Abstract

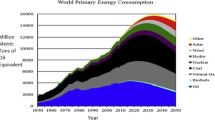

Heavy consumption of fossil fuels has raised concerns over the climate change and energy security in the past decades. In this review, hydrogen economy, as a clean and sustainable energy system, is receiving great attention. The success of future hydrogen economy strongly depends on the storage of renewable energy in hydrogen and hydrogen-rich chemicals through electrolyzers and conversion back to electricity via fuel cells. Electrocatalysts are at the heart of these critical technologies and great efforts have been devoted to preparing highly efficient nanomaterials. High-entropy alloys (HEAs), with their unique structural characteristics and intrinsic properties, have evolved to be one of the most popular catalysts for energy-related applications, especially those associated with hydrogen economy. Herein, recent advances regarding HEAs-based hydrogen economy are comprehensively reviewed. Attention is paid to the discussion of emerged HEAs as a new class of materials in hydrogen energy cycle, carbon-based hydrogen energy cycle, and nitrogen-based hydrogen energy cycle, covering the sustainable electrochemical synthesis of hydrogen and hydrogen-rich fuels and their direct application in fuel cells. Based on this overview, the challenges and promising directions are proposed to guide the development of HEAs research, aiming to achieve significant progress for further accessing hydrogen economy.

Graphical Abstract

摘要

在过去的几十年里,化石燃料的大量消耗引起了人们对气候变化和能源安全的担忧。氢经济作为一种清洁、可持续的能源体系受到学术界的高度重视。未来氢经济的实现很大程度上取决于可再生能源通过电解槽储存在氢和富氢化学品中,再通过燃料电池转换回电力。在这一能源转换路径中,高效纳米电催化剂是这些关键技术的核心。高熵合金以其独特的结构特征和内在性能,已成为能源领域特别是氢经济领域最受欢迎的催化剂之一。本文综述了近年来基于高熵合金的氢经济研究进展,重点讨论了氢能循环、碳基氢能循环、氮基氢能循环,涵盖了氢和富氢燃料的可持续电化学合成及其在燃料电池中的直接应用。在此基础上,提出了目前研究所面临的挑战和前景方向,以指导高熵合金催化剂的发展,以期进一步实现氢经济的重大进展。

Copyright 2020, Springer Nature. g Activities toward HER of FeCoPdIrPt, Pt/C, and pure CP electrodes; h chronopotentiometry curve for FeCoPdIrPt@GO; i amount of H2 during HER. Reproduced with permission from Ref. [59]. Copyright 2020, Springer Nature

Reproduced with permission from Ref. [62]. Copyright 2021, Springer Nature

Copyright 2020, American Chemical Society. c Comparative chronoamperometric responses in CO2 saturated electrolyte at different potentials (− 0.7, − 0.8 and − 0.9 V) for 1000 s with respective current density as inset; d bar diagram (with errors) for Faradaic efficiencies (FE) of their respective carbonaceous species and hydrogen gaseous products; e free energy diagram of CO2RR on AuAgPtPdCu HEA surface, and (inset) optimized structures of all intermediates on HEA surface, where gray, green, pink, yellow, blue, brown, red, and orange spheres represent Pt, Pd, Ag, Au, Cu, C, O, and H atoms, respectively. U is applied electrode potential. Reproduced with permission from Ref. [71]. Copyright 2020, American Chemical Society

Reproduced with permission from Ref. [73]. Copyright 2009, Elsevier. c ECSA-normalized and d mass-normalized CVs of np-PtRuCuOsIr and PtC catalysts for methanol electro-oxidation in 0.5 mol·L−1 H2SO4 + 0.5 mol·L−1 CH3OH solution; e electrochemical CO-stripping curves of np-PtRuCuOsIr and PtC catalysts in 0.5 mol·L−1 H2SO4 solution. Reproduced with permission from Ref. [74]. Copyright 2015, Elsevier. f Peak values of mass activity and area activity; g PDOSs for key intermediates of MOR; h energetic pathway of alkaline MOR; i energetic pathway of CO poisoning. Reproduced with permission from Ref. [58]. Copyright 2020, Springer Nature

Reproduced with permission from Ref. [75]. Copyright 2009, Elsevier

Reproduced with permission from Ref. [76]. Copyright 2020, American Chemical Society. e ECSA values and mass activities of different alloys; f CVs recorded in N2-saturated 1.0 mol·L−1 KOH + 0.5 mol·L−1 ethanol solution at a scan rate of 50 mV·s−1; g LSV curve and power densities at different current densities; h comparison of power density with literature data; i surface models with and without doped atoms of Pd used for modeling ethanol catalysis, where navy blue, orange, light blue, and green balls represent Pd, Cu, Mo, and Ni atoms, and red, brown, and light pink balls represent O, C, and H atoms in ethanol molecule, respectively. Reproduced with permission from Ref. [77]. Copyright 2020, Wiley–VCH

Reproduced with permission from Ref. [88]. Copyright 2021, American Chemical Society

Similar content being viewed by others

References

Chu S, Majumdar A. Opportunities and challenges for a sustainable energy future. Nature. 2012;488(7411):294. https://doi.org/10.1038/nature11475.

Liu SS, Wang MF, He YZ, Cheng QY, Qian T, Yan CL. Covalent organic frameworks towards photocatalytic applications: design principles, achievements, and opportunities. Coordin Chem Rev. 2023;475:214882. https://doi.org/10.1016/j.ccr.2022.214882.

Lackner KS. A guide to CO2 sequestration. Science. 2003;300(5626):1677. https://doi.org/10.1126/science.1079033.

Olah GA. Beyond oil and gas: the methanol economy. Angew Chem Int Ed. 2005;44(18):2636. https://doi.org/10.1002/anie.200462121.

Liu SS, Wang MF, Qian T, Ji HQ, Liu J, Yan CL. Facilitating nitrogen accessibility to boron-rich covalent organic frameworks via electrochemical excitation for efficient nitrogen fixation. Nat Commun. 2019;10(1):3898. https://doi.org/10.1038/s41467-019-11846-x.

Bockris J. A hydrogen economy. Science. 1972;176(4041):1323. https://doi.org/10.1126/science.176.4041.1323.

Bockris J. Hydrogen economy in the future. Int J Hydrog Energy. 1999;24(1):1. https://doi.org/10.1016/S0360-3199(98)00115-3.

Ohi J. Hydrogen energy cycle: an overview. J Mater Res. 2005;20(12):3180. https://doi.org/10.1557/jmr.2005.0408.

Falcone PM, Hiete M, Sapio A. Hydrogen economy and sustainable development goals: review and policy insights. Curr Opin Green Sust Chem. 2021;31:100506. https://doi.org/10.1016/j.cogsc.2021.100506.

Tseng P, Lee J, Friley P. A hydrogen economy: opportunities and challenges. Energy. 2005;30(14):2703. https://doi.org/10.1016/j.energy.2004.07.015.

Lin R, Guo JX, Li XJ, Patel P, Seifitokaldani A. Electrochemical reactors for CO2 conversion. Catalysts. 2020;10(5):473. https://doi.org/10.3390/catal10050473.

Kirubakaran A, Jain S, Nema R. A review on fuel cell technologies and power electronic interface. Renew Sust Energ Rev. 2009;13(9):2430. https://doi.org/10.1016/j.rser.2009.04.004.

Jiang YZ, Wang MF, Zhang LF, Liu SS, Cao YF, Qian SY, Cheng Y, Xu XN, Yan CL, Qian T. Distorted spinel ferrite heterostructure triggered by alkaline earth metal substitution facilitates nitrogen localization and electrocatalytic reduction to ammonia. Chem Eng J. 2022;450:138226. https://doi.org/10.1016/j.cej.2022.138226.

Liu SS, Wang MF, Cheng QY, He YZ, Ni JJ, Liu J, Yan CL, Qian T. Turning waste into wealth: sustainable production of high-value-added chemicals from catalytic coupling of carbon dioxide and nitrogenous small molecules. ACS Nano. 2022;16(11):17911. https://doi.org/10.1021/acsnano.2c09168.

Safizadeh F, Ghali E, Houlachi G. Electrocatalysis developments for hydrogen evolution reaction in alkaline solutions–a review. Int J Hydrog Energy. 2015;40(1):256. https://doi.org/10.1016/j.ijhydene.2014.10.109.

Fu XB, Zhang JH, Zhan SQ, Xia FJ, Wang CJ, Ma DS, Yue Q, Wu JS, Kang YJ. High-entropy alloy nanosheets for fine-tuning hydrogen evolution. ACS Catal. 2022;12(19):11955. https://doi.org/10.1021/acscatal.2c02778.

Feng DY, Dong YB, Nie P, Zhang L, Qiao Z. CoNiCuMgZn high entropy alloy nanoparticles embedded onto graphene sheets via anchoring and alloying strategy as efficient electrocatalysts for hydrogen evolution reaction. Chem Eng J. 2022;430:132883. https://doi.org/10.1016/j.cej.2021.132883.

Pan FP, Yang Y. Designing CO2 reduction electrode materials by morphology and interface engineering. Energy Environ Sci. 2020;13(8):2275. https://doi.org/10.1039/D0EE00900H.

Liu SS, Qian T, Wang MF, Ji HQ, Shen XW, Wang C, Yan CL. Proton-filtering covalent organic frameworks with superior nitrogen penetration flux promote ambient ammonia synthesis. Nat Catal. 2021;4(4):322. https://doi.org/10.1038/s41929-021-00599-w.

Wang MF, Liu SS, Ji HQ, Yang TZ, Qian T, Yan CL. Salting-out effect promoting highly efficient ambient ammonia synthesis. Nat Commun. 2021;12:3198. https://doi.org/10.1038/s41467-021-23360-0.

Strmcnik D, Uchimura M, Wang C, Subbaraman R, Danilovic N, Van D, Paulikas A, Stamenkovic V, Markovic N. Improving the hydrogen oxidation reaction rate by promotion of hydroxyl adsorption. Nat Chem. 2013;5(4):300. https://doi.org/10.1038/nchem.1574.

Iwasita T. Electrocatalysis of methanol oxidation. Electrochim Acta. 2002;47(22–23):3663. https://doi.org/10.1016/S0013-4686(02)00336-5.

Yu XW, Pickup P. Recent advances in direct formic acid fuel cells (DFAFC). J Power Sources. 2008;182(1):124. https://doi.org/10.1016/j.jpowsour.2008.03.075.

Ding QW, Luo Q, Lin L, Fu XP, Wang LS, Yue GH, Lin J, Xie QS, Peng DL. Facile synthesis of PdCu nanocluster-assembled granular films as highly efficient electrocatalysts for formic acid oxidation. Rare Met. 2022;41(8):2595. https://doi.org/10.1007/s12598-022-01997-0.

Liang ZX, Zhao TS, Xu JB, Zhu LD. Mechanism study of the ethanol oxidation reaction on palladium in alkaline media. Electrochim Acta. 2009;54(8):2203. https://doi.org/10.1016/j.electacta.2008.10.034.

Siddiqui O, Dincer I. A review and comparative assessment of direct ammonia fuel cells. Therm Sci Eng Prog. 2018;5:568. https://doi.org/10.1016/j.tsep.2018.02.011.

Seh Z, Kibsgaard J, Dickens C, Chorkendorff I, Nørskov J, Jaramillo T. Combining theory and experiment in electrocatalysis: insights into materials design. Science. 2017;355(6321):eaad4998. https://doi.org/10.1126/science.abj2421.

Wang MF, Liu SS, Qian T, Liu J, Zhou JQ, Ji HQ, Xiong J, Zhong J, Yan CL. Over 56.55% Faradaic efficiency of ambient ammonia synthesis enabled by positively shifting the reaction potential. Nat Commun. 2019;10:341. https://doi.org/10.1038/s41467-018-08120-x.

Shen XW, Liu SS, Xia XY, Wang MF, Ji HQ, Wang ZK, Liu J, Zhang XS, Yan CL, Qian T. Interfacial microextraction boosting nitrogen feed for efficient ambient ammonia synthesis in aqueous electrolyte. Adv Funct Mater. 2022;32(17):2109422. https://doi.org/10.1002/adfm.202109422.

Wu T, Sun MZ, Huang BL. Non-noble metal-based bifunctional electrocatalysts for hydrogen production. Rare Met. 2022;41(7):2169. https://doi.org/10.1007/s12598-021-01914-x.

Hou JB, Yang M, Ke CC, Wei GH, Priest C, Qiao Z, Wu G, Zhang JL. Platinum-group-metal catalysts for proton exchange membrane fuel cells: from catalyst design to electrode structure optimization. EnergyChem. 2020;2(1):100023. https://doi.org/10.1016/j.enchem.2019.100023.

An CH, Kang W, Deng QB, Hu N. Pt and Te codoped ultrathin MoS2 nanosheets for enhanced hydrogen evolution reaction with wide pH range. Rare Met. 2022;41(2):378. https://doi.org/10.1007/s12598-021-01791-4.

Sealy C. The problem with platinum. Mater Today. 2008;11(12):65. https://doi.org/10.1016/S1369-7021(08)70254-2.

Shi WH, Liu HW, Li ZZ, Li CH, Zhou JH, Yuan YF, Jiang F, Fu K, Yao YG. High-entropy alloy stabilized and activated Pt clusters for highly efficient electrocatalysis. SusMat. 2022;2(2):186. https://doi.org/10.1002/sus2.56.

Cantor B, Chang I, Knight P, Vincent A. Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A. 2004;375:213. https://doi.org/10.1016/j.msea.2003.10.257.

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater. 2004;6(5):299. https://doi.org/10.1002/adem.200300567.

George EP, Raabe D, Ritchie RO. High-entropy alloys. Nat Rev Mater. 2019;4(8):515. https://doi.org/10.1038/s41578-019-0121-4.

Qin YC, Wang FQ, Wang XM, Wang MW, Zhang WL, An WK, Wang XP, Ren YL, Zheng X, Lv DC, Ahmad A. Noble metal-based high-entropy alloys as advanced electrocatalysts for energy conversion. Rare Met. 2021;40(9):2354. https://doi.org/10.1007/s12598-021-01727-y.

Liu LH, Li N, Han M, Han JR, Liang HY. Scalable synthesis of nanoporous high entropy alloys for electrocatalytic oxygen evolution. Rare Met. 2022;41(1):125. https://doi.org/10.1007/s12598-021-01760-x.

Xin Y, Li SH, Qian YY, Zhu WK, Yuan HB, Jiang PY, Guo RH, Wang LB. High-entropy alloys as a platform for catalysis: progress, challenges, and opportunities. ACS Catal. 2020;10(19):11280. https://doi.org/10.1021/acscatal.0c03617.

Zhang YQ, Wang DD, Wang YS. High-entropy alloys for electrocatalysis: design, characterization, and applications. Small. 2022;18(7):2104339. https://doi.org/10.1002/smll.202104339.

Li HD, Lai JP, Li ZJ, Wang L. Multi-sites electrocatalysis in high-entropy alloys. Adv Funct Mater. 2021;31(47):2106715. https://doi.org/10.1002/adfm.202106715.

Sutherland BR. Charging up stationary energy storage. Joule. 2019;3(1):1. https://doi.org/10.1016/j.joule.2018.12.022.

Yeh JW. Alloy design strategies and future trends in high-entropy alloys. JOM. 2013;65(12):1759. https://doi.org/10.1007/s11837-013-0761-6.

Yao YG, Liu ZY, Xie PF, Huang ZN, Li TY, Morris D, Finfrock Z, Zhou JH, Jiao ML, Gao JL, Mao YM, Miao JW, Zhang P, Shahbazian Y, Wang C, Wang GF, Hu LB. Computationally aided, entropy-driven synthesis of highly efficient and durable multi-elemental alloy catalysts. Sci Adv. 2020;6(11):eaaz510. https://doi.org/10.1126/sciadv.aaz0510.

Yeh JW, Chang SY, Hong YD, Chen SK, Lin SJ. Anomalous decrease in X-ray diffraction intensities of Cu–Ni–Al–Co–Cr–Fe–Si alloy systems with multi-principal elements. Mater Chem Phys. 2007;103(1):41. https://doi.org/10.1016/j.matchemphys.2007.01.003.

Chen SJ, Oh HS, Gludovatz B, Kim SJ, Park ES, Zhang Z, Ritchie RO, Yu Q. Real-time observations of TRIP-induced ultrahigh strain hardening in a dual-phase CrMnFeCoNi high-entropy alloy. Nat Commun. 2020;11(1):826. https://doi.org/10.1038/s41467-020-14641-1.

Wang RX, Tang Y, Li S, Ai YL, Li YY, Xiao B, Zhu L, Liu XY, Bai SX. Effect of lattice distortion on the diffusion behavior of high-entropy alloys. J Alloys Compd. 2020;825:154099. https://doi.org/10.1016/j.jallcom.2020.154099.

Jien W. Recent progress in high entropy alloys. Ann Chim Sci Mat. 2006;31(6):633.

Batchelor TA, Pedersen JK, Winther SH, Castelli IE, Jacobsen KW, Rossmeisl J. High-entropy alloys as a discovery platform for electrocatalysis. Joule. 2019;3(3):834. https://doi.org/10.1016/j.joule.2018.12.015.

Wang YH, Li RQ, Li HB, Huang HL, Guo ZJ, Chen HY, Zheng Y, Qu KG. Controlled synthesis of ultrasmall RuP2 particles on N, P-codoped carbon as superior pH-wide electrocatalyst for hydrogen evolution. Rare Met. 2021;40(5):1040. https://doi.org/10.1007/s12598-020-01665-1.

Tian XY, Zhao PC, Sheng WC. Hydrogen evolution and oxidation: mechanistic studies and material advances. Adv Mater. 2019;31(31):1808066. https://doi.org/10.1002/adma.201808066.

Hao R, Feng QL, Wang XJ, Zhang YC, Li KS. Morphology-controlled growth of large-area PtSe2 films for enhanced hydrogen evolution reaction. Rare Met. 2022;41(4):1314. https://doi.org/10.1007/s12598-021-01877-z.

Chang L, Sun ZX, Hu YH. 1T phase transition metal dichalcogenides for hydrogen evolution reaction. Electrochem Energy Rev. 2021;4(2):194. https://doi.org/10.1007/s41918-020-00087-y.

Wu HM, Feng CQ, Zhang L, Zhang JJ, Wilkinson DP. Non-noble metal electrocatalysts for the hydrogen evolution reaction in water electrolysis. Electrochem Energy Rev. 2021;4(3):473. https://doi.org/10.1007/s41918-020-00086-z.

Jin ZY, Lv J, Jia HL, Liu WH, Li HL, Chen ZH, Lin X, Xie GQ, Liu XJ, Sun SH, Qiu HJ. Nanoporous Al-Ni-Co-Ir-Mo high-entropy alloy for record-high water splitting activity in acidic environments. Small. 2019;15(47):1904180. https://doi.org/10.1002/smll.201904180.

Wang P, Luo YZ, Zhang GX, Chen ZS, Ranganathan H, Sun SH, Shi ZC. Interface engineering of NixSy@MnOxHy nanorods to efficiently enhance overall-water-splitting activity and stability. Nano-Micro Lett. 2022;14(1):120. https://doi.org/10.1007/s40820-022-00860-2.

Li HD, Han Y, Zhao H, Qi WJ, Zhang D, Yu YD, Cai WW, Li SX, Lai JP, Huang BL, Wang L. Fast site-to-site electron transfer of high-entropy alloy nanocatalyst driving redox electrocatalysis. Nat Commun. 2020;11:5437. https://doi.org/10.1038/s41467-020-19277-9.

Gao SJ, Hao SY, Huang ZN, Yuan YF, Han S, Lei LC, Zhang XW, Shahbazian Y, Lu J. Synthesis of high-entropy alloy nanoparticles on supports by the fast moving bed pyrolysis. Nat Commun. 2020;11:2016. https://doi.org/10.1038/s41467-020-15934-1.

Davydova E, Mukerjee S, Jaouen F, Dekel D. Electrocatalysts for hydrogen oxidation reaction in alkaline electrolytes. ACS Catal. 2018;8(7):6665. https://doi.org/10.1021/acscatal.8b00689.

Cheng X, Shi Z, Glass N, Zhang L, Zhang JJ, Song DT, Liu ZS, Wang HJ, Shen J. A review of PEM hydrogen fuel cell contamination: impacts, mechanisms, and mitigation. J Power Sources. 2007;165(2):739. https://doi.org/10.1016/j.jpowsour.2006.12.012.

Zhan CH, Xu Y, Bu LZ, Zhu H, Feng YG, Yang T, Zhang Y, Yang ZQ, Huang BL, Shao Q, Huang XQ. Subnanometer high-entropy alloy nanowires enable remarkable hydrogen oxidation catalysis. Nat Commun. 2021;12:6261. https://doi.org/10.1038/s41467-021-26425-2.

Simon A, Liso V, Cui X, Li N, Zhu J, Sahlin S, Jensen S, Nielsen M, Kær S. A review of the methanol economy: the fuel cell route. Energies. 2020;13(3):596. https://doi.org/10.3390/en13030596.

Kamarudin S, Achmad F, Daud W. Overview on the application of direct methanol fuel cell (DMFC) for portable electronic devices. Int J Hydrog Energy. 2009;34(16):6902. https://doi.org/10.1016/j.ijhydene.2009.06.013.

Akhairi M, Kamarudin S. Catalysts in direct ethanol fuel cell (DEFC): an overview. Int J Hydrog Energy. 2016;41(7):4214. https://doi.org/10.1016/j.ijhydene.2015.12.145.

Xie H, Wang TY, Liang JS, Li Q, Sun SH. Cu-based nanocatalysts for electrochemical reduction of CO2. Nano Today. 2018;21:41. https://doi.org/10.1016/j.nantod.2018.05.001.

Deng BW, Huang M, Zhao XL, Mou SY, Dong F. Interfacial electrolyte effects on electrocatalytic CO2 reduction. ACS Catal. 2022;12(1):331. https://doi.org/10.1021/acscatal.1c03501.

Ma WC, He XY, Wang W, Xie SJ, Zhang QH, Wang Y. Electrocatalytic reduction of CO2 and CO to multi-carbon compounds over Cu-based catalysts. Chem Soc Rev. 2021;50:12897. https://doi.org/10.1039/D1CS00535A.

Gustavsen K, Wang KY. Recent advances on enhancing the multicarbon selectivity of nanostructured Cu-based catalysts. Phys Chem Chem Phys. 2021;23(22):12514. https://doi.org/10.1039/d1cp00908g.

Pedersen J, Batchelor T, Bagger A, Rossmeisl J. High-entropy alloys as catalysts for the CO2 and CO reduction reactions. ACS Catal. 2020;10(3):2169. https://doi.org/10.1021/acscatal.9b04343.

Nellaiappan S, Katiyar N, Kumar R, Parui A, Malviya K, Pradeep K, Singh A, Sharma S, Tiwary C, Biswas K. High-entropy alloys as catalysts for the CO2 and CO reduction reactions: experimental realization. ACS Catal. 2020;10(6):3658. https://doi.org/10.1021/acscatal.9b04302.

Hamnett A. Mechanism and electrocatalysis in the direct methanol fuel cell. Catal Today. 1997;38(4):445. https://doi.org/10.1016/S0920-5861(97)00054-0.

Tsai CF, Yeh KY, Wu PW, Hsieh YF, Lin P. Effect of platinum present in multi-element nanoparticles on methanol oxidation. J Alloys Compd. 2009;478(1–2):868. https://doi.org/10.1016/j.jallcom.2008.12.055.

Chen XT, Si CH, Gao YL, Frenzel J, Sun JZ, Eggeler G, Zhang ZH. Multi-component nanoporous platinum–ruthenium–copper–osmium–iridium alloy with enhanced electrocatalytic activity towards methanol oxidation and oxygen reduction. J Power Sources. 2015;273:324. https://doi.org/10.1016/j.jpowsour.2014.09.076.

Katiyar N, Nellaiappan S, Kumar R, Malviya K, Pradeep K, Singh A, Sharma S, Tiwary C, Biswas K. Formic acid and methanol electro-oxidation and counter hydrogen production using nano high entropy catalyst. Mater Today Energy. 2020;16:100393. https://doi.org/10.1016/j.mtener.2020.100393.

Wu DS, Kusada K, Yamamoto T, Toriyama T, Matsumura S, Kawaguchi S, Kubota Y, Kitagawa H. Platinum-group-metal high-entropy-alloy nanoparticles. J Am Chem Soc. 2020;142(32):13833. https://doi.org/10.1021/jacs.0c04807.

Li SY, Wang JQ, Lin X, Xie GQ, Huang Y, Liu XJ, Qiu HJ. Flexible solid-state direct ethanol fuel cell catalyzed by nanoporous high-entropy Al-Pd-Ni-Cu-Mo anode and spinel (AlMnCo)3O4 cathode. Adv Funct Mater. 2021;31(5):2007129. https://doi.org/10.1002/adfm.202007129.

He YZ, Wang MF, Liu SS, Zhang LF, Cheng QY, Yan CL, Qian T. A superaerophilic gas diffusion electrode enabling facilitated nitrogen feeding through hierarchical micro/nano channels for efficient ambient synthesis of ammonia. Chem Eng J. 2023;454:140106. https://doi.org/10.1016/j.cej.2022.140106.

Liu SS, Wang MF, Ji HQ, Shen XW, Yan CL, Qian T. Altering the rate-determining step over cobalt single clusters leading to highly efficient ammonia synthesis. Natl Sci Rev. 2021;8(5):nwaa136. https://doi.org/10.1093/nsr/nwaa136.

Afif A, Radenahmad N, Cheok Q, Shams S, Kim J, Azad A. Ammonia-fed fuel cells: a comprehensive review. Renew Sust Energ Rev. 2016;60:822. https://doi.org/10.1016/j.rser.2016.01.120.

Wang MF, Liu SS, Ji HQ, Liu J, Yan CL, Qian T. Unveiling the essential nature of Lewis basicity in thermodynamically and dynamically promoted nitrogen fixation. Adv Funct Mater. 2020;30(32):2001244. https://doi.org/10.1002/adfm.202001244.

Zhang D, Zhao H, Wu XK, Deng Y, Wang ZC, Han Y, Li HD, Shi Y, Chen XL, Li SX, Lai JP, Huang BL, Wang L. Multi-site electrocatalysts boost pH-universal nitrogen reduction by high-entropy alloys. Adv Funct Mater. 2021;31(9):2006939. https://doi.org/10.1002/adfm.202006939.

Yu YF, Zhang W, Sun FL, Fang QJ, Pan JK, Chen WX, Zhuang GL. High electrocatalytical performance of FeCoNiCuPd high-entropy alloy for nitrogen reduction reaction. Mol Catal. 2022;519:112141. https://doi.org/10.1016/j.mcat.2022.112141.

Lan R, Tao SW. Ammonia as a suitable fuel for fuel cells. Front Energy Res. 2014;2:35. https://doi.org/10.3389/fenrg.2014.00035.

Jin H, Lee S, Sohn Y, Lee S, Kim P, Yoo S. Capping agent-free synthesis of surface engineered Pt nanocube for direct ammonia fuel cell. Int J Energy Res. 2021;45(12):18281. https://doi.org/10.1002/er.6988.

Vidal I, Solla G, Montiel V, Feliu J, Aldaz A. Screening of electrocatalysts for direct ammonia fuel cell: ammonia oxidation on PtMe (Me: Ir, Rh, Pd, Ru) and preferentially oriented Pt (100) nanoparticles. J Power Sources. 2007;171(2):448. https://doi.org/10.1016/j.jpowsour.2007.06.015.

Li Y, Li X, Pillai H, Lattimer J, Mohd A, Karakalos S, Chen M, Guo L, Xu H, Yang J. Ternary PtIrNi catalysts for efficient electrochemical ammonia oxidation. ACS Catal. 2020;10(7):3945. https://doi.org/10.1021/acscatal.9b04670.

Saidi W, Shadid W, Veser G. Optimization of high-entropy alloy catalyst for ammonia decomposition and ammonia synthesis. J Phys Chem Lett. 2021;12(21):5185. https://doi.org/10.1021/acs.jpclett.1c01242.

Chung K, Luan J, Shek C. Strengthening and deformation mechanism of interstitially N and C doped FeCrCoNi high entropy alloy. J Alloys Compd. 2022;904:164118. https://doi.org/10.1016/j.jallcom.2022.164118.

He YZ, Liu SS, Wang MF, Ji HQ, Zhang LF, Cheng QY, Qian T, Yan CL. Advancing the electrochemistry of gas-involved reactions through theoretical calculations and simulations from microscopic to macroscopic. Adv Funct Mater. 2022;32(48):2208474. https://doi.org/10.1002/adfm.202208474.

Krishna Y, Jaiswal U, Rahul M. Machine learning approach to predict new multiphase high entropy alloys. Scr Mater. 2021;197:113804. https://doi.org/10.1016/j.scriptamat.2021.113804.

Mishra R, Shahi R. A systematic approach for enhancing magnetic properties of CoCrFeNiTi-based high entropy alloys via stoichiometric variation and annealing. J Alloys Compd. 2020;821:153534. https://doi.org/10.1016/j.jallcom.2019.153534.

Zhang L, Zhu JW, Li X, Mu SC, Verpoort F, Xue JM, Kou ZK, Wang J. Nurturing the marriages of single atoms with atomic clusters and nanoparticles for better heterogeneous electrocatalysis. Interdiscip Mater. 2022;1(1):51. https://doi.org/10.1002/idm2.12011.

Rao J, Diao H, Ocelík V, Vainchtein D, Zhang C, Kuo C, Tang Z, Guo W, Poplawsky J, Zhou Y. Secondary phases in AlxCoCrFeNi high-entropy alloys: an in-situ TEM heating study and thermodynamic appraisal. Acta Mater. 2017;131:206. https://doi.org/10.1016/j.actamat.2017.03.066.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. U21A20332, 52103226, 52202275, 52203314 and 12204253), the Distinguished Young Scholars Fund of Jiangsu Province (No. BK20220061) and the Fellowship of China Postdoctoral Science Foundation (No. 2021M702382).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, QY., Wang, MF., Ni, JJ. et al. High-entropy alloys for accessing hydrogen economy via sustainable production of fuels and direct application in fuel cells. Rare Met. 42, 3553–3569 (2023). https://doi.org/10.1007/s12598-023-02343-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02343-8