Abstract

There are historic subsurface dimension stones in the capital of Hungary (Budapest) that were excavated in porous limestone. The stability of these subsurface openings is important, since most of them are located in urban areas, where existing buildings or new structures are planned to be built. The paper presents a detailed study considering the geometry of the system and the mechanical parameters of the limestone. The geometry of the cellar system was obtained using terrestrial laser scanning (TLS). The cover beds are few meters in thickness, and the width of the pillar is between 2.50 and 3.98 m, according to the measurements. The rock mass parameters which were used in the calculations were obtained from laboratory tests. A finite element (FEM) software Rocscience (RS2) were applied to model the stability of the galleries. Calculations were made for various geometries taking into account the thickness of cover beds and the width of pillars. Altogether 70 models were made. A surface load of 150 kN/m2 was also applied to model the buildings. New relationships between cover bed thickness, pillar width and displacements are outlined to compare these results to previous works. The strength reduction factor was also calculated for all geometries, indicating the changes in the stability of these underground quarries and pointing out the importance of cellar geometries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The stability of engineering structures is an important topic in engineering practice; in some urban areas, cavities are serious challenges affecting the engineering design and construction activities, whether they are natural or man-made. There are several cities around the world that have areas that are undercut by cellars and cavities, which are suffering from stability problems caused by these openings. Such kind of issues exists in different European countries, such as in French Jura (Smeray et al. 2000), in Spain (Fuentes et al. 2010), and in Emilia-Romagna Region (Italy) (Tinti et al. 2015). The problem of pillar design have been studied in literatures the studies focused on the design of the pillar in coal mines (Wagner 1980), and room and rib pillar in Granite mine (Peila et al. 2008). Several known cellars and cavities exist in Budapest, Hungary (Hajnal 2006; Görög et al. 2013). The origin date of the cellars in Hungarian cities are representing various ages from the Middle Age to the nineteenth century (Gálos et al. 1981). In most cases, these cellars are cut in soft rocks, such as porous limestone (Görög et al. 2013) and tuffs (Vincze and Görög 2016; Mocsár-Vámos et al. 2015).

The usage of the cellars changed through the time; most of them related to previous mining activities, the host rocks of them were proper dimension stone. There are some which were built for wine cellars, or because of defence. Nowadays, some of them are using as wine storage (Fuentes et al. 2010), mushroom production, hosting events, as water sewer system (Marasović et al. 2014), and some of them are neglected. The areas which are affected by cellars located in a residential area; therefore, the cavities present hazards. If they are not in use, their state is not monitored regularly, they cause several problems such us surface settlements or collapse. Therefore, one of the serious geotechnical issues of these areas is to determine the stability of cellars and cavities; investigation the rock masses; displacement measurements and calculations; regular monitoring of them to monitor the effect of these cavities on the structure above and under the ground.

Subsurface quarries are common worldwide, and nowadays, the areas above these subsurface quarries are developing continually; those reasons led to study these subsurface quarries and evaluate their stability conditions of it. Subsurface quarries can be found in almost all countries, with some examples from, India (Vandana et al. 2020), China (He et al. 2016) and in Italy (Bartolo and Salvini 2019), and it used as construction material such as the Marble quarry which used to build the Milan Cathedral (Oggeri and Oreste 2015), limestone quarry in Germany (Siegesmund et al. 2010). Tunnels cut in limestone also have similar openings and their stability depend on several factors, such as the physical properties or accidental fire (Martínez Ibáñez et al. 2021).

These types of dimension stone quarries are known from many parts of the globe and have been described from Italy (Negri et al. 2015) (Bartolo and Salvini 2019), France (Al Heib et al. 2015), as well as in Hungary.

The stability of these openings are always in question, especially when they are used as tourist attractions (Rybár et al. 2017). Construction activity above these abandoned quarries and galleries causes the additional load, which lead to further stability problems to these openings (Zenah et al. 2019; Zenah and Görög 2021). Therefore, a detailed geotechnical investigation is necessary in such cases. It should start with the geometry measurements, which can be done with conventional geodetic tools. Since the geometry of these cellars is usually not regular, only a detailed measurement is appropriate to get the real geometry. The terrestrial laser scanning (TLS) method is able to measure the real geometry with imperfections (Zhao et al. 2019), reduced the time required for the field measurement (Kordić et al. 2019), monitoring the changes on coastal cliff faces (Rosser et al. 2005), or slopes in civil engineering works (Miščević et al. 2020), and can be the base of the numerical model of the cellar.

The second step of the stability analysis is to measure and evaluate the properties of the rock masses around the cavity. It can be done with conventional rock mechanical methods: core drillings, samplings, measurements of discontinuities and rock mass classification. The rock mass of this kind of cavities can be easily described, since the cellars are accessible, and there is no lining system, so the rocks are visible.

There are several software codes dealing with geotechnical analysis, such as MATLAB (Mollon et al. 2010; Janič et al. 2019), Rocscience (RS2 Bukaçi et al. 2016; Zenah et al. 2019), Examine (Andersson et al. 2004)), FLAC3D (Emad 2017), Abaqus (Sharma et al. 2018). The stability of this kind of cavities depends on several factors, such as material and rock mass properties, changes in the stress and geometrical characteristics (Cała et al. 2016). The effect of geometrical factors such as pillar width and cover thickness to the stability of cellars are investigated in this paper. The effect of the cover thickness was investigated by researchers using tunnels that are located at different depths (shallow to deep) (Sharma et al. 2020). The stability of the pillars controls the cellar/tunnel stability.

The aim of this paper is to evaluate the stability of cellar system under surface load, to protect valuable areas and new construction ones.

Numerical modelling gives the possibility to build different models and investigate the stability of cellars with different geometry and compare the results. The results may help to have clear scenarios about displacement, failure and safety of such cavities which lead to more understanding the structural behaviour of the cellars and safer design for the structures above.

Geological overview and historical quarries of porous limestone in Budapest

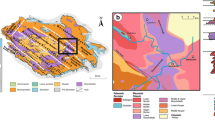

Budapest is located in the central part of Hungary (Fig. 1). The topography of capital city is divided into two parts by the river Danube. On the west side of the river are the Buda Mountains and on the east side is the Pest Plain. The morphology of the Buda Mountains is governed by faults and thrust belts, while the Pest Plain is filled with alluvial sediments (Bodnár et al. 2011). The stratigraphy of Budapest is very complex, with the oldest exposed Triassic carbonates to the youngest fluvial sediments of the Holocene period (Fig. 2). Sedimentary rocks prevail in the area of Budapest. From sedimentary rocks, various limestone types are the ones that are used mostly in moments. Besides the Triassic Dachstein limestone, Eocene Nummulitic limestone, Miocene porous limestone and Pleistocene travertine form the available stone resources. The present study focuses on the Miocene porous limestone. The study area is located in the southern part of Budapest (Buda side) and is covered by Miocene limestone (Fig. 1),. This limestone is underlain by clayey silty sediments and overlain by silty clay and evaporitic beds that are not exposed to the surface (Fig. 2). The Miocene carbonates (limestone) are the most common dimension stones of the entire sequence and the youngest dimension stones besides travertine. The exploitation of this limestone was first from surface quarries, then due to wine cultivation, subsurface galleries were cut, and limestone was extracted from those. This quarrying activity led to the excavation of thousands of square meters of underground cellars and left quarry yards, too (Fig. 3). The total length of these cellars is more than 100 km. The cellars have different cover depths depending on the quality of porous limestone, since stone extraction followed the best quality limestone banks. As a consequence, the depth of galleries, the width of pillars are also variable. Part of the studied cellar system are presented in Fig. 4., showing the modelled cross section. The hatched areas represent the pillars.

Materials and methods

The research plan and the applied methodology is summarized in Fig. 5. The history of quarrying and geological setting is given in the previous section (Section “Geological overview and historical quarries of porous limestone in Budapest”), while all other methods are described here.

The study area is covered of Miocene limestone, porous limestone which has different quality of layers. The most common type, which was the target of quarrying activity, is an ooidal limestone. The main components are carbonate grains that are ooids and micro-oncoids. The well to moderately rounded ooids and micro-oncoids are of 0.2–1.0 mm in diameter. The calcite is the main cement that forms circumgranular cement rims around the grains. Bioclasts such as gastropods, bivalves and foraminifers also form part of the rock. The stone is highly porous and the porosity is mainly related to intergranular pores (Fig. 6). Further description of this The pore-size distribution was previously studied in detail (Török and Szemerey-Kiss 2019). The micro-facies of the rock is ooid–micro-oncoid grainstone to packstone.

This material was one of Budapest's most widespread construction materials in the past centuries (Török 2003). Emblematic buildings, such as the Parliament building, Citadella and Mathias Church in Budapest was constructed from this stone (Török et al. 2007). Similar Miocene porous limestone was used in other countries, such as Austria (Bednarik et al. 2014), Czech Republic (Valtice) (Přikryl and Přikrylová 2004; Török et al. 2004), Belgium (De Kock et al. 2017), France (Beck and Al-Mukhtar 2008), Italy (Pappalardo et al. 2016), Cyprus (Modestou et al. 2016), Malta (Cassar 2002; Rothert et al. 2007; Grøntoft and Cassar 2020), Cologne Cathedral in Germany (Graue et al. 2011). The historic bridge of Mostar, Bosnia and Herzegovina was also made of limestone (Čorko et al. 2001). Extensive research on other limestones and evaluations of their properties were made in the past years in Turkey (Ozguven and Ozcelik 2013), in Slovakia (Laho et al. 2010), and in Sri Lanka (Jayawardena 2017). Despite this, there are several types of this rock with very different mechanical properties, so its investigation is essential in every case.

The geometries of the cellar were determined using Terrestrial Laser Scanner (TLS), which is a useful and effective method for measuring the real geometry of the cellars (Herrero et al. 2015), geometry of the buildings (Herrero et al. 2015) and the geometry of slopes (Török et al. 2016; Kordić et al. 2019). We used a phase-based terrestrial laser scanner (Faro Focus 120S) (Fig. 7) with ± 2 mm ranging accuracy and 120 m maximum measurement range.

Our TLS measurements signify that the cellar consists of a main corridor with seven side corridors to the right side and six air ventilation shafts (Fig. 8). The studied investigated cellar has almost no support system; there are only some separated brick and limestone masonry arches to avoid falling blocks. The result of TLS scan geometry was imported to 2D model that includes the hots rock and cover bed. The layered structure of the Miocene limestone was mapped through the ventilation shafts. The area is covered with topsoil with a thickness of around 0.1 m. It is underlain by a weathered porous limestone which has a thickness of 1.5 m. The cellars were cut in the high quality limestone layer (Fig. 9). The thickness of coverbed and the presence of covering weathered limestone was also proved historical archive by core drilling data.

The studied cross section is located far from the axis of the main corridor by 21 m and parallel to it. The width of the pillars between (2.50—3.98) m, the depth is around 6 m as the surface above the cellar is almost flat according to the studied cross section. The area above the cellar system is large. It is a new construction area, with some buildings. The load of the planned buildings according to the static design is 150 kN/m2.

Specimens were obtained from the cellar and tested under laboratory conditions. Several rock physical tests were done according to national standards, such as American Society for Testing and Materials (ASTM) and European Standards (EN): the dry density was calculated according to EN 1936:2006. The uniaxial compressive strength (UCS) test and Brazilian tests for dry conditions were performed according to ASTM D7012-14e1 with correcting the UCS value for (L/D = 2, D = 50 mm) (Gálos and Vásárhelyi 2006). The ultrasonic wave propagation velocity test made following the guidelines given by EN 14,579:2004. Altogether 32 specimens were tested in the laboratory as in Table 1. The sampling locations are marked by red circle in Fig. 8.

Rocscience (RS2) program was used for the calculations, one of the roc-science software packages; it is a 2D finite element program for soil and rock applications. RS2 can be used for: excavation design, slope stability, groundwater seepage, probabilistic analysis, consolidation, and dynamic analysis capabilities (Zenah et al. 2019; Bukaçi et al. 2016). Those calculations were done in different cases. First, in the current state of the cellar and second with a variable cover of the cellar and with variable width of the pillar. The dimensions of the cover and pillar width of the existing cellar network (Fig. 10). The current cover is 5.5 m, and it is reduced by 0.5 m till 2.5 m in every calculation step; the width of the pillars was also reduced from the original 2.5 m with 0.5 m increments down to 0.5 m. These calculations were made for one surface load of 150 kN/m2 in dry condition only. To conclude, 70 different models were generated with 7 different cover thicknesses, and for each of five different widths of the pillar were modelled under two different loads. Every model was run twice, once for calculating the strength reduction factor (SRF), and the second time to calculate the maximum displacements.

In this case, long-term stability is established when the safety factor is higher than 1.35. However, during the evaluation of the results, the cellar was considered stable if the stress reduction factor (SRF) was bigger than 1.00, if it is smaller than this value, the collapse of the cellar will happen.

Results and discussion

According to the on-site measurements, there was only one main joint direction with dip direction = 90° and dip angle = 74°, and the joint spacing is about 20 m, according to that the GSI = 80.

Results of lab tests

The results of laboratory tests are presented in Table 2,

The input parameters for the stability calculations in the models, were the parameters of the specimen which has the lowest UCS value as following:

The generalised Hoek–Brown failure criterion was used (Hoek et al. 2002) for the material model, the parameters for Hoek–Brown were partly obtained from laboratory tests (UCS) and from site survey (GSI):

The following Hoek–Brown’s parameters are calculated by modelling program (RS2):

The UCS reduced by 20% for the weathered limestone, because the rock at this depth is weathered and fractured, similarly to former studies of this area (Zenah et al. 2019) (Fig. 9).

Results of modelling

After running all the 70 models the results of strength reduction factor (SRF) and the displacements of the roof of one branch of the cellar are given in Tables 3 and 4, respectively.

Beside Tables 3 and 4, Fig. 11 shows the results of roof displacements for load 150 kN/m2. Under load 150 kN/m2 pillar's width under 1.0 m is not acceptable in term of displacements and SRF, while for pillar's width 1.0 m the border between safe and collapse area is not clear and it’s not preferable to have this width.

We considered the SRF > 1 is acceptable, so the previous discussion accepted the SRF equals one or more, and rejected SRF which is less than one.

For deeper understanding of changing the displacements (maximum and roof) in the models both displacements maximum and roof (the point where the roof displacements were measured is shown in Fig. 12, the graphs of the displacements for pillar width 2.5 m and 1.5 m drawn in Fig. 13; from Fig. 12, it’s clear that the maximum displacements happened in the weathered limestone layer, this idea could be more clear in Fig. 13 with the graphs, the maximum displacements are much more higher in values than the roof displacements till the weathered limestone layer is removed by decreasing the cover of the cellar.

For each pillar's width the SRF is increasing with the increasing of the cellar's cover; the displacement is increasing with shallowing the depth.

Other results match with these ones such as the results of Vu et al. (2015), where the effect of building deep foundation’s load on the settlement of the ground surface above a tunnel, the results showed that in granular and cohesive soils the maximum settlements increase with the decreasing the cover thickness in different rates according to the soil types.

The graphs after (Vu et al. 2015) study and this paper’s graphs (with pillar width 2.5 m) can be found in Fig. 14.

Displacement as a function of cover thickness: a previous works (Vu et al. 2015) and this study; b enlarged graph showing the results of this study

The two graphs have the same shape if we consider the increase in displacements because of the weak upper layer. The graphs in Vu et al. (2015) work are calculated from equations. In that work (Vu et al. 2015), the horizontal represent the cover value, while the vertical axes represent the maximum settlements of the ground surface.

The effect of shallow depth and deep depth studied by Gao (2012) the results were similar to our results, the shallow depth studied done for depth 0.6 m (model 1) and 5.0 m (model 2) and from the graph of the roof displacements it easy to obtain that the displacements are increasing from around 0.01 to 0.12 m when the depth decreased from 5.0 m to 0.6 m.

The effect of pillar width studied for coal pillar under road load by Le Quang et al. (2020) done for 8 widths between 4 and 20 m, it showed that the vertical displacements are increasing with reducing the width of the pillar as the same results that we got from this paper.

The thickness of the cover is very important, and it has a major effect on the stability of the cavities; the difference between the stability of shallow cavity and deep cavities was studied by Gao (2012), the study recommended to find the optimal depth of the cavities. According to our study the optimal depth (the minimum cover remains after drilling the ground) of cellar is 4 m if we have pillar width 1.5 m (Fig. 11).

The width of the pillar affects the stability of the pillar and then for sure the stability of the cellar. Le Quang et al. (2020) studied the role of the pillar width on the stability and displacements of the cellars under road load. Rahaman and Kumar (2020) studied singular and twin horse-shoe tunnels in the rock mass, and this study described the differences in stability of the tunnels under loading (load factor) with changing cover/width ratio the (H/B) of the tunnel in between 1 and 6. They used a generalized Hoek–Brown (GHB) failure criterion, and the computer modelling code to perform the finite element limit analysis was written in MATLAB. They have found that increasing cover/width ratio increased the stability (magnitude of load factor) of the twin tunnel. If one has a given width of the cellar, the cover thickness influences the stability of the cellar and the SRF is not proportional with the thickness of the cover, Table 3.

In this study, we focused on the differences in pillar width and its effect on deformations under a given load. These results suggest that maximum displacement was reached when the cover was thin; but increasing cover thickness did not cause a gradual decrease in displacement, but from a cover of 4–4.5 m, the displacements were increasing with increasing cover thickness. Compared to elliptical shape single natural cavities (Benito Olmeda et al. 2020), it was found that strength and condition of rock mass, thickness of the cover, width and value of the load were found to be the most affected parameter on the bearing capacity of the foundation. In summary, similarly to our study the bearing capacity of the foundation under fixed foundation load is increasing with the increase of the cover of the cavity in the studied range.

Similarly to the study of Benito Olmeda et al. (2020) in which a natural cavity with significant dimensions were studied using FLAC3D computer code to calculate the bearing capacity of a foundation the pillar width and the thickness of the cover are the main control factor of the stability according to our results (Tables 3 and 4). However, they have also emphasized that the thickness of the cover, the eccentricity of the load, the rock type (mi) and strength and condition of rock mass are also important parameters on the bearing capacity of the foundation.

In dual squared tunnels in a rock mass with surface load (Xiao et al. 2019) the displacements were modelled by Plaxis 2D. They demonstrated that for shallow depth, the stability number increases with increasing the space between the tunnels to diameter (L/B) value till it reaches the upper limit. The same results were obtained from the graphs, while the ratio (H/B) increased. Yamamoto et al. (2011) studied single shallow circular tunnel in soil with surface load; the study covered changes in cover to diameter ratio (H/D) and soil properties to find the stability number of the tunnel. Their results showed that for good soil properties (such as ϕ = 30°) the stability number increased with increasing the (H/D) ratio, in another words: if we fix the dimension of the diameter (D) so the increasing of H increase the stability number, as the result of our study, Table 3.

The collapse of subsurface galleries can also be attributed to natural processes and not necessarily by human activity linked an increase in surface load. Several examples are known, where limestone quarries are collapsed due to pillar instability, such as a mine in Pennsylvania (Esterhuizen et al. 2018). Newly formed sinkholes can also lead to the collapse of abandoned shallow underground limestone quarries, such as the ones in Belgium (Van Den Eeckhaut et al. 2007).

Conclusions

Porous limestone was intensively quarried for dimension stone from the nineteenth century in the Budapest region. Similarly to France, Italy and other countries of the Mediterranean region, it is one of the major construction materials of the monuments of the city.

The limestone was quarried in subsurface areas forming an extended network of cellar side corridors. These subsurface galleries pose a high risk due to the thin cover, and building load often collapse.

To estimate the risk of collapse, geometries of cellars were measured and used in computer modelling with various geometries, including cover thickness width of pillars.

Calculations with a 2D finite element program (RocScience2) software were performed using input parameters of the mechanical properties of porous limestone obtained from laboratory tests and cellar geometries measured by TLS.

As a result of 70 different scenario modelling, the safety factor increases, and the displacement decreases with the increasing cover of the cellars to a certain depth. However, the trend is not uniform, and it turns, namely, the cellars that are located deeper than 4 m show larger displacements and reduced factor of safety. It suggests that rock stresses due to rock load become more crucial at deeper cellar settings.

Based on these model results, it is possible to determine the critical depth and critical width of pillars under critical load for this type of porous limestone. It is necessary to emphasize that these results are valid for dry conditions, and water saturation reduces the strength of limestone almost to half; thus, inundation of cellars often lead to failure and roof collapse.

References

Al Heib M, Duval C, Theoleyre F et al (2015) Analysis of the historical collapse of an abandoned underground chalk mine in 1961 in Clamart (Paris, France). Bull Eng Geol Env 74:1001–1018. https://doi.org/10.1007/s10064-014-0677-6

Andersson C, Rinne M, Staub I, Wanne T (2004) The on-going pillar stability experiment at the äspö hard rock laboratory, Sweden. In: Elsevier geo-engineering book series. Elsevier, New York, pp 389–394

Bartolo SD, Salvini R (2019) Multitemporal terrestrial laser scanning for marble extraction assessment in an underground quarry of the Apuan Alps (Italy). Sensors 19:450. https://doi.org/10.3390/s19030450

Beck K, Al-Mukhtar M (2008) Formulation and characterization of an appropriate lime-based mortar for use with a porous limestone. Environ Geol 56:715–727. https://doi.org/10.1007/s00254-008-1299-8

Bednarik M, Moshammer B, Heinrich M et al (2014) Engineering geological properties of Leitha Limestone from historical quarries in Burgenland and Styria, Austria. Eng Geol 176:66–78. https://doi.org/10.1016/j.enggeo.2014.04.005

Benito Olmeda JL, Moreno Robles J, Sanz Pérez E, Olalla Marañón C (2020) Influence of natural cavities on the design of shallow foundations. Appl Sci 10:1119. https://doi.org/10.3390/app10031119

Bodnár N, Kovács J, Török Á (2011) Multivariate analysis of Miocene sediments: Rákóczi Square, new metro station area, Budapest, Hungary. Central Eur Geol 54:391–405. https://doi.org/10.1556/CEuGeol.54.2011.4.7

Bukaçi E, Korini Th, Periku E et al (2016) Reliability analysis for tunnel supports system by using finite element method. Am J Eng Res (AJER) 5:1–8

Cała M, Stopkowicz A, Kowalski M et al (2016) Stability analysis of underground mining openings with complex geometry. Studia Geotechnica Et Mechanica 38:25–32. https://doi.org/10.1515/sgem-2016-0003

Cassar J (2002) Deterioration of the globigerina limestone of the Maltese Islands. Geol Soc Lond Spec Publ 205:33–49. https://doi.org/10.1144/GSL.SP.2002.205.01.04

Čorko D, Lovrenčić D, Marić B, et al (2001) Remedial works on the foundation rock of the “Old Bridge” in Mostar. Havar, Croatia

de Jayawardena U, S, (2017) Laboratory studies of Miocene limestone in Sri Lanka. Q J Eng GeolHydrogeol 50:422–425. https://doi.org/10.1144/qjegh2016-106

De Kock T, Van Stappen J, Fronteau G et al (2017) Laminar gypsum crust on lede stone: Microspatial characterization and laboratory acid weathering. Talanta 162:193–202. https://doi.org/10.1016/j.talanta.2016.10.025

Emad MZ (2017) Numerical modelling approach for mine backfill. Sādhanā 42:1595–1604. https://doi.org/10.1007/s12046-017-0702-0

Esterhuizen GS, Tyrna PL, Murphy MM (2018) A case study of pillar collapse at a limestone mine in Pennsylvania. American Rock Mechanics Association, Washington, USA

Fuentes JM, Gallego E, García AI, Ayuga F (2010) New uses for old traditional farm buildings: The case of the underground wine cellars in Spain. Land Use Pol 27:738–748. https://doi.org/10.1016/j.landusepol.2009.10.002

Gálos M, Vásárhelyi B (2006) Kőzettestek Osztályozása az Építőmérnöki Gyakorlatban. Budapest, Hungary

Gálos M, Kertész P, Kürti I (1981) Engineering geological problems of cellars and caverns under historical centres of towns. In: Subsurface space. Elsevier, New York, pp 119–126

Gao BL (2012) Influence on the stability of the underground cavity by the buried depth. In: 2012 International Conference on Computer Science and Electronics Engineering. IEEE, Hangzhou, Zhejiang, China, pp 55–58

Görög P, Hangodi Á, Török Á (2013) Stability analyses of underground structures cut into porous limestone. Paris, pp 1707–1710

Graue B, Siegesmund S, Middendorf B (2011) Quality assessment of replacement stones for the Cologne Cathedral: mineralogical and petrophysical requirements. Environ Earth Sci 63:1799–1822. https://doi.org/10.1007/s12665-011-1077-x

Grøntoft T, Cassar J (2020) An assessment of the contribution of air pollution to the weathering of limestone heritage in Malta. Environ Earth Sci 79:288. https://doi.org/10.1007/s12665-020-09027-x

Hajnal G (2006) Hydrogeological study of the castle hill in Budapest. Szinergia Ház Közhasznú Egyesület, Hungary

He WT, Shang YJ, Sun YL et al (2016) Insight of the environmental awareness on waste rock disposal at Heidong Quarry dated 1000 years ago in SE China. Environ Earth Sci 75:163. https://doi.org/10.1007/s12665-015-4984-4

Herrero T, Pérez-Martín E, Conejo-Martín MA et al (2015) Assessment of underground wine cellars using geographic information technologies. Surv Rev 47:202–210. https://doi.org/10.1179/1752270614Y.0000000104

Hoek E, Carranza-Torres C, Corkum B (2002) Hoek-Brown failure criterion—2002 Edition. In: NARMS-TAC Conference. Toronto, pp 267–273

Janič P, Jadlovská S, Zápach J, Koska L (2019) Modeling of underground mining processes in the environment of MATLAB / Simulink. Acta Montanistica Slovaca 24:44–52

Kordić B, Lužar-Oberiter B, Pikelj K et al (2019) Integration of terrestrial laser scanning and UAS photogrammetry in geological studies: examples from Croatia. Periodica Polytechnica Civ Eng. https://doi.org/10.3311/PPci.14499

Laho M, Franzen C, Holzer R, Mirwald PW (2010) Pore and hygric properties of porous limestones: a case study from Bratislava, Slovakia. Geol Soc Lond Spec Publ 333:165–174. https://doi.org/10.1144/SP333.16

Marasović K, Perojević S, Margeta J (2014) Roman sewer of Dicletian’s palace in Split. GRAĐEVINAR. https://doi.org/10.14256/JCE.966.2013

Miščević P, Cvitanović NŠ, Vlastelica G (2020) Degradation processes in civil engineering slopes in soft rocks. In: Kanji M, He M, Ribeiro L (eds) Soft rock mechanics and engineering. Springer International Publishing, Cham, pp 335–371

Mocsár-Vámos M, Görög P, Török A (2015) Engineering geological characterization of the host rocks of underground cellars in Avas hill, Northern Hungary. In: Geotechnical Engineering for Infrastructure and Development. London

Modestou S, Theodoridou M, Fournari R, Ioannou I (2016) Physico-mechanical properties and durability performance of natural building and decorative carbonate stones from Cyprus. Geol Soc Lond Spec Publ 416:145–162. https://doi.org/10.1144/SP416.3

Mollon G, Dias D, Soubra A-H (2010) Face stability analysis of circular tunnels driven by a pressurized shield. J Geotech Geoenviron Eng 136:215–229. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000194

Negri S, Margiotta S, Quarta T et al (2015) Integrated analysis of geological and geophysical data for the detection of man-made underground caves in an area in southern Italy. JCKS 77:52–62. https://doi.org/10.4311/2014ES0107

Oggeri C, Oreste P (2015) Underground quarrying for marble: stability assessment through modelling and monitoring. Int J Mining Sci 1:35–42

Ozguven A, Ozcelik Y (2013) Investigation of some property changes of natural building stones exposed to fire and high heat. Constr Build Mater 38:813–821. https://doi.org/10.1016/j.conbuildmat.2012.09.072

Pappalardo G, Mineo S, Monaco C (2016) Geotechnical characterization of limestones employed for the reconstruction of a UNESCO world heritage Baroque monument in southeastern Sicily (Italy). Eng Geol 212:86–97. https://doi.org/10.1016/j.enggeo.2016.08.004

Peila D, Guardini C, Pelizza S (2008) Geomechanical design of a room and rib pillar granite mine. J Univ Sci Technol Beijing, Mineral, Metallurgy, Mater 15:97–103. https://doi.org/10.1016/S1005-8850(08)60020-1

Přikryl R, Přikrylová J (2004) Leithakalk limestones in the Lednice-Valtice area (southest Moravia, Czech Republic): their occurrences and properties. Prague, pp 149–156

Le Quang P, Zubov V, Duc TP (2020) Design a reasonable width of coal pillar using a numerical model. A case study of Khe Cham basin, Vietnam. E3S Web Conf 174:01043. https://doi.org/10.1051/e3sconf/202017401043

Rahaman O, Kumar J (2020) Stability analysis of twin horse-shoe shaped tunnels in rock mass. Tunn Undergr Space Technol 98:103354. https://doi.org/10.1016/j.tust.2020.103354

Rosser NJ, Petley DN, Lim M et al (2005) Terrestrial laser scanning for monitoring the process of hard rock coastal cliff erosion. Q J Eng GeolHydrogeol 38:363–375. https://doi.org/10.1144/1470-9236/05-008

Rothert E, Eggers T, Cassar JA et al (2007) Stone properties and weathering induced by salt crystallization of Maltese Globigerina Limestone. Geol Soc Lond Spec Publ 271:189–198. https://doi.org/10.1144/GSL.SP.2007.271.01.19

Rybár P, Hronček P, Domaracká L et al (2017) Underground quarries their possible use for mining tourism purposes—Slovak perspectives on the example of the underground stone quarry of Veľká Stráň. Acta Geoturistica 8:87–107. https://doi.org/10.1515/agta-2017-0009

Sharma P, Verma AK, Gautam P (2020) Stability analysis of underground pillar in the presence of overlying dump: a case study. Arab J Geosci 13:217. https://doi.org/10.1007/s12517-020-5133-2

Sharma H, Rao SK, Mishra S, Gupta NK (2018) Effect of cover depth on deformation in tunnel lining when subjected to impact load. Suntec City, Singapore

Siegesmund S, Grimm W-D, Dürrast H, Ruedrich J (2010) Limestones in Germany used as building stones: an overview. Geol Soc Lond Spec Publ 331:37–59. https://doi.org/10.1144/SP331.4

Smeray J, Mandin D, Chaumont J (2000) Annual variations of airborne fungal propagules in two wine cellars in French Jura. Cryptogam, Mycol 21:163–169. https://doi.org/10.1016/S0181-1584(00)80001-9

Tinti F, Barbaresi A, Benni S et al (2015) Experimental analysis of thermal interaction between wine cellar and underground. Energy Build 104:275–286. https://doi.org/10.1016/j.enbuild.2015.07.025

Török Á (2003) Surface strength and mineralogy of weathering crusts on limestone buildings in Budapest. Build Environ 38:1185–1192. https://doi.org/10.1016/S0360-1323(03)00072-6

Török Á, Szemerey-Kiss B (2019) Freeze-thaw durability of repair mortars and porous limestone: compatibility issues. Prog Earth Planet Sci 6:42. https://doi.org/10.1186/s40645-019-0282-1

Török Á, Siegesmund S, Müller C et al (2007) Differences in texture, physical properties and microbiology of weathering crust and host rock: a case study of the porous limestone of Budapest (Hungary). Geol Soc Lond Spec Publ 271:261–276. https://doi.org/10.1144/GSL.SP.2007.271.01.25

Török Á, Rozgonyi N, Prikryl R, Prikrylová J (2004) Leithakalk: the ornamental and building stone of Central Europe, an overview. Czech Republic, pp 89–93

Török Á, Bögöly Gy, Czinder B, et al (2016) Terrestrial laser scanner aided survey and stability analyses of rhyolite tuff cliff faces with potential rock-fall hazards, an example from Hungary. In: the ISRM International Symposium - EUROCK 2016. Ürgüp, Turkey, pp 877–881

Van Den Eeckhaut M, Poesen J, Dusar M et al (2007) Sinkhole formation above underground limestone quarries: a case study in South Limburg (Belgium). Geomorphology 91:19–37. https://doi.org/10.1016/j.geomorph.2007.01.016

Vandana M, John SE, Maya K, Padmalal D (2020) Environmental impact of quarrying of building stones and laterite blocks: a comparative study of two river basins in Southern Western Ghats. India Environ Earth Sci 79:366. https://doi.org/10.1007/s12665-020-09104-1

Vincze Á, Görög P (2016) Engineering geological investigation of a cave spa cut into rhyolite tuff. Romania, pp 119–122

Vu MN, Broere W, Bosch J (2015) Effects of cover depth on ground movements induced by shallow tunnelling. Tunn Undergr Space Technol 50:499–506. https://doi.org/10.1016/j.tust.2015.09.006

Wagner H (1980) Pillar design in coal mines. J S Afr Inst Mining Metallurgy 80:37–45

Xiao Y, Zhao M, Zhang R et al (2019) Stability of dual square tunnels in rock masses subjected to surcharge loading. Tunn Undergr Space Technol 92:103037. https://doi.org/10.1016/j.tust.2019.103037

Yamamoto K, Lyamin AV, Wilson DW et al (2011) Stability of a circular tunnel in cohesive-frictional soil subjected to surcharge loading. Comput Geotech 38:504–514. https://doi.org/10.1016/j.compgeo.2011.02.014

Zenah J, Török Á, Rehány N, Görög P (2019) Investigation of the effect of construction activities to underground cavities cut into porous limestone. Omiš—Split, Croatia, pp 453–458

Zenah J, Görög P (2021) Construction works above cavities, investigation of an undermined area. IOP Conf Ser Earth Environ Sci 833:012092. https://doi.org/10.1088/1755-1315/833/1/012092

Zhao X, Kermarrec G, Kargoll B et al (2019) Influence of the simplified stochastic model of TLS measurements on geometry-based deformation analysis. J Appl Geodesy 13:199–214. https://doi.org/10.1515/jag-2019-0002

Acknowledgements

The research reported in this paper is part of project no. BME-NVA-02, implemented with the support provided by the Ministry of Innovation and Technology of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021 funding scheme.

Funding

Open access funding provided by Budapest University of Technology and Economics. The research was partly funded by project no. BME-NVA-02 (Ministry of Innovation and Technology of Hungary from the National Research, Development and Innovation Fund), under the TKP2021 funding scheme.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a Topical Collection in Environmental Earth Sciences on “Building Stones and Geomaterials through History and Environments – from Quarry to Heritage. Insights of the Conditioning Factors”, guest edited by Siegfried Siegesmund, Luís Manuel Oliveira Sousa, and Rubén Alfonso López-Doncel.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zenah, J., Görög, P. & Török, Á. Historic subsurface dimension stone quarry and the stability of its galleries as a function of pillar width and thickness of cover bed. Environ Earth Sci 81, 414 (2022). https://doi.org/10.1007/s12665-022-10539-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-022-10539-x