, which are usually notated as xLi2MnO3·(1 − x)LiMnO2 or Li1+xM1−x O2 (M = Mn, Ni or Co), were first developed from the compound Li2MnO3 by Thackeray and co-workers in 1991 [25]. Similar to other intercalation cathode materials, the structure significantly influences the performance of LRMs. As the notation of LRMs xLi2MnO3·(1 − x)LiMO2 implies, this kind of material is a combination of two phases [15, 26, 27]. The first phase is Li2MnO3 (sometimes denoted as Li[Li1/3Mn2/3]O2) with a monoclinic structure (space group C2/m), in which 1/3 of the Mn sites are occupied by Li. The second phase is LiMO2 (M = Mn, Ni or Co) with a rhombohedral structure (space group R\(\overline{3}\)m). As shown in Fig. 1a, these two phases have similar structures, a close-packed cubic oxygen array, and all the octahedral sites are occupied by lithium (Li), transition metals (TMs) or Li/TM. Therefore, the two phases are highly compatible with each other [27]. Figure 1b demonstrates the combination of LiMO2 and Li2MnO3 phases. These two different systems have a similar layered structure, but the latter can provide extra Li source [26]. Figure 1c shows the different arrangements of oxygen arrays in conventional layered oxide and Li-rich Li2MnO3 oxide [15].

Copyright © 2013, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. b Combination of LiMO2 and Li2MnO3 phases in LRMs. Reprinted with permission from Ref. [26]. Copyright © 2015 Elsevier B.V. c Oxygen array arrangement in LiMO2 and Li2MnO3. Reprinted with permission from Ref. [15]. Copyright © 2013, American Chemical Society. d Typical XRD pattern of LRMs. Reprinted with permission from Ref. [28]. Copyright © 2015, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. e HAADF and ABF STEM images of the R\(\overline{3}\)m LiTMO2 structure and C2/m Li2MnO3 structure projected along the [100]mon direction. Insets: simulated local atomic arrangement. Reprinted with permission from Ref. [27]. Copyright © 2013, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim

a Schematic crystal models of the R\(\overline{3}\)m LiTMO2 and the C2/m Li2MnO3 phases. Reprinted with permission from Ref. [27].

To date, it is still debatable whether the crystal structure of LRMs is two phases co-existing as a solid solution or separate phases in different local areas. Earlier, X-ray diffraction was applied to characterize the structure of LRMs. From the typical X-ray diffraction (XRD) pattern shown as Fig. 1d, the main peaks can fit well with the R\(\overline{3 }\)m space group, while the broad and weak diffraction peaks in the 20°–25° range can indicate the existence of the space group C2/m [28]. However, there are debates on the source of these small peaks. Some researchers believe that these peaks indicate LiMn6 cation ordering in the Li2MnO3 phase, but the others claim that this indexes lithium ordering in the transition metal layer. As XRD can only show the overall crystal structure but cannot distinguish a solid solution from separated phases, more advanced characterization techniques are needed to analyze the local atomic arrangement of LRMs.

In recent years, a series of advanced techniques such as high-resolution transmission electron microscopy (HRTEM), high-angle annular dark field scanning transmission electron microscopy (HAADF-STEM), annular bright-field (ABF) STEM, diffraction scanning transmission electron microscopy (D-STEM) and electron energy-loss spectroscopy (EELS) were applied, attempting to directly visualize the local structure of LRMs. Although considerable research effort has been made in this field, there is still no clear conclusion on the local structure. Different research groups had contradictory explanations for the results. Some researchers gave evidence supporting the solid solution model [17, 29,30,31]. For example, Ferreira et al. only observed the monoclinic C2/m phase in their Li1.2Ni0.2Mn0.6O2 sample, and confirmed the absence of an R\(\overline{3 }\)m phase with D-STEM, indicating a single phase and a solid solution in this material. They believed that the broad weak peaks in the 20°–35° range in the XRD pattern are the result of thin planar defects in the (001) plane [31]. On the contrary, some researchers observed separated phases with HAADF-STEM or ABF-STEM [27, 30, 32]. For instance, Zhou et al. found individual domains of both monoclinic and rhombohedral symmetry within the same grain in their Li1.2Mn0.567Ni0.166Co0.067O2 sample, as shown in Fig. 1e, suggesting the co-existence of two separated phases [27]. Furthermore, many researchers tried to explain the reason for the different results mentioned above. It has been found that the structure of LRMs can be affected by multiple factors, such as composition, lithium ion content, synthesis temperature and cooling rates [33,34,35,36,37,38,39,40,41]. The widely accepted theory is that the composition, especially the content of lithium ions, is one of the most important factors controlling the local structure. It is believed that a higher ratio of lithium and transition metals, around 2:1, can make the structure of the LiMO2 phase shift to that of Li2MnO3. In this case, the overall structure will tend to form a homogeneous solid solution. However, a lower ratio of Li and TM cannot maintain periodic ordering of Li and TM, resulting in local separation of phases [33, 38]. Currently, the consensus tends to the solid solution model, but due to the complexity of LRMs, the study on their local structure needs to be continued in the future.

2.2 Activation Mechanism of LRMs

The LRMs family commonly has capacity larger than 250 mAh g−1 with a high-voltage plateau of 4.5 V. This is contributed by the unique activation process during the first charge–discharge cycle. Many researchers have attempted to determine the mechanism of this phenomenon. As shown in Fig. 2a, the initial charge cycle can be divided into two regions: the first region is 2.0–4.5 V, while the second is 4.5–4.8 V [42]. Within the first region, the TMs in the LiMO2 phase are oxidized to the M4+ valence state, along with the extraction of lithium ions. However, the Li2MnO3 phase cannot be oxidized, as the manganese is already in the Mn4+ valence state. Due to the difference in TM content, materials with variable composition can deliver various amounts of capacity at this stage. Meanwhile, in the second higher voltage stage, the oxygen in the lattice is oxidized. Simultaneously, Li ions in the Li2MnO3 phase are extracted [43]. Same as the first charge process, the mechanism of first discharge is also complex. During the first discharge, the Li ions re-insert into the cathode, and the TMs are reduced and revert to their initial state. However, not all the oxidized oxygen can be reduced in this process. Instead, some of the Mn4+ ions are reduced to Mn3+. During the first discharge, Li ions cannot fully return to the lattice, which also explain the high irreversible capacity in the first cycle. Operando neutron diffraction clearly demonstrated the Li+ movement during the initial electrochemical cycle of LRMs. During the initial charge, the capacity of the slope area is mainly contributed by the extraction of Li ions from the Li layer, while the capacity of the plateau region is provided by Li extraction from TM layers. Later in the first discharge, the Li can easily reinsert into the Li layers, but is difficult to intercalate back to TM layers (Fig. 2b) [44].

Copyright © 2018, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. b Electrochemical charge/discharge profile with corresponding lithium occupancy at different states of delithiation/lithiation for high Li-rich (left) and low Li-rich (right). Reprinted with permission from Ref. [44]. Copyright © 2016, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. c In situ Raman spectra directly demonstrating oxygen redox. Reprinted with permission from Ref. [46]. Copyright © 2018, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. d Schematic mechanism of activation reaction for Li[NixLi(1−2x)/3Mn(2−x)/3]O2 during the initial charge and discharge cycle (top) and charge–discharge curve (bottom). Reprinted with permission from Ref. [64]. Copyright © 2014, American Chemical Society. e Illustration of different proposed activation mechanisms. Reprinted with permission from Ref. [58]. Copyright © 2019, Springer Nature Limited. f Schematic of the structural, electron donation and Mn–O electron exchange evolutions during the charging of Li2MnO3. Reprinted with permission from Ref. [57]. Copyright © 2020, Elsevier

a Typical charge/discharge curve of LRM. Reprinted with permission from Ref. [42].

Since the first study on LRMs, researchers have made tremendous effort to explain the origin of activation process. However, the mechanism is still debated. There are various explanations for the activation of LRMs, which can be classified as six types of theories: oxygen dimer theory [45,46,47,48], oxygen ejection theory [16, 17, 49,50,51], trapped O2 gas redox theory [52,53,54,55], electron hole theory [13, 56], Mn high valence redox theory [57,58,59,60] and side reaction theory [61,62,63,64,65].

In the early reports, researchers believed the formation of oxygen dimers such as O2−/O22− or O2−/O2n− and their reversible redox originates the activation of LRM [45, 46]. As the essence of activation, many researchers have found evidence that the oxygen redox involves the formation of oxygen dimers such as O2−/O22− or O2−/O2n− [46,47,48]. For example, Fig. 2c clearly visualizes the oxygen redox reaction during the cycling [46]. Similarly, X-ray photoemission spectroscopy (XPS) and electron paramagnetic resonance (EPR) can directly identify oxygen dimers (O2)n− species (O–O distance 2.42 Å) [47]. Although these oxygen dimers are highly unstable and tend to be further oxidized or disproportioned into oxygen gas, researchers believe most of these dimers can reversibly return to the LRM lattice.

However, not all the researchers observed the existence of oxygen dimers, and thus proposed the oxygen ejection mechanism. Some studies stated that the initial capacity loss is caused by the simultaneous removal of O from the structure during the first charge [49]. Earlier studies confirmed that the O2 originates from the oxygen near the surface of the lattice during first charge [17]. The removal of oxygen led to oxygen vacancies, which in turn, decreased the number of available Li+ ion sites. Therefore, not all the Li+ ions can reversibly reinsert into the lattice. Furthermore, with these oxygen vacancies, the TMs tend to migrate into the Li layer, initiating the transformation to a spinel structure, which finally results in the breakdown of the crystal lattices [16]. This is a self-accelerated process, as the oxygen vacancies can reduce the TMs’ migration free energy, while the TMs’ migration can in turn promote the oxygen vacancy formation [50]. However, this theory has difficulty in explaining the lattice evolution by activation, as not all the TM migration is related to the activation. TM migration can occur in un-activatable cathode materials without the activation process, but the activation of LRM can accelerate the TM migration [51]. More importantly, this oxygen ejection cannot fully explain the high capacity of LRMs, as the charge is far beyond the amount that the released O2 gas can provide [53, 55]. There is no doubt that the extra charge capacity is provided by oxygen oxidation during charging, but if all the oxidized oxygen is irreversibly lost from the lattice, the reduction of TMs on discharging cannot fully compensate the charge during discharge.

To further explain the reversible high capacity of LRMs, the trapped O2 gas redox mechanism was proposed. This mechanism partially affirmed the oxygen ejection mechanism, but revealed further details. In this theory, although the formation of O2 gas is a fact, not all the O2 gas is irreversibly released during the activation. Instead, the majority of O2 is reserved in the bulk, and can participate in the subsequent reduction reaction. Thus, only the oxygen near the material surface will be released, whereas most oxygen in the lattice is reserved and can participate in the subsequent redox [53, 55]. High-resolution resonant inelastic X-ray scattering (HR-RIXS) spectroscopy, soft X-ray absorption spectroscopy (SXAS) and solid-state 17O magic angle spinning (MAS) NMR spectroscopy can directly prove the existence of molecular O2 gas after initial charging of LRMs, and 13% of the total lattice O participates in O2 formation. However, only 3% is detected in released O2 gas. Therefore, the majority of O2 must be trapped in the lattice. During the charge, the O2 in the bulk contributes to most of the capacity (~ 75%) when charged over 4.6 V. At the end of charge, the free O2 is directly observed instead of peroxo O22−, while the O2 is lost after discharge, indicating that this process is reversible. On the one hand, with the O extracted from the lattice at the > 4.6 V region, there is an irreversible rearrangement of TM honeycomb ordering. In this process, TMs migrate to Li sites, while the Li tends to cluster during the discharge. Such lattice rearrangement will leave the space to accommodate O2. These O2 are close to the TM redox center, and therefore can be reversibly reduced to O2− during the discharge. On the other hand, the O released from the surface will lead to layered-to-spinel phase transformation, which prevents the further loss of lattice oxygen [54]. However, such oxygen behavior is not the same in pure Li2MnO3, which is more representative to the activation study, as the capacity of this material is almost solely related to the oxygen redox. All the O in Li2MnO3 is coordinated with 4 Li ions and 2 TM ions. During the charge of Li2MnO3, the Li ions are extracted, accompanied by oxygen oxidization. These oxidized oxygen ions are undercoordinated and unstable, and can be easily released from the lattice. The soft X-ray spectroscopy, NMR and scanning transmission electron microscopy (STEM) reveal that O2 gas formation is the only way of charge compensation. Similar to other LRMs, the oxygen loss from the surface of Li2MnO3 is also not reversible. But in Li2MnO3, the oxygen loss will result in a highly disordered phase on the surface, rather than a spinel phase [52]. Although the trapped O2 gas redox mechanism can explain the reversible capacity, it cannot clarify the origin and location of oxygen redox. For example, some researchers believe that the TMs’ migration into Li layers lead to oxygen displacement, which is partially irreversible. Such displacement is the origin of oxygen redox, but it is only an oxygen disordering, but not a loss from the lattice [60]. More interestingly, recent theoretical calculations indicate that bulk oxygen redox occurs in the LiMO2 phase rather than the Li2MnO3 phase, while the Li2MnO3 is merely a source of extra Li. However, as this mechanism proposal is only based on the computational study, experimental verification is needed in the future research [59]. In addition, it is obvious that the activation behavior in Co/Ni containing LRM and pure Li2MnO3 is different. This is likely related to the O–Co/O–Ni bonding. The change in oxygen surrounding environment and electron configuration will change the way by which the electron extracted from the oxygen, as well as the way of oxygen movement.

With the support of advanced characterization techniques, researchers can see more details of the oxygen behavior during the activation of LRMs. Based on the new findings, the electron hole mechanism is proposed. This theory not only explains the reversible high capacity of LRMs, but also points out the origin of electrons involved in the activation. For example, during the initial charge of the material, when the voltage is \(\leqslant\) 4.5 V, oxygen is released from the lattice, although it is mostly in the form of CO2, rather than expected O2 gas. The source of such CO2 is not the electrolyte. Oppositely, the O atom in the CO2 is released from the lattice. However, the amount of released oxygen can only provide 0.05 e− per formula unit, while the actual electron involved in the activation is 0.55 e−. Thus, the other 0.5 e− must be provided by an alternative electrochemical process. Firstly, the Raman spectra did not show any evidence of O–O bonds with ∼1.45 Å length, which excluded the formation of O22− peroxide species. Secondly, K-edge XANES spectra of Mn, Ni, Co and O proved that there is no further oxidation on TMs beyond 4 + valence, but the MnO6 octahedrons are distorted. Furthermore, RIXS reveal that electronic environment around the oxygen changed significantly when the material is charged over 4.5 V. Therefore, the extra 0.5 e− is provided by electron holes on the oxygen, and the electron holes are located in the oxygen of Mn4+–O bonds. These electron holes on oxygen are reversible, whereas the oxygen released from the lattice is not reversible and will cause low initial Coulombic efficiency [13]. The DFT calculation also supports the electron hole theory. However, the results indicate that the electron originates from the Li–O–Li bond rather than the TM–O bond. In the simulation model, the excess Li in the LRMs will lead to a specific oxygen environment, in which one oxygen coordinates with four Li ions and two TM ions. In this environment, the unit has a linear orphaned Li–O–Li configuration, and the electron in this configuration is labile. When the material is deeply delithiated, the labile electron will be extracted from the Li–O–Li configuration, and leave electron holes [56].

In addition to the commonly accepted oxygen redox mechanism, there is also a highly debated Mn high valence redox mechanism. Recently, first-principle calculations suggested that Mn may experience oxidation beyond 4 + during activation of LRMs, as shown in Fig. 2e. In these calculations, Mn ions can redox between 4 + and 7 + , accompanied by simultaneous Mn migration from octahedral sites to tetrahedral sites or formation of oxygen dimers [58]. Similar theoretical calculations (Fig. 2f) suggest that Mn high valence redox can also occur in pure Li2MnO3. During charging, the ability of oxygen redox decreased with the reduced Li content in Li2MnO3, while the probability of Mn4+/Mn6+ or Mn4+/Mn7+ redox is increased at the same time. Then, the high valence Mn6+ or Mn7+ oxidizes their surrounding O ions and results in molecular O2 and Mn4+ [57]. However, practical experiments ruled out the Mn4+/Mn7+ redox mechanism in Li2MnO3 by quantitatively analyzing the capacity contributed by the activation process, as the charge change in Mn4+/Mn7+ redox cannot match with the actual capacity observed during cycling [59]. In addition, the most recent work reveals the change of O and Mn valences using operando XANES. This work provides further evidence against the hypothesis that Mn in LRMs can be oxidized beyond 4 + valence. It is obvious that Mn high valence redox theory has many conflicting reports. The reason of such variation may relate to the difference in LRM composition that researchers used, thus this theory needs to be further explored.

The electrolyte side-reaction mechanism is also a theory to explain the activation of LRMs. As a common phenomenon, LRMs can react with the electrolyte during the cycling [63]. In particular, the charging of LRMs will result in oxygen containing species forming on the material surface [62]. These byproducts, such as Li2CO3, can be reversibly formed and decomposed during the cycling, thus significantly contributing to the capacity [61]. In addition to the electrolyte oxidation, it is also reported that the activation of Li2MnO3 is caused by the reaction between cathodes and electrolytes, which finally leads to exchange of Li+ and H+ [65]. Both electrodes can react with the electrolyte during the cycling, forming a series of intermediate products such as H+, Li2CO3 and LiOH, and finally increase the capacity of LRMs. Such reactions are shown in Fig. 2d [64]. As the side reaction between an electrode and an electrolyte is difficult to be characterized, this theory still needs to be further studied.

It should be noted that various studies usually observed different phenomena in the experiments or theoretical calculations, which result in direct conflicting conclusions. However, in the above-mentioned works, most of the LRM objects are in varying chemical composition. As a complex type of materials, different ways of TM and O bonding will lead to significant changes in oxygen redox behavior. Therefore, the studies based on the same template materials are more meaningful for a reliable comparison. Despite the controversy regarding the mechanisms, oxygen redox is the determining process of the LRM activation because it decides the capacity and reversibility of the LRMs. Therefore, the adjustment of the activation extent and reversibility, in principle, relies on the tuning on oxygen redox behavior.

2.3 Challenges on the Practical Application of LRMs

Although LRMs have capacities far more than the traditional cathode materials for LIBs, there are still challenges hindering their practical application, such as lower capacity than the theoretical values, poor initial Coulombic efficiency, capacity/voltage decay and voltage hysteresis.

Low practical capacity. Depending on the composites, the LRMs have theoretical capacities of ~ 400 mAh g−1. However, only ~ 60%–75% (250–300 mAh g−1) of the theoretical capacities are practically achieved, whereas traditional cathode materials, such as LiMn2O4 [2] and LiFePO4 [3], already reached their theoretical capacity. This is partially because the capacity of layered cathode materials is limited by their structures. Taking typical layered LiCoO2 as an example, it has alternating Li layers and TM layers in its lattice. When delithiating, the spacing between TM layers will increase due to electrostatic repulsion. Eventually, its lattice structure will collapse under deep delithiation. Thus, this material can only deliver 150 mAh g−1 reversible capacity out of 274 mAh g−1 theoretical capacity, which means 55% of the Li+ ions are released [4, 66]. In contrast, LRMs are not a typically perfect layered material, as there is extra Li in the TM layers as shown in Fig. 1a [27]. This structure is more resistant to the electrostatic repulsion during delithiation, especially when the Li from the TM layers is extracted [67]. Thus, theoretically, LRMs are capable of releasing more Li than LiCoO2. However, the actual capacity of LRMs is far behind its theoretical value. For example, the most commonly studied LRM material, Li1.2Mn0.6Ni0.2O2, has a theoretical capacity of 378 mAh g−1, but the reported practical capacity is usually 200–300 mAh g−1, meaning only ~ 50%–75% of the Li is extracted [68, 69]. This can be attributed to the oxygen evolution during the activation, as the oxygen loss will induce TM diffusion, which blocks the Li extraction path [70].

Low initial Coulombic efficiency. During activation of LRMs, there are two irreversible processes: the oxygen ions are partially lost from the lattice, and some TMs migrate to the Li layer. Both facts can hinder the Li re-insertion into the lattice, causing low initial Coulombic efficiency [44, 71]. Although part of the initial capacity loss is attributed to the formation of a solid-electrolyte interface (SEI), the total capacity loss is far beyond that of the traditional layered LIB cathode materials, indicating the majority of the capacity is still sacrificed by the oxygen loss [72, 73]. Thus, stabilized activation with suppressed oxygen loss and TM migration can effectively improve the Coulombic efficiency.

Capacity/voltage decay. In addition to capacity and efficiency issues, the oxygen loss and TM migration during activation of LRMs can also cause continuous capacity/voltage decay with cycling [74]. Within these two, TM migration is the main factor triggering the capacity/voltage decay, while oxygen evolution is the accelerator [51]. Specifically, TM migration can occur in the absence of oxygen redox. Such migration will cause a phase transition from layered to spinel or quasi-spinel structure, which have a lower charge/discharge voltage [15, 16, 75]. At the same time, the oxygen loss and TM reduction in the lattice will weaken the TM–O bonds, especially the Ni–O bond, which leads to the TM migration to Li sites [76, 77], while Co can accelerate this process [78]. Moreover, after irreversible oxygen loss from the lattice, Mn4+ will be reduced to Mn3+ to compensate the charge during discharge. As Mn4+/Mn3+ redox has lower potential than that of O−/O2− or O2/O2−, the overall voltage of LRMs is decreased. Simultaneously, the loss of oxygen reduces the covalency of TM–O bonds, and suppresses the oxygen redox. As a consequence, the capacity of LRMs is decreased [79, 80].

Voltage hysteresis. LRMs suffer from massive voltage hysteresis between charge and discharge, which dramatically reduces their energy density. Although the mechanism of such a problematic phenomenon is still unclear, most researchers believe it is related to the TM and oxygen activity during the activation [54, 81,82,83,84,85,86,87,88,89]. Early research attributed the hysteresis to the TM migration and lattice restructuring [88, 89], but more recent studies demonstrate that oxygen redox is the key reason for hysteresis. Some researchers considered that voltage hysteresis originates from the energy difference between the formation and breaking of O–O or O–TM–O bonds [82, 86]. Others, however, believe the oxygen evolution during activation will cause irreversible lattice rearrangement and re-coordination of the oxygen environment, which in turn results in a decrease of voltage during discharge [54]. The most recent research decoupled the correlation of TM migration and hysteresis, but confirmed that hysteresis is highly related to the charge transfer in TM–O bonds. The voltage hysteresis will decrease with the increased TM–O covalence [81].

From the current challenges of LRMs, it is obvious that all these problems with LRMs are related to their activation process, especially the oxygen evolution and TM migration. Therefore, the strategies to optimize the activation process are important to design better LRMs.

3 Strategies to Optimize the Activation Process

Despite the fact that Li-rich cathode materials have excellent specific capacity, the Coulombic efficiency, capacity/voltage cycling stability, voltage hysteresis and activation kinetics hinder the commercialization of this kind of material. Many strategies are focused on mitigating the problematic poor rate performance, low Coulombic efficiency, severe voltage/capacity drop and voltage hysteresis of LRMs during cycling [24, 90,91,92,93,94]. However, it is rarely noticed that these methods can also change the activation behavior of LRMs. In the following section of this review, the influences of modification strategies, including composition adjustment, elemental substitution, and chemical treatment on the activation of LRMs, will be extracted from the literature and discussed in detail. Accordingly, a guideline of strategy selection towards accelerated and stabilized activation for high-performance LRMs will be proposed.

3.1 Compositional Adjustment

The performance of LRMs is related to their chemical composition. The commonest LRMs consist of manganese (Mn), nickel (Ni) or cobalt (Co), and each transition metal has different effects on the lattice structure and electrochemical behavior of the cathodes.

As one of the major transition metals in Li-rich NMC materials, the content of Mn not only determines the ratio of the Li-rich phase Li2MnO3 in the material but also determines the pathway of activation. The activation pathway can be analyzed by the in situ electrochemical quartz crystal microbalance (EQCM) technique. By comparing pure hexagonal LiNi0.3Co0.3Mn0.4O2, pure monoclinic Li2MnO3 and the Li-rich composite 0.5Li2MnO3·0.5LiNi0.3Co0.3Mn0.4O2, the importance of Mn can be demonstrated. In the Li-rich composite material, the hexagonal and monoclinic phases exhibit synergistic effects and therefore yield a significantly higher capacity than either parent phase. Such synergistic effects can also alter the activation process. During activation, the Li2MnO3 phase in the LRM decomposed into Li+, O22− and MnO2, rather than Li2O and MnO2 in pure Li2MnO3. As shown in Fig. 3a–c, this different activation pathway provides an additional source of Li+ that contributes to the extra capacity [95]. In addition to the synergistic effect, Mn also shows an unexpected electrochemical behavior during the activation of LRMs. As shown in Fig. 3d–h, in the initial charging process, Mn4+ in the Li[Li0.2Ni0.16Mn0.56Co0.08]O2 Li-rich materials partially reduced to Mn3+ at voltages > 4.5 V, instead of keeping its valence as the previous studies had suggested. This unique Mn valence evolution is in opposition to the general electrochemical reaction, where the valence increases as voltage increases [96]. The first-principles calculations demonstrate that during activation the oxygen O2− in the lattice is oxidized to an O2δ− dimer to compensate the charge increase due to delithiation. The Mn4+ remains unchanged at the early stage, acting as an electrocatalyst. However, with the increased extent of O2δ− dimer oxidization, the dimer releases electrons back to the Mn ions, which ultimately causes the reduction of Mn4+ to Mn3+. The electron loss from Mn and electron gain of O are illustrated in Fig. 3i and j [97]. All the above reports indicate that Mn is an essential element in common Mn-based LRM, as it triggers the anionic redox reaction of oxygen.

Copyright © 2019, American Chemical Society. d Initial cycling curve and voltage points for XANES measurement; e–h XANES spectra for O and Mn pre-edge at different voltages. Reprinted with permission from Ref. [96]. Copyright © 2019, American Chemical Society. i Average electron loss from the Mn and gain of oxygen at different stages of delithiation; j average magnetic moment values at different stages of delithiation. Reprinted with permission from Ref. [97]. Copyright © 2019, American Chemical Society

a Proposed electrochemical reactions in initial charge; b proposed electrochemical reactions in initial discharge; c illustration of proposed electrochemical behavior at high voltage above 4.5 V. Reprinted with permission from Ref. [95].

Ni is another key component in LRMs. In 2014, Wang et al. systematically studied the role of Ni by controlling its content in their Co-free LRMs. With increase in Ni content in their Li4/3–2x/3Mn2/3–x/3NixO2 (0.09 \(\leqslant\) x \(\leqslant\) 0.2), the materials show distinctly faster activation in the initial cycle. This is shown by the extension of the high-voltage activation plateau with an increase in the Ni to Mn ratio and faster reaching to the highest capacity (Fig. 4a and b). Through computational simulation, it is found that Ni in the Li layers can significantly reduce the energy barrier of oxygen evolution, while the oxygen removal can in turn cause Ni to diffuse into the Li layers. The whole process is like a chain reaction. Therefore, a little increase in Ni content can result in a significant increase in the activation rate. But with an appropriate ratio of Ni and Mn, the activation rate, capacity and structural stability can be balanced, as illustrated in Fig. 4c [28, 41]. Recent research investigated the role of Ni in LRMs within the model lattices Li1.15Ni0.47Sb0.38O2 (L1.15NSO), Li1.10Ni0.53Sb0.37O2 (L1.10NSO), and Li4NiTeO6 (LNTO), which eliminated the influence from other transition metals such as Mn and Co. As is consistent with previous reports, Ni2+ to Ni4+ is the main active redox cation during lower voltage charging before activation. However, it is found that not all the Ni can be oxidized at this stage. Ni ions on the particle surface are reduced in the activation region (where oxygen redox occurs), but not fully oxidized to Ni4+, because the evolution of oxygen can partially reduce the Ni. The process is shown in Fig. 4d. Although this reaction can significantly suppress the generation of oxygen gas, such a low oxidation state of Ni on the particles surface can hinder the Ni4+ in the bulk being fully reduced back to Ni2+ during discharge. This inevitably results in decreased reversibility. Therefore, the surface of Ni-containing LRMs must be protected [98]. Due to the higher electronegativity of Ni, the Ni2+/Ni4+ redox couple can deliver a higher voltage than that of Mn3+/Mn4+. Higher Ni content can lead to a higher activation voltage plateau and lower capacity than that of lower Ni materials (Fig. 4e and f). This indicates that too much Ni may have a negative effect on activation. Although the explanation for this phenomenon is not the focus of this work, our conjecture lies in excessive amount of Ni inducing over-activation [99]. Despite the fact that increased Ni content can improve the Coulombic efficiency and operating voltage and cycling stability of the LRM, the capacity, especially the part contributed by activation, was significantly sacrificed as shown in Fig. 4g. They further pointed out (in Fig. 4h) that Ni has a higher and stabler redox potential, as it has a much lower energy gap than that of Mn and Co when oxidized to lose the outermost electron. Ni can also decrease the bond energy of TM3d–O2p and non-bonding O2p. This can promote the formation of O1 but suppress the O2 coordination environment, and increase the valence state of Mn and Co [100]. Interestingly, some of these studies used Co-containing LRMs, and their capacities are much higher than that observed in Co-free LRMs, indicating the important role of Co in increasing the capacity of LRMs.

a Initial charge/discharge curves of LRMs with different Mn/Ni ratios; b prolonged cycling performance of these materials; c influence of Mn/Ni ratios on structure evolution and electrochemical behavior of LRMs. Reprinted with permission from Ref. [41]. Copyright © 2014, Tsinghua University Press and Springer-Verlag Berlin Heidelberg. d Schematic diagram of Ni and O behavior on the surface of particles. Reprinted with permission from Ref. [98]. Copyright © 2020, American Chemical Society. e The impact of Ni content on capacity and f specific energy. Reprinted with permission from Ref. [99]. Copyright © 2018, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. g The change of electrochemical behavior with different Ni contents; h 3d orbitals electronic state of Mn/Co/Ni ions in LRMs at different voltages and corresponding band structures. Reprinted with permission from Ref. [100]. Copyright © 2019, Elsevier Ltd. All rights reserved

Co is another key transition metal determining the activation process of LRMs. In the earlier study of LRMs, Co was found be able to trigger a capacity-increase-upon-cycling (CIUC) phenomenon in their Li[CoxLi1/3−x/3Mn2/3−2x/3]O2 (x = 0.087, 0.100, and 0.118) LRMs. With higher Co content, the capacity increase was faster, indicating faster activation, as shown in Fig. 5a–d [101]. With theoretical calculations, it is revealed that Co can shorten the non-bonding oxygen bond, significantly promoting the oxygen redox reaction. Also, similar to Ni, such promotion in oxygen evolution can in turn facilitate the Co diffusion and eventually become a chain reaction. This is explained by theoretical calculations (shown in Fig. 5e) which demonstrate that the removal and oxygen evolution of oxygen significantly reduces the Mn and Co migration energy barrier. Thus, the activation of the Li2MnO3 phase can be remarkably accelerated with a small amount of Co doping by exhibiting much larger capacity (shown in Fig. 5f) [102]. In addition, Co can induce extra hybrid trigonal lattice arrangement, thus promoting the activation process. The materials with Co can achieve a 256 mAh g−1 discharge capacity in the initial cycle, while the materials without Co can only deliver ~ 100 mAh g−1 [103]. Later, Wang and co-workers systematically studied a series of LRMs with various Co contents. With increase in Co content, the voltage plateau of activation shifted to a lower voltage, and the capacity contributed by activation was increased. This result clearly demonstrates that Co can accelerate the electrochemical activation of LRMs. However, with Co, the TMs will rapidly migrate from octahedral sites to cubic sites in the lithium layer during the initial 30 cycles, resulting in voltage decay and spinel-like phase formation. Then, most of the TMs have moved from cubic sites to their original octahedral sites with the mechanism illustrated in Fig. 5g, and the voltage is stabilized [104]. The acceleration in activation is related to the fact that the overlapping area between O2− 2p and Co3+ 3d6 bands is much larger than that with Ni3+ 3d7 and Mn3+ 3d4, as shown in Fig. 5h. This eases the oxidization of O in the lattice, hence accelerating the activation. However, the poor stability of the Co4+/Co3+ redox couple can eventually cause rapid voltage fading [105]. In general, LRMs with higher Co content (Fig. 5i) have an accelerated activation rate while materials with higher Ni (Fig. 5j) have a higher cycling stability. In addition to this unique function, the ratio of transition metals also has a profound influence on the activation process of LRMs. Changing the Ni/Co ratio can alter the lattice structure and cation arrangement in the LRMs, as shown in the XRD patterns in Fig. 5k. Materials with higher Ni content have a wider Li+ diffusion path due to the larger ionic radii of Ni than Co, which can lead to higher rate performance [106]. Notably, in all the Co containing LRMs discussed above, the activation rate increased with increase in Co content. Materials with higher Co content can be fully activated to their maximum capacity in fewer cycles than those with lower Co content. However, the cycling stability of those with a higher Co ratio show a deteriorative trend.

Copyright © 2014, Elsevier Ltd. g Schematic of TM ions migration. Reprinted with permission from Ref. [104]. Copyright © 2018, Elsevier Ltd. h Comparison of the band diagrams of Co/Ni/Mn-based layered oxides. Reprinted with permission from Ref. [105]. Copyright © 2006, Elsevier B.V. i Charge/discharge curves of LRMs with higher Co content; and j with lower Co content; k corresponding XRD patterns of these two materials. Reprinted with permission from Ref. [106]. Open access, Copyright © 2018, Electrochemical Society

a–d The electrochemical of LRMs with different Co contents. Reprinted with permission from Ref. [101]. Copyright ©2014, The Royal Society of Chemistry. e Change of energy barriers of TM ions with oxygen removal in Co containing LRMs; f cycling performance of Co containing LRMs. Reprinted with permission from Ref. [102].

During recent years, with the increase in concern regarding environmental damage, people are trying to avoid using Co in battery materials. Therefore, attempts to replace expensive and toxic Co with iron (Fe) have become a hot topic in the LRMs area due to the low-cost and nontoxicity of Fe. This family of materials usually contain Mn, Ni and Fe, so they are also known as MNF LRMs [107, 108]. The Fe3+/Fe4+ redox couple proved to be involved in the electrochemical reaction below 4.5 V. During the initial cycling, as shown in Fig. 6a and b, it is clear that Co containing Li1.2Ni0.13Co0.13Mn0.54O2 has a much higher capacity than that of Fe containing Li1.2Ni0.13Fe0.13Mn0.54O2, especially regarding the charge capacity contributed by activation (250 mAh g−1 of Co-based Li-rich and 180 mAh g−1 of Fe-based Li-rich). Thanks to the lower activation extent, as proven in Fig. 6c, Fe-based LRMs show better capacity retention during prolonged cycling. Moreover, during the activation, the conversion of the Li2MnO3 phase to the spinel phase is significantly retarded in the Fe-based LRM. The mechanism is still not clear, but it is speculated that the larger ionic radius of Fe3+ compared to that of Co3+ can impede the ion’s migration during activation, hence preventing the formation of the spinel structure [109]. In Fe containing LRM Li1.2Mn0.5Ni0.2Fe0.1O2, although the initial discharge capacity can achieve 226 mAh g−1, similar to that of common Li1.2Mn0.55Ni0.15Co0.10O2 (232 mAh g−1), the majority of the capacity is contributed by the Ni2+/Ni3+ and Fe3+/Fe4+ redox couples. The activation can only provide ~ 60 mAh g−1. XRD, XAFS, XANES and EDS analysis proved that the activation reaction, and the oxygen evolution, only occur in the Li2MnO3 phase as the number of Mn–O neighbors decreased upon the cycling, while the number of Ni–O and Fe–O neighbors remains unchanged (Fig. 6d). However, the activation of the Li2MnO3 phase did not lead to oxygen gas generation as NMC LRMs do. Instead, it converted to LiMnO2−x and Li2O2/Li2O. During the activation, only the Ni–O bond is expanded, while the Mn–O and Fe–O environment has a negligible variation (Fig. 6e). Such changes caused the lattice expansion, which in turn, resulted in a voltage change, as the expansion of the lattice can reduce the electrochemical potential of Li [110].

Copyright © 2016, Elsevier B.V. d Interatomic distances for Mn–O, Ni–O and Fe–O at different cycles; e number of near neighbors for Mn–O, Ni–O and Fe–O at different cycles. Reprinted with permission from Ref. [110]. Copyright ©2018, Electrochemical Society. f Voltage profile for the Li2Ru1−ySnyO3 with different Li extraction contents and y values; g the voltage profile upon cycling, capacity retention (the lower left inset) and rate capability (the top right inset) for a Li2Ru0.75Sn0.25O3; h the reversible (blue) and irreversible (green) Li-ions with different y values. Reprinted with permission from Ref. [47]. Copyright © 2013, Nature Publishing Group. i In-situ Raman spectra of LRMs; j cycling profile of Ru-based LRMs; k rate capability of the material. Reprinted with permission from Ref. [111]. Copyright © 2019, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim

a Initial cycles for Co containing LRMs; b initial cycles for Fe containing LRMs; c CV curves for Co and Fe containing LRMs. Reprinted with permission from Ref. [109].

In addition to Fe, some sporadic research on other transition ion replacements such as tin (Sn), ruthenium (Ru) and titanium (Ti) has also been tried in place of Co. These materials can still be electrochemically activated and exhibit O2−/O2n− anion redox at voltage above 4.5 V. Ru-based layered LRM was first reported by Tarascon et al. In this work, the TMs in the LRM are replaced by Sn and Ru, finally forming Li2Ru1−ySnyO3. As Sn is electrochemically inactive, the investigation on the single redox cation Ru4+/Ru5+ became feasible. In this composition, more Ru led to a higher reversible capacity (up to 250mAh g−1), while more Sn resulted in more stable cycling (Fig. 6f–h). Most importantly, the authors discovered that the reaction Ru6+ + O2− → Ru5+ + O− prevented the generation of O2 gas during the activation [47]. Ru-based LRMs can also form a rock-salt structure, in which Ru is in a 5+ valence state and cannot be further oxidized. Thus, the charge compensation below activation voltage is accomplished by the Ni2+/Ni4+ redox couple, while the O2−/O2n− redox can compensate the charge during activation. Notably, the lattice structure of this material is different from typical rock-salt LRMs. All the Ni, Ru and part of the Li occupy the 16d sites, while the 16c sites are fully filled by Li. Such a structure can facilitate the ordering of Li, leading to unobstructed Li diffusion paths and improving the kinetics. Also, the Li–O–Li arrangements are found in both the Li and TM layers in the lattice, which promotes oxygen evolution during activation. Additionally, Ru has a strong bond with O, only allowing O2− to be partially oxidized to O−, preventing it from being over oxidized and generating O2 gas during activation, proven by the highly reversible peak evolution of peroxo-oxygen in Fig. 6i. Therefore, this material exhibits high capacity (260 mAh g−1 at 10 mA g−1 current density), unnoticeable capacity/voltage decay over 150 cycles (94.2% capacity and nearly 100% voltage retention) and good rate performance, as shown in Fig. 6j and 6k [111].

Similarly, in Ti-based rock-salt LRMs, though the initial capacity is comparable to that of common NMC-based LRM, the capacity fading seems severer than the latter. Unlike common NMC-based LRMs, Mn ions in this Ti-based LRM are in the 3+ valence state, and the Mn3+/Mn4+ redox couple can compensate the charge difference at voltages < 4.5 V. In contrast, Ti is in the 4+ valence state and remains unchanged during the whole charge/discharge cycle. However, similar to NMC-based LRM, long cycling tests with different cutoff voltages reveal that the activation process is the main factor responsible for the capacity decay [111].

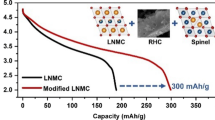

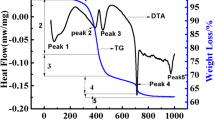

In summary, each composition of transition metals in LRMs has its unique function. Mn is the fundamental element of common LRMs. Firstly, it can trigger the activation of LRMs as the redox center at high voltage above 4.5 V. Secondly, Mn can introduce the synergistic effect between the Li2MnO3 phase and the LiTMO2 phase, altering the activation process by regulating the decomposition of the Li2MnO3 phase. This phase will decompose into Li+, O22− and MnO2, providing more Li which contributes to the extra capacity. Finally, Mn can absorb some of the electrons released by O during activation, increasing the reversibility during cycling. Ni has both positive and negative influences on LRMs. The major function of Ni is to elevate the operational voltage, stabilize the lattice structure, improve the Coulombic efficiency and promote the activation process when Ni content is low. Additionally, it has a similar effect to Mn in that it can absorb some electrons during activation and suppress the generation of O2 gas. However, if the Ni content is increased over a certain level, it will encumber the performance. Firstly, high Ni content will have the opposite effect to low Ni content and inhibit the activation. Secondly, as a result of the similar radius of Ni2+ and Li+, Ni2+ can easily occupy the Li+ sites. In fact, thermodynamically, the occupancy of Ni2+ in the Li 2b sites is preferable to the occupation of TM 4g sites in Li layers. The replacement of Ni with Li in TM layers is also possible. These Ni ions can block the diffusion pathways of Li, hindering the reaction. Co is widely believed to accelerate the activation of LRMs, as Co has a suitable outermost electron arrangement to ease the oxidization of O in the lattice. However, the Co4+/Co3+ redox couple has a low voltage and is unstable. This results in low operational voltages and rapid voltage decay of LRMs. Therefore, the balance between Mn, Ni and Co is critical to adjusting the performance toward a higher activation rate without sacrificing too much of the capacity and voltage of LRMs. Table 1 and Fig. 7 summarize the electrochemical performance of LRMs with variable Mn/Ni/Co composition. It is conspicuous that the LRMs with lager Mn/Ni content and appropriate amount of Co have higher overall capacity and activation contribution. In addition, Co composites can clearly improve the initial capacity. This is because the overlapping area between O2− 2p and Co3+ 3d6 bands is much larger than that with Ni3+ 3d7 and Mn3+ 3d4, and eases the oxidization of O in the lattice. Therefore, other elements with this property may also accelerate the activation of LRMs.

In addition to the commonest Mn, Ni and Co in LRMs, Fe, Ru, Sn and Ti have been studied by researchers to replace expensive and toxic Co. Fe has the advantage of low-cost and nontoxicity, and the capacity retention can be significantly improved in prolonged cycling. However, Fe can retard the activation of the Li2MnO3 phase, and result in lower capacity than NMC-based LRM. Thus, the future research of MNF-based Li-rich cathodes needs to be focused on enhancing the activation. Ru is a superior element for LRMs in both the layered and rock-salt structure. The most important advantage of Ru is to significantly promote activation while simultaneously eliminating the problematic O2 gas generation due to the strong bond between Ru and O. However, the high price of Ru can hamper the practical application of Ru-based LRMs. Sn can obviously enhance the stability of LRMs, but it can also damage the capacity as it is electrochemically inactive. The practical value of Sn may therefore be limited. Ti is also an abundant and nontoxic element. Ti-based LRMs can deliver comparable initial capacity as NMC-based LRMs, but the former suffers from rapid capacity decay with long cycling. Therefore, the priority of this kind of material is to improve the capacity retention. The influences of Fe, Ru, Sn and Ti components are also summarized and listed in Tables 1 and 2.

3.2 Elemental Substitution

Elemental substitution is also a promising strategy to enhance activation kinetics. The composition of LRMs consists of three essential parts: lithium, transition metals and oxygen. Thus, elemental substitution can be divided into three categories: cation doping that replaces Li, cation doping that replaces the TM ions, and anion doping that replaces the O in LRMs. Cation doping, such as sodium (Na), potassium (K), magnesium (Mg), aluminum (Al), iron (Fe), cobalt (Co), and ruthenium (Ru) cations, can increase the electronic conductivity and enlarge the size of the lattice. These changes can accelerate the migration of Li ions [18, 33, 112,113,114,115,116]. Anion doping is mainly focused on the selection of fluorine (F), chlorine (Cl), and sulfur (S). Using F doping as an example, the F-ions can form strong M–F bonds with TMs, which decrease the lattice size and stabilize the spinel structure during cycling. F− is also found to reduce the impedance of the cathode. On balance, however, F− doping can improve the rate capability by stabilizing the lattice structure and reducing the resistance, but at the expense of losing capacity by reducing the amount of diffusible Li+.

In the category of cations, the dopant can be further classified into alkali metals, alkaline-earth metals, transition metals and other metals. Alkali metals are mostly used to substitute for Li in LRMs. Among them, sodium (Na) and potassium (K) are the most commonly used alkali metals to dope LRMs due to their abundance and low cost, while the research on expensive rubidium (Rb) and cesium (Cs) doping is limited. All the alkali metals can stay in the lattice during Li diffusion and act as pillars of the lattice, which can enlarge the Li slab and improve the rate performance, as shown in Fig. 8a, b and c [114, 117,118,119]. In addition, these elements can largely increase the electronic conductivity of LRMs. Due to having the lowest ionic radii of the above-mentioned alkali metals, Na preferably occupies Li sites in the doping process. In addition to improving the rate performance, most Na ions stay in the Li layer during extraction of Li, supporting the structure and retarding the volume change and lattice collapse [118]. Under such an effect, Na changes the local environment of both Ni and O and lengthens the Ni–O bond. Thus, the layered to spinel conversion is suppressed because the Li/Ni disordering is thermodynamically restrained [120]. In addition, during activation, some of the Na is exchanged with Li from the electrolyte. This induces Ni migration to the Na vacancies and inhibits the formation of the spinel phase. This in turn significantly improves the cycling stability and Coulombic efficiency [121]. The ion exchange may also result in a thinner SEI film and reduce the charge transfer resistance during cycling [122]. Most importantly, although Na does not have a direct effect on activation capacity, the Na doped LRM only needs a single activation cycle (Fig. 8d) while the pristine material needs about a dozen cycles (Fig. 8e) to be fully activated. Qing and co-workers attribute this improvement in activation rates to the easier diffusion of Li ions caused by the pinning effect of Na, which also significantly improves the cycling reversibility [122]. However, as the Na replaces active Li in the lattice, Na doping will sacrifice some capacity in exchange for improving stability.

Copyright © 2013, the Electrochemical Society. d Initial cycling curves of pristine LRMs; e initial cycling curves of Na-doped LRMs. Reprinted with permission from Ref. [122]. Copyright © 2015, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. f Schematic diagram of Mn migration during charging in pristine LRMs; g schematic diagram of Mn migration during charging in K-doped LRMs. Reprinted with permission from Ref. [115]. Copyright © 2014, American Chemical Society

a Unit cell of Li2MnO3; b unit cell of LiMO2, c unit cell of NaMO2. Reprinted with permission from Ref. [118].

As an alkali metal, K can also replace some Li in the Li layers and enlarge the Li diffusion paths [123]. However, with a much larger ionic radius than that of the Na dopant, the K ion was reported to cause slight lattice distortion and introduce strain on the surrounding area. Such distortion and strain can result in a thicker LiO2 inter-slab layer in the lattice, which reduces the energy gap of Li migration and eventually accelerates the activation. In addition to the faster activation, as shown in Fig. 8f and g, K stays in the lattice as a pillar and blocks the adjacent octahedral sites. Thus, the migration of Mn ions and formation of the spinel phase is prevented as this process needs three empty adjacent octahedral sites to be thermodynamically favored. The large K ions can also reinforce the oxygen framework, which stabilizes the lattice during activation [115]. Additionally, K doping may alter the local orientation of the lattice in a direction which reduces the Li/Mn/Ni disordering, which eventually leads to a high capacity and rate capability [124]. Moreover, K doping is also speculated to promote Mn to participate in the electrochemical reaction and contribute to the capacity, although the mechanism for this is still unclear. Due to the large radius of K, the mobility of K is limited. The ion exchange of K and Li in the electrolyte is therefore difficult [124].

Apart from Na and K ions, only limited research has been conducted on the large alkali metals like Rb and Cs. Rb doping has a similar effect on LRMs as that of Na and K. However, though the mechanism is still unclear, Rb is also speculated to cause Mn participation in the activation [114]. While Cs proved to promote activation as the Li extraction from the Li2MnO3 phase is found to be accelerated. It is also notable that excessive doping can cause undesirable spinel phase formation [117].

It can be concluded that all the alkali metals including Na, K, Rb and Cs can replace Li in LRMs. These alkali metal ions can enlarge the lattice to facilitate the extraction/insertion of Li to enhance the Coulombic efficiency and rate performance. Also, they can stay in the lattice to act like pillars, stabilizing the lattice and blocking the migration paths of transition metals, hence improving the cycle stability. The main differences between these alkali metals are: (1) Na doping can lower the activation voltage, despite none of the papers mentioning the mechanism, and (2) K, Rb and Cs are speculated to be able to accelerate the activation of the Li2MnO3 phase, but the mechanism is still unknown. In addition, as summarized in Table 3, no evidence shows that one alkali metal is significantly more effective than others, so Na and K doping are more practically applicable in industry due to their abundance and low cost. Future research should therefore focus on the mechanism of the change of activation voltage and activation rates induced by Na/K doping.

The research on alkaline-earth metal doping in LRMs is mostly conducted with magnesium (Mg), calcium (Ca) and barium (Ba) in the past few years. All these metals have the same type of pillar effect, but each of them has some unique features. For instance, as the smallest alkaline-earth metal, Mg can either substitute for Li or TMs (preferably Ni) in LRMs [125,126,127]. When replacing Li, Mg only exhibits the pillar effect, but has negligible influence on the activation process [125]. When Mg occupies both Li and Ni sites, in addition to the pillar effect, the activation voltage near the end of the charge is also reduced to some extent. This indicates that Mg can promote oxygen redox at higher voltages. This phenomenon was not explained in this paper, and it is worth more research towards better understanding [127].

Unlike Mg, Ca can only substitute for Li in the LRMs. Early theoretical calculations predicted that Ca would preferentially occupy Ni sites in the LRMs, and the lattice of Ca doped LRM was unstable, especially during the charging process. This result rules out the possibility of practical TM substitution by Ca [128]. Then, experimental work proves that Ca indeed can only be doped in Li layers [129]. After Ca doping, the activation voltage of doped LRMs is higher than that of pristine and the overall capacity is therefore increased. This indicates that oxygen redox still occurs during activation, but is more difficult. This phenomenon can be attributed to the high electronegativity of Ca2+. The Ca–O bond is stronger and more ionic than the Mg–O bond, and so the oxygen gas generation is thermodynamically more difficult. Therefore, the oxygen loss during the activation is suppressed without sacrificing capacity.

Ba is found to substitute for Ni rather than Li, possibly because it has a much larger ionic radius compared with Mg and Ca. Ba-doped LRMs show a significantly shortened but elevated activation plateau compared to that of pristine samples. Meanwhile, the discharge capacity is not reduced. This indicates that oxygen loss during activation is suppressed. Although there is a lack of direct evidence, it is hypothesized that Ba2+ can stabilize the generation of oxygen radical intermediates formed during activation. Thus, in the presence of Ba2+, which has low positive charge density, the oxygen dimer intermediates cannot be further oxidized to O2 gas [130].

In the above literature on alkaline-earth metals (Table 4), it can be concluded that alkaline-earth metals can stabilize the lattice of Li-materials, and most importantly, suppress oxygen loss during activation. Although there is no evidence that shows that these metals can accelerate the activation, they also have no clear negative impact on the activation process. In future, it may be possible to dope alkaline-earth metals in LRMs as an activation stabilizer while simultaneously introducing other methods to accelerate the activation. This strategy is likely to simultaneously achieve fast activation and stable cycling.

In the past few years, there was significant research into the substitution of transition metals in LRMs. Doping of transition metals was extensively studied. According to the first principal calculations on the reaction energy of oxygen evolution during activation in LRMs consisting of 3d, 4d and 5d metals, metals with the 3d electron arrangement, or 4d and 5d metals with the d0 electronic configuration, are predicted to have irreversible oxygen evolution. Heavier 4d metals with a d2−4 electronic configuration or 5d metals with a d2−6 electronic configuration are predicted to reduce or even suppress the irreversible oxygen redox during activation [131].

Titanium (Ti) is a typical 3d metal with a d0 electronic configuration. In the experimental work, as predicted, Ti-doped LRMs exhibit significant irreversible oxygen evolution during the initial cycle in the 2.0–4.8 V voltage window [132]. However, when the voltage window is reduced to 2.00–4.45 V, the irreversibility is prevented without loss of discharge capacity (Fig. 9a and b). The mechanism is that Ti4+ has completely empty d orbitals, and can therefore only coordinate with adjacent O2− by ionic bonding and not through covalent bonding. As the O2p-Ti3d hybridization state is near the Fermi level, the Ti in the lattice can ease the oxygen evolution and activate the Li2MnO3 phase. Thus, Ti doped LRM can be activated at 4.4 V, about 0.1 V lower than that of Ti-free LRMs. When the voltage window is reduced to 2.00–4.45 V, the irreversibility is prevented without loss of discharge capacity. Furthermore, such O2p-Ti3d hybridization can weaken the O2p-TM3d hybridization of other TM ions, especially Ni and Co, which suppresses the O2 gas generation during activation. It is noteworthy that Ti can be doped in both the TM and Li layers to provide pillar effect (Fig. 9c) [132]. In addition, Ti doping is believed to alleviate lattice deformation during activation [133]. Thus, Ti doping can also improve the lattice’s structural stability in the activation process.

Copyright © 2019, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. d Phase evolution paths of pristine (P-type) and Cr-doped (C-type) LRMs. Reprinted with permission from Ref. [138]. Copyright © 2016, The Royal Society of Chemistry. e Change of initial cycling with different contents of Cr doping. Published by Elsevier Ltd. Reprinted with permission from Ref. [139]. Copyright © 2018, Hydrogen Energy Publications LLC. f Initial cycling of LRMs with different levels of Fe-doping and g corresponding dQ/dV curves. Reprinted with permission from Ref. [142]. Copyright © 2014, Elsevier Ltd. h Initial cycling of LRMs with different levels of Cu-doping. Reprinted with permission from Ref. [143]. Copyright © 2018, Elsevier Ltd. and Techna Group S.r.l. i Initial discharge curves of LRM with different levels of Zn-doping. Reprinted with permission from Ref. [144]. Copyright © 2015, Elsevier Ltd. and Techna Group S.r.l

a Initial cycle of Ti-doped LRM at different voltage windows; b CV profile of pristine and Ti-doped LRM; c schematic of Ti-doped LRM. Reprinted with permission from Ref. [132].

Zirconium (Zr) with a 4d0 orbital has also been used to dope LRMs, showing similar pillar effect. However, Zr doping has no obvious positive impact on activation, giving a similar activation capacity to undoped pristine materials. In fact, Zr can diminish the redox of other transition metals, resulting in a much lower capacity for both charging and discharging [134].

Cr is an electrochemically active metal with 3d electrons, which can provide extra Cr3+/Cr6+ redox couples. Thus, Cr is active and doping with Cr in LRMs will not sacrifice the overall capacity by introducing inactive materials. Earlier reports pointed out that Cr can suppress oxygen loss during activation [135, 136]. Some studies even found that Cr can accelerate the activation of the Li2MnO3 phase as a catalyst, because the initial capacity increases with Cr content [137]. However, the lower voltage slope before activation and the high-voltage activation plateau were not clearly distinguished. Thus, this improvement of capacity may have been contributed by the extra Cr3+/Cr6+ redox couple rather than an extended Li2MnO3 phase activation. The later reports supported this speculation by clearly showing the prolonged TM redox slope and shortened activation plateau [136, 138, 139]. For example, a reduced capacity contribution from activation is observed in the Cr doped LRMs [138]. With the help of in-situ synchrotron XRD, researchers confirmed that Cr can suppress the activation of the Li2MnO3 phase (Fig. 9d). Although such suppression can improve the lattice structure’s stability, the capacity contributed by oxygen redox is sacrificed. However, this loss of capacity can be compensated by the extra Cr3+/Cr6+ redox couple. Thus, the overall capacity of Cr-doped LRM is still larger than that of pristine [138]. As a result, increasing the Cr doping content shortens the activation plateau and gradually shifts it to a lower voltage (Fig. 9e). This change can be attributed to the existence of a stronger Cr–O bond (427 kJ mol−1) than TM–O bond (402 kJ mol−1 for Mn–O, 391.6 kJ mol−1 for Ni–O and 368 kJ mol−1 for Co–O), which retards the O22− oxidation during the activation [139].

Iron (Fe) is another commonly used dopant metal with the 3d electronic configuration, and is not as toxic as Cr. Unfortunately, the shortening of the capacity plateau and the prolonging of the TM redox slope are still observed by researchers [140, 141]. Fe can promote oxygen redox during activation because high valence Fe3+δ ions from the oxidation of Fe3+ during low voltage charging (below 4.5 V), can later capture the electron released by oxygen during high-voltage charging above 4.5 V. This reaction can accelerate the oxygen evolution from the lattice. However, such a reaction does not involve any Li+ extraction because the electrons released from the oxygen ions are trapped in the cathode by the Fe3+δ ions. The capacity is therefore not increased (Fig. 9f). The observed improvement of capacity is from the extra Fe3+/Fe3+δ redox couple, as proven by the dQ/dV curve shown in Fig. 9g [142]. All these results are in good agreement with Fe-based LRMs as mentioned above, suggesting that Fe is mainly a structural stabilizer rather than an activation accelerator.

Besides the commonly used metals, the research on other 3d transition metals such as copper (Cu) and zinc (Zn) is limited. Sorboni and co-workers examined the influence of Cu doping in their Li1.25Mn0.50Ni0.125Co0.125O2 cathode, and found that the initial capacity, and especially the portion contributed by activation decay, decreased with increased Cu content (Fig. 9h). This result suggests that Cu doping can suppress the activation of LRMs. The authors explain the decay in overall capacity by speculating that (1) the Cu2+ ions occupy Li+ sites and inhibit the diffusion of Li+, and (2) the existence of Cu2+ can cause oxidation of Ni2+, which decreases the number of Ni2+/Ni4+ redox couples. However, the electrochemically inactive Cu can stabilize the structure of LRM, resulting in better cycling stability [143]. Zn has pillar effect, helping to improve the rate performance, but the doped LRMs show clear capacity decay with increased Zn content compared to that of pristine materials (Fig. 9i). There are two reasons for this change. Firstly, Zn2+ may occupy Li+ sites due to having a similar size to Li+, which decreases the extractable Li content. Secondly, the strong Zn–O bond can impede oxygen redox during activation [144, 145].

In all the above-mentioned transition metals with 3d electronic orbitals (Table 5), only Ti facilitates the activation process, while Cr, Fe, Cu and Zn can suppress the activation but improve the cycling stability. Among them, electrochemically active Cr and Fe can compensate for the capacity loss from activation by providing extra redox couples. However, Cu and Zn sacrifice capacity contributions from both TM redox and oxygen redox, suggesting that they may not be suitable dopants for achieving a high capacity.

The options for transition metals with 4d2−4 or 5d2−6 configuration are Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, W, Re, Os, Ir, Pt, Au and Hg. Among them, only niobium (Nb), molybdenum (Mo), ruthenium (Ru), tungsten (W), and rhenium (Re) substitutions were experimentally or theoretically studied for LRMs. First principal calculations predicted that Nb can provide extra free electrons to compensate for the charge during activation and suppress the oxygen gas generation, evidenced by more Li removal before O2 generation energy reaches to zero than that of other dopant (Fig. 10a). The strong binding between Nb and O also reduced the oxygen evolution (Fig. 10b). The experiment also supports this calculation’s result [146]. Nb thermodynamically occupied Li sites near the particle surface (Fig. 10c), and it remained in a 5+ valence state during electrochemical cycling. Although Nb did not change the TM’s valence state and bulk oxygen environment, it can reduce the local TM3d-O2p hybridization. The weakened TM3d-O2p hybridization and strong Nb–O bond synergistically stabilized the local oxygen framework and suppressed the oxygen oxidation during activation. However, this only occurs near the Nb-containing particle surface, while the bulk oxygen ions are still active during cycling. Therefore, the initial charge/discharge capacities are not reduced, and are even slightly increased as shown in Fig. 10d. The increase in capacity is speculated to be caused by Li vacancies induced by Nb doping in Li layers that can lead to more Li insertion upon discharge [147]. In the other experimental work on Nb doping, in which Nb was homogenously doped into the bulk, the initial discharge capacity, cycling stability and rate performance were increased after Nb doping. This is because Nb5+ (0.64 Å) is larger than Mn4+ (0.53 Å) and Co3+ (0.54 Å) and can enlarge the interlayer spacing, facilitating Li+ diffusion. However, the charge capacity, including the part contributed by activation, shows no obvious change [148]. However, some researchers also observed an increased overall capacity but reduced activation contribution with Nb doping. They proved the suppression in activation through theoretical calculations and reported the formation energy of oxygen vacancies in LRMs is significantly increased from 2.63 to 3.66 eV after Nb doping (Fig. 10e and f). In addition, the existence of Nb in Li sites can reduce the energy barrier of Li+ diffusion, which results in improved cycling stability and rate performance. The easier transport of Li+ also leads to the TM’s redox slope gradually shifting towards lower voltages with increased Nb content (Fig. 10g) [149].

a Calculated O2 release energy with different metal dopings at different delithiation states; b binding energy between different metals and oxygen. Reprinted with permission from Ref. [146]. Copyright © 2015, American Chemical Society. c Schematic of Nb-doped structure; d initial cycling of LRM before and after Nb-doping. Reprinted with permission from Ref. [147]. Copyright © 2018, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. Schematic of structure and Nb–O binding energy when Nb is in e TM layers and f Li layers; g initial cycling profile with different levels of Nb-doping. Reprinted with permission from Ref. [149]. Copyright © 2019, American Chemical Society. h Initial cycling profile before and after Mo-doping; corresponding dQ/dV curves i before and j after Mo-doping. Reprinted with permission from Ref. [151]. Copyright © 2019, Elsevier B.V. k Initial cycling profile with different levels of W-doping. Reprinted with permission from Ref. [153]. Copyright © 2019, Springer-Verlag GmbH Germany, part of Springer Nature. l Change of bond lengths/distances in angstrom before and after Re-doping. Reprinted with permission from Ref. [154]. Copyright © 2019, American Chemical Society

Mo is also predicted to have a similar size to Mn/Ni/Co and strong bonding with oxygen according to first principle calculations. But the Li migration in Mo doped LRM is predicted to be more difficult due to a higher energy barrier and narrower Li diffusion paths. The operational voltage is also predicted to be lower than that of pristine [26]. However, the experimental work of two other groups proved that Li diffusion is actually not hindered after Mo doping, as they observed higher rate performance and lower electrochemical impedance [150, 151]. In Guo and co-workers’ report, both the initial charge and discharge capacity is lower in Mo doped LRMs compared to that of pristine materials, because electrochemically inactive Mo6+ reduces the number of redox couples. However, the activation shows no obvious change with or without Mo [150]. While Chu et al. point out that the doping of Mo6+ can reduce the valence state of Ni, and so the charge plateau voltage is lower than that of pristine. Extra Ni2+ can provide more electrons to boost the capacity. Moreover, the activation plateau is less distinguishable after Mo doping (Fig. 10h), possibly due to the decrease in Mn content. However, the differential plots of capacity versus voltage (dQ/dV) curves and ex-situ XPS indicate stabler oxygen redox in the Mo-doped sample (Fig. 10i and j) [151]. It is notable that the capacity change in the above two reports are in conflict. The contrasting results may originate from the different Mo substitution sites.

As discussed above, in the composition adjustment section, Ru can accelerate the activation and prevent oxygen gas generation if used in large fractions in LRMs. Due to Ru being an expensive metal, such a high Ru content is not practical for industrial applications. To investigate the effect of low Ru content, Song and co-workers reported on a Ru trace doped LRM. In this work, Ru substitutes for Co and enlarges the interlayer space of the lattice, which increases Li mobility in the material. The charging voltage plateau above 4.5 V is apparently prolonged after Ru doping, indicating deeper activation [39]. However, the improvement of cycling stability is not as significant as the Ru-based LRM, possibly because the Ru content is not high enough.

W is a 5d transition metal with strong covalent bonding with oxygen, so it is expected to stabilize the lattice structure of LRMs during cycling. In the past 3 years, the influence of W doping on electrochemical performance both on the surface and in the bulk were studied [152, 153]. In both reports, the activation plateau during initial charging is prolonged after W doping (Fig. 10k), indicating a larger activation extent [153]. However, the underlying mechanism is still not clear. At the same time, the initial discharge capacities also increased, suggesting suppressed irreversible oxygen evolution. In addition, W doped LRMs show better capacity and voltage retention in long cycling. This may be related to the strong W–O bonding, which can restrain the migration of transition metal ions and the subsequent formation of a spinel phase.