Abstract

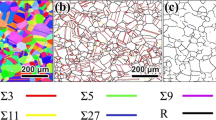

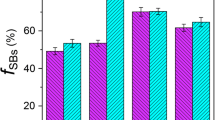

Grain boundary engineering (GBE) has shown a promising application in improving resistance to intergranular corrosion (IGC) of polycrystalline metallic materials with low-stacking fault energy, such as austenitic stainless steels. However, the traditionally uniform plastic pre-straining methods, such as cold rolling, in thermomechanical processing are hard to implement on complicated surfaces. Here, we demonstrate a novel approach using gradient plastic strain induced by surface mechanical grinding treatment with a rotary tool and subsequent annealing to optimize grain boundary character distribution (GBCD) in the near-surface layer. The gradient plastic strain followed by long-time annealing (24–96 h) in 304 stainless steels achieved an optimized GBCD with over 75% frequency of coincidence site lattice (CSL) boundaries and disconnected random boundary network in the near-surface layer. The intergranular corrosion tests showed that the resulting 304 stainless steels with the optimized GBCD in the near-surface layer present an excellent resistance to IGC behavior due to a high fraction of \(\Sigma {3^\mathrm{{n}}}\) boundaries. During the annealing process, severe plastic strain near the surface results in small size grain clusters via strain recrystallization, while low-level plastic strain in the subsurface promotes the formation of high fraction of CSL boundaries and large size grain clusters via strain-induced boundary migration. After the complete depletion of gradient plastic strain, the directional growth of grain clusters promotes the further extension of surface GBE into interior region. Thus, the thickness of surface GBE region can be regulated by the annealing time.

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available upon reasonable request.

References

Watanabe T (1978) An approach to grain boundary design for strong and ductile polycrystals. Res MechInt J Struct Mech Mater Sci 11(1):47–84

Palumbo G, Lehockey EM, Lin P (1998) Applications for grain boundary engineered materials. JOM 50(2):40–43. https://doi.org/10.1007/s11837-998-0248-z

Watanabe T (2011) Grain boundary engineering: historical perspective and future prospects. J Mater Sci 46(12):4095–4115. https://doi.org/10.1007/s10853-011-5393-z

Bozzolo N, Bernacki M (2020) Viewpoint on the Formation and evolution of annealing twins during thermomechanical processing of FCC metals and alloys. Metall Mater Trans A 51(6):2665–2684. https://doi.org/10.1007/s11661-020-05772-7

Michiuchi M, Kokawa H, Wang Z, Sato Y, Sakai K (2006) Twin-induced grain boundary engineering for 316 austenitic stainless steel. Acta Mater 54(19):5179–5184. https://doi.org/10.1016/j.actamat.2006.06.030

Hu C, Xia S, Li H, Liu T, Zhou B, Chen W, Wang N (2011) Improving the intergranular corrosion resistance of 304 stainless steel by grain boundary network control. Corros Sci 53(5):1880–1886. https://doi.org/10.1016/j.corsci.2011.02.005

West E, Was G (2009) IGSCC of grain boundary engineered 316L and 690 in supercritical water. J Nucl Mater 392(2):264–271. https://doi.org/10.1016/j.jnucmat.2009.03.008

Liu T, Xia S, Shoji T (2021) Intergranular stress corrosion cracking in simulated BWR water of 316L stainless steels manufactured with different procedures. Corros Sci 183:109344. https://doi.org/10.1016/j.corsci.2021.109344

Bechtle S, Kumar M, Somerday BP, Launey ME, Ritchie RO (2009) Grain-boundary engineering markedly reduces susceptibility to intergranular hydrogen embrittlement in metallic materials. Acta Mater 57(14):4148–4157. https://doi.org/10.1016/j.actamat.2009.05.012

Kobayashi S, Nakamura M, Tsurekawa S, Watanabe T (2011) Effect of grain boundary microstructure on fatigue crack propagation in austenitic stainless steel. J Mater Sci 46(12):4254–4260. https://doi.org/10.1007/s10853-010-5238-1

Kobayashi S, Yang W, Tomobe Y, Okada R, Tsurekawa S (2020) Low-angle boundary engineering for improving high-cycle fatigue property of 430 ferritic stainless steel. J Mater Sci 55(22):9273–9285. https://doi.org/10.1007/s10853-020-04555-0

Shi F, Tian P, Jia N, Ye Z, Qi Y, Liu C, Li X (2016) Improving intergranular corrosion resistance in a nickel-free and manganese-bearing high-nitrogen austenitic stainless steel through grain boundary character distribution optimization. Corros Sci 107:49–59. https://doi.org/10.1016/j.corsci.2016.02.019

Barr CM, Leff AC, Demott RW, Doherty RD, Taheri ML (2018) Unraveling the origin of twin related domains and grain boundary evolution during grain boundary engineering. Acta Mater 144:281–291. https://doi.org/10.1016/j.actamat.2017.10.007

Guan X, Shi F, Ji H, Li X (2020) A possibility to synchronously improve the high-temperature strength and ductility in face-centered cubic metals through grain boundary engineering. Scr Mater 187:216–220. https://doi.org/10.1016/j.scriptamat.2020.06.026

Watanabe T, Tsurekawa S (2004) Toughening of brittle materials by grain boundary engineering. Mater Sci Eng A 387–389:447–455. https://doi.org/10.1016/j.msea.2004.01.140

Barr CM, Thomas S, Hart JL, Harlow W, Anber E, Taheri ML (2018) Tracking the evolution of intergranular corrosion through twin-related domains in grain boundary networks. npj MaterDegrad 2(1):14. https://doi.org/10.1038/s41529-018-0032-7

Kokawa H, Shimada M, Michiuchi M, Wang Z, Sato Y (2007) Arrest of weld-decay in 304 austenitic stainless steel by twin-induced grain boundary engineering. Acta Mater 55(16):5401–5407. https://doi.org/10.1016/j.actamat.2007.06.005

Fang X, Zhang K, Guo H, Wang W, Zhou B (2008) Twin-induced grain boundary engineering in 304 stainless steel. Mater Sci Eng A 487(1–2):7–13. https://doi.org/10.1016/j.msea.2007.09.075

Randle V, Coleman M (2009) A study of low-strain and medium-strain grain boundary engineering. Acta Mater 57(11):3410–3421. https://doi.org/10.1016/j.actamat.2009.04.002

Feng W, Yang S, Yan Y (2018) Effects of deformation mode and strain level on grain boundary character distribution of 304 Austenitic stainless steel. Metall Mater Trans A 49(6):2257–2268. https://doi.org/10.1007/s11661-018-4589-0

Randle V (1999) Mechanism of twinning-induced grain boundary engineering in low stacking-fault energy materials. Acta Mater 47(15–16):4187–4196. https://doi.org/10.1016/s1359-6454(99)00277-3

Lehockey EM, Palumbo G, Lin P (1998) Improving the weldability and service performance of nickel-and iron-based superalloys by grain boundary engineering. Metall Mater Trans A 29(12):3069–3079. https://doi.org/10.1007/s11661-998-0214-y

Thaveeprungsriporn V, Sinsrok P, Thong-Aram D (2001) Effect of iterative strain annealing on grain boundary network of 304 stainless steel. Scr Mater 44(1):67–71. https://doi.org/10.1016/s1359-6462(00)00582-0

Kumar M, King WE, Schwartz AJ (2000), Modifications to the microstructural topology in f.c.c. materials through thermomechanical processing. Acta Mater 48 (9) 281–291. https://doi.org/10.1016/s1359-6454(00)00045-8

Shimada M, Kokawa H, Wang Z, Sato Y, Karibe I (2002) Optimization of grain boundary character distribution for intergranular corrosion resistant 304 stainless steel by twin-induced grain boundary engineering. Acta Mater 50(9):2331–2341. https://doi.org/10.1016/S1359-6454(02)00064-2

Yang X, Wang P, Huang M (2022) Grain boundary evolution during low-strain grain boundary engineering achieved by strain-induced boundary migration in pure copper. Mater Sci Eng A 833:142532. https://doi.org/10.1016/j.msea.2021.142532

Yang S, Wang ZJ, Kokawa H, Sato YS (2007) Grain boundary engineering of 304 austenitic stainless steel by laser surface melting and annealing. J Mater Sci 42(3):847–853. https://doi.org/10.1007/s10853-006-0063-2

Alyousif OM, Engelberg DL, Marrow TJ (2008) Surface grain boundary engineering of shot-peened type 304 stainless steel. J Mater Sci 43(4):1270–1277. https://doi.org/10.1007/s10853-007-2252-z

Tokita S, Kokawa H, Kodama S, Sato YS, Sano Y, Li Z, Feng K, Wu Y (2020) Suppression of intergranular corrosion by surface grain boundary engineering of 304 austenitic stainless steel using laser peening plus annealing. Mater Today Commun 25:101572. https://doi.org/10.1016/j.mtcomm.2020.101572

Telang A, Gill AS, Tammana D, Wen X, Kumar M, Teysseyre S, Mannava SR, Qian D, Vasudevan VK (2015) Surface grain boundary engineering of Alloy 600 for improved resistance to stress corrosion cracking. Mater Sci Eng A 648:280–288. https://doi.org/10.1016/j.msea.2015.09.074

Davim JP et al (2010) Surface integrity in machining. Springer, USA

Li W, Tao N, Lu K (2008) Fabrication of a gradient nano-micro-structured surface layer on bulk copper by means of a surface mechanical grinding treatment. Scr Mater 59(5):546–549. https://doi.org/10.1016/j.scriptamat.2008.05.003

Zeng Z, Li X, Xu D, Lu L, Gao H, Zhu T (2016) Gradient plasticity in gradient nano-grained metals. Extrem Mech Lett 8:213–219. https://doi.org/10.1016/j.eml.2015.12.005

Kokawa H, Shimada M, Sato YS (2000) Grain-boundary structure and precipitation in sensitized austenitic stainless steel. JOM. https://doi.org/10.1007/s11837-000-0159-0

Brandon D (1966) The structure of high-angle grain boundaries. Acta Metall 14(11):1479–1484. https://doi.org/10.1016/0001-6160(66)90168-4

Kokawa H, Watanabe T, Karashima S (1987) Reexamination of deviation angles from exact CSL misorientations in early work on grain boundary characterization. Scr Metall 21(6):839–842. https://doi.org/10.1016/0036-9748(87)90333-4

Lee JJB (1983) Modification of the ASTM standard ferric sulfate-sulfuric acid test and copper-copper sulfate-sulfuric acid test for determining the degree of sensitization of ferritic stainless steels. Corrosion 39(12):469–474. https://doi.org/10.5006/1.3577368

Sonmez FO, Demir A (2007) Analytical relations between hardness and strain for cold formed parts. J Mater Process Technol 186(1–3):163–173. https://doi.org/10.1016/j.jmatprotec.2006.12.031

Reed BW, Kumar M (2006) Mathematical methods for analyzing highly-twinned grain boundary networks. Scr Mater 54(6):1029–1033. https://doi.org/10.1016/j.scriptamat.2005.11.045

Xia S, Zhou B, Chen W (2008) Effect of single-step strain and annealing on grain boundary character distribution and intergranular corrosion in Alloy 690. J Mater Sci 43(9):2990–3000. https://doi.org/10.1007/s10853-007-2164-y

Bober DB, Lind J, Mulay RP, Rupert TJ, Kumar M (2017) The formation and characterization of large twin related domains. Acta Mater 129:500–509. https://doi.org/10.1016/j.actamat.2017.02.051

Tokita S, Kokawa H, Sato YS, Fujii HT (2017) In situ EBSD observation of grain boundary character distribution evolution during thermomechanical process used for grain boundary engineering of 304 austenitic stainless steel. Mater Charact 131:31–38. https://doi.org/10.1016/j.matchar.2017.06.032

Zhang W, Wang X, Hu Y, Wang S (2018) Quantitative studies of machining-induced microstructure alteration and plastic deformation in AISI 316 stainless steel using EBSD. J Mater Eng Perform 27(2):434–446. https://doi.org/10.1007/s11665-018-3129-9

Yun Bi H, Kokawa H, Jie Wang Z, Shimada M, Sato YS (2003) Suppression of chromium depletion by grain boundary structural change during twin-induced grain boundary engineering of 304 stainless steel. Scr Mater 49(3):219–223. https://doi.org/10.1016/S1359-6462(03)00261-6

Gertsman V, Bruemmer S (2001) Study of grain boundary character along intergranular stress corrosion crack paths in austenitic alloys. Acta Mater 49(9):1589–1598. https://doi.org/10.1016/S1359-6454(01)00064-7

Schwartz AJ, Kumar M, Adams BL, Field DP (2009), Electron backscatter diffraction in materials science. Springer, USA https://doi.org/10.1007/978-0-387-88136-2

Koo JB, Yoon DY (2001) Abnormal grain growth in bulk Cu-The dependence on initial grain size and annealing temperature. Metall Mater Trans A 32(8):1911–1926. https://doi.org/10.1007/s11661-001-0004-2

Booth M, Randle V, Owen G (2005) Time evolution of sigma 3 annealing twins in secondary recrystallized nickel. J Microsc 217(2):162–166. https://doi.org/10.1111/j.1365-2818.2005.01422.x

Ueno K, Ritzdorf T, Grace S (1999) Seed layer dependence of room-temperature recrystallization in electroplated copper films. J Appl Phys 10(1063/1):371462

Harper JME, Cabral C, Andricacos PC, Gignac L, Noyan IC, Rodbell KP, Hu CK (1999) Mechanisms for microstructure evolution in electroplated copper thin films near room temperature. J Appl Phys 86(5):2516–2525. https://doi.org/10.1063/1.371086

Lee S, Yoon D, Henry M (2000) Abnormal grain growth and grain boundary faceting in a model Ni-base superalloy. Acta Mater 48(12):3071–3080. https://doi.org/10.1016/S1359-6454(00)00119-1

Acknowledgements

This work was supported by the National Natural Science Foundation of China [grant number 51875219] and the Scientific Research Project of Hubei Provincial Department of Education (grant number Q20239404).

Author information

Authors and Affiliations

Contributions

Xinli Jiang contributed to conceptualization, methodology, software, writing—original draft. Chongwen Yang contributed to methodology, visualization. Wenqian Zhang contributed to software, reviewing, editing. Xuelin Wang contributed to reviewing, editing, supervision, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Handling Editor: Sophie Primig

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, X., Yang, C., Zhang, W. et al. Surface grain boundary engineering in 304 stainless steel by means of mechanical grinding treatment-induced gradient plastic strain and annealing. J Mater Sci 57, 21798–21812 (2022). https://doi.org/10.1007/s10853-022-07983-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07983-2