Abstract

This study explores explore the failure characteristics of high temperature granite under different numbers of heating–cooling cycles. Combining a series of laboratory uniaxial compression tests with acoustic emission (AE) monitoring, it reveals the AE characteristics and damage behavior of high temperature granite in different damage stages. Increasing the number of heating–cooling cycles exponentially raised the mass-loss and volume-increase rates of the granite and exponentially decreased the P-wave velocity. These results indicate that multiple heating–cooling cycles irreversibly damaged the high temperature rock mass. Moreover, the variations in both the P-wave velocity and the stress threshold at each stage gradually plateaued after three thermal cycles. Under uniaxial compression, the evolution mechanism of microcracks in the rock was successfully described by the AE characteristic parameters and real-time spatial AE position. The cumulative AE counts and AE energy rates were consistent in different damage stages of the rock specimen. Both quantities began increasing after entering the unstable crack growth stage. As the number of heating–cooling cycles increased, the main fracture mechanism of rock rupture transitioned from mixed mode to shear mode, as evidenced by the distributions of rise angle and average frequency. Meanwhile, the gradually increasing b-value indicated that small-scale fracture events gradually dominated the rock damage. The present results can assist the design of deep geothermal-resource mining schemes and safe mining constructions.

Highlights

-

1.

The heating–cooling cycle impacts significantly reduce the mechanical properties of granite and promote the evolution of microcracks.

-

2.

The damage degree of granite is weakened after more than three heating–cooling cycles.

-

3.

AE characteristic parameters can effectively describe the evolution mechanism of microcracks.

-

4.

The heating–cooling cycle shocks can promote fracture network complexity in geothermal resource extraction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The increasing energy demands of human society have continuously depleted the supplies of non-renewable energy sources such as oil and natural gas, necessitating the development of clean and efficient new green energy sources (Sayed et al. 2021; Furlan and Mortarino 2018). Geothermal resources have been suggested as green and renewable resources that can be sustainably developed (Michaelides 2015; Wang et al. 2018; Spittler et al. 2020). Hot dry rock is a high-quality geothermal resource with huge reserves worldwide. However, despite its large usable value and broad development prospects, hot rock has never been developed in large quantities (Hu et al. 2021; Wang et al. 2021). Hot dry rock is subjected to multiple high temperature and water-cooling cycles during the mining process. Consequent damage and fracture affect the stability and efficiency of geothermal development of hot dry rock. Therefore, the fracturing mechanism of hot dry rocks must be investigated at different temperature under different heating–cooling cycles.

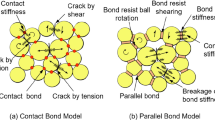

The physico-mechanical properties and fracture mechanisms of rock are greatly affected by high temperature conditions. Under thermal loading, accumulated damage caused by thermal stress can change the mechanical properties a of rock; meanwhile, the mismatched thermal expansions of the rock minerals lead to microcracks (Zhao 2016; Zhang et al. 2020; Pan et al. 2023a). Owing to its low permeability and high strength, granite is a well-recognized candidate reservoir of enhanced geothermal systems (Zhao et al. 2013; Chen et al. 2017; Miao et al. 2020). Although high temperatures are known to decrease the compressive strength, elastic modulus, tensile strength, and fracture toughness of granite (Liu and Xu 2014; Rong et al. 2018; Wu et al. 2021). However, a quantitative determination of the threshold temperature, beyond which granite undergoes a transition from brittle to ductile state, is not available. Granite has been thermally treated between room temperature and 800 °C. The threshold for the transition of granite mechanical properties has been observed at 300 °C in some studies (Géraud et al. 1992; Su et al. 2016) and at 400 °C or higher in others (Liu and Xu 2015; Yin et al. 2016). In addition, microscale measurements can clarify the macroscopic mechanical damage mechanism of heated granite (Pan et al. 2023b). Homand-Etienne and Houpert (1989) found that the crack width changed more remarkably than the crack length with the temperature increase. Yang et al. (2017) found that intercrystalline cracks form at the quartz–feldspar boundaries in rock at temperature below 400 °C. Transgranular cracks appear at higher temperatures and visible surface cracks appear at 700 °C. Acoustic emission (AE) technology can locate the sources of microcracks during the failure process and reveal the evolution characteristics of internal microcracks in real time. For this reason, AE is widely used in rock-damage research (Zhu et al. 2020; Wang et al. 2023).

After high temperature treatment, the rock is commonly cooled by natural cooling, blowing, water-cooling, and liquid nitrogen cooling (Kumari et al. 2019; Sha et al. 2020). Previous studies have shown that water-cooling induces more severe microstructural tissue damage and mechanical behavior deterioration in high temperature rocks than the slow cooling (Shao et al. 2014). This finding can be explained by the large temperature difference between the high temperature rock mass and cold water, which induces rapid cooling. The transient thermal stresses generated by a large temperature difference usually manifest as tensile stress on the surface and compressive stress in the center of the body. The combined action of tensile and compressive stress generates thermal cracks that greatly increase the crack density inside high temperature rock (Collin and Rowcliffe 2002; David et al. 2012). Cold treatment with liquid nitrogen also promotes microcrack propagation, thereby increasing rock permeability, and reducing fracture pressure. Consequently, the fracture network in the granite specimens is denser after liquid nitrogen cooling than after natural cooling and water-cooling (Kang et al. 2021; Xi et al. 2022).

The research on the damage behavior of high temperature rock under different heating–cooling cycles has been increasingly studied in recent years. Ge and Sun (2018) studied the AE and b-value during rock fracture at different stress levels and temperatures. Zhu et al. (2021) observed that heating–cooling cycling treatment can further deteriorate and weaken the physical and mechanical properties of granite; Kant et al. (2017) found that the thermal diffusivity and thermal conductivity of Central Aare granite are irreversibly changed after the first heating–cooling cycle because thermal shock damage causes thermal cracks along grain boundaries in the rock. However, the damage evolution law in high temperature rock after different heating–cooling cycle treatments at different damage stages is not fully clarified. In particular, the effects of heating–cooling cycling on the AE characteristics and damage process of granite must be further investigated.

In this study, uniaxial compression tests and AE monitoring were performed on dense granite after heating–cooling cycles. The effects of heating–cooling cycling on the physical and mechanical properties of granite, (mass, volume, P-wave velocity, stress–strain curve, and failure mode) are systematically analyzed. Based on the stress–strain response, the damage process of granite is divided into different stages, and the dependence of the characteristic stress threshold on number of heating–cooling cycles is obtained. Finally, the effects of heating–cooling cycling on the mechanism of granite microcrack formation are discussed in terms of the obtained AE characteristic parameters (AE high-magnitude events, cumulative AE counts, AE energy rates, rise angle–average frequency (RA–AF) characteristics, and b-value). The insights gained are expected to guide the efficient development of geothermal resources.

2 Methods

2.1 Description of rock specimens and testing system

The experimental material was granite sourced from Rizhao, Shandong Province, China. Following the test procedures of the International Society of Rock Mechanics (Ulusay 2014), the granite specimens were formed into cylindrical specimens sized 50 mm × 100 mm (diameter × length) through cutting and polishing. The parallelism and surface flatness of the processing were controlled within ± 0.05 mm and ± 0.02 mm, respectively (Fig. 1a). Polarizer analysis confirmed the mineral composition of the granite as quartz (25%–30%), plagioclase (25%–30%), K-feldspar (35%–40%), and minor minerals such as amphibole and biotite (Fig. 1b). To reduce the discreteness of experimental results, the P-wave velocities of the specimens were ultrasonically tested on three independent specimens in each experimental group.

The granite specimens were subjected to different numbers of heating–cooling cycles followed by uniaxial compression tests on a rock mechanics testing system, as shown in Fig. 2a. The granite specimen received an axial load under an axial-displacement control loading method with a constant loading speed (0.001 mm/s). To acquire the axial strain, the built-in vertical displacement of the system loading plate was recorded and the circumferential strain was monitored in real time using a circumferential strain gauge (Fig. 2b). To clearly record the AE parameters and locate the rupture sources during the experiment, six AE sensors were affixed to the specimen surfaces (Fig. 2b). The AE sensors were divided into three symmetrically installed groups (1 and 6, 2 and 4, 3 and 5). Groups 1, 2, and 3 (groups 4, 5, 6) were installed at approximately 25 mm from the top (bottom) end of the specimen (Fig. 2c). This orthogonal arrangement optimally covers the entire area of the cylindrical specimen, enabling location of the fracture source (Tham et al. 2004). In addition, the contact surfaces between AE sensors and the specimen were daubed with Vaseline to facilitate acoustic coupling. Prior to AE monitoring, the gain value of the pre-amplifier and the AE-detection threshold were both set to 40 dB to ensure the reliability of the acoustic emission signal.

2.2 Experimental scheme

After a given number of heating–cooling cycles, the damage to granite strongly depended on temperature. Junique et al. (2021) found that the magnitude of granite damage began declining after 10 heating–cooling cycles at 200 °C. At 400 °C, the greatest damage was observed during the first five cycles. Therefore, prior to the formal heating–cooling cycling experiment, we tested the thermal damage law of granite under different temperatures (25 °C–600 °C) to determine the target temperature. At temperatures above 400 °C, the stress–strain curve of the specimen markedly changed, showing a large reduction in peak strength, and a large enhancement in ductility (Fig. 3). In summary, 400 °C was regarded as the threshold temperature at which the mechanical properties of granite transformed. Therefore, this temperature was set as the target temperature and cold water was selected as the cooling medium for heating–cooling cycling treatment of high temperature granite specimens.

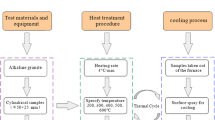

The experimental specimens were first heated to 400 °C in a muffle furnace at 10 °C/min and maintained at that temperature for 2 h. The specimens were then removed from the furnace and cooled immediately to room temperature by water. The number of heating–cooling cycles was varied as 0 (no thermal shock treatment), 1, 3, 5, and 7. Figure 4 is a schematic of the experimental design.

3 Results

3.1 Characteristics of the mass and volume evolutions

Mass loss of the rock specimens after the thermal treatment was mainly attributable to evaporation of water (e.g. absorbed, bounded, and mineral water) from the granite interior (Sun et al. 2015; Su et al. 2022). Moreover, granite is composed of mineral particles with different thermal expansion coefficients. Exfoliation of mineral grains caused by the expansion and contraction of mineral particles at high temperatures will also increase the mass loss. This process generates microcracks and consequent new pores that increase the overall volume of the rock (Wu et al. 2022). Variations in mass and volume can be represented by the mass loss rate (MLR) Km (defined as the ratio of the mass loss to the initial mass) and the volume expansion rate (VER) Kv (defined as the ratio of the volume increase to the initial volume). As shown in Fig. 5, both the MLR and VER of the granite specimens increased exponentially with number of heating–cooling cycles. The data were well-fitted to exponential curves with R2 = 0.99 in all cases.

3.2 Characteristics of the P-wave velocity evolution

The propagation of P-waves is affected by various factors such as mineral composition, degree of grain cementation, and porosity of granite (Sha et al. 2020). A P-wave passing through a granite specimen with a dense interior behaves equivalently to a P-wave passing through a continuous solid medium and the wave speed is fast. In a rock specimen with cracks and defects, P-wave bounce through the cavities. The path of the P-wave lengthens and the wave velocity decreases (Yu et al. 2021). Therefore, the variation of the P-wave velocity can indicate the damage degree inside the rock.

The average P-wave velocity through the granite specimens was 4990 m/s. Figure 6 shows the variation characteristics in the P-wave velocity after multiple heating–cooling cycles. The P-wave velocity decreased exponentially with increasing number of heating–cooling cycles at 400 °C. Note that the P-wave velocity decreased sharply during the first three heating–cooling cycles, and was gently attenuated during later cycles, consistent with a previous study (Liu et al. 2021).

3.3 Damage stage divisions and stress thresholds

The stress–strain curve of brittle rock under uniaxial compression is usually divided into five stages: crack closure (I), elastic deformation (II), stable crack growth (III), unstable crack growth (IV), and post-peak stage (V) (Xue et al. 2014, 2015a; Chen et al. 2018; Zhai et al. 2022a). Figure 7 shows the stress–strain curves of granite specimens under different heating–cooling cycles. According to previous researches (Martin and Chandler 1994; Xue et al. 2015a), the damage stages in stress–strain curves are separated by the following demarcation points: crack closure stress σcc (endpoint of I), crack initiation stress σci (endpoint of II), crack damage stress σcd (endpoint of III), and the peak strength σucs (end point of IV). The thresholds of the damage stages are obtained through the total volumetric strain and crack volumetric strain (blue and red lines, respectively, in Fig. 7). σcc corresponds to the start point of the flat region of the crack volumetric strain curve, indicating that the numerous fine cracks present in red sandstone have completely closed and the specimen is entering the elastic deformation stage. σci corresponds to the endpoint of the flat region of the crack volumetric strain curve, indicating the end of elastic deformation, the emergence of stress-induced microcracks, and the start of rock damage. σcd corresponds to the peak point of the total volumetric strain curve, at which the fracture process changes from stable to unstable. At this point, the specimen falls into the accelerated-failure stage and its volume state tends to change from shrinkage to expansion. Therefore, this point is usually referred to as the volume-expansion point. Finally, σucs indicates the formation of macroscopic and penetrating failure, which corresponds to the peak stress.

To clarify the stress state of the specimen before fracture, the post-peak region is omitted from Fig. 7. During the crack closure stage (I), the initial defects in the granite are compacted, and the relationship between the axial stress and the axial strain is concave upward. The contraction region at this stage is characterized by an increase in crack volume strain and total volume strain. The crack closure stage gradually extended with increasing number of heating–cooling cycles, indicating that repetitive heating and cooling can exacerbate the evolution of microcracks in granite. As the cracks in the rock mass gradually close, the stress reaches the crack closure stress σcc. The rock deformation then enters stage (II), in which the axial stress increases linearly with axial strain. The gradient of this relationship defines the elastic modulus of the rock. Note that the total volumetric strain also shows a linear increase, indicating that the granite is linearly shrinking at this time. In addition, the crack volume strain remains almost constant, affirming that almost no new cracks are generated at this stage. When an inflection point appears in the crack volume strain (indicating the start of strain decrease), the third stage begins. At this time, the rock damage exits the elastic deformation stage and enters the stable crack growth stage (III). Generally speaking, the further evolution of cracks usually requires a continuous external load at this stage, meaning that the crack growth can be terminated by controlling the applied load. Meanwhile, the total volumetric strain continued to gradually increase, and the rock remains in the shrinking state. The unstable crack growth stage (IV) is triggered when the total volumetric strain reaches the peak point (also called the volume expansion point). Once the rock has been loaded to the volume expansion point, it will eventually fail even if the load remains constant; therefore, this point is sometimes regarded as a precursor of rock rupture (Xue et al. 2014, 2015a, 2015b). As the crack propagation continued to intensify, obvious macroscopic cracks appeared and the rock fractured instantaneously when the peak stress was reached.

Based on the above-mentioned division of damage stages in the uniaxial compression curves of granite, we recorded the characteristic stress thresholds of the specimens after different numbers of heating–cooling cycles, as shown in Fig. 8.The σcc, σci, σcd, and σucs all decreased with increasing number of heating–cooling cycles. The main damage occurred during the first three cycles, with σcc, σci, σcd, and σucs reductions of 58.07%, 51.87%, 49.64%, and 43.59%, respectively. After three heating–cooling cycles, the stress thresholds stabilized, indicating that the samples were not further damaged by increasing the number of cycles, which is similar to the experimental phenomenon of Rong et al. (2018). The P-wave velocity shows the same behavior (see Fig. 6).

Figure 9 plots the axial strain proportions (the ratio of axial strain in each stage to total axial strain before the peak strength point) after different numbers of heating–cooling cycles in the four typical damage stages before granite fracture. The crack closure stage and the stable crack growth stage were more sensitive to number of heating–cooling cycles than the other stages. Increasing the increase in the number of heating–cooling cycles, increased the proportion of the crack closure stage and concomitantly decreased the proportion of the stable crack growth stage. After seven heating–cooling cycles, the stable crack-growth stage contributed only 2% of the total strain. This result implies that the thermal effect of high temperature followed by quenching with cold water aggravated the evolution of microcracks inside the specimen; consequently, the microcrack density was increased. Moreover, as the heating–cooling cycles continued, the rock accumulated internal damage and became more likely to enter the unstable crack growth stage under an external force.

3.4 Crack evolution determined from AE locations

The real-time AE localization method is widely used in rock mechanics (Yang et al. 2021) because it can trace the crack initiation, propagation, and coalescence processes in a loaded rock specimen. Figure 10 shows the spatial locations of the AE source and the rock failure modes in the four damage stages after different numbers of heating–cooling cycles. The AE counts increased exponentially as the specimen progressed from load to failure. During the crack closure stage (I), the events recorded by AE sensors are mainly low-magnitude events (gray dots), and relatively few high-magnitude events (red dots). However, as the number of heating–cooling cycles increased in this stage, the number of high-magnitude events increased accordingly and were uniformly distributed, indicating an irregular distribution of microcracks induced by the heating–cooling cycling action. In addition, high-magnitude events were sporadically concentrated near the specimen surface, possibly reflecting the sharp temperature drop of the specimen surface at the moment of cold quenching. Owing to the extreme temperature difference between the inside and surface of the rock (Shen et al. 2021), microcracks were generated on the surface of the specimen. During the elastic deformation and stable crack growth stages, the AE events were scattered across the specimen because the initiation of new cracks in rock is random. To clarify the location of AE source during rock failure stage, Fig. 10 excludes the low-magnitude events in the unstable crack-growth stage (IV). Observing the locations of the AE source and the fracture patterns of the specimen, we find that the main rupture zones formed by the distribution of high-magnitude AE events roughly coincide with the observed fracture locations of the specimen.

3.5 Evolutions of AE parameters

During the uniaxial compression experiment, many AE signals were generated and macroscopic fracture of specimens was observed. Various parameters of the AE signals in different damage stages of rock can effectively reflect the fracture behavior and damage process of rock (Miao et al. 2020; Zhai et al. 2022b; Bu et al. 2022). This subsection investigates the microcrack behavior of the granite specimens during loading in terms of the AE energy rate, cumulative AE counts, RA–AF value, and b-value.

3.5.1 AE energy rate and cumulative AE counts

The cumulative AE counts and energy rate reflect the crack generation frequency and intensity of granite specimens under uniaxial compression (Eberhardt et al. 1998). To clarify the evolution of the AE energy rate before the granite specimen failed, the recorded energy data were logarithmically processed in this study.

Figure 11 shows the evolutions of AE energy rate and cumulative AE counts with axial strain at different damage stages of granite subjected to different numbers of heating–cooling cycles. In the crack closure stage (I), the cumulative AE counts plateaued after a brief rise and the corresponding energy rates were briefly dense and gradually became sparse (Fig. 11a–c). These behaviors were mainly caused by the end friction effect between the specimen and the loading plate. As the increasing number of heating–cooling cycles increased, the cumulative AE counts no longer plateaued after the initial rise but continued rising with a certain slope (Fig. 11d, e). After many heating–cooling cycles (≥ 5 cycles), the crack closure frequency began to increase, and the corresponding energy rate became denser, mainly because the number of irregular microcracks increased in the specimen. In the elastic deformation stage (II), the AE activity was reduced and the cumulative AE counts remained almost constant. The energy rate was similarly inactive. In the stable crack growth stage (III), the cumulative AE counts remained stable and their increase rate was small, but the AE energy rate began to increase. When the specimen was damaged to the unstable crack growth stage (IV), the cumulative AE counts began increasing sharply and the corresponding energy rate was higher than in the previous three stages, indicating rapid expansion and connection of the microcracks to form the main fracture zone. In this stage, the cumulative AE counts and energy rates increased with increasing the number of heating–cooling cycles. When loaded to its peak strength, the rock specimen ruptured rapidly with a loud noise, and the peak strength rapidly declined.

3.5.2 RA–AF characteristics

The mechanisms of the AE events were determined using the AE waveform-parameter method. The variations characteristics of the rise angle (RA value) and average frequency (AF value) can determine the type of microcracks generated in the rock mass during the loading process (Liu et al. 2020), which are respectively computed as:

The rise time, maximum amplitude, AE ring counts, and duration time in Eqs.1 and 2 are depicted in Fig. 12.

In general, shear-mode events are characterized by longer waveforms (lower AF values) and longer rise time (higher RA values); in contrast, the tensile-mode AE events are characterized by shorter waveforms (higher AF values) and shorter rise times (lower RA values) (Chen et al. 2021). Figure 13 illustrates the moving mean RA and AF values (with 500 events in each calculating interval) versus loading time in granite specimens at different damage stages after different numbers of heating–cooling cycles. Increasing the number of heating–cooling cycles increased the number of AE events, consistent with the conclusions in subSect. 3.5.1. In stages I–III of specimen damage, the AF was raised while the RA was lowered, indicating that the first three stages of rock damage were dominated by tensile failure mode. When entering the unstable crack growth stage (IV) (that is, when the stress exceeds the crack damage stress σcd), the AF began decreasing while the RA value increased sharply, indicating the development of numerous shear-mode fractures that penetrated to form the main fracture zone. This behavior mirrors the large increase in the number of high-magnitude events that formed the main fracture zone after entering the unstable crack growth stage in subSect. 3.4.

During the uniaxial compression experiment, the tensile-mode failure (higher AF, lower RA) and the shear-mode failure (lower AF, higher RA) modes were often accompanied by another failure mode characterized by lower AF and lower RA. Ohtsu (1991) defined such events as mixed-mode failures. Chen et al. (2021) found that shear-mode failures can be reasonably determined from the RA and AF levels of the specimen at the volume expansion point (i.e., the outset of damage stage IV). The RA value corresponding to the volume expansion point of the granite specimen was between 5 and 7 ms /V and the AF value was approximately 100 kHz (Fig. 13). Therefore, we define AE events with RA > 6 ms /V and AF < 100 kHz to shear-mode failure, AE events with RA < 6 ms /V and AF > 100 kHz to tensile-mode failure, and all remaining events can be classified as mixed-mode failure.

Figure 14 plots the RA–AF distributions and proportions of failure modes in the granite specimens. After zero, one, or three heating–cooling cycles, the RA–AF plot was concentrated around the lower left corner (Fig. 14a–c), indicating a dominance of mixed-mode failure. The same conclusion can be drawn from the proportions of mixed-mode events. As the number of heating–cooling cycles increased, the RA–AF distribution shifted the abscissa axis and the proportion of shear-mode events increased accordingly (Fig. 14d, e). Notably, the decreased proportion of mixed-mode failure complemented increased proportion of shear-mode failure as the number of heating–cooling cycles increased (Fig. 14f), indicating that after many heating–cooling cycles, the failure mode of the specimen is dominated by shear failure. This finding is consistent with the variation patterns of the dynamic RA and AF values observed in subSect. 3.5.2.

3.5.3 AE b-value

During the uniaxial compression experiment, the AE events were monitored to reflect the occurrence and evolution of internal cracks in rock specimens (Bu et al. 2022). The AE amplitude A (in dB) depends on the energy released by the fracture event. Originating in seismology, the b-value describes the relationship between the magnitude and frequency of earthquake waves. The famous Gutenberg–Richter relationship used in seismology has been fitted to AE events (Gutenberg and Richter 1944) as follows:

where M denotes the earthquake magnitude, N is the cumulative number of earthquakes with magnitudes above M, and a and b are two statistical constants.

The AE magnitude can be calculated from the AE energy by the formula proposed by Gutenberg (1956), which is given as:

where E is the AE energy in Joules. The b-value reveals the characteristics of magnitude distribution. When the b-value is large, the specimen is dominated by small-scale fracture; conversely, when the b-value is small, the specimen is dominated by large-scale fracture. Figure 15 shows the b-values calculated by the least-squares regression method, the frequency-magnitude relationship, and the cumulative numbers of AE events with magnitudes exceeding a certain value. All AE magnitudes followed a normal distribution, mainly between − 16 and − 12, and the linear fits between logN and earthquake magnitude were excellent. In addition, the b-values trended upward with number of heating–cooling cycles, especially when the number of heating–cooling cycles exceeds 3 times, the b-value increased linearly with number of cycles. This indicates that the more the number of heating–cooling cycles, the more the number of microcracks inside the rock caused by thermal shock damage. At this time, the failure mode of the specimen under uniaxial compression was dominated by small-scale fracture events.

4 Discussion

High-temperature granite has become an important reservoir material in enhanced geothermal systems. The heat stored in granite must be transformed using a hydraulic or some other artificial fracturing technique, forming a fracture network with high permeability and good connectivity in high temperature strata. Energy conversion is achieved under the flow of a low temperature medium (Li et al. 2022), as shown in Fig. 16. However, due to the characteristics of high in-situ stress and high strength of hot dry rock, it is difficult to crack and is lowly permeable (Xing et al. 2019). According to the above experimental results, a large number of microcracks can be randomly generated in high-temperature granite rock after repeated heating–cooling cycles. Therefore, by analyzing the crack generation mechanism of high temperature granite under heating–cooling cycle impact, we can expect to improve the percolation effect of thermal reservoirs.

Under the cyclic heating–cooling treatment, granite was mainly damaged by high temperature shock, followed by the cold quenching effect, which cause cumulative damage. During the thermal treatment stage, the continuous high-temperature application released the free water, bound water, and crystal water from the granite as gas, inducing the emergence and development of microcracks and thereby reducing the P-wave velocity (Fig. 6). Granite is mainly composed of quartz, feldspar, and biotite (Fig. 1), which have thermal expansion coefficients of 11 × 106, 6 × 106, and 3 × 106/°C, respectively. Owing to their different thermal expansion coefficients, the minerals were asynchronously deformed during thermal treatment and microcracks were formed. During the cooling treatment, the water rapidly reduced the surface temperature of high temperature rock, plunging the specimen into an extremely unstable temperature field. The huge temperature gradient caused serious damage to the rock. In addition, the uncoordinated deformations of the different mineral components enhanced the propagation of internal microcracks through the rock. Repeated high temperature application weakened the bonding force between mineral particles, and promoted the development of microcracks in the rock specimens, further facilitating the microfractures (Yin et al. 2022). The microfractures then combined with surrounding microfractures, forming large pores. The appearance of visible macroscopic fractures is an important precursor of granite rupture. In addition, some scholars have shown that ultra-low temperature media such as liquid nitrogen can effectively promote fracture generation in high temperature rock masses (Shen et al. 2020, 2021; Xi et al. 2022). Therefore, if a low temperature fluid, such as cold water or liquid nitrogen, is repeatedly injected into a high temperature rock mass before the hydraulic fracturing, thermal shock will generate a large number of hot cracks in the hot dry rock. This mechanism is expected to increase the complexity of the reservoir crack network, improve the permeability and porosity, and consequently improve the extraction efficiency of geothermal energy.

5 Conclusions

This paper systematically investigated the effect of repeated heating–cooling cycles on the mechanical properties and fracture characteristics of granite at a specific temperature (400 °C). The investigation was performed using AE monitoring technology and the main conclusions are summarized below.

-

1.

Increasing the number of heating–cooling cycles exponentially increased the MLR and VER of granite specimens, while decreasing the P-wave velocity and stress threshold. The changes became gentle after three heating–cooling cycles.

-

2.

The high-magnitude events recorded by AE increased significantly and were evenly distributed with the increase in the number of heating–cooling cycles. The main fracture zone gradually formed after the rock entered the unstable crack growth stage.

-

3.

The cumulative AE counts and AE energy rates began notably increasing after entering the unstable crack growth stage. Meanwhile, as the number of heating–cooling cycles increased, the main fracture mechanism of rock fracture transitioned from mixed mode to shear mode (as evidenced by the RA–AF distribution) and the b-value gradually increased, indicating that small-scale fracture events gradually dominated the rock damage.

-

4.

Cyclic heating–cooling treatment mainly damaged the granite specimens through high temperature shock in the thermal treatment stage, the cold quenching effect in the cooling treatment stage, and the cumulative damage as the cycles proceeded.

Data availability

Data will be made available on request.

References

Bu F, Xue L, Zhai M, Huang X, Dong J, Liang N, Xu C (2022) Evaluation of the characterization of acoustic emission of brittle rocks from the experiment to numerical simulation. Sci Rep 12(1):498. https://doi.org/10.1038/s41598-021-03910-8

Chen Y, Wang S, Ni J, Azzam R, Fernández-steeger TM (2017) An experimental study of the mechanical properties of granite after high temperature exposure based on mineral characteristics. Eng Geol 220:234–242. https://doi.org/10.1016/j.enggeo.2017.02.010

Chen H, Qin S, Xue L, Yang B, Zhang K (2018) A physical model predicting instability of rock slopes with locked segments along a potential slip surface. Eng Geol 242:34–43. https://doi.org/10.1016/j.enggeo.2018.05.012

Chen H, Di Q, Zhang W, Li Y, Niu J (2021) Effects of bedding orientation on the failure pattern and acoustic emission activity of shale under uniaxial compression. Geomech Geophys Geo-Energ Geo-Resour 7:20–37. https://doi.org/10.1007/s40948-021-00216-x

Collin M, Rowcliffe D (2002) The morphology of thermal cracks in brittle materials. J Eur Ceram Soc 22:435–445. https://doi.org/10.1016/S0955-2219(01)00319-3

David EC, Brantut N, Schubnel A, Zimmerman RW (2012) Sliding crack model for nonlinearity and hysteresis in the uniaxial stress–strain curve of rock. Int J Rock Mech Min Sci 52:9–17. https://doi.org/10.1016/j.ijrmms.2012.02.001

Eberhardt E, Stead D, Stimpson B, Read RS (1998) Identifying crack initiation and propagation thresholds in brittle rock. Can Geotech J 35:222–233. https://doi.org/10.1139/cgj-35-2-222

Furlan C, Mortarino C (2018) Forecasting the impact of renewable energies in competition with non-renewable sources. Renew Sustain Energy Rev 81:1879–1886. https://doi.org/10.1016/j.rser.2017.05.284

Ge Z, Sun Q (2018) Acoustic emission (AE) characteristics of granite after heating and cooling cycles. Eng Fract Mech 200:418–429. https://doi.org/10.1016/j.engfracmech.2018.08.011

Géraud Y, Mazerolle F, Raynaud S (1992) Comparison between connected and overall porosity of thermally stressed granites. J Struct Geol 14(89):981–990. https://doi.org/10.1016/0191-8141(92)90029-v

Gutenberg B (1956) The energy of earthquakes. Q J Geol Soc Lond 112(1–4):1–14. https://doi.org/10.1144/GSL.JGS.1956.112.01-04.02

Gutenberg B, Richter CF (1944) Frequency of earthquakes in California. Bull Seismol Soc Am 34(4):185–188. https://doi.org/10.1785/BSSA0340040185

Homand-Etienne F, Houpert R (1989) Thermally induced microcracking in granites: characterization and analysis. Int J Rock Mech Win Sci Geomech Abstr 26(2):125–134. https://doi.org/10.1016/0148-9062(89)90001-6

Hu J, Xie H, Sun Q, Li C, Liu G (2021) Changes in the thermodynamic properties of alkaline granite after cyclic quenching following high temperature action. Int J Min Sci Technol 31(5):843–852. https://doi.org/10.1016/j.ijmst.2021.07.010

Junique T, Vazquez P, Benavente D, Thomachot-Schneider C, Géraud Y (2021) Experimental investigation of the effect of quenching cycles on the physico-chemical properties of granites. Geothermics 97:102235. https://doi.org/10.1016/j.geothermics.2021.102235

Kang F, Jia T, Li Y, Deng J, Tang C, Huang X (2021) Experimental study on the physical and mechanical variations of hot granite under different cooling treatments. Renew Energy 179:1316–1328. https://doi.org/10.1016/j.renene.2021.07.132

Kant MA, Ammann J, Rossi E, Madonna C, Höser D, Rudolf von Rohr P (2017) Thermal properties of Central Aare granite for temperatures up to 500°C: Irreversible changes due to thermal crack formation. Geophys Res Lett 44(2):771–776. https://doi.org/10.1002/2016gl070990

Kumari WGP, Beaumont DM, Ranjith PG, Perera MSA, Avanthi Isaka BL, Khandelwal M (2019) An experimental study on tensile characteristics of granite rocks exposed to different high-temperature treatments. Geomech Geophys Geo-Energ Geo-Resour 5(1):47–64. https://doi.org/10.1007/s40948-018-0098-2

Li S, Wang S, Tang H (2022) Stimulation mechanism and design of enhanced geothermal systems: A comprehensive review. Renew Sust Energ Rev 155:111914. https://doi.org/10.1016/j.rser.2021.111914

Liu S, Xu J (2014) Mechanical properties of Qinling biotite granite after high temperature treatment. Int J Rock Mech Min Sci 71:188–193. https://doi.org/10.1016/j.ijrmms.2014.07.008

Liu S, Xu J (2015) An experimental study on the physico-mechanical properties of two post-high-temperature rocks. Eng Geol 185:63–70. https://doi.org/10.1016/j.enggeo.2014.11.013

Liu X, Liu Z, Li X, Gong F, Du K (2020) Experimental study on the effect of strain rate on rock acoustic emission characteristics. Int J Rock Mech Min Sci 133:104420. https://doi.org/10.1016/j.ijrmms.2020.104420

Liu H, Zhang K, Liu T, Cao H, Wang Y (2021) Experimental and numerical investigations on tensile mechanical properties and fracture mechanism of granite after cyclic thermal shock. Geomech Geophys Geo-Energ Geo-Resour 8(1):18–40. https://doi.org/10.1007/s40948-021-00325-7

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci Geomech Abstr 31(6):643–659. https://doi.org/10.1016/0148-9062(94)90005-1

Miao S, Pan P, Zhao X, Shao C, Yu P (2020) Experimental study on damage and fracture characteristics of beishan granite subjected to high-temperature treatment with DIC and AE techniques. Rock Mech Rock Eng 54(2):721–743. https://doi.org/10.1007/s00603-020-02271-4

Michaelides EE (2015) Future directions and cycles for electricity production from geothermal resources. Energy Convers Manag 107:3–9. https://doi.org/10.1016/j.enconman.2015.07.057

Ohtsu M (1991) Simplified moment tensor analysis and unified decomposition of acoustic emission source: Application to in situ hydrofracturing test. J Geophys Res Sol Earth 96(B4):6211–6221. https://doi.org/10.1029/90jb02689

Pan J, Xi X, Wu X, Guo Q, Ren F, Cai M (2023a) Physical properties evolution and microscopic mechanisms of granite modified by thermal and chemical stimulation. Case Stud Therm Eng 41:102633. https://doi.org/10.1016/j.csite.2022.102633

Pan J, Zhang Y, Li P, Wu X, Xi X (2023b) Mechanical properties and thermo-chemical damage constitutive model of granite subjected to thermal and chemical treatments under uniaxial compression. Constr Build Mater 390:131755. https://doi.org/10.1016/j.conbuildmat.2023.131755

Rong G, Peng J, Cai M, Yao M, Zhou C, Sha S (2018) Experimental investigation of thermal cycling effect on physical and mechanical properties of bedrocks in geothermal fields. Appl Therm Eng 141:174–185. https://doi.org/10.1016/j.applthermaleng.2018.05.126

Sayed ET, Wilberforce T, Elsaid K, Rabaia MKH, Abdelkareem MA, Chae KJ, Olabi AG (2021) A critical review on environmental impacts of renewable energy systems and mitigation strategies: wind, hydro, biomass and geothermal. Sci Total Environ 766:144505. https://doi.org/10.1016/j.scitotenv.2020.144505

Sha S, Rong G, Chen Z, Li B, Zhang Z (2020) Experimental evaluation of physical and mechanical properties of geothermal reservoir rock after different cooling treatments. Rock Mech Rock Eng 53(11):4967–4991. https://doi.org/10.1007/s00603-020-02200-5

Shao S, Wasantha PLP, Ranjith PG, Chen BK (2014) Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int J Rock Mech Min Sci 70:381–387. https://doi.org/10.1016/j.ijrmms.2014.04.003

Shen Y, Hou X, Yuan J, Xu Z, Gu L, Liu Z (2020) Thermal deterioration of high-temperature granite after cooling shock: multiple-identification and damage mechanism. B Eng Geol Environ 79(10):5385–5398. https://doi.org/10.1007/s10064-020-01888-7

Shen Y, Yuan J, Hou X, Hao J, Bai Z, Li T (2021) The strength changes and failure modes of high-temperature granite subjected to cooling shocks. Geomech Geophys Geo-Energy Geo-Resour 7(1):75–95. https://doi.org/10.1007/s40948-020-00214-5

Spittler N, Shafiei E, Davidsdottir B, Juliusson E (2020) Modelling geothermal resource utilization by incorporating resource dynamics, capacity expansion, and development costs. Energy 190:116407. https://doi.org/10.1016/j.energy.2019.116407

Su G, Chen Z, Yin H, Zhang X, Mo J (2016) True triaxial tests on rockburst of granite after high temperatures. Chin J Geotech Eng 38(9):1586–1594. https://doi.org/10.11779/CJGE201609005

Su H, Feng Y, Zhang Q, Yu L (2022) Experimental study on the fracturing process of thermally treated granite under mixed mode I-II loading. Geomech Geophys Geo-Energy Geo-Resour 8(2):75–95. https://doi.org/10.1007/s40948-022-00379-1

Sun Q, Zhang W, Xue L, Zhang Z, Su T (2015) Thermal damage pattern and thresholds of granite. Environ Earth Sci 74(3):2341–2349. https://doi.org/10.1007/s12665-015-4234-9

Tham LG, Liu H, Tang CA, Lee PKK, Tsui Y (2004) On tension failure of 2-D rock specimens and associated acoustic emission. Rock Mech Rock Eng 38(1):1–19. https://doi.org/10.1007/s00603-004-0031-6

Ulusay R (2014) The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014. Springer International Publishing 15(1):47–48. https://doi.org/10.1007/978-3-319-07713-0

Wang K, Yuan B, Ji G, Wu X (2018) A comprehensive review of geothermal energy extraction and utilization in oilfields. J Petrol Sci Eng 168:465–477. https://doi.org/10.1016/j.petrol.2018.05.012

Wang D, Bian X, Qin H, Sun D, Yu B (2021) Experimental investigation of mechanical properties and failure behavior of fluid-saturated hot dry rocks. Nat Resour Res 30(1):289–305. https://doi.org/10.1007/s11053-020-09760-x

Wang C, Du G, Han Y, He K, Li E (2023) Evolution characteristics of acoustic emission and strain energy for deep granite under different damage stages. Geomech Geophys Geo-Energ Geo-Resour 9(1):14–35. https://doi.org/10.1007/s40948-023-00557-9

Wu Y, Li X, Huang Z, Xue S (2021) Effect of temperature on physical, mechanical and acoustic emission properties of Beishan granite, Gansu Province, China. Nat Hazards 107(2):1577–1592. https://doi.org/10.1007/s11069-021-04647-3

Wu XH, Cai MF, Ren FH, Sun JL, Guo QF, Wu X, Zhang J, Zhang LW (2022) Evolutions of P-wave velocity and thermal conductivity of granite under different thermal treatments. Chin J Rock Mech Eng 41:457–467. https://doi.org/10.13722/j.cnki.jrme.2021.0532

Xi Y, Wang H, Li J, Dong W, Li H, Guo B (2022) Experimental comparison of mechanical properties and fractal characteristics of geothermal reservoir rocks after different cooling treatments. Energy Rep 8:5158–5176. https://doi.org/10.1016/j.egyr.2022.03.207

Xing Y, Zhang G, Luo T, Jiang Y, Ning S (2019) Hydraulic fracturing in high-temperature granite characterized by acoustic emission. J Petrol Sci Eng 178:475–484. https://doi.org/10.1016/j.petrol.2019.03.050

Xue L, Qin S, Sun Q, Wang Y, Lee LM, Li W (2014) A study on crack damage stress thresholds of different rock types based on uniaxial compression tests. Rock Mech Rock Eng 47(4):1183–1195. https://doi.org/10.1007/s00603-013-0479-3

Xue L, Qi M, Qin S, Li G, Li P, Wang M (2015a) A potential strain indicator for brittle failure prediction of low-porosity rock: part i—experimental studies based on the uniaxial compression test. Rock Mech Rock Eng 48(5):1763–1772. https://doi.org/10.1007/s00603-014-0675-9

Xue L, Qi M, Qin S, Li G, Li P, Wang M (2015b) A potential strain indicator for brittle failure prediction of low-porosity rock: part ii—theoretical studies based on renormalization group theory. Rock Mech Rock Eng 48(5):1773–1785. https://doi.org/10.1007/s00603-014-0681-y

Yang SQ, Ranjith PG, Jing HW, Tian WL, Ju Y (2017) An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 65:180–197. https://doi.org/10.1016/j.geothermics.2016.09.008

Yang J, Yang SQ, Liu GJ, Wl T, Li Y (2021) Experimental study of crack evolution in prefabricated double-fissure red sandstone based on acoustic emission location. Geomech Geophys Geo-Energ Geo-Resour 7(1):18–38. https://doi.org/10.1007/s40948-021-00219-8

Yin T, Shu R, Li X, Wang P, Liu X (2016) Comparison of mechanical properties in high temperature and thermal treatment granite. Trans Nonferr Met Soc 26(7):1926–1937. https://doi.org/10.1016/s1003-6326(16)64311-x

Yin Q, Wu J, Jiang Z, Zhu C, Su H, Jing H, Gu X (2022) Investigating the effect of water quenching cycles on mechanical behaviors for granites after conventional triaxial compression. Geomech Geophys Geo-Energ Geo-Resour 8(2):77–105. https://doi.org/10.1007/s40948-022-00388-0

Yu L, Peng H, Li G, Zhang Y, Han Z, Zhu H (2021) Experimental study on granite under high temperature-water cooling cycle. Rock Soil Mech 42(4):1025–1035. https://doi.org/10.16285/j.rsm.2020.1154

Zhai M, Xu C, Xue L, Cui Y, Dong J (2022a) Loading rate dependence of staged damage behaviors of granite under uniaxial compression: insights from acoustic emission characteristics. Theor Appl Fract Mech 122:103633. https://doi.org/10.1016/j.tafmec.2022.103633

Zhai M, Xue L, Bu F, Yang B, Huang X, Liang N, Ding H (2022b) Effects of bedding planes on progressive failure of shales under uniaxial compression: Insights from acoustic emission characteristics. Theor Appl Fract Mec 119:103343. https://doi.org/10.1016/j.tafmec.2022.103343

Zhang Y, Zhao GF, Li Q (2020) Acoustic emission uncovers thermal damage evolution of rock. Int J Rock Mech Min Sci 132:104388. https://doi.org/10.1016/j.ijrmms.2020.104388

Zhao Z (2016) Thermal influence on mechanical properties of granite: a microcracking perspective. Rock Mech Rock Eng 49(3):747–762. https://doi.org/10.1007/s00603-015-0767-1

Zhao XG, Cai M, Wang J, Ma LK (2013) Damage stress and acoustic emission characteristics of the Beishan granite. Int J Rock Mech Min Sci 64:258–269. https://doi.org/10.1016/j.ijrmms.2013.09.003

Zhu D, Jing H, Yin Q, Ding S, Zhang J (2020) Mechanical characteristics of granite after heating and water-cooling cycles. Rock Mech Rock Eng 53(4):2015–2025. https://doi.org/10.1007/s00603-019-01991-6

Zhu Z, Ranjith PG, Tian H, Jiang G, Dou B, Mei G (2021) Relationships between P-wave velocity and mechanical properties of granite after exposure to different cyclic heating and water cooling treatments. Renew Energy 168:375–392. https://doi.org/10.1016/j.renene.2020.12.048

Funding

This work was supported by the National Natural Science Foundation of China (Grant Nos. 42090052 and 41977249) and the National Key Research and Development Program of China (Grant No. 2019YFC1509701).

Author information

Authors and Affiliations

Contributions

YC: conceptualization, methodology, formal analysis, investigation, writing—original draft, visualization. LX: conceptualization, methodology, writing—review & editing, supervision, funding acquisition. MZ: formal analysis, validation, methodology. CX: validation, data curation, visualization; FB: validation, formal analysis, investigation; LW: formal analysis, data curation, investigation.

Corresponding author

Ethics declarations

Consent for publication

All authors agreed to publish.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cui, Y., Xue, L., Zhai, M. et al. Experimental investigation on the influence on mechanical properties and acoustic emission characteristics of granite after heating and water-cooling cycles. Geomech. Geophys. Geo-energ. Geo-resour. 9, 88 (2023). https://doi.org/10.1007/s40948-023-00627-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-023-00627-y