Abstract

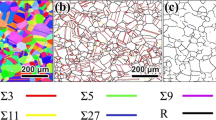

Optimization of grain boundary engineering (GBE) process is explored in a Fe–20Cr–19Mn–2Mo–0.82 N high-nitrogen and nickel-free austenitic stainless steel, and its intergranular corrosion (IGC) property after GBE treatment is experimentally evaluated. The proportion of low Σ coincidence site lattice (CSL) boundaries reaches 79.4% in the sample processed with 5% cold rolling and annealing at 1423 K for 72 h; there is an increase of 32.1% compared with the solution-treated sample. After grain boundary character distribution optimization, IGC performance is noticeably improved. Only Σ3 boundaries in the special boundaries are resistant to IGC under the experimental condition. The size of grain cluster enlarges with increasing fraction of low ΣCSL boundaries, and the amount of Σ3 boundaries interrupting the random boundary network increases during growth of the clusters, which is the essential reason for the improvement of IGC resistance.

Similar content being viewed by others

References

T. Watanabe, Res. Mech. 11, 47 (1984)

G. Palumbo, P.J. King, K.T. Aust, U. Erb, P.C. Lichtenberger, Scr. Metall. Mater. 25, 1775 (1991)

M. Shimada, H. Kokawa, Z.J. Wang, Y.S. Sato, I. Karibe, Acta Mater. 50, 2331 (2002)

M. Michiuchi, H. Kokawa, Z.J. Wang, Y.S. Sato, K. Sakai, Acta Mater. 54, 5179 (2006)

C.L. Hu, S. Xia, H. Li, T.G. Liu, B.X. Zhou, W.J. Chen, N. Wang, Corros. Sci. 53, 1880 (2011)

K. Kurihara, H. Kokawa, S. Sato, Y.S. Sato, H.T. Fujii, M. Kawai, J. Mater. Sci. 46, 4270 (2011)

S. Xia, H. Li, T.G. Liu, B.X. Zhou, J. Nucl. Mater. 416, 303 (2011)

S.H. Kim, U. Erb, K.T. Aust, G. Palumbo, Scr. Mater. 44, 835 (2001)

F. Shi, P.C. Tian, N. Jia, Z.H. Ye, Y. Qi, C.M. Liu, X.W. Li, Corros. Sci. 107, 49 (2016)

T. Watanabe, S. Tsurekawa, Mater. Sci. Eng. A 387–389, 447 (2004)

A. Telang, A.S. Gill, M. Kumar, S. Teysseyre, D. Qian, S.R. Mannava, V.K. Vasudevan, Acta Mater. 113, 180 (2016)

S. Kobayashi, M. Hirata, S. Tsurekawa, T. Watanabe, Procedia Eng. 10, 112 (2011)

Z. Zhuo, S. Xia, Q. Bai, B.X. Zhou, J. Mater. Sci. 53, 2844 (2018)

W.Z. Jin, S. Yang, H. Kokawa, Z.J. Wang, Y.S. Sato, J. Mater. Sci. Technol. 23, 785 (2007)

J.W. Simmons, Mater. Sci. Eng. A 207, 159 (1996)

H. Hänninen, J. Romu, R. Ilola, J. Tervo, A. Laitinen, J. Mater. Process. Technol. 117, 424 (2001)

M.G. Pujar, U.K. Mudali, S.S. Singh, Corros. Sci. 53, 4178 (2011)

H. Baba, T. Kodama, Y. Katada, Corros. Sci. 44, 2393 (2002)

F. Shi, Y. Qi, C.M. Liu, J. Mater. Sci. Technol. 27, 1125 (2011)

F. Shi, L.J. Wang, W.F. Cui, C.M. Liu, J. Iron Steel Res. Int. 15, 72 (2008)

F. Vanderschaeve, R. Taillard, J. Foct, J. Mater. Sci. 30, 6035 (1995)

O. Makoto, H. Kazuo, K. Yasuyuki, S. Masayuki, T. Susumu, ISIJ Int. 42, 1391 (2002)

H.B. Li, Z.H. Jiang, Z.R. Zhang, Y. Cao, Y. Yang, Int. J. Min. Met. Mater. 16, 654 (2009)

R. Beneke, R.F. Sandenbergh, Corros. Sci. 29, 543 (1989)

Y.S. Yoon, H.Y. Ha, T.H. Lee, S. Kim, Corros. Sci. 80, 28 (2014)

K. Alvarez, S.K. Hyun, H. Tsuchiya, S. Fujimoto, H. Nakajima, Corros. Sci. 50, 183 (2008)

H. Kokawa, W.Z. Jin, Z.J. Wang, M. Michiuchi, Y.S. Sato, W. Dong, Y. Katada, Mater. Sci. Forum 539–543, 4962 (2007)

F. Shi, X.W. Li, Y.T. Hu, C. Su, C.M. Liu, Acta Metall. Sin. (Engl. Lett.) 26, 497 (2013)

H.B. Li, Z.H. Jiang, Y. Yang, Y. Cao, Z.R. Zhang, Int. J. Min. Met. Mater. 16, 517 (2009)

H.Y. Ha, T.H. Lee, J.H. Bae, D.W. Chun, Metals 8, 1 (2018)

D.G. Brandon, Acta Metall. 14, 1479 (1966)

F. Shi, X.W. Li, Y. Qi, C.M. Liu, Steel Res. Int. 84, 1034 (2013)

J.B. Lee, Corrosion 39, 469 (1983)

S. Tokita, H. Kokawa, Y.S. Sato, H.T. Fujii, Mater. Charact. 131, 31 (2017)

V. Randle, Acta Metall. Mater. 42, 1769 (1994)

B.W. Reed, M. Kumar, Scr. Mater. 54, 1029 (2006)

Q.Y. Li, J.R. Cahoon, N.L. Richards, Mater. Sci. Eng. A 527, 263 (2009)

W. Wang, F. Brisset, A.L. Helbert, D. Solas, I. Drouelle, M.H. Mathon, T. Baudin, Mater. Sci. Eng. A 589, 112 (2014)

X.J. Guan, F. Shi, H.M. Ji, X.W. Li, Mater. Sci. Eng. A 765, 138299 (2019)

J. Kim, M. Kwon, B.C. De Cooman, Acta Mater. 141, 444 (2017)

X.W. Li, X.M. Wu, Z.G. Wang, Y. Umakoshi, Metall. Mater. Trans. A 34, 307 (2003)

Q.X. Dai, A.D. Wang, X.N. Cheng, J. Iron Steel Res. 14, 34 (2002)

V. Gavriljuk, Yu. Petrov, B. Shanina, Scr. Mater. 55, 537 (2006)

R. Jones, V. Randle, Mater. Sci. Eng. A 527, 4275 (2010)

X.Y. Fang, Ph.D. thesis, Shanghai University (2008)

M.S. Laws, P.J. Goodhew, Acta Metall. Mater. 39, 1525 (1991)

V. Randle, Scr. Mater. 54, 1011 (2006)

C.M. Barr, A.C. Leff, R.W. Demott, R.D. Doherty, M.L. Taheri, Acta Mater. 144, 281 (2018)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51871048 and 51571058).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Shi, F., Gao, RH., Guan, XJ. et al. Application of Grain Boundary Engineering to Improve Intergranular Corrosion Resistance in a Fe–Cr–Mn–Mo–N High-Nitrogen and Nickel-Free Austenitic Stainless Steel. Acta Metall. Sin. (Engl. Lett.) 33, 789–798 (2020). https://doi.org/10.1007/s40195-020-01000-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01000-8