Abstract

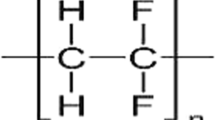

Polyvinylidene fluoride (PVDF) is known as a favorite polymer from the family of fluoropolymers due to its excellent piezoelectric properties, thermal stability, and mechanical strength. It has a good processability, and it also possess chemical resistance property to different materials such as different acids, bases, organic solvents, oil, and fat. The present study reveals an overview of the recent growth and development in the application perspective and modification of PVDF membranes, majorly focus on sensors and actuators, spin-valve devices, magnetoelectric materials, energy harvesting applications, tissue engineering, modeling engineering, and other biomedical engineering and devices. From an electronic point of view, ferroelectric polymers are insulating, polar, and possess a non-conjugated backbone; therefore, they are termed as highly insulating materials. The insulating polymers are most attractive for the study of charge transportation and storage. Such polymers also yield the best electrets for practical application because of their insulating properties and high concentration of deep trapping sites. Thus, the objective of this review is to present the physical, chemical, thermal, and mechanical properties of PVDF. This article also provides an intelligent direction in the progress of PVDF in different fields of science and technology.

Graphical abstract

Similar content being viewed by others

References

Curie P, Curie J (1880) Dévelopment, par pression, de l’électricité polaire dans les cristaux hémièdres à faces inclinées. C R Acad Sci 91:294–295

Nalwa HS (1995) Ferroelectric polymers: chemistry, physics, and applications. CRC Press, Marcel Dekker Inc

Kawai H (1969) The piezoelectricity of polyvinylidene fluoride. Jpn J Appl Phys 8:975–976

Lei KF, Hsieh YZ, Chiu YY, Wu MH (2015) The structure design of piezoelectric poly(vinylidene fluoride) (PVDF) polymer-based sensor patch for the respiration monitoring under dynamic walking conditions. Sensors 15(8):18801–18812

Niizeki K, Nishidate I, Uchida K, Kuwahara M (2005) Unconstrained cardiorespiratory and body movement monitoring system for home care. Med Biol Eng Comput 43:716–724

Folke M, Cernerud L, Ekstrom M, Hok B (2003) Critical review of non-invasive respiratory monitoring in medical care. Med Biol Eng Comput 41:377–383

Ford TA, Hanford WE (1948) Polyvinylidene fluoride and process for obtaining the same, U.S. Patent # 2435537

Furukawa T (1989a) Ferroelectric properties of vinylidene fluoride copolymers. Phase Transitions 18(3–4):143–211

Lovinger AJ (1982) Poly (viny1idene fluoride): In Developments in crystalline polymers. Ed. Bassett DC, Applied Science Publishers, London, p 195

Eisenmenger W, Schmidt H, Dehlen B (1999) Space charge and dipoles in polyvinylidenefluoride. Braz J Phys 29(2):295–305

Sajkiewicz P, Wasiak A, Goclowski Z (1999) Phase transition during stretching of poly (vinylidene fluoride). Eur Polymer J 35(3):423–429

Davis GT, McKinney JE, Broadhurst MG, Roth SC (1978) Electric-field-induced phase changes in poly (vinylidene fluoride). J Appl Phys 49(10):4998–5002

Dohaney JE, Dukert AA, Preston SS (1971) Viylidene fluoride polymers In Encyclopedia of polymer science and technology. Eds. Bikales NM, John Wiley, New York, Vol. 14, pp 600–610

Omnexus, Plastics and Elastomers (2020) https://omnexus.specialchem.com/selection-guide/polyvinylidene-fluoride-pvdf-plastic

All Plastics, PVDF Material properties datasheet (2020), www.allplastics.com.au; all plastics- KYNAR (PVDF) data sheet.pdf

Teesing. www.teesing.com/properties of PVDF, rectus chemical resistance, rectum PVDF

Burkert: Chemical Resistance chart. https://www.burkert.in/en/Service-Support/Support/Glossary/Chemical-Resistance-Chart

IPEX Chemical Resistance Guide for PVDF (Polyvinylidene fluoride for waste drainage systems chemical resistance data. www.ipexna.com

KYNAR (PVDF) Chemical Compatibility & Chemical Resistance Chart. www.allplastic.com.au

Zhang SC, Shen J, Qiu XP, Weng DS, Zhu WT (2006) ESR and vibrational spectroscopy study on poly(vinylidene fluoride) membranes with alkaline treatment. J Power Sources 153(2):234–238. https://doi.org/10.1016/j.jpowsour.2005.05.020

Hashim NA, Liu Y, Li K (2011a) Stability of PVDF hollow fibre membranes in sodium hydroxide aqueous solution. Chem Eng Sci 66(8):1565–1575. https://doi.org/10.1016/j.ces.2010.12.019

Hoa SV, Ouellette P (1983) Stress-corrosion cracking of poly(vinylidene fluoride) in sodium-hydroxide. Polym Eng Sci 23(4):202–205. https://doi.org/10.1002/pen.760230407

Hou DY, Wang J, Qu D, Luan ZK, Ren XJ (2009) Fabrication and characterization of hydrophobic PVDF hollow fiber membranes for desalination through direct contact membrane distillation. Sep Purif Technol 69(1):78–86. https://doi.org/10.1016/j.seppur.2009.06.026

Ross GJ, Watts JF, Hill MP, Morrissey P (2000) Surface modification of poly(vinylidene fluoride) by alkaline treatment 1. The degradation mechanism Polymer (Vol. 41, pp. 1685–1696)

Ross GJ, Watts JF, Hill MP, Morrissey P (2001) Surface modification of poly(vinylidene fluoride) by alkaline treatment: Part 2. Process modification by the use of phase transfer catalysts. Polymer 42(2):403–413. https://doi.org/10.1016/S0032-3861(00)00328-1

Zhao XD, Song LZ, Fu J, Tang P, Liu F (2011) Experimental and DFT investigation of surface degradation of polyvinylidene fluoride membrane in alkaline solution. Surf Sci 605(11–12):1005–1015. https://doi.org/10.1016/j.susc.2011.02.022

Nguyen T (1985) Degradation of poly(vinyl fluoride) and poly(vinylidene fluoride). J Macromol Sci Polym Rev 25(2):227–275. https://doi.org/10.1080/15583728509412823

Komaki Y (1979) Growth of fine holes by the chemical etching of fission tracks in polyvinylidene fluoride. Nuclear Tracks 3(1–2):33–44

Shinohara H (1979) Fluorination of polyhydrofluoroethylenes. II. Formation of perfluoroalkyl carboxylic acids on the surface region of poly(vinylidene fluoride) film by oxyfluorination, fluorination, and hydrolysis. J Polym Sci Polym Chem Ed 17(5):1543–1556. https://doi.org/10.1002/pol.1979.170170526

Komaki Y, Otsu H (1981) Observation of nuclear track development in polyvinylidene fluoride with several etchants. J Electron Microsc 30(4):292–297

Kise H, Ogata H (1983) Phase transfer catalysis in dehydrofluorination of poly(vinylidene fluoride) by aquos sodium hydroxide solutions. J Polym Sci Part A-1 Polym Chem 21(12):3443–3451

Wegener M, Kuenstler W, Gerhard-Multhaupt R (2006) Poling behavior and optical absorption of partially dehydrofluorinated and uniaxially stretched polyvinylidene fluoride. Ferroelectrics 336(1):3–8. https://doi.org/10.1080/00150190600694761

Benzinger WD, Parekh BS, Eichelberger JL (1980) High-temperature ultrafiltration with Kynar® poly(vinylidene fluoride) membranes. Sep Sci Technol 15(4):1193–1204. https://doi.org/10.1080/01496398008076294

Vigo F, Uliana C, Cavazza B, Salvemini F (1984) Mechanical, chemical and bacterial-resistance of modified polyvinylidene fluoride membranes suitable for ultrafiltration of oily emulsions. J Membr Sci 21(3):295–306. https://doi.org/10.1016/S0376-7388(00)80220-3

Hashim NA, Liu Y, Li K (2011b) Preparation of PVDF hollow fiber membranes using SiO2 particles: the effect of acid and alkali treatment on the membrane performances. Ind Eng Chem Res 50(5):3035–3040

Puspitasari V, Granville A, Le-Clech P, Chen V (2010) Cleaning and aging effect of sodium hypochlorite on polyvinylidene fluoride (PVDF) membrane. Sep Purif Technol 72(3):301–308. https://doi.org/10.1016/j.seppur.2010.03.001

Wang Z, Wang Z, Wu QZ, Yang D (2010) Effect of hypochlorite cleaning on the physiochemical characteristics of polyvinylidene fluoride membranes. Chem Eng J 162(3):1050–1056. https://doi.org/10.1016/j.cej.2010.07.019

Liu F, Hashim NA, Liu Y, Abed MRM, Li K (2011) Progress in the production and modification of PVDF membranes. J Membr Sci 375(1–2):1–27. https://doi.org/10.1016/j.memsci.2011.03.014

O’Hagan D (2008) Understanding organofluorine chemistry. An introduction to the C-F bond. Chem Soc Rev 37(2):308–319. https://doi.org/10.1039/b711844a

Dargaville TR, George GA, Hill DJT, Whittaker AK (2003) High energy radiation grafting of fluoropolymers. Prog Polym Sci 28(9):1355–1376

Madorsky SL (1964) Thermal degradation of organic polymers fluorocarbon and chlorocarbon polymers: John Wiley & Sons Inc., pp 130–172

Lovinger AJ, Freed DJ (1980) Inhomogeneous thermal-degradation of poly(vinylidene fluoride) crystallized from the melt. Macromolecules 13(4):989–994. https://doi.org/10.1021/Ma60076a044

PVDF Material Properties Data Sheet. https://omnexus.specialchem.com/selection-guide/polyvinylidene-fluoride-pvdf-plastic

Collier A, Wang HJ, Yuan XZ, Zhang JJ, Wilkinson DP (2006) Degradation of polymer electrolyte membranes. Int J Hydrogen Energy 31(13):1838–1854. https://doi.org/10.1016/j.ijhydene.2006.05.006

Tamura M, Yamaguchi T, Oyaba T, Yoshimi T (1975) Electroacoustic transducers with piezoelectric high polymer films. J Audio Eng Soc 23:21–26

Ribeiro C, Panadero J, Sencadas V, Lanceros-Méndez S, Tamano M, Moratal D, Salmerón-Sánchez M, Ribelles JG (2012) Fibronectin adsorption and cell response on electroactive poly(vinylidene fluoride) films. Biomed Mater 7:035004

Jeon J-H, Kang S-P, Lee S, Oh I-K (2009) Novel biomimetic actuator based on SPEEK and PVDF. Sens Actuators B Chem 143:357–364

Panwar V, Cha K, Park J-O, Park S (2012) High actuation response of PVDF/PVP/PSSA based ionic polymer metal composites actuator. Sens Actuators B Chem 161:460–470

Zhang Y, Niu H, Xie S, Zhang X (2008) Numerical and experimental investigation of active vibration control in a cylindrical shell partially covered by a laminated PVDF actuator. Smart Mater Struct 17:035024

Chen Z, Kwon K-Y, Tan X (2008) Integrated IPMC/PVDF sensory actuator and its validation in feedback control. Sens Actuators A Phys 144:231–241

Shirinov A, Schomburg W (2008) Pressure sensor from a PVDF film. Sens Actuators A Phys 142:48–55

Fujitsuka N, Sakata J, Miyachi Y, Mizuno K, Ohtsuka K, Taga Y, Tabata O (1998) Monolithic pyroelectric infrared image sensor using PVDF thin film. Sens Actuators A Phys 66:237–243

Mazurek B, Janiczek T, Chmielowiec J (2001) Assessment of vehicle weight measurement method using PVDF transducers. J Electrost 51:76–81

Xu G, Zhang M, Zhou Q, Chen H, Gao T, Li C, Shi G (2017) A small graphene oxide sheet/polyvinylidene fluoride bilayer actuator with large and rapid responses to multiple stimuli. Nanoscale 9:17465–17470

Wang F, Ko SY, Park JO, Park SH, Kee CD (2015) Electroactive polymer actuator based on PVDF and graphene through electrospinning. Adv Mater Res 1105:311–314

Fukushima T, Asaka K, Kosaka A, Aida T (2005) Fully plastic actuator through layer-by-layer casting with ionic-liquid-based bucky gel. Angew Chem Int Ed 44:2410–2413

Mukai K, Asaka K, Kiyohara K, Sugino T, Takeuchi I, Fukushima T, Aida T (2008) High performance fully plastic actuator based on ionic-liquid-based bucky gel. Electrochim Acta 53:5555–5562

Saketi P, Latifi SK, Hirvonen J, Rajala S, Vehkaoja A, Salpavaara T, Lekkala J, Kallio P (2015) PVDF microforce sensor for the measurement of Z-directional strength in paper fiber bonds. Sens Actuators A Phys 222:194–203

Choi S-C, Park J-S, Kim J-H (2006) Active damping of rotating composite thin-walled beams using MFC actuators and PVDF sensors. Compos Struct 76:362–374

Ying Z, Jiang Y, Du X, Xie G, Yu J, Wang H (2007) PVDF coated quartz crystal microbalance sensor for DMMP vapor detection. Sens Actuators B Chem 125:167–172

Shin K-Y, Lee JS, Jang J (2016) Highly sensitive, wearable and wireless pressure sensor using free-standing ZnO nanoneedle/PVDF hybrid thin film for heart rate monitoring. Nano Energy 22:95–104

Yoon S, Prabu AA, Ramasundaram S, Kim KJ (2008) PVDF nanoweb touch sensors prepared using electro-spinning process for smart apparels applications. Adv Sci Technol 60:52–57

Wang Y, Zheng J, Ren G, Zhang P, Xu C (2011) A flexible piezoelectric force sensor based on PVDF fabrics. Smart Mater Struct 20:045009

Al-Saygh A, Ponnamma D, AlMaadeed MA, Poornima Vijayan P, Karim A, Hassan MK (2017) Flexible pressure sensor based on PVDF nanocomposites containing reduced graphene oxide-titania hybrid nanolayers. Polymers 9(2):33

Spanu A, Pinna L, Viola F, Seminara L, Valle M, Bonfiglio A, Cosseddu P (2016) A high-sensitivity tactile sensor based on piezoelectric polymer PVDF coupled to an ultra-low voltage organic transistor. Org Electron 36:57–60

Tseng H-J, Tian W-C, Wu W-J (2013) P(VDF-TrFE) polymer-based thin films deposited on stainless steel substrates treated using water dissociation for flexible tactile sensor development. Sensors (Basel, Switzerland) 13:14777–14796. https://doi.org/10.3390/s131114777

Naber RC, Asadi K, Blom PW, de Leeuw DM, de Boer B (2010) Organic nonvolatile memory devices based on ferroelectricity. Adv Mater 22:933–945

Scott JC, Bozano LD (2007) Nonvolatile memory elements based on organic materials. Adv Mater 19:1452–1463

Singh TB, Marjanović N, Matt G, Sariciftci N, Schwödiauer R, Bauer S (2004) Nonvolatile organic field-effect transistor memory element with a polymeric gate electret. Appl Phys Lett 85:5409–5411

Li Y, Sinitskii A, Tour JM (2008) Electronic two-terminal bistable graphitic memories. Nat Mater 7:966–971

Liang S, Yang H, Yang H, Tao B, Djeffal A, Chshiev M, Huang W, Li X, Ferri A, Desfeux R (2016) Ferroelectric control of organic/ferromagnetic spinterface. Adv Mater 28:10204–10210

Zhang X, Tong J, Zhu H, Wang Z, Zhou L, Wang S, Miyashita T, Mitsuishi M, Qin G (2017) Room temperature magnetoresistance effects in ferroelectric poly(vinylidene fluoride) spin valves. J Mater Chem C 5:5055–5062

Zhu H, Yamamoto S, Matsui J, Miyashita T, Mitsuishi M (2015) Asymmetric ferroelectric switching based on an Al/PVDF Langmuir-Blodgett nanofilm/PEDOT:PSS/Al device. Mol Cryst Liq Cryst 618(1):89–94

Eerenstein W, Mathur N, Scott JF (2006) Multiferroic and magnetoelectric materials. Nature 442:759–765

Kleemann W, Binek C (2013) Multiferroic and magnetoelectric materials. In Magnetic Nanostructures; Springer: Berlin, Germany, pp 163–187

Martins P, Lanceros-Méndez S (2013) Polymer-based magnetoelectric materials. Adv Funct Mater 23:3371–3385

Dong X, Wang B, Wang K, Wan J, Liu JM (2009) Ultra-sensitive detection of magnetic field and its direction using bilayer PVDF/Metglas laminate. Sens Actuators A Phys 153:64–68

Qi Y, Jafferis NT, Lyons K, Jr., Lee, C.M., Ahmad, H., McAlpine, M.C. (2010) Piezoelectric ribbons printed onto rubber for flexible energy conversion. Nano Lett 10:524–528

Gutiérrez J, Lasheras A, Barandiarán JM, Vilas JL, Sebastián MS, León LM (2012) Temperature response of magnetostrictive/piezoelectric polymer magnetoelectric laminates. MRS Online Proc. Libr. Arch., 1398

Fiebig M (2005) Revival of the magnetoelectric effect. J Phys D Appl Phys 38:R123

Nan C, Bichurin M, Dong S, Viehland D, Srinivasan G (2008) Multiferroic magnetoelectric composites: historical perspective, status, and future directions. J Appl Phys 103:031101

Chu Y-H, Martin LW, Holcomb MB, Gajek M, Han S-J, He Q, Balke N, Yang C-H, Lee D, Hu W (2008) Electric-field control of local ferromagnetism using a magnetoelectric multiferroic. Nat Mater 7:478–482

Scott J, Morrison F, Miyake M, Zubko P (2006) Nano-ferroelectric materials and devices. Ferroelectrics 336:237–245

Zhai J, Dong S, Xing Z, Li J, Viehland D (2006) Giant magnetoelectric effect in Metglas/polyvinylidene-fluoride laminates. Appl Phys Lett 89:083507

Yang F, Wen Y, Li P, Zheng M (2006) Magnetoelectric response of magnetostrictive/piezoelectric/magnetostrictive laminate composite. In Proceedings of the 2006 IEEE International Conference on Information Acquisition, Weihai, China, 20–23 August 2006; pp 1010–1014

Lasheras A, Gutiérrez J, Reis S, Sousa D, Silva M, Martins P, Lanceros-Mendez S, Barandiarán J, Shishkin D, Potapov A (2015) Energy harvesting device based on a metallic glass/PVDF magnetoelectric laminated composite. Smart Mater Struct 24:065024

Fang Z, Lu S, Li F, Datta S, Zhang Q, El Tahchi M (2009) Enhancing the magnetoelectric response of Metglas/polyvinylidene fluoride laminates by exploiting the flux concentration effect. Appl Phys Lett 95:112903

Fetisov L, Baraban I, Fetisov YK, Burdin D, Vopson M (2017) Nonlinear magnetoelectric effects in flexible composite ferromagnetic—piezopolymer structures. J Magn Magn Mater 441:628–634

Wang Y, Gray D, Berry D, Gao J, Li M, Li J, Viehland D (2011) An extremely low equivalent magnetic noise magnetoelectric sensor. Adv Mater 23(35):4111–4114

Lu S, Jin J, Zhou X, Fang Z, Wang Q, Zhang Q (2011) Large magnetoelectric coupling coefficient in poly(vinylidene fluoride-hexafluoropropylene)/Metglas laminates. J Appl Phys 110:104103

Lee M, Chen CY, Wang S, Cha SN, Park YJ, Kim JM, Chou LJ, Wang ZL (2012) A hybrid piezoelectric structure for wearable nanogenerators. Adv Mater 24:1759–1764

Kim HS, Kim JH, Kim J (2011) A review of piezoelectric energy harvesting based on vibration. Int J Precis Eng Manuf 12:1129–1141

Vatansever D, Hadimani R, Shah T, Siores E (2011) An investigation of energy harvesting from renewable sources with PVDF andPZT. Smart Mater Struct 20:055019

Gusarov B, Gusarova E, Viala B, Gimeno L, Boisseau S, Cugat O, Vandelle E, Louison B (2016) Thermal energy harvesting by piezoelectric PVDF polymer coupled with shape memory alloy. Sens Actuators A Phys 243:175–181

Tamang A, Ghosh SK, Garain S, Alam MM, Haeberle J, Henkel K, Schmeisser D, Mandal D (2015) DNA-assisted β phase nucleation and alignment of molecular dipoles in PVDF film: a realization of self-poled bioinspired flexible polymer nanogenerator for portable electronic devices. ACS Appl Mater Interfaces 7:16143–16147

Farinholt KM, Pedrazas NA, Schluneker DM, Burt DW, Farrar CR (2009) An energy harvesting comparison of piezoelectric and ionically conductive polymers. J Intell Mater Syst Struct 20:633–642

Sun C, Shi J, Bayerl DJ, Wang X (2011) PVDF microbelts for harvesting energy from respiration. Energy Environ Sci 4:4508–4512

Li S, Crovetto A, Peng Z, Zhang A, Hansen O, Wang M, Li X, Wang F (2016) Bi-resonant structure with piezoelectric PVDF films for energy harvesting from random vibration sources at low frequency. Sens Actuators A Phys 247:547–554

Pi Z, Zhang J, Wen C, Zhang Z-B, Wu D (2014) Flexible piezoelectric nanogenerator made of poly(vinylidenefluoride-co-trifluoroethylene) (PVDF-TrFE) thin film. Nano Energy 7:33–41

Lallart M, Cottinet P-J, Lebrun L, Guiffard B, Guyomar D (2010) Evaluation of energy harvesting performance of electrostrictive polymer and carbon-filled terpolymer composites. J Appl Phys 108:034901

Wankhade SH, Tiwari S, Gaur A, Maiti P (2020) PVDF–PZT nanohybrid based nanogenerator for energy harvesting applications. Energy Rep 6:358–364

Li Z, Elhassan A, Abdalla I, Zhu M, Yu J, Ding B (2019) Wearable triboelectric nanogenerators constructed from electrospun nanofibers. Energy Harvesting Properties of Electrospun Nanofibers. Published December 2019: 8–1 to 8–25

Telega JJ, Wojnar R (2002) Piezoelectric effects in biological tissues. J Theor Appl Mech 40:723–759

Chang H, Wang Y (2011) Regenerative medicine and tissue engineering—cells and biomaterials; InTech: Rijeka, Croatia; pp 569–588

Marques L, Holgado LA, Simões RD, Pereira JD, Floriano JF, Mota LS, Graeff CF, Constantino CJ, Rodriguez-Perez M, Matsumoto M (2013) Subcutaneous tissue reaction and cytotoxicity of polyvinylidenefluoride and polyvinylidene fluoride-trifluoroethylene blends associated with natural polymers. J Biomed Mater Res Part B Appl Biomater 101:1284–1293

Ribeiro C, Sencadas V, Correia DM, Lanceros-Méndez S (2015) Piezoelectric polymers as biomaterials for tissue engineering applications. Colloids Surf B Biointerfaces 136:46–55

Ma Z, Kotaki M, Inai R, Ramakrishna S (2005) Potential of nanofiber matrix as tissue-engineering scaffolds. Tissue Eng 11:101–109

Young TH, Lu JN, Lin DJ, Chang CL, Chang HH, Cheng LP (2008) Immobilization of L-lysine on dense and porous poly(vinylidene fluoride) surfaces for neuron culture. Desalination 234:134–143

Wang F, Tanaka M, Chonan S (2002) A PVDF piezopolymer sensor for unconstrained cardiorespiratory monitoring during sleep. Int J Appl Electromagn Mech 16:181–188

Bohlén M, Bolton K (2014) Conformational studies of poly(vinylidene fluoride), poly(trifluoroethylene) and poly(vinylidene fluoride-co-trifluoroethylene) using density functional theory. Phys Chem Chem Phys 16:12929–12939

Ortiz E, Cuan A, Badillo C, Cortés-Romero C, Wang Q, Norena L (2010) DFT study of ferroelectric properties of the copolymers: Poly(vinylideneflouride-trifluoroethylene) and poly(vinylidenefluoride-chlorotrifluoroethylene). Int J Quantum Chem 110:2411–2417

Wang ZY, Fan HQ, Su KH, Wen ZY (2006) Structure and piezoelectric properties of poly(vinylidene fluoride) studied by density functional theory. Polymer 47:7988–7996

Ramos MM, Correia HM, Lanceros-Mendez S (2005) Atomistic modelling of processes involved in poling of PVDF. Comput Mater Sci 33:230–236

Holman RW, Kavarnos GJ (1996) A molecular dynamics investigation of the structural characteristics of amorphous and annealed poly(vinylidene fluoride) and vinylidene fluoride-trifluoroethylene copolymers. Polymer 37:1697–1701

Bohlén M, Bolton K (2013) Molecular dynamics studies of the influence of single wall carbon nanotubes on the mechanical properties of Poly(vinylidene fluoride). Comput Mater Sci 68:73–80

Satyanarayana KC, Bohlén M, Lund A, Rychwalski RW, Bolton K (2012) Analysis of the torsion angle distribution of poly(vinylidene fluoride) in the melt. Polymer 53:1109–1114

López-Encarnación JM, Burton J, Tsymbal EY, Velev JP (2010) Organic multiferroic tunnel junctions with ferroelectric poly(vinylidene fluoride) barriers. Nano Lett 11:599–603

Velev JP, López-Encarnación JM, Burton JD, Tsymbal EY (2012) Multiferroic tunnel junctions with poly(vinylidene fluoride). Phys Rev B 85:125103

Liu Y, Genzer J, Dickey MD (2016) “2D or not 2D”: Shape-programming polymer sheets. Prog Polym Sci 52:79–106

Ionov L (2013) Biomimetic hydrogel-based actuating systems. Adv Funct Mater 23:4555–4570

Zhao Q, Dunlop JW, Qiu X, Huang F, Zhang Z, Heyda J, Dzubiella J, Antonietti M, Yuan J (2014) An instant multi-responsive porous polymer actuator driven by solvent molecule sorption. Nat Commun 5:4293

Arazoe H, Miyajima D, Akaike K, Araoka F, Sato E, Hikima T, Kawamoto M, Aida T (2016) An autonomous actuator driven by fluctuations in ambient humidity. Nat Mater 15:1084–1089

Deng H, Dong Y, Zhang C, Xie Y, Zhang C, Lin J (2018) An instant responsive polymer driven by anisotropy of crystal phases. Mater Horiz 5:99–107

Barbosa J, Correia DM, Gonçalves R, Ribeiro C, Botelho G, Martins P, Lanceros-Mendez S (2016) Magnetically controlled drug release system through magnetomechanical actuation. Adv Healthc Mater 5:3027–3034

Webber MJ, Langer R (2017) Drug delivery by supramolecular design. Chem Soc Rev 46:6600–6620

James HP, John R, Alex A, Anoop KR (2014) Smart polymers for the controlled delivery ofdrugs—a concise overview. Acta Pharm Sin B 4:120–127

He T, Wang J, Huang P, Zeng B, Li H, Cao Q, Zhang S, Luo Z, Deng DYB, Zhang H et al (2015) Electrospinning polyvinylidene fluoride fibrous membranes containing anti-bacterial drugs used as wound dressing. Colloids Surf B Biointerfaces 130:278–286

Abednejad A, Ghaee A, Morais ES, Sharma M, Neves BM, Freire MG, Nourmohammadi J, Mehrizi AA (2019) Polyvinylidene fluoride–Hyaluronic acid wound dressing comprised of ionic liquids for controlled drug delivery and dual therapeutic behavior. Acta Biomater 100:142–157. ISSN 1742–7061, https://doi.org/10.1016/j.actbio.2019.10.007

Xi Y et al (2020) Optimization, characterization and evaluation of ZnO/polyvinylidene fluoride nanocomposites for orthopedic applications: improved antibacterial ability and promoted osteoblast growth. Drug Delivery 27(1):1378–1385. https://doi.org/10.1080/10717544.2020.1827084

Alvarez-Lorenzo C, Concheiro A (2019) Smart drug release from medical devices. J Pharmacol Exp Ther 370(3):544–554. https://doi.org/10.1124/jpet.119.257220

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saxena, P., Shukla, P. A comprehensive review on fundamental properties and applications of poly(vinylidene fluoride) (PVDF). Adv Compos Hybrid Mater 4, 8–26 (2021). https://doi.org/10.1007/s42114-021-00217-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00217-0