Abstract

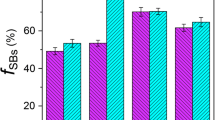

The grain boundary character distribution (GBCD) optimization and its effect on the intergranular stress corrosion cracking (IGSCC) resistance in a cold-rolled and subsequently annealed Fe–18Cr–17Mn–2Mo–0.85N high-nitrogen nickel-free austenitic stainless steel were systematically explored. The results show that stacking faults and planar slip bands appearing at the right amount of deformation (lower than 10%) are beneficial cold-rolled microstructures to the GBCD optimization. The proportion of special boundaries gradually increases in the subsequent stages of recrystallization and grain growth, accompanying with the growth of twin-related domain in the experimental steel. In this way, the fraction of low Σ coincidence site lattice (CSL) boundaries can reach as high as 82.85% for the specimen cold-rolled by 5% and then annealed at 1423 K for 72 h. After GBCD optimization, low Σ CSL boundaries and the special triple junctions (J2, J3) of high proportion can greatly hinder the nitride precipitation along grain boundaries and enhance the capability for intergranular crack arrest, thus improving the IGSCC resistance of the experimental steel.

Similar content being viewed by others

References

J. Gao, J.B. Tan, X.Q. Wu, S. Xia, Corros. Sci. 152, 190 (2019)

T. Watanabe, J. Mater. Sci. 46, 4095 (2011)

K. Deepak, S. Mandal, C.N. Athreya, D.I. Kim, B.D. Boer, V.S. Sarma, Corros. Sci. 106, 293 (2016)

G. Palumbo, P.J. King, K.T. Aust, U. Erb, P.C. Lichtenberger, Scr. Metall. Mater. 25, 1775 (1991)

T. Watanabe, S. Tsurekawa, Mater. Sci. Eng. A 387, 447 (2004)

T. Watanabe, Res. Mech. 11, 47 (1984)

C.L. Hu, S. Xia, H. Li, T.G. Liu, B.X. Zhou, W.J. Chen, N. Wang, Corros. Sci. 53, 1880 (2011)

M. Shimada, H. Kokawa, Z.J. Wang, Y.S. Sato, I. Karibe, Acta Mater. 50, 2331 (2002)

H. Kokawa, M. Shimada, M. Michiuchi, Z.J. Wang, Y.S. Sato, Acta Mater. 55, 5401 (2007)

M. Michiuchi, H. Kokawa, Z.J. Wang, Y.S. Sato, K. Sakai, Acta Mater. 54, 5179 (2006)

E.A. West, G.S. Was, J. Nucl. Mater. 392, 264 (2009)

T.G. Liu, S. Xia, Q. Bai, B.X. Zhou, L.F. Zhang, Y.H. Lu, T. Shoji, J. Nucl. Mater. 498, 290 (2018)

T.G. Liu, S. Xia, D.H. Du, Q. Bai, L.F. Zhang, Y.H. Lu, Mater. Lett. 234, 201 (2019)

P. Lin, G. Palumbo, U. Erb, K.T. Aust, Scr. Mater. 33, 1387 (1995)

A. Telang, A.S. Gill, D. Tammana, X.S. Wen, M. Kumar, S. Teysseyre, S.R. Mannava, D. Qian, V.K. Vasudevan, Mater. Sci. Eng. A 648, 280 (2015)

E.M. Lehockey, A.M. Brennenstuhl, I. Thompson, Corros. Sci. 46, 2383 (2004)

V.Y. Gertsman, S.M. Bruemmer, Acta Mater. 49, 1589 (2001)

A. Telang, A.S. Gill, M. Kumar, S. Teysseyre, D. Qian, S.R. Mannava, V.K. Vasudevan, Acta Mater. 113, 180 (2016)

S. Xia, H. Li, T.G. Liu, B.X. Zhou, J. Nucl. Mater. 416, 303 (2011)

H.Y. Ha, T.H. Lee, C.S. Oh, S.J. Kim, Scr. Mater. 61, 121 (2009)

J.W. Simmons, Mater. Sci. Eng. A 207, 159 (1996)

Y.S. Yoon, H.Y. Ha, T.H. Lee, S. Kim, Corros. Sci. 80, 28 (2014)

H. Baba, T. Kodama, Y. Katada, Corros. Sci. 44, 2393 (2002)

I. Olefjord, L. Wegrelius, Corros. Sci. 38, 1203 (1996)

M.G. Pujar, U.K. Mudali, S.S. Singh, Corros. Sci. 53, 4178 (2011)

M. Metikoš-Huković, R. Babić, Z. Grubač, Ž Petrović, N. Lajci, Corros. Sci. 53, 2176 (2011)

H.B. Li, Z.H. Jiang, Z.R. Zhang, Y. Cao, Y. Yang, Int. J. Min. Met. Mater. 16, 654 (2009)

M. Ogawa, K. Hiraoka, Y. Katada, M. Sagara, S. Tsukamoto, ISIJ Int. 42, 1391 (2002)

F. Shi, L.J. Wang, W.F. Cui, C.M. Liu, J. Iron Steel Res. Int. 15, 72 (2008)

F. Shi, Y. Qi, C.M. Liu, J. Mater. Sci. Technol. 27, 1125 (2011)

H. Kokawa, W.Z. Jin, Z.J. Wang, M. Michiuchi, Y.S. Sato, W. Dong, Y. Katada, Mater. Sci. Forum 539, 4962 (2007)

F. Shi, R.H. Gao, X.J. Guan, C.M. Liu, X.W. Li, Acta Metall. Sin. -Engl. Lett. 33, 789 (2020)

F. Shi, P.C. Tian, N. Jia, Z.H. Ye, Y. Qi, C.M. Liu, X.W. Li, Corros. Sci. 107, 49 (2016)

F. Shi, X.W. Li, Y.T. Hu, C. Su, C.M. Liu, Acta Metall. Sin. -Engl. Lett. 26, 497 (2013)

D.G. Brandon, Acta Metall. 14, 1479 (1966)

X.J. Guan, F. Shi, H.M. Ji, X.W. Li, Mater. Sci. Eng. A 765, 138299 (2019)

X.J. Guan, F. Shi, Z.P. Jia, X.W. Li, Mater. Charact. 170, 110689 (2020)

S. Tokita, H. Kokawa, Y.S. Sato, H.T. Fujii, Mater. Charact. 131, 31 (2017)

V. Randle, Acta Metall. Mater. 42, 1769 (1994)

B.W. Reed, M. Kumar, Scr. Mater. 54, 1029 (2006)

B.R. Kumar, S.K. Das, B. Mahato, A. Das, S.G. Chowdhury, Mater. Sci. Eng. A 454–455, 239 (2007)

X.Y. Fang, W.G. Wang, Z.X. Cai, C.X. Qin, B.X. Zhou, Mater. Sci. Eng. A 527, 1571 (2010)

F. Shi, L.J. Wang, W.F. Cui, C.M. Liu, Acta Metall. Sin. -Engl. Lett. 20, 95 (2007)

H.U. Hong, B.S. Rho, S.W. Nam, Mater. Sci. Eng. A 318, 285 (2001)

M. Kurban, U. Erb, K.T. Aust, Scr. Mater. 54, 1053 (2006)

M. Kumar, W.E. King, A.J. Schwartz, Acta Mater. 48, 2081 (2000)

C.A. Schuh, M. Kumar, W.E. King, Acta Mater. 51, 687 (2003)

A. Toppo, V. Shankar, R.P. George, J. Philip, Corrosion 76, 591 (2020)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51871048 and 52171108) and the Fundamental Research Funds for the Central Universities (Grant Nos. N2002014 and N2202011).

The authors state that there are no conflicts of interest to disclose.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Shi, F., Yan, L., Hu, J. et al. Improving Intergranular Stress Corrosion Cracking Resistance in a Fe–18Cr–17Mn–2Mo–0.85N Austenitic Stainless Steel Through Grain Boundary Character Distribution Optimization. Acta Metall. Sin. (Engl. Lett.) 35, 1849–1861 (2022). https://doi.org/10.1007/s40195-022-01427-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-022-01427-1