Abstract

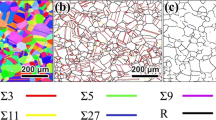

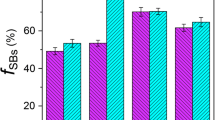

Strain-annealing based thermo-mechanical processing has been performed to promote grain boundary engineering (GBE) in an extra-low carbon type austenitic stainless steel without altering the grain size and residual strain to evaluate its sole influence on intergranular corrosion. Single-step processing comprising low pre-strain (~ 5 and 10 pct) followed by annealing at 1273 K for 1 hour have resulted in a large fraction of Σ3n boundaries and significant disruption in random high-angle grain boundaries (RHAGBs) connectivity. This is due to the occurrence of prolific multiple twinning in these specimens as confirmed by their large twin-related domain and twin-related grain size ratio. Among the iterative processing, the schedule comprising two cycles of 10 and 5 pct deformation followed by annealing at 1173 K for 1 hour has yielded the optimum GBE microstructure with the grain size and residual strain akin to the as-received condition. The specimens subjected to the higher number of iterations failed to realize GBE microstructures due to the occurrence of partial recrystallization. Owing to the optimum grain boundary character distribution, the GBE specimen has exhibited remarkable resistance against sensitization and intergranular corrosion as compared to the as-received condition. Furthermore, the lower depth of percolation in the GBE specimen is due to the significant disruption of RHAGBs connectivity as confirmed from its large twin-related domain and lower fractal dimension.

Similar content being viewed by others

References

E.A. Trillo and L.E. Murr: Acta Mater., 1998, vol. 47, pp. 235-45.

R.C. Newman, K. Sieradzki and H.S. Isaacs: Metall. Trans. A, 1982, vol. 13, pp. 2015-26.

W.J. Li, M.C. Young, C.L. Lai, W. Kai and L.W. Tsay: Corrosion Sci., 2013, vol. 68, pp. 25-33.

E.A. Trillo, R. Beltran, J.G. Maldonado, R.J. Romero, L.E. Murr, W.W. Fisher and A.H. Advani: Mater. Charac., 1995, vol. 35, pp. 99-112.

R.E. Hehemann: Metall. Trans. A., 1985, vol. 16, pp. 1909-23.

M. Shimada, H. Kokawa, Z.J. Wang, Y.S. Sato and I. Karibe: Acta Mater., 2002, vol. 50, pp. 2331-41.

M. Michiuchi, H. Kokawa, Z.J. Wang, Y.S. Sato and K. Sakai: Acta Mater., 2006, vol. 54, pp. 5179-84.

N. Parvathavarthini, S. Mulki, R.K. Dayal, I. Samajdar, K. V. Mani and B. Raj: Corrosion Sci., 2009, vol. 51, pp. 2144-50.

R. Jones and V. Randle: Mater. Sci. Eng., A, 2010, vol. 527, pp. 4275-80.

C. Hu, S. Xia, H. Li, T. Liu, B. Zhou, W. Chen and N. Wang: Corrosion Sci., 2011, vol. 53, pp. 1880-86.

F. Shi, P.C. Tian, N. Jia, Z.H. Ye, Y. Qi, C.M. Liu and X.W. Li: Corrosion Sci., 2016, vol.107, pp. 49-59.

G. Hou, H. Luo and J. Lv: Mater. Sci. Technol., 2014, vol. 30, pp. 1447-52.

E.M. Lehockey, G. Palumbo, P. Lin and A. Brennenstuhl: Metall. Mater. Trans. A, 1998, vol. 29, pp. 387-96.

S. Tsurekawa, S. Nakamichi and T. Watanabe: Acta Mater., 2006, vol. 54, pp. 3617-26.

S. Kobayashi, R. Kobayashi and T. Watanabe: Acta Mater., 2016, vol. 102, pp. 397-405.

P.M. Ahmedabadi, V. Kain, B.K. Dangi and I. Samajdar: Corrosion Sci., 2013, vol. 66, pp. 242-55.

P.M. Ahmedabadi, V. Kain, K. Venkata Muralidhar and I. Samajdar: J. Nucl. Mater., 2013, vol. 432, pp. 243-51.

S.K. Pradhan, T.S. Prithiv and S. Mandal: Mater. Charac., 2017, vol. 134, pp. 134-42.

S.X. Li, Y.N. He, S.R. Yu and P.Y. Zhang: Corrosion Sci., 2013, vol. 66, pp. 211-16.

R. Singh, S.G. Chowdhury, B. Ravi Kumar, S.K. Das, P.K. De, and I. Chattoraj: Scripta Mater., 2007, vol. 57, pp. 185-88.

R. Singh, S.G. Chowdhury and I. Chattoraj: Metall. Mater. Trans. A, 2008, vol. 39, pp. 2504-12.

V. Randle: Acta Mater., 2004, vol. 52, pp. 4067-81.

S. Mandal, P.V. Sivaprasad, B. Raj and V.S. Sarma: Metall. Mater. Trans. A, 2008, vol. 39, pp. 3298-3307.

M. Kumar, A.J. Schwartz and W.E. King: Acta Mater., 2002, vol. 50, pp. 2599-2612.

V. Randle: Mater. Sci. Technol., 2010, vol. 26, pp. 253–61.

V. Randle and R. Jones: Mater. Sci. Eng., A, 2009, vol. 524, pp. 134-42.

S. Mandal, A.K. Bhaduri and V.S. Sarma: J. Mater. Sci., 2011, vol. 46, pp. 275-84.

K.S. Swaroop, S. Mandal, C.N. Atherya, B. de Boer and V.S. Sarma: Metall. Mater. Trans. A, 2015, vol. 46, pp. 4740-54.

B.M. Guyot and N.L. Richards: J. Mater. Proces. Technol., 2007, vol. 189, pp. 162-68.

V. Randle and M. Coleman: Acta Mater., 2009, vol. 57, pp. 3410-21.

S. Mandal, A.K. Bhaduri and V.S. Sarma: Mater. Sci. Eng., A, 2009, vol. 515, pp. 134-40.

H. Kokawa, M. Shimada, M. Michiuchi, Z.J. Wang and Y.S. Sato: Acta Mater., 2007, vol. 55, pp. 5401-07.

D. Brandon: Acta Metall., 1966, vol. 14, pp. 1479-84.

C. Cayron, B. Artaud and L. Briottet: Mater. Charac., 2006, vol. 57, pp. 386-401.

C. Cayron: J. App. Crystall., 2007, vol. 40, pp. 1183-88.

E. Charkaluk, M. Bigerelle and A. Iost: Eng. Fract. Mech., 1998, vol. 61, pp. 119-39.

B. Dubuc, J.F. Quiniou, C.R. Carmes, C. Tricot and S.W. Zucker: Phys. Rev. A., 1989, vol. 39, pp. 1500-12.

H. Samet and M.K. Tamminen: IEEE Trans. Pattern Anal. Mach. Intell.,1988, vol. 10, pp. 579-86.

M.B. Dillencourt, H. Samet and M. Tamminen: J. ACM., 1992, vol. 39, pp. 253-80.

V. Ĉíhal and R. Stefec: Electrochim. Acta., 2001, vol. 46, pp. 3867-77.

BS EN ISO 12732:2008: Corrosion of metals and alloys Electrochemical potentio-kinetic reactivation measurement using the double loop method (based on Cihal’s method).

ASTM A262-2015: Standard practices for detecting susceptibility to intergranular attack in austenitic stainless steels.

Y. Gao, R.O. Ritchie, M. Kumar and R.K. Nalla: Metall. Mater. Trans. A, 2005, vol. 36, pp. 3325-33.

A. Telang, A.S. Gill, D. Tammana, X. Wen, M. Kumar, S. Teysseyre, S.R. Mannava, D. Qian and V.K. Vasudevan: Mater. Sci. Eng., A., 2015, vol. 648, pp. 280-88.

T. Watanabe: Res Mech., 1984, vol. 11, pp. 47-84.

H. Gleiter: Acta Metal., 1969, vol. 17, pp. 1421-28.

G. Owen and V. Randle: Scripta Mater., 2006, vol. 55, pp. 959-62.

L.C. Lim and R. Raj: Acta Metal., 1984, vol. 32, pp. 1177-81.

W. Wang and H. Guo: Mater. Sci. Eng., A, 2007 vol. 445–446, pp.155-62.

M. Coleman and V. Randle: Metall. Mater. Trans. A, 2008, vol. 39, pp. 2175-83.

A.H. King: Scripta Metal., 1985, vol. 19, pp. 1517-20.

T.S. Prithiv, P. Bhuyan, S.K. Pradhan, V.S. Srama and S. Mandal: Acta Mater., 2018, vol. 146, pp. 187-201.

A. Telang, A.S. Gill, M. Kumar, S. Teysseyre, D. Qian, S.R. Mannava and V.K. Vasudevan: Acta Mater., 2016, vol. 113, pp. 180-93.

T.H. Lee, H.Y. Ha and S.J. Kim: Metall. Mater. Trans. A, 2011, vol. 42, pp. 3543-48.

S. Zhang, Z. Jiang, H. Li, H. Feng and B. Zhang: J. Alloys Compd., 2017, vol. 695, pp. 3083-93.

N. Srinivasan, V. Kain, N. Birbilis, K. V. Mani Krishna, S. Shekhawat and I. Samajdar: Corrosion Sci., 2015, vol. 100, pp. 544-55.

H.Y. Bi, H. Kokawa, Z.J. Wang, M. Shimada and Y.S. Sato: Scripta Mater., 2003, vol. 49, pp. 219-23.

N. Keskar, A.K. Pattanaik, K. V. Mani Krishna, D. Srivastava and G.K. Dey: Metall. Mater. Trans. A., 2017, vol. 48, pp. 3096-3107.

J. Qian, C. Chen, H. Yu, F. Liu, H. Yang and Z. Zhang: Corrosion Sci., 2016, vol. 111, pp. 352-61.

T.H. Lee, Y.J. Lee, S.H. Joo, H.H. Nersisyan, K.T. Park and J.H. Lee: Metall. Mater. Trans. A., 2015, vol. 46, pp. 4020-26.

G. Yamada, H. Kokawa, Y. Yasuda, S. Tokita, T. Yokoyama, Y.S. Sato, H.T. Fujii and S. Tsurekawa: Philos. Mag., 2013, vol. 93, pp. 1443-53.

K. Deepak, S. Mandal, C.N. Athreya, D.I. Kim, B. de Boer and V.S. Sarma: Corrosion Sci., 2016, vol. 106, pp. 293-97.

V.Y. Gertsman and C.H. Henager: Interface Sci., 2003, vol. 11, pp. 403-15.

D.B. Bober, J. Lind, R.P. Mulay, T.J. Rupert and M. Kumar: Acta Mater., 2017, vol. 129, pp. 500-09.

Acknowledgments

The research grant received from the Indian National Science Academy (INSA) (SP/YSP/112/2015/1091) for this work is gratefully acknowledged. The authors are also grateful to C. Cayron for providing the ARPGE software for Twin-Related Domain analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 4, 2017.

Rights and permissions

About this article

Cite this article

Pradhan, S.K., Bhuyan, P., Kaithwas, C. et al. Strain-Annealing Based Grain Boundary Engineering to Evaluate its Sole Implication on Intergranular Corrosion in Extra-Low Carbon Type 304L Austenitic Stainless Steel. Metall Mater Trans A 49, 2817–2831 (2018). https://doi.org/10.1007/s11661-018-4608-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4608-1