Abstract

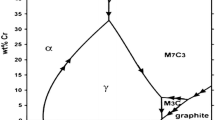

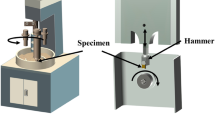

In this study, tribological wear and Brinell hardness number characteristics of Inconel 713 alloy in its as-received state, following heat treatment was explored. The investigation focused on the effects of heat treatment at temperatures of −140 °C and −196 °C for durations of 24, 36, and 48 h using DCT Process. At room temperature, Inconel 713 alloy maintains a stable γ phase with a face-centered cubic (FCC) structure, which imparts excellent mechanical properties along with corrosion and oxidation resistance. However, despite its commendable mechanical traits, the alloy demonstrates insufficient wear resistance in cutting tool applications, prompting a quest for enhanced wear properties. Thus, this study endeavors to improve wear resistance by subjecting the specimen to a heat treatment environment, facilitating the transformation from austenite to martensite without embrittlement. Through comprehensive analysis, including examination of microstructure, wear behavior, and hardness, we aim to elucidate the alloy’s performance under these conditions.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are included within the article. Further data or information is available from the corresponding author upon request.

References

P. Jonsta, Z. Jonsta, J. Sojka, L. Cizek, A. Hernas, Structural characteristics of nickel super alloy INCONEL 713LC after heat treatment. J. Achiev. Mater. Manuf. Eng. 21(2), 29–32 (2007)

L. Kunz, P. Lukáš, R. Konečná, High-cycle fatigue of Ni-base superalloy Inconel 713LC. Int. J. Fatigue 32(6), 908–913 (2010)

D.B. Lee, High-temperature oxidation of Ni-based Inconel 713 alloys at 800–1100℃ in air. J. Korean Inst. Surf. Eng. 44(5), 196–200 (2011)

K. Łyczkowska et al., Properties of the Inconel 713 Alloy within the high temperature brittleness range. Arch. Foundry Eng. 17 (2017)

R.R. Boyer, J.D. Cotton, M. Mohaghegh, R.E. Schafrik, Materials considerations for aerospace applications. MRS Bull. 40(12), 1055–1066 (2015)

P.P. Raut, A.S. Rao, S. Sollapur et al., Investigation on the development and building of a voice coil actuator-driven XY micro-motion stage with dual-range capabilities. Int. J. Interact. Des. Manuf. (2023). https://doi.org/10.1007/s12008-023-01665-2

O.B. Loureda, J.O. Gomes, W. Vireira, Analysis about Machinability of Superalloys applied on Turbines of LRE Turbopumps. in 49th AIAA/ASME/SAE/ASEE Joint PropulsionConference (2013), p. 4067

K.B.S. Rao, H.P. Meurer, H. Schuster, Creep-fatigue interaction of Inconel 617 at 950 C in simulated nuclear reactor helium. Mater. Sci. Eng. A 104, 37–51 (1988)

Inconel-713LC gas turbine blades. Mater. Sci. Eng.: A. 642, 230–240

S. Dehghan, E. Soury, A comparative study on machining and tool performance in friction drilling of difficult-to-machine materials AISI304, Ti-6Al-4V, Inconel718. J. Manuf. Process. 61, 128–152 (2021)

V.G. Sanap, V.D. Shinde, Machinability improvement of Inconel 718 during heat treatment-A review. in Journal of Physics: Conference Series, vol. 1706, no. 1 (2020), p. 012175. IOP Publishing

G.R. Chate et al., Ceramic material coatings: emerging future applications. in Advanced Ceramic Coatings for Emerging Applications (Elsevier, 2023). pp 3–17. https://doi.org/10.1016/B978-0-323-99624-2.00007-3

B.K. Yoo, H.K. Choi, H.I. Park, H.Y. Jeong, The Effect of Heat Treatment on the microstructures and mechanical properties of Inconel 713C alloy vacuum investment castings. J. Korea Foundry Soc. 40(2), 16–24 (2020)

P.G. Bedmutha, P.M. Waghmare, S.B. Sollapur, Mechanical properties of bamboo fiber reinforced plastics. Int. J. Sci. Adv. Res. Technol. 3(9), 365–368 (2017)

S. Sollapur, M.S. Patil, K. Chaporkar, A. Misal, R. Bhoyar, K. Dhole, Design and Development of Constrain Based XY Flexural Mechanism, in Techno-Societal 2018. ed. by P. Pawar, B. Ronge, R. Balasubramaniam, A. Vibhute, S. Apte (Springer, Cham, 2020). https://doi.org/10.1007/978-3-030-16962-6_27

J.R. Zhao, F.Y. Hung, C.S. Lu, I.C. Lai, Comparison of laser powder bed fusion and cast Inconel 713 alloy in terms of their microstructure, mechanical properties, and fatigue life. Adv. Eng. Mater. 23(6), 2001366 (2021)

M. Lachowicz, W. Dudziński, K. Haimann, M. Podrez-Radziszewska, Microstructure transformations and cracking in the matrix of γ–γ′ superalloy Inconel 713C melted with electron beam. Mater. Sci. Eng. A 479(1–2), 269–276 (2008)

K. Wu, S.W. Chee, W. Sun, A.W.Y. Tan, S.C. Tan, E. Liu, W. Zhou, Inconel 713C coating by cold spray for surface enhancement of Inconel 718. Metals 11(12), 2048 (2021)

M. Godec, S. Malej, D. Feizpour, Č Donik, M. Balažic, D. Klobčar, L. Pambaguian, M. Conradi, A. Kocijan, Hybrid additive manufacturing of Inconel 718 for future space applications. Mater CharactCharact. 172, 110842 (2021)

D.D. Baviskar, A.S. Rao, S. Sollapur et al., Development and testing of XY stage compliant mechanism. Int. J. Interact. Des. Manuf. (2023). https://doi.org/10.1007/s12008-023-01612-1

J. Schneider, L. Farris, G. Nolze, S. Reinsch, G. Cios, T. Tokarski, S. Thompson, Microstructure evolution in Inconel 718 produced by powder bed fusion additive manufacturing. J. Manuf. Mater. Proc. 6(1), 20 (2022)

P. Waghmare, Development and Performance Investigation of Solar Concrete Collector at Different Climatic Conditions. Indian J. Eng. Mater. Sci. (2023). https://doi.org/10.56042/ijems.v30i2.1384

S.L. Chittewar, N.G. Patil, Surface integrity of conventional and additively manufactured nickel superalloys: a review. Mater Today: Proc. 44, 701–708 (2021)

D. Deng, Additively Manufactured Inconel 718: Microstructures and Mechanical Properties (vol. 1798) (Linköping University Electronic Press, Linköping, 2018)

I.S. Jawahir, H. Attia, D. Biermann, J. Duflou, F. Klocke, D. Meyer, S.T. Newman, F. Pusavec, M. Putz, J. Rech, V. Schulze, Cryogenic manufacturing processes. CIRP Ann. 65(2), 713–736 (2016)

S. Sollapur, D. Saravanan et al., Tribological properties of filler and green filler reinforced polymer composites. Mater. Today: Proc. 50, 2065–2072 (2022). https://doi.org/10.1016/j.matpr.2021.09.414

K.P. Toradmal, P.M. Waghmare, S.B. Sollapur, Three point bending analysis of honeycomb sandwich panels: experimental approach. Int. J. Eng. Tech. 3(5), 1–5 (2017)

U.A. Khilare, S.B. Sollapur, Investigation of residual stresses and its effect on mechanical behaviour of AISI310. J. Res. 2(5), 42–46 (2016) ISSN: 2395-7549

B. Gireesh, B. SollapurShrishail, V.N. Satwik, Finite element & experimental investigation of composite torsion shaft. Int. J. Engg. Res. Appl. 3(2), 1510–1517 (2013)

K. Łyczkowska, J. Adamiec, The phenomena and criteria determining the cracking susceptibility of repair padding welds of the Inconel 713C Nickel Alloy. Materials 15(2), 634 (2022)

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Comparison of high temperature wear behavior of microwave assisted HVOF sprayed CoMoCrSi-WC-CrC-Ni/WC-12Co composite coatings. Silicon, Springer 12, 3027–3045 (2020). https://doi.org/10.1007/s12633-020-00398-1

A. Chamanfar, M. Jahazi, A. Bonakdar, E. Morin, A. Firoozrai, Cracking in fusion zone and heat affected zone of electron beam welded Inconel-713LC gas turbine blades. Mater. Sci. Eng. A 642, 230–240 (2015)

P.M. Waghmare, P.G. Bedmutha, S.B. Sollapur, Investigation of effect of hybridization and layering patterns on mechanical properties of banana and kenaf fibers reinforced epoxy biocomposite. Mater. Today: Proc. 46, 3220–3224 (2021). https://doi.org/10.1016/j.matpr.2020.11.194

T. Shinde et al., Fatigue analysis of alloy wheel using cornering fatigue test and its weight optimization. Mater. Today: Proc. 62, 1470–1474 (2022). https://doi.org/10.1016/j.matpr.2022.02.023

M. Vinod, C.A. Kumar, S.B. Sollapur et al., Study on fabrication and mechanical performance of flax fibre-reinforced aluminium 6082 laminates. J. Inst. Eng. India Ser. D. (2023). https://doi.org/10.1007/s40033-023-00605-4

C. Durga Prasad, A. Jerri, M.R. Ramesh, Characterization and sliding wear behavior of iron based metallic coating deposited by HVOF process on low carbon steel substrate. J Bio- Tribo-Corros., Springer (2020). https://doi.org/10.1007/s40735-020-00366-7

S.S. Shinde, S.B. Sollapur, Effect of Residual Stress on the Mechanical Behavior of AISI 304, For TIG Welding. in International Journal of Scientific & Engineering Research, vol 8, no. 10, October 2017

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, Microstructure and tribological resistance of flame sprayed CoMoCrSi/WC-CrC-Ni and CoMoCrSi/WC-12Co composite coatings remelted by microwave hybrid heating. J. Bio- Tribo-Corros., Springer 6, 124 (2020). https://doi.org/10.1007/s40735-020-00421-3

C. Venkate Gowda, T.K. Nagaraja, K.B. Yogesha et al., Study on structural behavior of HVOF-Sprayed NiCr/Mo coating. J. Inst. Eng. India Ser. D. (2024). https://doi.org/10.1007/s40033-024-00641-8

S.B. Sollapur, P.C. Sharath, P. Waghmare, Applications of Additive Manufacturing in Biomedical and Sports Industry, in Practical Implementations of Additive Manufacturing Technologies. Materials Horizons: From Nature to Nanomaterials. ed. by S. Rajendrachari (Springer, Singapore, 2024). https://doi.org/10.1007/978-981-99-5949-5_13

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Influence of microwave hybrid heating on the sliding wear behaviour of HVOF sprayed CoMoCrSi coating. Mater. Res. Express, IOP 5, 086519 (2018). https://doi.org/10.1088/2053-1591/aad44e

S. Sollapur, T. Shinde, S. Raut, A. Atpadkar, P. Nimbalkar, M. Rathod, Design and Development of High-Precision Scanning Flexural Mechanism Using PID, in Recent Advances in Operations Management and Optimization. CPIE 2023. Lecture Notes in Mechanical Engineering. ed. by A. Sachdeva, K.K. Goyal, R.K. Garg, J.P. Davim (Springer, Singapore, 2024). https://doi.org/10.1007/978-981-99-7445-0_4

Y. Yildiz, M. Nalbant, A review of cryogenic cooling in machining processes. Int. J. Mach. Tools Manuf 48(9), 947–964 (2008)

R.N. Chikkangoudar, C. Patil, R.N. Panchal et al., Investigating joint-free mechanical systems with PLA and ABS materials using the fuse deposition modelling method. J. Inst. Eng. India Ser. D. (2024). https://doi.org/10.1007/s40033-024-00659-y

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Effect of microwave heating on microstructure and elevated temperature adhesive wear behavior of HVOF deposited CoMoCrSi-Cr3C2 composite coating. Surf. Coatings Technol, Elsevier Sci. 374, 291–304 (2019). https://doi.org/10.1016/j.surfcoat.2019.05.056

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Microstructure and tribological behavior of flame sprayed and microwave fused CoMoCrSi/CoMoCrSi-Cr3C2 coatings. Mater. Res. Express, IOP 6(2019). https://doi.org/10.1088/2053-1591/aaebd9

M. Vinod, C.A. Kumar, S.B. Sollapur et al., Study on Low-Velocity Impact Performance of Chemical Treated Flax Fibre-Reinforced Aluminium 6082 Laminates. J. Inst. Eng. India Ser. D. (2024). https://doi.org/10.1007/s40033-024-00657-0

U.M.R. Paturi, N.S. Reddy, Progress of machinability on the machining of Inconel 718: a comprehensive review on the perception of cleaner machining. Clean. Eng. Technol. 5, 100323 (2021)

N.G. Siddeshkumar, R. Suresh, C. Durga Prasad, L. Shivaram, N.H. Siddalingaswamy, Evolution of the surface quality and tool wear in the high speed turning of Al2219/n-B4C/MoS2 metal matrix composites. Int. J. Cast Met. Res., Taylor Francis. (2023). https://doi.org/10.1080/13640461.2023.2285177

C. Durga Prasad, S. Kollur, C.R. Aprameya, T.V. Chandramouli, T. Jagadeesha, B.N. Prashanth, Investigations on tribological and microstructure characteristics of WC-12Co/FeNiCrMo composite coating by HVOF process. JOM J. Miner., Met. Mater. Soc. (TMS), Springer (2023). https://doi.org/10.1007/s11837-023-06242-2

S. Gotagunaki, V.S. Mudakappanavar, R. Suresh, C. Durga Prasad, Studies on the mechanical properties and wear behavior of an AZ91D magnesium metal matrix composite utilizing the stir casting method. Metallogr., Microstruct., Anal., Springer. (2023). https://doi.org/10.1007/s13632-023-01017-2

C. Durga Prasad, S. Kollur, M. Nusrathulla, G. SatheeshBabu, M.B. Hanamantraygouda, B.N. Prashanth, N. Nagabhushana, Characterisation and wear behaviour of SiC reinforced FeNiCrMo composite coating by HVOF process. Trans. IMF, Taylor Francis, (2023). https://doi.org/10.1080/00202967.2023.2246259

T. Naik, C. MahantayyaMathapathi, D. Prasad, H.S. Nithin, M.R. Ramesh, Effect of laser post treatment on microstructural and sliding wear behavior of HVOF sprayed NiCrC and NiCrSi coatings. Surf. Rev. Lett. 29(1), 225000 (2022). https://doi.org/10.1142/S0218625X2250007X

C. Durga Prasad, S. Lingappa, M.R. SharnappaJoladarashi, S.B. Ramesh, Characterization and sliding wear behavior of CoMoCrSi+Flyash composite cladding processed by Microwave irradiation. Mater. Today Proc., Elsevier Sci. 46, 2387–2391 (2021). https://doi.org/10.1016/j.matpr.2021.01.156

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suryawanshi, V.P., Deshmukh, P.D. Investigations on the Effect of Heat Treatment on Wear Behavior and Structure of Inconel 713 Alloy. J. Inst. Eng. India Ser. D (2024). https://doi.org/10.1007/s40033-024-00757-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-024-00757-x