Abstract

Piezoelectric nanogenerator (PENG) is a leading-edge mechanical energy harvesting device used in portable power supply and self-powered sensor systems. Advanced 3D printers have been recently used to create 3D printed (3DP) PENGs. This has facilitated the rapid fabrication of PENGs and their integration into wearable electronics, biomedical systems, and internet of things devices. However, researchers face several critical challenges in developing robust 3DP-PENGs that can produce adequate electrical energy for self-powered systems. Therefore, this review on 3DP-PENGs is conducted to highlight their recent developments and challenges. This paper presents the latest 3D-printed piezoelectric nanogenerators in terms of their materials selection and functionalization, design and architecture formation, and applications including pressure sensors, flow sensors, microphones, and implants. Finally, crucial challenges and optimization strategies that considerably impact the output performance of 3DP-PENGs, along with a roadmap for their future enhancement are given. It is envisioned that this work will help reduce the gap between 3D printing and PENG technologies and accelerate the research and development of 3DP-PENGs.

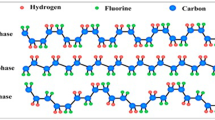

Graphical Abstract

Similar content being viewed by others

References

Hwang, G.T., Byun, M., Jeong, C.K., Lee, K.J.: Flexible piezoelectric thin-film energy harvesters and nanosensors for biomedical applications. Adv. Healthc. Mater. 4(5), 646–658 (2015). https://doi.org/10.1002/adhm.201400642

Shi, B., et al.: Body-integrated self-powered system for wearable and implantable applications. ACS Nano 13(5), 6017–6024 (2019). https://doi.org/10.1021/acsnano.9b02233

Wang, Z.L., Song, J.: Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 312(5771), 242–246 (2006). https://doi.org/10.1126/science.1124005

He, J., et al.: A high-resolution flexible sensor array based on PZT nanofibers. Nanotechnology (2020). https://doi.org/10.1088/1361-6528/ab667a

Renteria, A., et al.: Optimization of 3D printing parameters for BaTiO3 piezoelectric ceramics through design of experiments. Res. Express Mater. (2019). https://doi.org/10.1088/2053-1591/ab200e

Bodkhe, S., Turcot, G., Gosselin, F.P., Therriault, D.: One-step solvent evaporation-assisted 3D printing of piezoelectric PVDF nanocomposite structures. ACS Appl. Mater. Interfaces 9(24), 20833–20842 (2017)

Jin, L., et al.: Polarization-free high-crystallization β-PVDF piezoelectric nanogenerator toward self-powered 3D acceleration sensor. Nano Energy 50(May), 632–638 (2018). https://doi.org/10.1016/j.nanoen.2018.05.068

Hwang, G.T., et al.: Self-powered cardiac pacemaker enabled by flexible single crystalline PMN-PT piezoelectric energy harvester. Adv. Mater. 26(28), 4880–4887 (2014). https://doi.org/10.1002/adma.201400562

Dagdeviren, C., Li, Z., Wang, Z.L.: Energy harvesting from the animal-human body for self-powered electronics. Annu. Rev. Biomed. Eng. 19, 85–108 (2017). https://doi.org/10.1146/annurev-bioeng-071516-044517

Parvez Mahmud, M.A., Huda, N., Farjana, S.H., Asadnia, M., Lang, C.: Recent advances in nanogenerator-driven self-powered implantable biomedical devices. Adv. Energy Mater. 8(2), 1–25 (2018). https://doi.org/10.1002/aenm.201701210

Mahmud, M.A.P., et al.: 3D-printed triboelectric nanogenerators: state of the art, applications, and challenges. Adv. Energy Sustain. Res. 2(3), 2000045 (2021). https://doi.org/10.1002/aesr.202000045

Mahmud, M.A.P., Lee, J.J., Kim, G.H., Lim, H.J., Choi, K.B.: Improving the surface charge density of a contact-separation-based triboelectric nanogenerator by modifying the surface morphology. Microelectron. Eng. 159, 102–107 (2016). https://doi.org/10.1016/j.mee.2016.02.066

Wu, N., et al.: In vivo delivery of Atoh1 gene to rat cochlea using a dendrimer-based nanocarrier. J. Biomed. Nanotechnol. 9(10), 1736–1745 (2013). https://doi.org/10.1166/jbn.2013.1684

Choi, Y.S., Jing, Q., Datta, A., Boughey, C., Kar-Narayan, S.: A triboelectric generator based on self-poled Nylon-11 nanowires fabricated by gas-flow assisted template wetting. Energy Environ. Sci. 10(10), 2180–2189 (2017). https://doi.org/10.1039/c7ee01292f

Li, J., Wang, X.: Research update: materials design of implantable nanogenerators for biomechanical energy harvesting. APL Mater. (2017). https://doi.org/10.1063/1.4978936

He, X., et al.: A hierarchically nanostructured cellulose fiber-based triboelectric nanogenerator for self-powered healthcare products. Adv. Funct. Mater. 28(45), 1–8 (2018). https://doi.org/10.1002/adfm.201805540

Zhang, S., Rhee, S., Randall, C.A., Shrout, T.R.: Shear-mode piezoelectric properties of Pb (Yb 1/2 Nb 1/2) O 3–PbTiO 3 single crystals. Appl. Phys. Lett. 81(5), 892–894 (2002)

T. L. B. Tseng, A. Akundi, and H. Kim 2018 4-D printing of pressure sensors and energy harvesting devices for engineering education. In: ASEE Annu. Conf. Expo. Conf. Proc., vol. 2018 June. https://doi.org/10.18260/1-2--29654.

Rayate, A., Jain, P.K.: A review on 4d printing material composites and their applications. Mater. Today Proc. 5(9), 20474–20484 (2018). https://doi.org/10.1016/j.matpr.2018.06.424

Zhou, X., et al.: All 3D-printed stretchable piezoelectric nanogenerator with non-protruding kirigami structure. Nano Energy 72, 104676 (2020). https://doi.org/10.1016/j.nanoen.2020.104676

Yoon, H.J., et al.: 3D-printed biomimetic-villus structure with maximized surface area for triboelectric nanogenerator and dust filter. Nano Energy 63, 103857 (2019). https://doi.org/10.1016/j.nanoen.2019.103857

Yang, Y., et al.: Three dimensional printing of high dielectric capacitor using projection based stereolithography method. Nano Energy 22, 414–421 (2016). https://doi.org/10.1016/j.nanoen.2016.02.045

Mitchell, A., Lafont, U., Hołyńska, M., Semprimoschnig, C.: Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 24, 606–626 (2018). https://doi.org/10.1016/j.addma.2018.10.038

Chandrashekar, B.N., et al.: Roll-to-roll green transfer of CVD graphene onto plastic for a transparent and flexible triboelectric nanogenerator. Adv. Mater. 27(35), 5210–5216 (2015). https://doi.org/10.1002/adma.201502560

Zheng, Q., Shi, B., Li, Z., Wang, Z.L.: Recent progress on piezoelectric and triboelectric energy harvesters in biomedical systems. Adv. Sci. 4(7), 1–23 (2017). https://doi.org/10.1002/advs.201700029

Jiang, D., et al.: A 25-year bibliometric study of implantable energy harvesters and self-powered implantable medical electronics researches. Mater. Today Energy 16, 100386 (2020). https://doi.org/10.1016/j.mtener.2020.100386

Seol, M.L., et al.: All 3D printed energy harvester for autonomous and sustainable resource utilization. Nano Energy 52(July), 271–278 (2018). https://doi.org/10.1016/j.nanoen.2018.07.061

Tan, P., et al.: A battery-like self-charge universal module for motional energy harvest. Adv. Energy Mater. 9(36), 1–9 (2019). https://doi.org/10.1002/aenm.201901875

Tcho, I.W., Kim, W.G., Choi, Y.K.: A self-powered character recognition device based on a triboelectric nanogenerator. Nano Energy 70, 104534 (2020). https://doi.org/10.1016/j.nanoen.2020.104534

Lee, A.Y., An, J., Chua, C.K.: Two-way 4D printing: a review on the reversibility of 3D-printed shape memory materials. Engineering 3(5), 663–674 (2017). https://doi.org/10.1016/J.ENG.2017.05.014

Li, X., Shang, J., Wang, Z.: Intelligent materials: a review of applications in 4D printing. Assem. Autom. 37(2), 170–185 (2017). https://doi.org/10.1108/AA-11-2015-093

J. Lee, H. C. Kim, J. W. Choi, and I. H. Lee 2017 A review on 3D printed smart devices for 4D printing. Int. J. Precis. Eng. Manuf. Green Technol. 4(3):373–383. https://doi.org/10.1007/s40684-017-0042-x

Khoo, Z.X., et al.: 3D printing of smart materials: a review on recent progresses in 4D printing. Virtual Phys. Prototyp. 10(3), 103–122 (2015). https://doi.org/10.1080/17452759.2015.1097054

Chen, C., et al.: Additive manufacturing of piezoelectric materials. Adv. Funct. Mater. 30(52), 1–29 (2020). https://doi.org/10.1002/adfm.202005141

Smirnov, A., Chugunov, S., Kholodkova, A., Isachenkov, M., Vasin, A., Shishkovsky, I.: Progress and challenges of 3D-printing technologies in the manufacturing of piezoceramics. Ceram. Int. 47(8), 10478–10511 (2021). https://doi.org/10.1016/j.ceramint.2020.12.243

E. R. Cholleti and I. Gibson 2018 ABS Nano Composite Materials in Additive Manufacturing. In: IOP Conf. Ser. Mater. Sci. Eng. https://doi.org/10.1088/1757-899X/455/1/012038.

Li, H., et al.: 3D printed flexible triboelectric nanogenerator with viscoelastic inks for mechanical energy harvesting. Nano Energy 58, 447–454 (2019)

Schaffner, M., Faber, J.A., Pianegonda, L., Rühs, P.A., Coulter, F., Studart, A.R.: 3D printing of robotic soft actuators with programmable bioinspired architectures. Nat. Commun. 9(1), 1–9 (2018)

Li, Y., Cheng, G., Lin, Z.-H., Yang, J., Lin, L., Wang, Z.L.: Single-electrode-based rotationary triboelectric nanogenerator and its applications as self-powered contact area and eccentric angle sensors. Nano Energy 11, 323–332 (2015)

Zolfagharian, A., Kaynak, A., Kouzani, A.: Closed-loop 4D-printed soft robots. Mater. Des. 188, 108411 (2020)

Kim, H., Torres, F., Wu, Y., Villagran, D., Lin, Y., Tseng, T.-L.: Integrated 3D printing and corona poling process of PVDF piezoelectric films for pressure sensor application. Smart Mater. Struct. 26(8), 085027 (2017). https://doi.org/10.1088/1361-665x/aa738e

Cheng, J., Chen, Y., Wu, J.W., Ji, X.R., Wu, S.H.: 3d printing of BaTiO3 piezoelectric ceramics for a focused ultrasonic array. Sensors (Switzerland) (2019). https://doi.org/10.3390/s19194078

Kim, H., et al.: Fabrication of bulk piezoelectric and dielectric BaTiO 3 ceramics using paste extrusion 3D printing technique. J. Am. Ceram. Soc. 102(6), 3685–3694 (2019). https://doi.org/10.1111/jace.16242

Goat, C.A., Whatmore, R.W.: The effect of grinding conditions on lead zirconate titanate machinability. J. Eur. Ceram. Soc. 19(6), 1311–1313 (1999). https://doi.org/10.1016/S0955-2219(98)00426-9

Yao, G., et al.: Effective weight control via an implanted self-powered vagus nerve stimulation device. Nat. Commun. 9(1), 1–10 (2018)

J. B. Lando, H. G. Olf, and A. Peterlin 1966 Nuclear magnetic resonance and x-ray determination of the structure of poly vinylidene fluoride. J. Polym. Sci. Part A 1 Polym. Chem. 4(4): 941–951

Pavlović, V.P., et al.: Structural properties of composites of polyvinylidene fluoride and mechanically activated BaTiO3 particles. Phys. Scr. 2013(T157), 14006 (2013)

Pavlović, V.P., Popović, D., Krstić, J., Dojčilović, J., Babić, B., Pavlović, V.B.: Influence of mechanical activation on the structure of ultrafine BaTiO3 powders. J. Alloys Compd. 486(1–2), 633–639 (2009)

Mendes, S.F., Costa, C.M., Caparrós, C., Sencadas, V., Lanceros-Méndez, S.: Effect of filler size and concentration on the structure and properties of poly (vinylidene fluoride)/BaTiO 3 nanocomposites. J. Mater. Sci. 47(3), 1378–1388 (2012)

Yao, J., Bastiaansen, C.W.M., Peijs, T.: High strength and high modulus electrospun nanofibers. Fibers 2(2), 158–186 (2014)

Roy, M., Nelson, J.K., MacCrone, R.K., Schadler, L.S., Reed, C.W., Keefe, R.: Polymer nanocomposite dielectrics-the role of the interface. IEEE Trans. Dielectr. Electr. Insul. 12(4), 629–643 (2005)

Chen, Z., et al.: 3D printing of piezoelectric element for energy focusing and ultrasonic sensing. Nano Energy 27, 78–86 (2016)

Kim, K., et al.: 3D optical printing of piezoelectric nanoparticle-polymer composite materials. ACS Nano 8(10), 9799–9806 (2014). https://doi.org/10.1021/nn503268f

Han, L.-H., Suri, S., Schmidt, C.E., Chen, S.: Fabrication of three-dimensional scaffolds for heterogeneous tissue engineering. Biomed. Microdevices 12(4), 721–725 (2010)

G. Mapili, Y. Lu, S. Chen, and K. Roy 2005 Laser-layered microfabrication of spatially patterned functionalized tissue-engineering scaffolds. J. Biomed. Mater. Res. Part B Appl. Biomater. An Off. J. Soc. Biomater. Japanese Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater., vol. 75, no. 2, pp. 414–424, 2005.

Chen, D., Jiao, X.: Solvothermal synthesis and characterization of barium titanate powders. J. Am. Ceram. Soc. 83(10), 2637–2639 (2000)

Xu, S., Yeh, Y., Poirier, G., McAlpine, M.C., Register, R.A., Yao, N.: Flexible piezoelectric PMN–PT nanowire-based nanocomposite and device. Nano Lett. 13(6), 2393–2398 (2013)

Yao, D., et al.: Achieving the upper bound of piezoelectric response in tunable, wearable 3D printed nanocomposites. Adv. Funct. Mater. 29(42), 1–11 (2019). https://doi.org/10.1002/adfm.201903866

Maillard, F., Savinova, E.R., Stimming, U.: CO monolayer oxidation on Pt nanoparticles: further insights into the particle size effects. J. Electroanal. Chem. 599(2), 221–232 (2007)

Griffith, M.L., Halloran, J.W.: Freeform fabrication of ceramics via stereolithography. J. Am. Ceram. Soc. 79(10), 2601–2608 (1996)

Sundstrom, D.W.: Viscosity of suspensions in polymeric solutions. Rheol. acta 22(4), 420–423 (1983)

Cui, H., et al.: Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nat. Mater. 18(3), 234–241 (2019)

Colombo, M., et al.: Biological applications of magnetic nanoparticles. Chem. Soc. Rev. 41(11), 4306–4334 (2012)

Jabbari, M., Hattel, J.: Bingham plastic fluid flow model in tape casting of ceramics using two doctor blades–analytical approach. Mater. Sci. Technol. 30(3), 283–288 (2014)

Lin, L., et al.: An elastic-spring-substrated nanogenerator as an active sensor for self-powered balance. Energy Environ. Sci. 6(4), 1164–1169 (2013)

Fan, F.-R., Tian, Z.-Q., Wang, Z.L.: Flexible triboelectric generator. Nano Energy 1(2), 328–334 (2012)

Xie, Y., et al.: High-efficiency ballistic electrostatic generator using microdroplets. Nat. Commun. 5(1), 1–5 (2014)

Fuh, Y.K., Wang, B.S., Tsai, C.Y.: Self-powered pressure sensor with fully encapsulated 3D printed wavy substrate and highly-aligned piezoelectric fibers array. Sci. Rep. 7(1), 1–7 (2017). https://doi.org/10.1038/s41598-017-07360-z

Marandi, M., Tarbutton, J.: Additive manufacturing of single- and double-layer piezoelectric PVDF-TrFE copolymer sensors. Procedia Manuf. 34, 666–671 (2019). https://doi.org/10.1016/j.promfg.2019.06.194

Lovinger, A.J.: Recent developments in the structure, properties, and applications of ferroelectric polymers. Jpn. J. Appl. Phys. 24(S2), 18 (1985)

Martins, P., Lopes, A.C., Lanceros-Mendez, S.: Electroactive phases of poly (vinylidene fluoride): determination, processing and applications. Prog. Polym. Sci. 39(4), 683–706 (2014)

Yoon, J.-Y., Kim, G.-W.: Harnessing the bilinear nonlinearity of a 3D printed biomimetic diaphragm for acoustic sensor applications. Mech. Syst. Signal Process. 116, 710–724 (2019). https://doi.org/10.1016/j.ymssp.2018.07.020

Haque, R.I., Ogam, E., Loussert, C., Benaben, P., Boddaert, X.: Fabrication of capacitive acoustic resonators combining 3D printing and 2D inkjet printing techniques. Sensors 15(10), 26018–26038 (2015)

Tiller, B., et al.: Piezoelectric microphone via a digital light processing 3D printing process. Mater. Des. 165, 107593 (2019). https://doi.org/10.1016/j.matdes.2019.107593

Chen, Y., Zhou, D., Lam, K.H., Cheung, K.F., Dai, J., Chan, H.L.W.: Endoscopic ultrasound radial array transducers fabricated with PZT tube by a rotate-and-dice method. Sensors Actuators A Phys. 201, 357–362 (2013). https://doi.org/10.1016/j.sna.2013.07.015

Yang, J.-M., et al.: Simultaneous functional photoacoustic and ultrasonic endoscopy of internal organs in vivo. Nat. Med. 18(8), 1297–1302 (2012)

Park, K., et al.: Highly-efficient, flexible piezoelectric PZT thin film nanogenerator on plastic substrates. Adv. Mater. 26(16), 2514–2520 (2014)

Kawai, H.: The piezoelectricity of poly (vinylidene fluoride). Jpn. J. Appl. Phys. 8(7), 975–976 (1969). https://doi.org/10.1143/jjap.8.975

A. J. Lovinger, “Poly (vinylidene fluoride),” In: Developments in crystalline polymers—1, Springer, 1982, pp. 195–273.

Fukada, E.: History and recent progress in piezoelectric polymers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 47(6), 1277–1290 (2000)

Salimi, A., Yousefi, A.A.: Analysis method: FTIR studies of β-phase crystal formation in stretched PVDF films. Polym. Test. 22(6), 699–704 (2003). https://doi.org/10.1016/S0142-9418(03)00003-5

Ramadan, K.S., Sameoto, D., Evoy, S.: A review of piezoelectric polymers as functional materials for electromechanical transducers. Smart Mater. Struct. 23(3), 33001 (2014)

Li, H., Tian, C., Denga, Z.D.: Applied physics reviews. Appl. Phys. Lett 113904, 104 (2014). https://doi.org/10.1063/1.4869130

Jin, H., Abu-Raya, Y.S., Haick, H.: Advanced materials for health monitoring with skin-based wearable devices. Adv. Healthc. Mater. 6(11), 1700024 (2017)

Chorsi, M.T., et al.: Piezoelectric biomaterials for sensors and actuators. Adv. Mater. 31(1), 1802084 (2019)

Dong, L., Closson, A.B., Jin, C., Trase, I., Chen, Z., Zhang, J.X.J.: Vibration-energy-harvesting system: transduction mechanisms, frequency tuning techniques, and biomechanical applications. Adv. Mater. Technol. 4(10), 1900177 (2019)

Wei, C., Jing, X.: A comprehensive review on vibration energy harvesting: modelling and realization. Renew. Sustain. Energy Rev. 74, 1–18 (2017)

Shi, B., Li, Z., Fan, Y.: Implantable energy-harvesting devices. Adv. Mater. 30(44), 1801511 (2018)

Liu, H., Zhong, J., Lee, C., Lee, S.-W., Lin, L.: A comprehensive review on piezoelectric energy harvesting technology: materials, mechanisms, and applications. Appl. Phys. Rev. 5(4), 41306 (2018)

Dagdeviren, C., et al.: Recent progress in flexible and stretchable piezoelectric devices for mechanical energy harvesting, sensing and actuation. Extrem. Mech. Lett. 9, 269–281 (2016)

Tandon, B., Blaker, J.J., Cartmell, S.H.: Piezoelectric materials as stimulatory biomedical materials and scaffolds for bone repair. Acta Biomater. 73, 1–20 (2018)

Shuai, C., et al.: Functionalized BaTiO3 enhances piezoelectric effect towards cell response of bone scaffold”. Colloids Surf. B Biointerfaces 185, 110587 (2020)

Tariverdian, T., Behnamghader, A., Brouki Milan, P., Barzegar-Bafrooei, H., Mozafari, M.: 3D-printed barium strontium titanate-based piezoelectric scaffolds for bone tissue engineering. Ceram. Int. 45(11), 14029–14038 (2019). https://doi.org/10.1016/j.ceramint.2019.04.102

Polley, C., et al.: 3D printing of piezoelectric barium titanate-hydroxyapatite scaffolds with interconnected porosity for bone tissue engineering. Materials (Basel) 13(7), 1773 (2020)

H. Kim, K. Lee, G. Jo, J.-S. Kim, M. Lim, and Y. Cha, Tendon-Inspired Piezoelectric Sensor for Biometric Application. IEEE/ASME Trans. Mechatronics, 2020.

Zhang, S., Yu, F.: Piezoelectric materials for high temperature sensors. J. Am. Ceram. Soc. 94(10), 3153–3170 (2011)

Zhang, S., Randall, C.A., Shrout, T.R.: High Curie temperature piezocrystals in the BiScO 3-PbTiO 3 perovskite system. Appl. Phys. Lett. 83(15), 3150–3152 (2003)

Zhang, S., Luo, J., Hackenberger, W., Shrout, T.R.: Characterization of Pb (InNb) O-Pb (MgNb) O-PbTiO ferroelectric crystal with enhanced phase transition temperatures. J. Appl. Phys. 104, 1–5 (2008)

Zhang, S., Lee, S., Kim, D., Lee, H., Shrout, T.R.: Electromechanical properties of PMN–PZT piezoelectric single crystals near morphotropic phase boundary compositions. J. Am. Ceram. Soc. 90(12), 3859–3862 (2007)

Li, F., Zhang, S., Xu, Z., Wei, X., Luo, J., Shrout, T.R.: Composition and phase dependence of the intrinsic and extrinsic piezoelectric activity of domain engineered (1–x) Pb (Mg 1/3 Nb 2/3) O 3–x PbTiO 3 crystals. J. Appl. Phys. 108(3), 34106 (2010)

Tian, J., Han, P., Huang, X., Pan, H., Carroll, J.F., III., Payne, D.A.: Improved stability for piezoelectric crystals grown in the lead indium niobate–lead magnesium niobate–lead titanate system. Appl. Phys. Lett. 91(22), 222903 (2007)

N. Mohamad Nor, H. H. Hamzah, and K. Abdul Razak, “Chapter 9 - Recent advancement in sustainable energy harvesting using piezoelectric materials,” K. Y. Cheong and L.-C. B. T.-S. M. for N. G. E. D. Chen, Eds. Elsevier, 2021, pp. 221–248.

Kim, H., et al.: Increased piezoelectric response in functional nanocomposites through multiwall carbon nanotube interface and fused-deposition modeling three-dimensional printing. MRS Commun. 7(4), 960–966 (2017). https://doi.org/10.1557/mrc.2017.126

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work. There is no professional or other personal interest of any nature or kind in any product, service, and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahmud, M.A.P., Adhikary, P., Zolfagharian, A. et al. Advanced Design, Fabrication, and Applications of 3D-Printable Piezoelectric Nanogenerators. Electron. Mater. Lett. 18, 129–144 (2022). https://doi.org/10.1007/s13391-021-00327-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-021-00327-3