Abstract

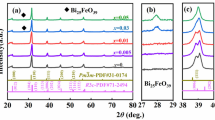

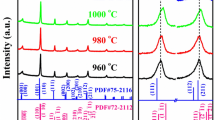

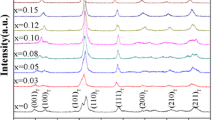

BiFeO3–BaTiO3 (BF–BT) lead-free piezoelectric ceramics have high piezoelectricity and high Curie temperature (TC), but the mixed-valence Fe ions and Bi3+ volatilization would promote the formation of Bi25FeO40/Bi2Fe4O9 and oxygen vacancy, which greatly degrade the insulation properties required for polarization. In this study, it was found that the modification of BiAlO3 (BA) in BF–BT ceramics could effectively solve these problems, reducing the leakage current to 1 × 10−9 A·cm−2 and transiting the space charge-limited conduction to ohmic conduction. Because of the enhanced insulation properties and appropriate rhombohedral-pseudocubic phase ratio (CR/CPC), BF–BT–xBA ceramics in an optimized composition obtain enhanced piezoelectric performance: piezoelectric charge coefficient (d33) = 196 pC·N−1, planar electromechanical coupling coefficient (kp) = 31.1%, TC = 487 °C and depolarization temperature (Td) = 250 °C; unipolar strain (Suni) = 0.17% and piezoelectric strain coefficient (d33*) = 335 pm·V−1 at 100 °C. Especially, d33 exceeds 283 pC·N−1 at 233 °C and d33* is 335 pm·V−1 at 100 °C, showing an excellent high-temperature piezoelectricity and high depolarization temperature. The results are attributed to the domain structure of rhombohedral-pseudocubic phase coexistence and its high-temperature switching behavior. This work provides a feasible and effective approach to improve the high temperature piezoelectric properties of BF–BT–xBA ceramics, making them more suitable for high temperature applications.

Graphical abstract

摘要

BiFeO3-BaTiO3 (BF-BT) 具有高压电性和高居里温度(TC), 但铁离子变价和Bi3+挥发会促进Bi25FeO40/Bi2Fe4O9和氧空位的形成, 严重降低了极化所需的绝缘性能。本研究发现BiAlO3掺杂改性可以有效地将BF- BT基陶瓷的漏电流降低至10−9 A·cm−2, 其漏电流传导机制由空间电荷限制传导转变为缺陷浓度低的欧姆传导。由于绝缘性能的提高和合适的R-PC两相比例, BF-BT-0.03BA陶瓷具有优异的压电性能:d33 = 196 pC·N−1, kp = 31.1%, TC = 487 °C 和 Td = 250 ℃; 在 100 ℃时, Suni = 0.17% 和 dd33 = 335 pm·V−1。由于R-PC共存相特征的畴结构及其高温翻转, 233 ℃时获得的d33 = 283 pC·N−1和在100 ℃时获得的d33* = 335 pm·V−1, 均表眀BF-BT-xBA陶瓷具有良好的高温压电性能和较高的去极化温度, 该正向温度相关性使得BF-BT-xBA陶瓷更适用于高温环境。

Similar content being viewed by others

References

Li JF. Lead-free piezoelectric materials. Wiley. 2021. https://doi.org/10.1002/9783527817047.

Cheng S, Zhang BP, Zhao L, Wang KK. Enhanced insulating and piezoelectric properties of 0.7BiFeO3–0.3BaTiO3 lead-free ceramics by optimizing calcination temperature: analysis of Bi3+ volatilization and phase structures. J Mater Chem C. 2018;6(15):3982. https://doi.org/10.1039/C8TC00329G.

Mangaiyarkkarasi J, Saravanan R. Charge distribution around Ba–O and Ti–O bonds in BaTi1−xZrxO3 through powder X-ray diffraction. Rare Met. 2021;40(12):3660. https://doi.org/10.1007/s12598-016-0812-6.

Lee MH, Kim DJ, Park JS, Kim SW, Song TK, Kim MH, Kim WJ, Do D, Jeong IK. High-performance lead-free piezoceramics with high Curie temperatures. Adv Mater. 2015;27(43):6976. https://doi.org/10.1002/adma.201502424.

Leontsev SO, Eitel RE. Dielectric and piezoelectric properties in Mn-modified (1−x)BiFeO3–xBaTiO3 ceramics. J Am Ceram Soc. 2009;92(12):2957. https://doi.org/10.1111/j.1551-2916.2009.03313.x.

Zhou C, Yang H, Zhou Q, Cen Z, Li W, Yuan C, Wang H. Dielectric, ferroelectric and piezoelectric properties of La-substituted BiFeO3–xBaTiO3 ceramics. Ceram Int. 2013;39(4):4307. https://doi.org/10.1016/j.ceramint.2012.11.012.

Zheng Q, Luo L, Lam KH, Jiang N, Guo Y, Lin D. Enhanced ferroelectricity, piezoelectricity, and ferromagnetism in Nd-modified BiFeO3–xBaTiO3 lead-free ceramics. J Appl Phys. 2014;116(18):184101. https://doi.org/10.1063/1.4901198.

Wan Y, Li Y, Li Q, Zhou W, Zheng Q, Wu X, Xu C, Zhu B. Microstructure, ferroelectric, piezoelectric, and ferromagnetic properties of Sc-modified BiFeO3–xBaTiO3 multiferroic ceramics with MnO2 addition. J Am Ceram Soc. 2014;97(6):1809. https://doi.org/10.1111/jace.12827.

Wang T, Jin L, Tian Y, Shu L, Hu Q, Wei X. Microstructure and ferroelectric properties of Nb2O5-modified BiFeO3–xBaTiO3 lead-free ceramics for energy storage. Mater Lett. 2014;137:79. https://doi.org/10.1016/j.matlet.2014.08.133.

Peng XY, Tang YC, Zhang BP, Zhu LF, Xun BW, Yu JR. High Curie temperature BiFeO3–xBaTiO3 lead-free piezoelectric ceramics: Ga3+ doping and enhanced insulation properties. J Appl Phys. 2021;130:144104. https://doi.org/10.1063/5.0060780.

Zhu LF, Zhang BP, Li S, Zhao L, Wang N, Shi XC. Enhanced piezoelectric properties of Bi(Mg1/2Ti1/2)O3 modified BiFeO3–BaTiO3 ceramics near the morphotropic phase boundary. J Alloys Compd. 2016;664:602. https://doi.org/10.1016/j.jallcom.2016.01.003.

Lin Y, Zhang L, Yu J. Piezoelectric and ferroelectric property in Mn-doped 0.69BiFeO3–0.04Bi(Zn1/2Ti1/2)O3–0.27BaTiO3 lead-free piezoceramics. J Mater Sci Mater Electron. 2016;27:1955. https://doi.org/10.1007/s10854-015-3978-z.

Hieno A, Sakamoto W, Moriya M, Yogo T. Synthesis of BiFeO3-Bi0.5Na0.5TiO3 thin films by chemical solution deposition and their properties. Jpn J Appl Phys. 2011;50(9S2):09NB04. https://doi.org/10.1143/JJAP.50.09NB04.

Kaczkowski J. Electronic structure, ferroelectric properties, and phase stability of BiGaO3 under high pressure from first principles. J Mater Sci. 2016;51:9761. https://doi.org/10.1007/s10853-016-0211-2.

Baettig P, Schelle CF, LeSar R, Waghmare UV, Spaldin NA. Theoretical prediction of new high-performance lead-free piezoelectrics. Chem Mater. 2005;17(6):1376. https://doi.org/10.1021/cm0480418.

Mazumdar D, Knut R, Thöle F, Gorgoi M, Faleev S, Mryasov ON, Shelke V, Ederer C, Spaldin NA, Gupta A, Karis O. The valence band electronic structure of rhombohedral-like and tetragonal-like BiFeO3 thin films from hard X-ray photoelectron spectroscopy and first-principles theory. J Electron Spectrosc Relat Phenom. 2016;208:63. https://doi.org/10.1016/j.elspec.2015.10.002.

Ullah A, Ahn CW, Hussain A, Lee SY, Kim IW. Phase transition, electrical properties, and temperature-insensitive large strain in BiAlO3-modified Bi0.5(Na0.75K0.25)0.5TiO3 lead-free piezoelectric ceramics. J Am Ceram Soc. 2011;94(11):3915. https://doi.org/10.1111/j.1551-2916.2011.04595.x.

Sun X, Deng J, Liu L, Liu S, Shi D, Fang L, Elouadi B. Dielectric properties of BiAlO3-modified (Na, K, Li)NbO3 lead-free ceramics. Mater Res Bull. 2016;73:437. https://doi.org/10.1016/j.materresbull.2015.10.005.

Cen Z, Zhou C, Yang H, Zhou Q, Li W, Yan C, Cao L, Song J, Peng L. Remarkably high-temperature stability of Bi(Fe1−xAlx)O3–BaTiO3 solid solution with near-zero temperature coefficient of piezoelectric properties. J Am Ceram Soc. 2013;96(7):2252. https://doi.org/10.1111/jace.12326.

Zheng T, Jiang Z, Wu J. Enhanced piezoelectricity in (1−x)Bi1.05Fe1−yAyO3–xBaTiO3 lead-free ceramics: site engineering and wide phase boundary region. Dalton Trans. 2016;45(28):11277. https://doi.org/10.1039/C6DT01805J.

Khan SA, Ahmed T, Habib M, Akram F, Bae J, Song TK, Lim DH, Jeong SJ, Kim MH, Lee S. Large electromechanical strain response in BiFeO3–BaTiO3-based ceramics at elevated temperature. J Phys Chem Solids. 2021;156:110133. https://doi.org/10.1016/j.jpcs.2021.110133.

Cheng S, Zhao L, Zhang BP, Wang KK. Lead-free 0.7BiFeO3–0.3BaTiO3 high-temperature piezoelectric ceramics: nano-BaTiO3 raw powder leading to a distinct reaction path and enhanced electrical properties. Ceram Int. 2019;45(8):10438. https://doi.org/10.1016/j.ceramint.2019.02.104.

Guan S, Yang H, Qiao G, Sun Y, Qin F, Hou H. Effects of Li2CO3 and CuO as composite sintering aids on the structure, piezoelectric properties, and temperature stability of BiFeO3–BaTiO3 ceramics. J Electron Mater. 2020;49:6199. https://doi.org/10.1007/s11664-020-08365-7.

Li Y, Zheng T, Wu J. Multiple property enhancement in bismuth ferrite-based ferroelectrics by balancing nanodomain and relaxor state. J Am Ceram Soc. 2022;105(2):1241. https://doi.org/10.1111/jace.18180.

Maître A, François M, Gachon JC. Experimental study of the Bi2O3–Fe2O3 pseudo-binary system. J Phase Equilib Diffus. 2004;25(1):59. https://doi.org/10.1361/10549710417687.

Tang YC, Yin Y, Song AZ, Liu H, Zhang R, Zhong SJ, Li HZ, Zhang BP. Boosting the high performance of BiFeO3–BaTiO3 lead-free piezoelectric ceramics: one-step preparation and reaction mechanisms. ACS Appl Mater Interfaces. 2022;14(27):30991. https://doi.org/10.1021/acsami.2c06164.

Yao Z, Xu C, Liu H, Hao H, Cao M, Wang Z, Song Z, Hu W, Ullah A. Greatly reduced leakage current and defect mechanism in atmosphere sintered BiFeO3–BaTiO3 high temperature piezoceramics. J Mater Sci Mater Electron. 2014;25:4975. https://doi.org/10.1007/s10854-014-2260-0.

Qin Y, Yang J, Xiong P, Huang W, Song J, Yin L, Tong P, Zhu X, Sun Y. The effects of quenching on electrical properties, and leakage behaviors of 0.67BiFeO3–0.33BaTiO3 solid solutions. J Mater Sci Mater Electron. 2018;29:7311. https://doi.org/10.1007/s10854-018-8720-1.

Huang S, Li Q, Yang L, Xu J, Zhou C, Chen G, Yuan C, Rao G. Enhanced piezoelectric properties by reducing leakage current in Co modified 0.7BiFeO3–0.3BaTiO3 ceramics. Ceram Int. 2018;44(8):8955. https://doi.org/10.1016/j.ceramint.2018.02.095.

Shu M, Wang D, Li S, Yang B, Yin L, Song W, Yang J, Zhu X, Sun Y. Improved ferroelectric, piezoelectric, and magnetic properties in BiFeO3–(Ba0.85Ca0.15)TiO3 ceramics through Mn addition. J Appl Phys. 2020;128(16):164101. https://doi.org/10.1063/5.0026210.

Pan Y, Bai X, Feng J, Huang L, Li G, Chen Y. Influences of holmium substitution on the phase structure and piezoelectric properties of BiFeO3–BaTiO3-based ceramics. J Alloys Compd. 2022;918:165582. https://doi.org/10.1016/j.jallcom.2022.165582.

Chen JY, Zhang BP, Zhu LF, Cheng S, Tang YC. Enhanced insulation resistance and electrical properties of BiFe1−x(Zn0.5Ti0.5)xO3–BaTiO3 lead-free piezoceramics. Ceram Int. 2018;44(7):8409. https://doi.org/10.1016/j.ceramint.2018.02.034.

Xun BW, Tang YC, Chen JY, Zhang BP. Enhanced resistance in Bi(Fe1−xScx)O3–0.3BaTiO3 lead-free piezoelectric ceramics: facile analysis and reduction of oxygen vacancy. J Eur Ceram Soc. 2019;39(14):4085. https://doi.org/10.1016/j.jeurceramsoc.2019.06.015.

Pabst GW, Martin LW, Chu YH, Ramesh R. Leakage mechanisms in BiFeO3 thin films. Appl Phys Lett. 2007;90:072902. https://doi.org/10.1063/1.2535663r.

Auromun K, Choudhary RNP. Structural, dielectric, and electrical characteristics of selenium-modified BiFeO3–(BaSr)TiO3 ceramics. J Mater Sci Mater Electron. 2020;31(16):13415. https://doi.org/10.1007/s10854-020-03896-5.

Sharma S, Cruz MP, Siqueiros JM, Raymond-Herrera O, Alvarez VE, Dwivedi RK. Investigation of electrical, magneto-dielectric and transport properties of multiferroic (1−x)BiFeO3-(x)BaSr0.7Ti0.3O3 solid solutions. J Mater Sci Mater Electron. 2019;30:7447. https://doi.org/10.1007/s10854-019-01058-w.

Cai W, Gao R, Fu C, Yao L, Chen G, Deng X, Wang Z, Cao X, Wang F. Microstructure, enhanced electric and magnetic properties of Bi0.9La0.1FeO3 ceramics prepared by microwave sintering. J Alloys Compd. 2019;774:61. https://doi.org/10.1016/j.jallcom.2018.09.316.

Wang C, Takahashi M, Fujino H, Zhao X, Kume E, Horiuchi T, Sakai S. Leakage current of multiferroic (Bi0.6Tb0.3La0.1)FeO3 thin films grown at various oxygen pressures by pulsed laser deposition and annealing effect. J Appl Phys. 2006;99(5):054104. https://doi.org/10.1063/1.2177430.

Auromun K, Choudhary RNP. Structural, dielectric and electrical characteristics of manganese modified (Bi0.5Ba0.25Sr0.25) (Ti0.5Fe0.5)O3 relaxor. Phys Scr. 2021;96(3):035804. https://doi.org/10.1088/1402-4896/abd1ff.

Lampert MA. Volume-controlled current injection in insulators. Rep Prog Phys. 1964;27(1):329. https://doi.org/10.1088/0034-4885/27/1/307.

Wang L, Liang R, Zhou Z, Dong X. High electrostrain with high Curie temperature in BiFeO3–BaTiO3-based ceramics. Scr Mater. 2019;164:62. https://doi.org/10.1016/j.scriptamat.2019.01.028.

Li Y, Chen J, Cai P, Wen Z. An electrochemically neutralized energy-assisted low-cost acid-alkaline electrolyzer for energy-saving electrolysis hydrogen generation. J Mater Chem A. 2018;6(12):4948. https://doi.org/10.1039/C7TA10374C.

Xun B, Song A, Yu J, Yin Y, Li JF, Zhang BP. Lead-free BiFeO3–BaTiO3 ceramics with high Curie temperature: fine compositional tuning across the phase boundary for high piezoelectric charge and strain coefficients. ACS Appl Mater Interfaces. 2021;13(3):4192. https://doi.org/10.1021/acsami.0c20381.

Wang D, Khesro A, Murakami S, Feteira A, Zhao Q, Reaney IM. Temperature dependent, large electromechanical strain in Nd-doped BiFeO3–BaTiO3 lead-free ceramics. J Eur Ceram Soc. 2017;37(4):1857. https://doi.org/10.1016/j.jeurceramsoc.2016.10.027.

Zheng T, Zhao C, Wu J, Wang K, Li JF. Large strain of lead-free bismuth ferrite ternary ceramics at elevated temperature. Scr Mater. 2018;155:11. https://doi.org/10.1016/j.scriptamat.2018.06.007.

Ansell TY, Cann DP, Sapper E, Rödel J. Thermal depolarization in the high-temperature ternary piezoelectric system xPbTiO3–yBiScO3–zBi(Ni1/2Ti1/2)O3. J Am Ceram Soc. 2015;98(2):455. https://doi.org/10.1111/jace.13268.

Zheng D, Zuo R. A novel BiFeO3–BaTiO3–BaZrO3 lead-free relaxor ferroelectric ceramic with low-hysteresis and frequency-insensitive large strains. J Am Ceram Soc. 2015;98(12):3670. https://doi.org/10.1111/jace.13989.

Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, Homma T, Nagaya T, Nakamura M. Lead-free piezoceramics. Nature. 2004;432(7013):84. https://doi.org/10.1038/nature03028.

Wang R, Wang K, Yao F, Li JF, Schader FH, Webber KG, Jo W, Rodel J. Temperature stability of lead-free niobate piezoceramics with engineered morphotropic phase boundary. J Am Ceram Soc. 2015;98(7):2177. https://doi.org/10.1111/jace.13604.

Bai W, Bian Y, Hao J, Shen B, Zhai J. The composition and temperature-dependent structure evolution and large strain response in (1−x)(Bi0.5Na0.5)TiO3–xBa(Al0.5Ta0.5)O3 ceramics. J Am Ceram Soc. 2013;96(1):246. https://doi.org/10.1111/jace.12039.

Liu X, Tan X. Giant strains in non-textured (Bi1/2Na1/2)TiO3-based lead-free ceramics. Adv Mater. 2016;28(3):574. https://doi.org/10.1002/adma.201503768.

Cen Z, Zhou C, Cheng J, Zhou X, Li W, Yan C, Feng S, Liu Y, Lao D. Effect of Zr4+ substitution on thermal stability and electrical properties of high temperature BiFe0.99Al0.01O3–BaTi1−xZrxO3 ceramics. J Alloys Compd. 2013;567:110. https://doi.org/10.1016/j.jallcom.2013.03.065.

Zhou Q, Zhou C, Yang H, Yuan C, Chen G, Cao L, Fan Q. Piezoelectric and ferroelectric properties of Ga modified BiFeO3–BaTiO3 lead-free ceramics with high Curie temperature. J Mater Sci Mater Electron. 2014;25:196. https://doi.org/10.1007/s10854-013-1573-8.

Chen J, Cheng J. High electric-induced strain and temperature-dependent piezoelectric properties of 0.75BF–0.25BZT lead-free ceramics. J Am Ceram Soc. 2016;99(2):536. https://doi.org/10.1111/jace.14003.

Zhou Q, Zhou C, Yang H, Chen G, Li W, Wang H. Dielectric, ferroelectric, and piezoelectric properties of Bi(Ni1/2Ti1/2)O3-modified BiFeO3–BaTiO3 ceramics with high Curie temperature. J Am Ceram Soc. 2012;95(12):3889. https://doi.org/10.1111/j.1551-2916.2012.05387.x.

Zhou X, Zhou C, Zhou Q, Yang H, Cen Z, Cheng J, Cao L, Fan Q. Investigation of structural and electrical properties of B-site complex ion (Mg1/3Nb2/3)4+-modified high-Curie-temperature BiFeO3–BaTiO3 ceramics. J Electron Mater. 2014;43:755. https://doi.org/10.1007/s11664-013-2952-x.

Liu Q, Zhang Y, Gao J, Zhou Z, Yang D, Lee KY, Studer A, Hinterstein M, Wang K, Zhang X, Li L, Li JF. Practical high-performance lead-free piezoelectrics: structural flexibility beyond utilizing multiphase coexistence. Natl Sci Rev. 2020;7(2):355. https://doi.org/10.1093/nsr/nwz167.

Zheng T, Wu J. Perovskite BiFeO3–BaTiO3 ferroelectrics: engineering properties by domain evolution and thermal depolarization modification. Adv Electron Mater. 2020;6(5):2000079. https://doi.org/10.1002/aelm.202000079.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 52072028 and 52032007) and National Key Research and Development Program (No. 2022YFB3807400).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, XX., Tang, YC., Li, HZ. et al. BiAlO3-modified BiFeO3–BaTiO3 high Curie temperature lead-free piezoelectric ceramics with enhanced performance. Rare Met. 42, 3839–3850 (2023). https://doi.org/10.1007/s12598-023-02407-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02407-9