Abstract

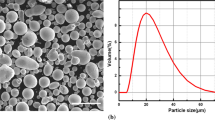

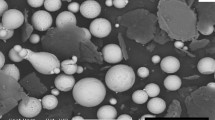

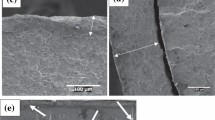

This study investigates the structural behavior of HVOF-sprayed NiCr/Mo coating. The main objective of the coating is to improve the surface properties such as micro-cutting, cavity, and cracks, to avoid the corrosion, and to determine self-life and wear resistance at room temperature and high temperature also. The coating structures are very sensitive to processing and working conditions, to overcome all these aspects, the surface metal has to undergo microstructure analysis, porosity, microstructure hardness, and X-ray diffraction (XRD), and to improve mechanical properties of metal. HVOF spraying technique was used to deposit the coating on mild steel plate than the coated sample characterized using scanning electron microscope (SEM), X-ray diffraction (XRD), microhardness, microindentation, and wear test. Moreover, we introduce the NiCr/Mo at different percentage levels (5%, 10%, and 15%) to evaluate the mechanical properties, to improve the performance and life span of the fracturing operations in aggressive conditions, which is essential in components replacement and economic savings in various industries such as aerospace, automotive, marine, etc.

Similar content being viewed by others

Data Availability

Not applicable.

References

V. Matikainen, G. Bolelli, H. Koivuluoto, P. Sassatelli, L. Lusvarghi, P. Vuoristo, Sliding wear behaviour of HVOF and HVAF sprayed Cr3C2 based coating. Wear 388, 57–71 (2017)

T.K. Mishra, A. Kumar, S.K. Sinha, S. Sharma, Investigation of sliding wear behavior of HVOF carbide coating. Mater. Today Proc. 5(9), 3–8 (2018)

R. Subbaih, A. Arun, A.A. Lakshmi, A.N.S. Harika, N. Ram, N. Sateesh, Experimental study of wear behavior on Al-2014 alloy coating with thermal spray HVOF and plasma spray process. Mater. Today Proc. 18, 5151–5157 (2019)

H. Wang, Q. Qiu, M. Gee, C. Hou, X. Liu, X. Song, Wear resistance of HVOF sprayed WC-CO Coating by Complete densification of starting powder. Mater. Des. 191, 10586 (2020)

D.G. Bhosle, W.S. Rathod, Investigation of wear behaviour of SS316L atmosperic plasma and HVOF sprayed WC- Cr3C2-N coating for fracture tools. Surf. Coat. Technol. 390, 125679 (2020)

E.H. Williamson, M. Gee, D. Robertson, J.F. Watts, M.J. Whiting, J.A. Yeomans, A comparitive study of the wear performances of hard coatings for nuclear applications. Wear 488–489, 204124 (2022)

Wear Performance analysis and characterization HVOF deposited Ni-20 Cr2O3, Ni-30 Al2O3 and Al2O3–13TiO2 coatings (2021)

C.Y. Lee, T.-J. Lin, H.H. Sheu, H. Binley, A study on corrosion wear behavior of Fe – based amorphous alloy coating prepared by HVOF Method. J. Mater. Rese. Technol. 15, 4880–4895 (2021)

J. Pulford, F. Venturi, S. Kamnis, T. Hussain, Sliding wear behavior of WC-CO reinforced NiCrFeSiB HVOF thermal spray coating against WC-Co and Al2O3 counter bodies. J. Surf. Coat. 386, 125468 (2020)

R. Khuengpukheiw, A. Wisitsoraat, C. Saikaew, Wear behaviors of HVOF sprayed NiSiCrFeB, WC-Co/NiSiCrFeB and WC-Co coatings evaluated using a pin-on-disc tester with C45 steel pins. Wear 484, 203699 (2020)

N.G. Siddeshkumar, R. Suresh, C. Durga Prasad, L. Shivaram, N.H. Siddalingaswamy, Evolution of the surface quality and tool wear in the high speed turning of Al2219/n-B4C/MoS2 metal matrix composites. Int. J. Cast Met. Res. (2023). https://doi.org/10.1080/13640461.2023.2285177

N. Praveen, U.S. Mallik, A.G. Shivasiddaramaiah, N. Nagabhushana, C. Durga Prasad, S. Kollur, Effect of CNC end milling parameters on Cu-Al-Mn ternary shape memory alloys using Taguchi method. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-023-00579-3

C. Durga Prasad, S. Kollur, C.R. Aprameya, T.V. Chandramouli, T. Jagadeesha, B.N. Prashanth, Investigations on tribological and microstructure characteristics of WC-12Co/FeNiCrMo composite coating by HVOF process. JOM J. Miner. Met. Mater. Soc. (TMS) (2023). https://doi.org/10.1007/s11837-023-06242-2

V. Srinivasa Chari, S. Jhavar, T.N. Sreenivasa, H. Hanumanthappa, C. Durga Prasad, B.K. Shanmugam, Impact of post-processing techniques on the wear resistance of plasma beam treatment on SS316L components. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-023-00584-6

S. Gotagunaki, V.S. Mudakappanavar, R. Suresh, C. Durga Prasad, Studies on the mechanical properties and wear behavior of an AZ91D magnesium metal matrix composite utilizing the stir casting method. Metallogr. Microstruct. Anal. (2023). https://doi.org/10.1007/s13632-023-01017-2

K.S. Lokesh, K. Shashank Kumar, N. Keerthan, R. Revanth, S. Sandeep, S.B. Lakkundi, V. Bharath, H. Hanumanthappa, C. Durga Prasad, B.K. Shanmugam, Experimental analysis of the rice husk and eggshell powder-based natural fibre composite. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-023-00557-9

G. Srinivasa Rao, U. Mukkamala, H. Hanumanthappa, C. Durga Prasad, H. Vasudev, B. Shanmugam, K.C. Kishore Kumar, Evaluating and optimizing surface roughness using genetic algorithm and artificial neural networks during turning of AISI 52100 steel. Int. J. Interact. Des. Manuf. (IJIDeM) (2023). https://doi.org/10.1007/s12008-023-01549-5

C. Manjunatha, T.N. Sreenivasa, P. Sanjay, C. Durga Prasad, Optimization of friction stir welding parameters to enhance weld nugget hardness in AA6061-B4C composite material. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-023-00562-y

C. Durga Prasad, S. Kollur, M. Nusrathulla, G. SatheeshBabu, M.B. Hanamantraygouda, B.N. Prashanth, N. Nagabhushana, Characterisation and wear behaviour of SiC reinforced FeNiCrMo composite coating by HVOF process. Trans. IMF (2023). https://doi.org/10.1080/00202967.2023.2246259

M. Arunadevi, M. Rani, R. Sibinraj, M.K. Chandru, C. Durga Prasad, Comparison of k-nearest neighbor & artificial neural network prediction in the mechanical properties of aluminum alloys. Mater. Today Proc. (2023). https://doi.org/10.1016/j.matpr.2023.09.111

H. Sharanabasava, M. Raviprakash, C. Durga Prasad, M.R. Ramesh, M.V. Phanibhushana, H. Vasudev, S. Kumar, Microstructure, mechanical and wear properties of SiC and Mo reinforced NiCr microwave cladding. Adv. Mater. Process. Technol. (2023). https://doi.org/10.1080/2374068X.2023.2257937

G.S. Kulkarni, N.G. Siddeshkumar, C. Durga Prasad, L. Shankar, R. Suresh, Drilling of GFRP with liquid silicon rubber reinforced with fine aluminium powder on hole surface quality and tool wear using DOE. J. Bio Tribo Corros. 9, 53 (2023). https://doi.org/10.1007/s40735-023-00771-8

S.D. Kulkarni, M. Manjunatha, U. Chandrasekhar, K.V. Manjunath, C. Durga Prasad, H. Vasudev, Design and optimization of polyvinyl-nitride rubber for tensile strength analysis. Int. J. Interact. Des. Manuf. (IJIDeM) (2023). https://doi.org/10.1007/s12008-023-01405-6

N. Praveen, U.S. Mallik, A.G. Shivasiddaramaih, R. Suresh, C. Durga Prasad, L. Shivaramu, Synthesis and wire EDM characteristics of Cu–Al–Mn ternary shape memory alloys using Taguchi method. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-023-00501-x

G. MadhuSudana Reddy, C. Durga Prasad, S. Kollur, A. Lakshmikanthan, R. Suresh, C.R. Aprameya, Investigation of high temperature erosion behaviour of NiCrAlY/TiO2 plasma coatings on titanium substrate. JOM J. Miner. Met. Mater. Soc. (TMS) (2023). https://doi.org/10.1007/s11837-023-05894-4

N. Praveen, U.S. Mallik, A.G. Shivasiddaramaih, R. Suresh, L. Shivaramu, C. Durga Prasad, M. Gupta, Design and Analysis of shape memory alloys using optimization techniques. Adv. Mater. Process. Technol. (2023). https://doi.org/10.1080/2374068X.2023.2208021

G. Madhusudana Reddy, C. Durga Prasad, P. Patil, N. Kakur, M.R. Ramesh, High temperature erosion performance of NiCrAlY/Cr2O3/YSZ plasma spray coatings. Trans. IMF (2023). https://doi.org/10.1080/00202967.2023.2208899

H. Sharanabasva, C. Durga Prasad, M.R. Ramesh, Characterization and wear behavior of NiCrMoSi microwave cladding. J. Mater. Eng. Perform. (2023). https://doi.org/10.1007/s11665-023-07998-z

G. Madhusudana Reddy, C. Durga Prasad, P. Patil, N. Kakur, M.R. Ramesh, Investigation of plasma sprayed NiCrAlY/Cr2O3/YSZ coatings on erosion performance of MDN 420 steel substrate at elevated temperatures. Int. J. Surf. Sci. Eng. 17(3), 180–194 (2023). https://doi.org/10.1504/IJSURFSE.2023.10054266

H. Sharanabasva, C. Durga Prasad, M.R. Ramesh, Effect of Mo and SiC reinforced NiCr microwave cladding on microstructure, mechanical and wear properties. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-022-00445-8

H.S. Nithin, K.M. Nishchitha, D.G. Pradeep, C. Durga Prasad, M. Mathapati, Comparative analysis of CoCrAlY coatings at high temperature oxidation behavior using different reinforcement composition profiles. Weld. World 67, 585–592 (2023). https://doi.org/10.1007/s40194-022-01405-2

G. Madhusudana Reddy, C. Durga Prasad, G. Shetty, M.R. Ramesh, T.N. Rao, P. Patil, Investigation of thermally sprayed NiCrAlY/TiO2 and NiCrAlY/Cr2O3/YSZ cermet composite coatings on titanium alloys. Eng. Res. Express 4, 025049 (2022). https://doi.org/10.1088/2631-8695/ac7946

C. Venkate Gowda, H. Hanumanthappa, B.K. Shanmugam, C. Durga Prasad, T.N. Sreenivasa, M.S. Rajendra Kumar, High-temperature tribological studies on hot forged Al6061-Tib2 in-situ composites. J. Bio Tribo-Corros. 8, 101 (2022). https://doi.org/10.1007/s40735-022-00699-5

G. Madhusudana Reddy, C. Durga Prasad, P. Patil, N. Kakur, M.R. Ramesh, Elevated temperature erosion performance of plasma sprayed NiCrAlY/TiO2 coating on MDN 420 steel substrate. Surf. Topogr. Metrol. Prop. 10, 025010 (2022). https://doi.org/10.1088/2051-672X/ac6a6e

G. Madhusudana Reddy, C. Durga Prasad, G. Shetty, M.R. Ramesh, T.N. Rao, P. Patil, High temperature oxidation behavior of plasma sprayed NiCrAlY/TiO2 & NiCrAlY/Cr2O3/YSZ coatings on titanium alloy. Weld. World (2022). https://doi.org/10.1007/s40194-022-01268-7

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, A. Sarkar, High temperature gradient cobalt based clad developed using microwave hybrid heating. Am. Inst. Phys. 1943, 020111 (2018). https://doi.org/10.1063/1.5029687

G. Madhusudana Reddy, C. Durga Prasad, G. Shetty, M.R. Ramesh, T.N. Rao, P. Patil, High temperature oxidation studies of plasma sprayed NiCrAlY/TiO2 & NiCrAlY/Cr2O3/YSZ cermet composite coatings on MDN-420 special steel alloy. Metallogr. Microstruct. Anal. 10, 642–651 (2021). https://doi.org/10.1007/s13632-021-00784-0

M. Mathapati, K. Amate, C. Durga Prasad, M.L. Jayavardhana, T.H. Raju, A review on fly ash utilization. Mater. Today Proc. 50(5), 1535–1540 (2022). https://doi.org/10.1016/j.matpr.2021.09.106

C. Durga Prasad, S. Lingappa, S. Joladarashi, M.R. Ramesh, B. Sachin, Characterization and sliding wear behavior of CoMoCrSi + Flyash composite cladding processed by microwave irradiation. Mater. Today Proc. 46, 2387–2391 (2021). https://doi.org/10.1016/j.matpr.2021.01.156

G. Madhu, K.M. MrityunjayaSwamy, D.A. Kumar, C. Durga Prasad, U. Harish, Evaluation of hot corrosion behavior of HVOF thermally sprayed Cr3C2–35NiCr coating on SS 304 boiler tube steel. Am. Inst. Phys. 2316, 030014 (2021). https://doi.org/10.1063/5.0038279

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, Microstructure and tribological resistance of flame sprayed CoMoCrSi/WC-CrC-Ni and CoMoCrSi/WC-12Co composite coatings remelted by microwave hybrid heating. J. Bio Tribo-Corros. 6, 124 (2020). https://doi.org/10.1007/s40735-020-00421-3

R. Dinesh, R.S. Raykar, T.L. Rakesh, M.G. Prajwal, M. Shashank Lingappa, C. Durga Prasad, Feasibility study on MoCoCrSi/WC-Co cladding developed on austenitic stainless steel using microwave hybrid heating. J. Mines Met. Fuels 69(12A), 260–264 (2021). https://doi.org/10.18311/jmmf/2021/30113

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, Comparative investigation of HVOF and flame sprayed CoMoCrSi coating. Am. Inst. Phys. 2247, 050004 (2020). https://doi.org/10.1063/5.0003883

C. Durga Prasad, A. Jerri, M.R. Ramesh, Characterization and sliding wear behavior of iron based metallic coating deposited by HVOF process on low carbon steel substrate. J. Bio Tribo Corros. 6, 69 (2020). https://doi.org/10.1007/s40735-020-00366-7

T. Naik, M. Mathapathi, C. Durga Prasad, H.S. Nithin, M.R. Ramesh, Effect of laser post treatment on microstructural and sliding wear behavior of HVOF sprayed NiCrC and NiCrSi coatings. Surf. Rev. Lett. 29(1), 225000 (2022). https://doi.org/10.1142/S0218625X2250007X

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Comparison of high temperature wear behavior of microwave assisted HVOF sprayed CoMoCrSi-WC-CrC-Ni/WC-12Co composite coatings. Silicon 12, 3027–3045 (2020). https://doi.org/10.1007/s12633-020-00398-1

M.S. Reddy, C. Durga Prasad, P. Patil, M.R. Ramesh, N. Rao, Hot corrosion behavior of plasma sprayed NiCrAlY/TiO2 and NiCrAlY/Cr2O3/YSZ cermets coatings on alloy steel. Surf. Interfaces 22, 100810 (2021). https://doi.org/10.1016/j.surfin.2020.100810

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Effect of microwave heating on microstructure and elevated temperature adhesive wear behavior of HVOF deposited CoMoCrSi–Cr3C2 composite coating. Surf. Coat. Technol. 374, 291–304 (2019). https://doi.org/10.1016/j.surfcoat.2019.05.056

K.G. Girisha, R. Rakesh, C. Durga Prasad, K.V. Sreenivas Rao, Development of corrosion resistance coating for AISI 410 grade steel. Appl. Mech. Mater. 813–814, 135–139 (2015). https://doi.org/10.4028/www.scientific.net/AMM.813-814.135

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Development and sliding wear behavior of Co–Mo–Cr–Si cladding through microwave heating. Silicon 11, 2975–2986 (2019). https://doi.org/10.1007/s12633-019-0084-5

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Microstructure and tribological behavior of flame sprayed and microwave fused CoMoCrSi/CoMoCrSi–Cr3C2 coatings. Mater. Res. Express 6, 026512 (2019). https://doi.org/10.1088/2053-1591/aaebd9

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Influence of microwave hybrid heating on the sliding Wear behaviour of HVOF sprayed CoMoCrSi coating. Mater. Res. Express 5, 086519 (2018). https://doi.org/10.1088/2053-1591/aad44e

K.G. Girisha, K.V. Sreenivas Rao, C. Durga Prasad, Slurry Erosion resistance of martenistic stainless steel with plasma sprayed Al2O3–40%TiO2 coatings. Mater. Today Proc. 5, 7388–7393 (2018). https://doi.org/10.1016/j.matpr.2017.11.409

K.G. Girisha, C. Durga Prasad, K.C. Anil, K.V. Sreenivas Rao, Dry sliding wear behaviour of Al2O3 coatings for AISI 410 grade stainless steel. Appl. Mech. Mater. 766–767, 585–589 (2015). https://doi.org/10.4028/www.scientific.net/AMM.766-767.585

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Venkate Gowda, C., Nagaraja, T.K., Yogesha, K.B. et al. Study on Structural Behavior of HVOF-Sprayed NiCr/Mo Coating. J. Inst. Eng. India Ser. D (2024). https://doi.org/10.1007/s40033-024-00641-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-024-00641-8