Highlights

-

Three-dimensional (3D) core‐shell heterostructured NixSy@MnOxHy nanorods grown on nickel foam (NixSy@MnOxHy/NF) were successfully fabricated via a simple hydrothermal reaction and a subsequent electrodeposition process.

-

The fabricated NixSy@MnOxHy/NF shows outstanding bifunctional activity and stability for hydrogen evolution reaction and oxygen evolution reaction, as well as overall‐water‐splitting performance.

-

The main origins are the interface engineering of NixSy@MnOxHy, the shell‐protection characteristic of MnOxHy, and the 3D open nanorod structure, which remarkably endow the electrocatalyst with high activity and stability.

Abstract

Exploring highly active and stable transition metal-based bifunctional electrocatalysts has recently attracted extensive research interests for achieving high inherent activity, abundant exposed active sites, rapid mass transfer, and strong structure stability for overall water splitting. Herein, an interface engineering coupled with shell-protection strategy was applied to construct three-dimensional (3D) core‐shell NixSy@MnOxHy heterostructure nanorods grown on nickel foam (NixSy@MnOxHy/NF) as a bifunctional electrocatalyst. NixSy@MnOxHy/NF was synthesized via a facile hydrothermal reaction followed by an electrodeposition process. The X-ray absorption fine structure spectra reveal that abundant Mn‐S bonds connect the heterostructure interfaces of NixSy@MnOxHy, leading to a strong electronic interaction, which improves the intrinsic activities of hydrogen evolution reaction and oxygen evolution reaction (OER). Besides, as an efficient protective shell, the MnOxHy dramatically inhibits the electrochemical corrosion of the electrocatalyst at high current densities, which remarkably enhances the stability at high potentials. Furthermore, the 3D nanorod structure not only exposes enriched active sites, but also accelerates the electrolyte diffusion and bubble desorption. Therefore, NixSy@MnOxHy/NF exhibits exceptional bifunctional activity and stability for overall water splitting, with low overpotentials of 326 and 356 mV for OER at 100 and 500 mA cm–2, respectively, along with high stability of 150 h at 100 mA cm–2. Furthermore, for overall water splitting, it presents a low cell voltage of 1.529 V at 10 mA cm–2, accompanied by excellent stability at 100 mA cm–2 for 100 h. This work sheds a light on exploring highly active and stable bifunctional electrocatalysts by the interface engineering coupled with shell-protection strategy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The massive consumption of fossil fuels produces some serious negative effects, such as environmental pollution and energy crisis [1,2,3]. Therefore, developing renewable energy sources, such as hydrogen (H2) energy, has attracted great attention because H2 is considered a green energy alternative to fossil fuels due to its high energy density and environmentally friendly features [4, 5]. Among all kinds of H2 production, electrochemical water splitting, composed of cathodic hydrogen evolution reaction (HER) and anodic oxygen evolution reaction (OER), represents an ideal commercialized technology owing to the simple processing condition, zero carbon footprint, and high purity. However, low energy conversion efficiency for electrochemical water splitting greatly hinders its large‐scale application. Although Pt‐based and Ir/Ru‐based materials are regarded as the state‐of‐the‐art electrocatalysts for HER and OER, respectively, and their high cost and scarcity hamper their commercial applications [6,7,8]. As a consequence, it is an imperative call for researchers to design efficient electrocatalysts for water splitting by using non-noble materials.

Lately, transition metal-based electrocatalysts are being explored extensively due to their good activities and stabilities, such as transition‐metal oxides, chalcogenides, phosphides, and nitrides. In particular, resource‐rich nickel sulfides electrocatalysts, such as NiS [9], Ni3S2 [10, 11], NiS2 [12, 13], have been widely researched due to their high electronic conductivity and unique structural configuration. Unfortunately, these pure nickel sulfides electrocatalysts cannot satisfy the needs of commercial applications because of their insufficient activities and stabilities. Moreover, it is difficult for single‐component electrocatalysts to simultaneously own outstanding HER and OER activities as bifunctional electrocatalysts for overall water splitting due to the presence of different reaction intermediates in HER and OER processes [14]. As a result, substantial efforts have been devoted to exploring varieties of strategies to enhance the intrinsic activities of bifunctional electrocatalysts for overall water splitting, including foreign metal‐atom doping [15,16,17], interface engineering [18,19,20], and vacancy engineering [21, 22]. Among those strategies, it has been proposed that the interface engineering is a remarkably efficient route to boost both HER and OER intrinsic activities through coupling different active components for constructing heterostructures as bifunctional electrocatalysts. For example, Mu et al. reported an interface engineering of Co nanoparticles and Co2C nanowires with Co/Co2C heterostructures, requiring low overpotentials of 261 mV for OER and 96 mV for HER at 10 mA cm–2 in alkaline media, which can be attributed to that the Co and Co2C play a key role in HER and OER processes, respectively [23]. Besides, Ghosh et al. prepared bimetallic phosphide heterostructure of Ni2P–CuP2 on Ni foam‐graphene‐carbon nanotubes with ultralow overpotentials of 32 mV at 10 mA cm–2 for HER and 140 mV at 20 mA cm–2 for OER in alkaline mediums, exhibiting outstanding overall‐water‐splitting activities, because the synergistic effect in the Ni2P–CuP2 heterostructures accelerates the HER and OER kinetics [24]. In addition, three‐dimensional (3D) nanostructure is quite often used in the electrodes, for example, Li et al. presented a core‐shell electrocatalyst composed of 3D ordered macroporous Co(OH)2 cavity array‐encapsulated NiMo alloy on a flexible carbon cloth with a low cell voltage of 1.52 V at 10 mA cm–2 for overall water splitting, in which the 3D structure exposes abundant active sites and ensures a rapid mass transfer by accelerating the bubble evolution and desorption process [25].

Apart from the activity of electrocatalysts, their stabilities are another important indicator for commercial applications. The main reason for stability decreasing is that active components of electrocatalysts are changed in the HER or OER process, especially at high potentials. Many researchers have demonstrated that transition metal chalcogenides, nitrides, and phosphides can be easily oxidized to the corresponding metal oxides/(oxy)hydroxides in the OER process [26,27,28,29]. Accordingly, a shell-protection strategy can efficiently enhance the stabilities of the catalysts [30, 31]. For example, Bao et al. prepared a core‐shell structured electrocatalyst of ultrathin graphene shells encapsulating a uniform CoNi nanoalloy with high stability and activity for HER in acidic media, in which the carbon shells protect the CoNi nanoalloy from acid corrosion, leading to the improved stability [32]. In our previous work, hierarchical CoNi2S4@NiMn‐layered double hydroxide heterostructures were synthesized, where the NiMn‐layered double hydroxide acts as a protective layer that remarkably enhances the OER stability of the electrocatalyst at high potentials [33]. Besides, transition metal oxides and (oxy)hydroxides have attracted extensive research interest as the most common and stable OER catalysts [34,35,36]. For example, Sun et al. prepared nano‐architectured turbostratic δ-MnOx on carbon nanotubes, which reaches 10 mA cm–2 at a low overpotential of 270 mV for OER [37]. Besides, Yang et al. reported a 2D NiFe LDH–Birnessite (MnO2·nH2O) hybrid, which shows outstanding catalytic activity (an overpotential of 258 mV at 10 mA cm−2) and excellent stability (20 h at 100 mA cm–2) for OER under a close to industrial hydrogen production condition (85 ℃ and 6 M KOH)) [38]. Accordingly, in order to synthesize excellent bifunctional HER and OER electrocatalysts for long‐term stability, transition metal oxides or (oxy)hydroxides as an OER active component can be applied as a shell to protect the core of HER active component. Furthermore, in situ growing electrocatalysts on nickel foam (NF) substrate remarkably improve the exposure and utilization of active sites owing to the characteristic of NF substrate, such as binder or adhesive-free, large surface area, and high electrical conductivity [39].

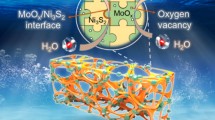

Herein, 3D core‐shell heterostructured NixSy@MnOxHy nanorods grown on NF (NixSy@MnOxHy/NF) were successfully fabricated via a simple hydrothermal reaction and a subsequent electrodeposition process, in which the NixSy is composed of Ni3S2 and NiS, while the MnOxHy is a hybrid of MnOOH, Mn(OH)2, and MnO(OH)2. We demonstrate that proper modification of nickel sulfides-based electrocatalysts, i.e., MnOxHy as a shell is combined with NixSy core to construct heterostructures, can efficiently enhance both activities and stabilities of HER and OER. In addition, 3D nanorods on NF not only provide plentiful active sites, but also accelerate electrolyte access and bubble diffusion. As expected, the fabricated NixSy@MnOxHy/NF demonstrates outstanding bifunctional activity with low overpotentials of 270 mV for HER and 326 mV for OER at 100 mA cm–2 in 1.0 M KOH electrolyte, along with robust stability of 150 h for OER. Moreover, when it was applied as both anode and cathode for overall water splitting in the same alkaline media, the electrocatalyst affords 10 mA cm–2 at a low cell voltage of 1.529 V with excellent stability at 100 mA cm–2 for 100 h.

2 Experimental Section

2.1 Chemicals and Materials

Sulfur powder, hydrazine hydrate, cetyltrimethylammonium bromide (CTAB), MnSO4·H2O, CH3COONa, and concentrated HCl were purchased from the Sinopharm Chemical Reagent Co., Ltd. Commercial NF was provided by Lizhiyuan Battery Materials Co., Ltd. Pt/C (20 wt%) and RuO2 (99.95%) were obtained from Alfa Aesar.

2.2 Preparation of Electrocatalysts

2.2.1 Preparation of 3D NixSy Nanorods Grown on NF (NixSy/NF)

First, NF was ultrasonicated in 3.0 mol L−1 HCl solution, deionized (DI) water, and ethanol for 10 min, respectively, to remove the surface oxides and residues. Then, 2.2 mmol CTAB and 5 mL of hydrazine hydrate were dissolved in 60 mL of DI water. After transferring the above solution into a 100-mL Teflon‐lined stainless steel autoclave containing 4.4 mmol sulfur powder and a piece of NF (2.0 × 3.0 cm2), the autoclave was maintained at 160 ℃ for 12 h. Finally, NixSy/NF was obtained after being washed and dried.

2.2.2 Preparation of 3D Core‐shell Heterostructured NixSy@MnOxHy Nanorods Grown on NF (NixSy@MnOxHy/NF)

NixSy@MnOxHy/NF was synthesized through a simple electrodeposition process in a three-electrode system, consisting of the NixSy/NF as the working electrode, a Pt wire as the counter electrode, and a saturated calomel electrode as the reference electrode. The anodic galvanostatic electrodeposition was conducted at 0.5 mA cm−2 for different time in 50 mL of electrolyte containing 7.5 mmol MnSO4·H2O and 15.0 mmol CH3COONa. After the electrodeposition process, NixSy@MnOxHy/NF was prepared after being rinsed and dried.

2.2.3 Preparation of Cotton-shaped MnOxHy Grown on NF (MnOxHy/NF)

MnOxHy/NF was prepared with the same electrodeposition method, except that the NixSy/NF was replaced with bare NF.

2.3 Physical Characterizations

The crystal structure was analyzed by X-ray diffraction (XRD) on a Rigaku D/Max 2400 X-ray diffractometer instrument. Scanning electron microscope (SEM, HITACHI UHR FE-SEM SU8200) and transmission electron microscopy (TEM, Talos F200S) were used to characterize the morphology. Inductively coupled plasma mass spectrometry (ICP-MS, Thermo, ICAP RQ) was carried out to detect the element content. X-ray photoelectron spectroscopy (XPS) measurements were carried out on a Thermo Scientific K-Alpha electron spectrometer with an exciting Al source (Kα = 1486.6 eV), in which all binding energies were corrected by referencing C 1 s peak (284.8 eV). X-ray absorption fine structure spectroscopy (XAFS) was conducted at the HXMA, SXRMB, and SGM beamlines at the Canadian Light Source (detail in supporting information).

2.4 Electrochemical Measurements

All electrochemical measurements were performed at 25 ℃ in 1.0 M KOH electrolyte with a three-electrode system (Autolab PGSTAT302 N/FRA system), where NF with different electrocatalysts, a Hg/HgO electrode, and a carbon rod acted as the working, reference, and counter electrodes, respectively. All measured potentials were calibrated to the reversible hydrogen electrode (RHE) using ERHE = EHg/HgO + 0.059 × pH + 0.098 (pH = 14). Linear sweep voltammetry (LSV) was conducted at a scan rate of 2 mV s−1, and electrochemical impedance spectroscopy (EIS) was obtained with a frequency range of 105 to 0.1 Hz. For achieving the electrochemical active surface area (ECSA), cyclic voltammetry (CV) was tested at various scan rates. Chronopotentiometry curves were used to evaluate the stabilities of electrocatalysts. For overall-water-splitting tests, NixSy@MnOxHy/NF was applied as both anode and cathode in a two-electrode system.

3 Result and Discussion

3.1 Characterization of Morphology and Composition

The fabricated procedure of NixSy@MnOxHy/NF is shown in Fig. 1. Initially, 3D NixSy nanorods grown on NF were prepared via a facile hydrothermal sulfurization reaction, in which NF and sulfur powder, respectively, act as Ni and S sources in the presence of CTAB and hydrazine hydrate. Subsequently, through an electrodeposition process, NixSy/NF was uniformly covered with MnOxHy to construct core–shell heterostructured NixSy@MnOxHy nanorods. Besides, the mass loading of MnOxHy can be optimized by adjusting the electrodeposition time.

In order to investigate the morphology of as-prepared electrocatalysts, SEM characterization was utilized. As shown in Fig. 2a-c, 3D NixSy nanorods were in situ grown successfully on the surface of NF via a facile hydrothermal reaction, compared with pure NF (Fig. S1a–c). Their high-magnified SEM images manifest that these nanorods possess a diameter of about 100–400 nm with relatively smooth surfaces. Such a 3D nanorod structure is beneficial to exposing abundant active sites and accelerating electrolyte contact and gas diffusion, leading to enhanced electrocatalytic activity. After the electrodeposition process, Fig. 2d–f shows that the entire surfaces of NixSy nanorods are covered with many MnOxHy nanosheets, which can be confirmed by the SEM image and the corresponding elemental mapping images (Fig. S2) of NixSy@MnOxHy/NF. As a comparison, MnOxHy was electrodeposited on the surface of NF (Fig. S3a–c), showing its cotton-shaped structure when pure NF was applied as an electrodeposited substrate, which indicates that the composition of substrates has a great influence on the morphology of electrodeposited materials. Subsequently, TEM was applied to further analyze the morphological property. Figs. 2g–h and k–l present the nanorod structure of NixSy and NixSy@MnOxHy, respectively. High-resolution TEM (HRTEM) images (Fig. 2i–j) of NixSy nanorod demonstrate an interplanar spacing of 0.24 nm, corresponding to the (003) plane of Ni3S2 and (220) plane of NiS, which reveals that NixSy consists of Ni3S2 and NiS. For NixSy@MnOxHy nanorod (Fig. 2m), a clear interface is observed between NixSy and MnOxHy. In addition, its HRTEM image (Fig. 2n) exhibits the crystalline MnOxHy and the existence of lattice spacing of 0.24 nm which is from NixSy, confirming the existence of heterostructured NixSy@MnOxHy. Besides, Fig. S4 shows the scanning transmission electron microscopy (STEM) and corresponding energy dispersive X-ray (EDX) spectrum of NixSy@MnOxHy nanorod, which also confirms the existence of Ni, S, Mn, and O in the NixSy@MnOxHy nanorod, and the Mn/Ni molar ratio is 1:40.3. Meanwhile, the STEM and corresponding EDX element mapping images (Fig. 2o–s) of NixSy@MnOxHy nanorod demonstrate the homogeneous spatial distribution of Ni, S, Mn, and O throughout the nanorod structure. Therefore, 3D core‐shell heterostructured NixSy@MnOxHy nanorods were successfully grown on the surface of NF.

The composition and crystalline structure of MnOxHy/NF, NixSy/NF, and NixSy@MnOxHy/NF were studied with XRD (Fig. 3a). Three obvious characteristic peaks marked by * can be ascribed to NF. The other peaks of NixSy/NF and NixSy@MnOxHy/NF match well with those of Ni3S2 (PDF#44–1418) and NiS (PDF#12–0041), revealing that NixSy is a hybrid of Ni3S2 and NiS. However, after the electrodeposition procedure, no peaks of MnOxHy can be observed in the XRD pattern of NixSy@MnOxHy/NF, which might be because the mass loading of the electrodeposited MnOxHy is too low to generate diffusion peaks. Furthermore, XPS was applied to investigate the surface chemical composition and valence of as-prepared electrocatalysts. The XPS survey spectra (Fig. S5) manifest the existence of Ni, S, Mn, and O elements, consistent with the element mapping results. As shown in Fig. 3b, regarding Ni 2p XPS spectra of NixSy/NF and NixSy@MnOxHy/NF, the Ni 2p3/2 peak located at 852.5 eV is attributed to the Ni–Ni bonds in Ni3S2 [40, 41]. For NixSy/NF, the peak located at 855.6 eV belongs to Ni–S [42, 43]. When NixSy/NF was coupled with MnOxHy, the second peak of Ni 2p3/2 positively shifts from 855.6 to 855.8 eV, suggesting that some electrons can be transferred from Ni in the NixSy by electrodepositing MnOxHy. The positive shift of 0.2 eV implies that MnOxHy can result in the redistribution of charge density for Ni active sites in NixSy@MnOxHy/NF, further leading to enhanced electrocatalytic activities by optimizing the adsorption/desorption energy of intermedia. The peak at about 861.3 eV is related to the satellite, referred to as “Sat.” In Fig. 3c, the S 2p XPS spectra of NixSy/NF and NixSy@MnOxHy/NF were reasonably deconvoluted. The characteristic peak of S–O at approximately 168.4 eV comes from oxidized S species because of the air oxidation [44]. The first doublet of S 2p3/2 and S 2p1/2 at about 161.1 and 162.3 eV is associated with S2−, while the other doublet, corresponding to S22−, appears at near 162.0/163.2 eV. In addition, for NixSy@MnOxHy/NF, the peak at 164.4 eV can be ascribed to some other S ligands, which are generated during the anodic electrodeposition process, where S-containing compositions, such as NixSy and SO42−, were transformed into some other S ligands. For Mn 2p3/2 (Fig. 3d), three peaks of MnOxHy/NF appear at 640.6, 641.8, and 643.19 eV, which are assigned to Mn2+, Mn3+, and Mn4+, respectively, signifying that MnOxHy may be composed of Mn2+, Mn3+, and Mn4+ species [45]. Due to the partial overlapping of the Ni LMM Auger peaks and Mn 2p, the Mn 2p3/2 of NixSy@MnOxHy/NF is difficult to be deconvoluted exactly into multiple peaks. High‐resolution Mn 3s XPS spectra for MnOxHy/NF and NixSy@MnOxHy/NF were used to further analyze the Mn valence states. The peak separation (ΔE) of Mn 3s peaks can be used to distinguish Mn oxidation states [46]. Fig. S6 shows that the ΔE of MnOxHy/NF is 5.3 eV, indicating the existence of Mn2O3 in MnOxHy/NF. However, for NixSy@MnOxHy/NF, no obvious peaks appear, implying that manganese oxides are not contained in NixSy@MnOxHy/NF, owing to the same electrodeposition condition. Consequently, the MnOxHy in NixSy@MnOxHy/NF may be a containing‐OH hybrid of Mn2+, Mn3+, and Mn4+. With regard to O 1s (Fig. S7), the peak at 529.6 eV is related to Mn–O, which is consistent with the result of Mn 3s spectra. The other two peaks are located at 531.0 and 531.8 eV, corresponding to –OH and –OOH, respectively. When the MnOxHy was electrodeposited on NixSy/NF substrate, the electrodeposited potentials are much lower than the electrochemical oxidation potential (1.37 V) of NixSy/NF (Figs. S8 and S9), which results in no formation of nickel (oxy)hydroxide in the electrodeposition process. Therefore, –OH and –OOH are attributed to Mn species. According to the above results of Mn 2p, Mn 3s and O 1s, the MnOxHy in MnOxHy/NF may consist of Mn(OH)2, MnOOH, Mn2O3, and MnO(OH)2, while the MnOxHy in NixSy@MnOxHy/NF may be composed of Mn(OH)2, MnOOH, and MnO(OH)2. In brief, MnOxHy was successfully coupled to NixSy/NF to form NixSy@MnOxHy/NF via an electrodeposition method, while an electronic coupling interaction exists in the heterostructure interfaces.

Moreover, XAFS was conducted to further investigate the electronic states and coordination environments of as-prepared electrocatalysts [47]. The X-ray absorption near edge structure (XANES) spectra of Ni, S, and Mn K-edges of NixSy/NF and NixSy@MnOxHy/NF are shown in Fig. 4a–c, respectively. The Ni K‐edge XANES spectrum of NixSy/NF is very close to that of NixSy@MnOxHy/NF. The much more positive energy position of the white line of NixSy/NF and NixSy@MnOxHy/NF than that of Ni foil manifests that NixSy/NF and NixSy@MnOxHy/NF have oxidized Ni. Fig. 4b shows that for the pre-edge of S K‐edge, the peak position of NixSy@MnOxHy/NF shifts to the higher photon energy than NixSy/NF, which is ascribed to that an electronic interaction exists between NixSy and MnOxHy. Additionally, the magnified Ni and S K‐edges spectrum (insets in Fig. 4a–b) show that NixSy@MnOxHy/NF possesses higher Ni K‐edge energy and lower S K‐edge energy than NixSy/NF, which can be attributed to that the electrodeposited MnOxHy leads to the electron transfer from Ni to S for NixSy@MnOxHy/NF. Hence, an electronic interaction exists between NixSy and MnOxHy for NixSy@MnOxHy/NF, which is coincident with the XPS results. For Mn K-edge (Fig. 4c), the shape of the post-edge of NixSy@MnOxHy/NF is different to that of the MnO2 standard sample, implying that the MnOxHy in NixSy@MnOxHy/NF and MnO2 own different crystal structures. Besides, the Mn K‐edge position of NixSy@MnOxHy/NF is much higher than that of Mn foil, but lower than that of MnO2 standard sample, verifying that the average valence of Mn in NixSy@MnOxHy/NF is lower than + 4. More evidence is shown in Mn L-edge spectra (Fig. 4d). The peak positions of MnO2 are located in much higher photon energies than those of NixSy@MnOxHy/NF, indicating the Mn valence in NixSy@MnOxHy/NF is lower than + 3, in agreement with the result of Mn K‐edge spectra. In addition, Fourier transformed extended X-ray absorption fine structure (FT‐EXAFS) spectra were used to further characterize the coordinative geometry. Fig. 4e shows Ni K-edge FT‐EXAFS oscillation functions k2χ(k) of NixSy/NF, NixSy@MnOxHy/NF, and Ni foil, in which NixSy/NF and NixSy@MnOxHy/NF present similar Ni coordinative geometry with two main peaks of Ni–S at about 1.7 Å and Ni–Ni at around 2.0 Å [48]. However, the peak intensity of Ni–S of NixSy@MnOxHy/NF is lower than that of NixSy/NF, revealing the decrease in the Ni–S coordination number in NixSy@MnOxHy/NF, which could be attributed to the formation of Mn–S bonds. Besides, the appearance of Ni–O peak at 1.2 Å may be due to the oxidation of NixSy in air. For Mn K-edge FT‐EXAFS oscillation functions k2χ(k) (Fig. 4f), an obvious Mn–S peak appears at 1.9 Å for NixSy@MnOxHy/NF, further confirming the existence of Mn–S bonds. In addition, two peaks located at 1.3 and 2.7 Å can be assigned to the Mn–O and Mn–Mn bonds, respectively. In the meantime, two main peaks of the MnO2 standard sample, related to the Mn–Mn bonds, are located at 2.4 and 3.0 Å, signifying MnOxHy and MnO2 have different crystal structures, corresponding to the Mn K-edge near edge spectra result (Fig. 4c). The corresponding wavelet transform of Ni and Mn K-edge EXAFS oscillations was carried out to further present the atomic dispersion [49]. For Ni K-edge EXAFS (Fig. 4g), the maximum intensity positions of Ni foil and NixSy/NF are located at about 2.2 Å, which can be ascribed to the contribution of Ni–Ni bonds. However, the maximum intensity position of NixSy@MnOxHy/NF, associated with Ni–Ni bonds, positively shift to about 2.3 Å, which may be attributed to the Ni–Mn contribution from the NixSy@MnOxHy heterostructure interfaces. Fig. 4h shows that NixSy@MnOxHy/NF, Mn foil, and MnO2 standard sample display different Mn atom dispersion, in accord with the Mn K-edge FT‐EXAFS result. For Mn foil, two maximum intensities at 2.3 and 3.6 Å come from the Mn–Mn bonds, while for the MnO2 standard sample, two maximum intensities at 1.4 and 2.7 Å are ascribed to the Mn–O and Mn–Mn bonds, respectively. Besides, two maximum intensities of NixSy@MnOxHy/NF, located at 1.8 and 2.6 Å, are assigned to the Mn–O and Mn–Mn bonds, respectively. For NixSy@MnOxHy/NF, the positive shift of the maximum intensity position, associated with the Mn–O bond, is dominated by the Mn–S contribution from the interfaces. Therefore, the two crystal phases (NixSy and MnOxHy) are connected through Mn–S bonds to construct heterostructures with electronic coupling effects in NixSy@MnOxHy/NF, which could modulate surface electronic structure to optimize adsorption/desorption energies of reaction intermediates during the HER/OER process, leading to enhanced electrocatalytic activity for water splitting.

a Normalized Ni K-edge XANES spectra of NixSy/NF, NixSy@MnOxHy/NF, and Ni foil. b Normalized S K-edge XANES spectra of NixSy/NF and NixSy@MnOxHy/NF. c Normalized Mn K-edge XANES spectra of NixSy@MnOxHy/NF, Ni foil, and MnO2 standard sample. d Normalized Mn L-edge XANES spectra of MnO2 standard sample and NixSy@MnOxHy/NF. e Ni K-edge FT‐EXAFS oscillation functions k2χ(k) of NixSy/NF, NixSy@MnOxHy/NF, and Ni foil. f Mn K-edge FT‐EXAFS oscillation functions k2χ(k) of NixSy@MnOxHy/NF, Ni foil, and MnO2 standard sample. g Corresponding wavelet transform of Ni K-edge EXAFS oscillation for Ni foil, NixSy/NF, and NixSy@MnOxHy/NF. h Corresponding wavelet transform of Mn K-edge EXAFS oscillation for Mn foil, MnO2 standard sample, and NixSy@MnOxHy/NF

3.2 Electrocatalytic OER Measurement

The OER performance of as-synthesized electrocatalysts was studied with a standard there-electrode configuration in 1.0 M KOH electrolyte, as shown in Fig. 5. To begin with, the OER activities of NixSy@MnOxHy/NF with different electrodeposition time were investigated. Fig. S9 shows that the catalyst prepared with 150 s electrodeposition time can achieve the highest OER activity. In addition, for comparison, LSV curves of NixSy/NF, MnOxHy/NF, and RuO2/NF were collected in the same condition (Fig. 5a). The OER activity of NixSy@MnOxHy/NF is similar to that of noble metal RuO2/NF under the low‐current‐density range, but higher than that of RuO2/NF under the high‐current‐density range, testifying that NixSy@MnOxHy/NF owns an excellent OER activity. Besides, it also presents better OER activity than NixSy/NF and MnOxHy/NF, indicating that a synergistic effect between NixSy and MnOxHy endows NixSy@MnOxHy/NF with the enhanced OER activity. Fig. 5b compares OER activities of as‐prepared electrocatalysts at different high current densities. NixSy@MnOxHy/NF can afford 100, 300, and 500 mA cm–2 at low overpotentials of 326, 347, and 356 mV, respectively, whereas NixSy/NF and MnOxHy/NF need overpotentials of 381 and 345 mV to reach 100 mA cm–2, respectively. Furthermore, Tafel slopes of electrocatalysts are used to study the reaction kinetics and intrinsic activity. Fig. 5c shows that the Tafel slope of NixSy@MnOxHy/NF is 39.0 mV dec–1, smaller than those of NixSy/NF (111.5 mV dec–1), MnOxHy/NF (47.5 mV dec–1), and RuO2/NF (68.1 mV dec–1), suggesting that NixSy@MnOxHy/NF secures the fast reaction kinetics and outstanding inherent activity for OER, which enables NixSy@MnOxHy/NF to outperform most reported non‐noble metal OER electrocatalysts (Table S1).

a LSV curves of NixSy/NF, MnOxHy/NF, NixSy@MnOxHy/NF, and RuO2/NF for OER in 1.0 M KOH electrolyte. b Comparison of OER activities for as-prepared electrocatalysts at different high current densities. c Corresponding Tafel plots of the electrocatalysts and RuO2/NF. d The estimated Cdl, e corresponding LSV curves normalized by ECSA, and f Nyquist plots at a potential of 1.53 V for the electrocatalysts. g Multi‐current process of NixSy@MnOxHy/NF at 50 mA cm–2 per stair from 50 to 500 mA cm–2. h Chronopotentiometry curves of NixSy/NF and NixSy@MnOxHy/NF at 100 mA cm–2. i Comparison of LSV curves for NixSy@MnOxHy/NF before and after the 5000‐cycle stability

Moreover, the electrochemical active surface area (ECSA), which has a linear relation with the double-layer capacitance (Cdl), is another important parameter to reflect the activities of electrocatalysts (Fig. S10). As shown in Fig. 5d, NixSy@MnOxHy/NF attains a larger Cdl (9.8 mF cm−2) than NixSy/NF (6.7 mF cm−2), MnOxHy/NF (6.9 mF cm−2), revealing that NixSy@MnOxHy/NF has the largest ECSA among as-synthesized electrocatalysts. In other words, more exposed active sites are available on the surface of NixSy@MnOxHy/NF, manifesting that the fabricated heterostructures are beneficial to creating more electrochemically accessible active sites [50, 51]. Moreover, the ECSA was utilized to calculate the intrinsic activity, and the corresponding LSV curves based on the specific current density (JECSA) are shown in Fig. 5e. Apparently, NixSy@MnOxHy/NF achieves the higher inherent OER activity than NixSy/NF and MnOxHy/NF, which can be ascribed to the synergy in the heterostructure interfaces. In addition, the EIS was conducted to further assess the electrode kinetics and electron transport capability of these samples. Their Nyquist plots (Fig. 5f) demonstrate that the charge‐transfer resistance (Rct) of NixSy@MnOxHy/NF is 2.3 Ω, smaller than those of NixSy/NF (5.8 Ω) and MnOxHy/NF (3.3Ω), signifying that NixSy@MnOxHy/NF owns an enhanced reaction kinetics toward OER, leading to the rapid electron transfer, guaranteed by the synergistic effect in heterostructures, which is consistent with the result of Tafel plots.

Stability is an important metric for examining commercial applications. Firstly, the multi‐current process of NixSy@MnOxHy/NF was studied to evaluate the robust stability (Fig. 5g). The current density started at 50 mA cm–2, while the potential responded fast and remained stable for 500 s. Then, the current density increased to 500 mA cm–2 with 50 mA cm–2 per stair. At last, when it went back to the initial 50 mA cm–2, it was still stable, manifesting the robust stability of NixSy@MnOxHy/NF, whereafter the chronopotentiometry was applied to compare the stabilities of NixSy/NF and NixSy@MnOxHy/NF (Fig. 5h). NixSy@MnOxHy/NF can almost maintain its potential at 100 mA cm–2 for 150 h, whereas the potential of NixSy/NF decreases by 130 mV within 120 h, which verifies that NixSy@MnOxHy/NF owns an excellent OER stability owing to the MnOxHy shell. In the literature, to evaluate the stability, most reported non‐noble metal OER electrocatalysts are usually characterized at low current densities (< 100 mA cm−2) or short test time (< 100 h), which is far away from commercial requirements. As can be seen, the stability of NixSy@MnOxHy/NF outperforms almost all of non‐noble metal OER electrocatalysts (Table S1). At the same time, the instability of NixSy and the high stability of NixSy@MnOxHy/NF under high anodic oxidized potentials prove that the MnOxHy as a protective shell can efficiently inhibit the electrochemical corrosion under high anodic oxidized potentials, leading to the remarkably improved OER stability. Hence, those results demonstrate the great potential of as‐prepared NixSy@MnOxHy/NF for large‐scale applications. Additionally, after 5000 cycles, the collected LSV curve of NixSy@MnOxHy/NF almost coincides with its initial curve (Fig. 5i), further confirming its consistent high OER durability.

3.3 Electrocatalytic HER Measurement

Apart from the OER performance, the HER performance of the electrocatalysts was also assessed in 1.0 M KOH electrolyte. Fig. 6a shows LSV curves of as-fabricated electrocatalysts and Pt/C/NF. As expected, the HER activity of NixSy@MnOxHy/NF is better than those of NixSy/NF and MnOxHy/NF, as well as close to that of Pt/C/NF, which is attributed to the synergistic effect enabled by the electronic interaction between NixSy and MnOxHy. Besides, NixSy@MnOxHy/NF requires overpotentials of 179 and 270 mV to achieve 10 and 100 mA cm–2, respectively, exhibiting efficient HER activity, which can compare favorably with most non-noble metal electrocatalysts for HER (Table S2). As shown in Fig. 6b, NixSy@MnOxHy/NF owns a smaller Tafel slope (95.1 mV dec–1) than those of NixSy/NF (106.4 mV dec–1) and MnOxHy/NF (111.5 mV dec–1), implying that NixSy@MnOxHy/NF possesses favorable reaction kinetics for HER.

a LSV curves and b the corresponding Tafel plots of NixSy/NF, MnOxHy/NF, NixSy@MnOxHy/NF, and Pt/C/NF for HER in 1.0 M KOH electrolyte. c The estimated Cdl, d corresponding LSV curves normalized by ECSA, and e Nyquist plots at a potential of -0.2 V for the electrocatalysts. f Chronopotentiometry curves of NixSy@MnOxHy/NF and NixSy/NF at 100 mA cm–2

The ECSA of NixSy@MnOxHy/NF is measured according to the Cdl (Figs. S11 and 6c). The Cdl of NixSy@MnOxHy/NF is 14.6 mF cm−2, larger than those of NixSy/NF (8.8 mF cm−2) and MnOxHy/NF (2.1 mF cm−2), which indicates that NixSy@MnOxHy/NF owns the largest ECSA with the most exposed active sites among as-prepared electrocatalysts. Subsequently, the JECSA is also evaluated to study the intrinsic activity. Fig. 6d demonstrates that NixSy@MnOxHy/NF possesses higher inherent activity than NixSy/NF and MnOxHy/NF, which is ascribed to the electronic coupling effect in the heterostructured NixSy@MnOxHy/NF. Furthermore, EIS was also used to study the electrode kinetics toward HER. As shown in Fig. 6e, NixSy@MnOxHy/NF exhibits smaller Rct (4.0 Ω) than NixSy/NF (5.0 Ω) and MnOxHy/NF (34.5 Ω), suggesting the rapid reaction kinetics of NixSy@MnOxHy/NF, in agreement with the result of Tafel plots. In addition, Fig. 6f shows the chronopotentiometry curves of NixSy@MnOxHy/NF and NixSy/NF at 100 mA cm–2. After 10 h, the potential of NixSy/NF increases by 20 mV, whereas the potential of NixSy@MnOxHy/NF can remain mostly unchanged for 100 h, testifying that due to the MnOxHy shell, NixSy@MnOxHy/NF owns excellent HER stability at high current densities, which surpasses most recently reported non‐noble metal HER electrocatalysts (Table S2).

3.4 Electrocatalytic Overall‐Water‐Splitting Measurement

Inspired by the outstanding OER and HER performance, NixSy@MnOxHy/NF as a bifunctional electrocatalyst was applied as both the anode and cathode for overall water splitting in 1.0 M KOH electrolyte (Fig. 7a). As shown in Fig. 7b, NixSy@MnOxHy/NF attains superior activity for overall water splitting with a low cell voltage of 1.530 V at 10 mA cm–2. Besides, it only needs cell voltages of 1.829 and 1.888 V to drive 100 and 200 mA cm–2, respectively. Fig. 7c shows its cell voltage can remain almost unchanged at the high current density of 100 mA cm–2 for 100 h. Besides, its chronoamperometry curve also indicates its excellent stability at the cell voltage of 1.83 V for 200 h (Fig. S12). Currently, many researchers reported their stability tests at low current densities, such as 10, 20, and 50 mA cm–2 [23, 25, 52]. However, such low current densities of water splitting are not significant enough to meet the practical applications. As a consequence, electrocatalytic activities at the high current density region (≥ 100 mA cm–2) are considered for possible industrial applications. The excellent stability at 100 mA cm–2 for NixSy@MnOxHy/NF testifies its potential industrial applications, outperforming almost all of the recently reported non‐noble metal electrocatalysts for overall water splitting (Table S3). Furthermore, the faradaic efficiency (FE) of NixSy@MnOxHy/NF was measured to assess the efficiency of H2 and O2 production via a simple drainage method (Fig. S13). Fig. 7d demonstrates the time-dependent volumes of H2 and O2 collected by the drainage method, and the corresponding volume ratio (2.04:1) of H2/O2 is very close to the theoretical volume ratio of 2:1, which indicates that NixSy@MnOxHy/NF has a high FE of almost 100% for overall water splitting. In addition, the overall-water-splitting activity of NixSy@MnOxHy/NF is compared with recently reported different non-noble metal bifunctional electrocatalysts at 10 and 100 mA cm–2 (Fig. 7e and Table S3), signifying that the bifunctional activity of NixSy@MnOxHy/NF outperforms those of most recently non-noble metal bifunctional electrocatalysts. The superior activity and stability with low price enable NixSy@MnOxHy/NF to become a potential candidate for large-scale applications.

a Schematic illustration of the two-electrode system for overall water splitting. b CV curve and c Chronopotentiometry curve of NixSy@MnOxHy/NF as both the anode and cathode for overall water splitting. d The time-dependent volume of H2 and O2 collected by the drainage method, and the corresponding volume ratio of H2/O2. e Comparison of cell voltages for recently different electrocatalysts (Table S3) at 10 and 100 mA cm–2.

3.5 High‐Performance Origination Analysis

To further investigate the origination of the high bifunctional activity and stability of NixSy@MnOxHy/NF, its anodic and cathodic composition and chemical valences after the stability test at 100 mA cm–2 for 100 h were analyzed by XRD and XPS. As shown in Fig. S14a, XRD patterns of initial NixSy@MnOxHy/NF and the corresponding anode and cathode exhibit that after the stability test, the peaks, related to Ni3S2, remain unaltered, while the peaks of NiS disappear, which implies that NiS may be unstable in both HER and OER processes or dissolved in the alkaline solution. Then, the Ni content of the electrolyte after the stability measurement was detected by ICP‐MS, and the corresponding result indicates almost no Ni content exits in the electrolyte. In the meantime, after NixSy@MnOxHy/NF was immersed in 1.0 M KOH electrolyte for 100 h, its XRD pattern (Fig. S14b) shows the existence of both NiS and Ni3S2. The above results testify that NiS may be transformed into amorphous Ni species (NiOxHy). Furthermore, high‐resolution XPS spectra (Fig. S15) of Ni 2p, Mn 2p, S 2p, and O 1s for the cathode and anode demonstrate that chemical valences of these elements can be stable even after the stability test, manifesting that Ni3S2 and MnOxHy maintain exceptionally long-term stability at high current densities. Therefore, it can be concluded that the MnOxHy as an efficient protective shell can dramatically enhance the stability at high current densities in HER and OER processes. Meanwhile, Ni3S2/NiOxHy@MnOxHy are applied as the electrocatalytic active phases to effectively facilitate the HER and OER processes.

4 Conclusions

In summary, 3D core‐shell NixSy@MnOxHy heterostructure nanorods were successfully grown on the surface of NF by a simple two‐step method of hydrothermal and electrodeposition process. The MnOxHy and NixSy are integrated to form heterostructures with enriched Mn–S bonds, leading to a strong electronic interaction. The synergistic effect between MnOxHy and NixSy efficiently accelerates the kinetics and enhances the charge transfer in HER and OER processes. Besides, the MnOxHy is applied as an efficient protective shell to remarkably improve the stability for water splitting. Moreover, the 3D nanorod structure is beneficial to exposing abundant active sites and accelerating the electrolyte access and bubbles diffusion. Therefore, as‐constructed NixSy@MnOxHy/NF exhibits outstanding bifunctional activity and stability for overall water splitting in alkaline solution, compared to recently reported non-noble metal electrocatalysts. For OER, NixSy@MnOxHy/NF only needs low overpotentials of 326 and 356 mV to afford 100 and 500 mA cm–2, respectively, with outstanding stability at 100 mA cm–2 for 150 h, while for HER, it can achieve 10 and 100 mA cm–2 at overpotentials of 179 and 270 mV, respectively. Moreover, it requires a low cell voltage of 1.529 V at 10 mA cm–2 for overall water splitting with excellent stability at 100 mA cm–2 for 100 h. Accordingly, such superior performance with low prices enables NixSy@MnOxHy/NF to become a promising candidate for large-scale applications. Furthermore, the interface engineering coupled with the shell-protection strategy sheds a light on developing highly efficient bifunctional electrocatalysts.

References

C.X. Zhao, J.N. Liu, J. Wang, D. Ren, B.Q. Li et al., Recent advances of noble-metal-free bifunctional oxygen reduction and evolution electrocatalysts. Chem. Soc. Rev. 50(13), 7745–7778 (2021). https://doi.org/10.1039/d1cs00135c

L. Yao, J. Lin, Y. Chen, X. Li, D. Wang et al., Supramolecular-mediated ball-in-ball porous carbon nanospheres for ultrafast energy storage. InfoMat (2021). https://doi.org/10.1002/inf2.12278

W.J. Jiang, T. Tang, Y. Zhang, J.S. Hu, Synergistic modulation of non-precious-metal electrocatalysts for advanced water splitting. Acc. Chem. Res. 53(6), 1111–1123 (2020). https://doi.org/10.1021/acs.accounts.0c00127

Z. Zhou, Z. Pei, L. Wei, S.L. Zhao, X. Jian et al., Electrocatalytic hydrogen evolution under neutral pH conditions: current understandings, recent advances, and future prospects. Energy Environ. Sci. 13(10), 3185–3206 (2020). https://doi.org/10.1039/d0ee01856b

J. Chen, H. Chen, T. Yu, R. Li, Y. Wang et al., Recent advances in the understanding of the surface reconstruction of oxygen evolution electrocatalysts and materials development. Electrochem. Energy Rev. 4, 566–600 (2021). https://doi.org/10.1007/s41918-021-00104-8

T. Zhao, Y. Wang, S. Karuturi, K. Catchpole, Q. Zhang et al., Design and operando/in situ characterization of precious-metal-free electrocatalysts for alkaline water splitting. Carbon Energy 2(4), 582–613 (2020). https://doi.org/10.1002/cey2.79

W. Zhang, Y. Chao, W. Zhang, J. Zhou, F. Lv et al., Emerging dual-atomic-site catalysts for efficient energy catalysis. Adv. Mater. 33(36), 2102576 (2021). https://doi.org/10.1002/adma.202102576

H. Wu, C. Feng, L. Zhang, J. Zhang, D.P. Wilkinson, Non-noble metal electrocatalysts for the hydrogen evolution reaction in water electrolysis. Electrochem. Energy Rev. 4, 473–507 (2021). https://doi.org/10.1007/s41918-020-00086-z

J.S. Chen, J. Ren, M. Shalom, T. Fellinger, M. Antonietti, Stainless steel mesh-supported NiS nanosheet array as highly efficient catalyst for oxygen evolution reaction. ACS Appl. Mater. Interfaces 8(8), 5509–5516 (2016). https://doi.org/10.1021/acsami.5b10099

M. Tong, L. Wang, P. Yu, C. Tian, X. Liu et al., Ni3S2 nanosheets in situ epitaxially grown on nanorods as high active and stable homojunction electrocatalyst for hydrogen evolution reaction. ACS Sustain. Chem. Eng. 6(2), 2474–2481 (2018). https://doi.org/10.1021/acssuschemeng.7b03915

W. Zhou, X.J. Wu, X. Cao, X. Huang, C. Tan et al., Ni3S2 nanorods/Ni foam composite electrode with low overpotential for electrocatalytic oxygen evolution. Energy Environ. Sci. 6(10), 2921–2924 (2013). https://doi.org/10.1039/C3EE41572D

C. Karakaya, N. Solati, U. Savacı, E. Keleş, S. Turan et al., Mesoporous thin-film NiS2 as an idealized pre-electrocatalyst for a hydrogen evolution reaction. ACS Catal. 10(24), 15114–15122 (2020). https://doi.org/10.1021/acscatal.0c03094

P. Wang, T. Wang, R. Qin, Z. Pu, C. Zhang et al., Swapping catalytic active sites from cationic Ni to anionic S in nickel sulfide enables more efficient alkaline hydrogen generation. Adv. Energy Mater. 12(8), 2103359 (2022). https://doi.org/10.1002/aenm.202103359

Y. Wang, W. Qiu, E. Song, F. Gu, Z. Zheng et al., Adsorption-energy-based activity descriptors for electrocatalysts in energy storage applications. Natl. Sci. Rev. 5, 327–341 (2017). https://doi.org/10.1093/nsr/nwx119

Q. Xiong, Y. Wang, P.F. Liu, L.R. Zheng, G. Wang et al., Cobalt covalent doping in MoS2 to induce bifunctionality of overall water splitting. Adv. Mater. 30(29), 1801450–1801456 (2018). https://doi.org/10.1002/adma.201801450

H. Su, S. Song, S. Li, Y. Gao, L. Ge et al., High-valent bimetal Ni3S2/Co3S4 induced by Cu doping for bifunctional electrocatalytic water splitting. Appl. Catal. B Environ. 293, 120225 (2021). https://doi.org/10.1016/j.apcatb.2021.120225

T. Tang, W.J. Jiang, S. Niu, N. Liu, H. Luo et al., Electronic and morphological dual modulation of cobalt carbonate hydroxides by Mn doping toward highly efficient and stable bifunctional electrocatalysts for overall water splitting. J. Am. Chem. Soc. 139(24), 8320–8328 (2017). https://doi.org/10.1021/jacs.7b03507

T. Wu, E. Song, S. Zhang, M. Luo, C. Zhao et al., Engineering metallic heterostructure based on Ni3N and 2M-MoS2 for alkaline water electrolysis with industry-compatible current density and stability. Adv. Mater. 34(9), 2108505 (2021). https://doi.org/10.1002/adma.202108505

P. Wang, J. Qi, C. Li, X. Chen, T. Wang et al., N-doped carbon nanotubes encapsulating Ni/MoN heterostructures grown on carbon cloth for overall water splitting. ChemElectroChem 7(3), 745–752 (2020). https://doi.org/10.1002/celc.202000023

Y. Guo, P. Yuan, J. Zhang, H. Xia, F. Cheng et al., Co2P–CoN double active centers confined in N-doped carbon nanotube: heterostructural engineering for trifunctional catalysis toward HER, ORR, OER, and Zn–air batteries driven water splitting. Adv. Funct. Mater. 28(51), 1805641 (2018). https://doi.org/10.1002/adfm.201805641

L. Zhang, C. Lu, F. Ye, R. Pang, Y. Liu et al., Selenic acid etching assisted vacancy engineering for designing highly active electrocatalysts toward the oxygen evolution reaction. Adv. Mater. 33(14), 2007523–2007533 (2021). https://doi.org/10.1002/adma.202007523

J. Duan, S. Chen, C.A. Ortiz-Ledon, M. Jaroniec, S.Z. Qiao, Phosphorus vacancies that boost electrocatalytic hydrogen evolution by two orders of magnitude. Angew. Chem. Int. Ed. 59(21), 8181–8186 (2020). https://doi.org/10.1002/anie.201914967

P. Wang, J. Zhu, Z. Pu, R. Qin, C. Zhang et al., Interfacial engineering of Co nanoparticles/Co2C nanowires boosts overall water splitting kinetics. Appl. Catal. B Environ. 296, 120334 (2021). https://doi.org/10.1016/j.apcatb.2021.120334

S. Riyajuddin, K. Azmi, M. Pahuja, S. Kumar, T. Maruyama et al., Super-hydrophilic hierarchical Ni-foam-graphene-carbon nanotubes-Ni2P-CuP2 nano-architecture as efficient electrocatalyst for overall water splitting. ACS Nano 15(3), 5586–5599 (2021). https://doi.org/10.1021/acsnano.1c00647

Q. Zhang, W. Xiao, W.H. Guo, Y.X. Yang, J.L. Lei et al., Macroporous array induced multiscale modulation at the surface/interface of Co(OH)2/NiMo self-supporting electrode for effective overall water splitting. Adv. Funct. Mater. 31(33), 2102117 (2021). https://doi.org/10.1002/adfm.202102117

S. Jin, Are metal chalcogenides, nitrides, and phosphides oxygen evolution catalysts or bifunctional catalysts? ACS Energy Lett. 2(8), 1937–1938 (2017). https://doi.org/10.1021/acsenergylett.7b00679

N. Kornienko, N. Heidary, G. Cibin, E. Reisner, Catalysis by design: development of a bifunctional water splitting catalyst through an operando measurement directed optimization cycle. Chem. Sci. 9(24), 5322–5333 (2018). https://doi.org/10.1039/c8sc01415a

X. Wang, W. Li, D. Xiong, D.Y. Petrovykh, L. Liu, Bifunctional nickel phosphide nanocatalysts supported on carbon fiber paper for highly efficient and stable overall water splitting. Adv. Funct. Mater. 26(23), 4067–4077 (2016). https://doi.org/10.1002/adfm.201505509

X. Li, G.Q. Han, Y.R. Liu, B. Dong, W.H. Hu et al., NiSe@NiOOH core–shell hyacinth-like nanostructures on nickel foam synthesized by in situ electrochemical oxidation as an efficient electrocatalyst for the oxygen evolution reaction. ACS Appl. Mater. Interfaces 8(31), 20057–20066 (2016). https://doi.org/10.1021/acsami.6b05597

J. Deng, D. Deng, X. Bao, Robust catalysis on 2D materials encapsulating metals: concept, application, and perspective. Adv. Mater. 29(43), 1606967–1606989 (2017). https://doi.org/10.1002/adma.201606967

P. Wang, Y. Luo, G. Zhang, M. Wu, Z. Chen et al., MnOx-decorated nickel-iron phosphides nanosheets: interface modifications for robust overall water splitting at ultra-high current densities. Small 18(7), 2105803 (2022). https://doi.org/10.1002/smll.202105803

J. Deng, P. Ren, D. Deng, X. Bao, Enhanced electron penetration through an ultrathin graphene layer for highly efficient catalysis of the hydrogen evolution reaction. Angew. Chem. Int. Ed. 54(7), 2100–2104 (2015). https://doi.org/10.1002/anie.201409524

P. Wang, J. Qi, C. Li, W. Li, T. Wang et al., Hierarchical CoNi2S4@NiMn-layered double hydroxide heterostructure nanoarrays on superhydrophilic carbon cloth for enhanced overall water splitting. Electrochim. Acta 345, 136247–136257 (2020). https://doi.org/10.1016/j.electacta.2020.136247

Y. Hao, Y. Li, J. Wu, L. Meng, J. Wang et al., Recognition of surface oxygen intermediates on NiFe oxyhydroxide oxygen-evolving catalysts by homogeneous oxidation reactivity. J. Am. Chem. Soc. 143(3), 1493–1502 (2021). https://doi.org/10.1021/jacs.0c11307

K. Zhu, X. Zhu, W. Yang, Application of in situ techniques for the characterization of NiFe-based oxygen evolution reaction (OER) electrocatalysts. Angew. Chem. Int. Ed. 58(5), 1252–1265 (2018). https://doi.org/10.1002/anie.201802923

F. Song, L. Bai, A. Moysiadou, S. Lee, C. Hu et al., Transition metal oxides as electrocatalysts for the oxygen evolution reaction in alkaline solutions: an application-inspired renaissance. J. Am. Chem. Soc. 140(25), 7748–7759 (2018). https://doi.org/10.1021/jacs.8b04546

B. Zhang, Y. Li, M. Valvo, L. Fan, Q. Daniel et al., Electrocatalytic water oxidation promoted by 3D nano-architectured turbostratic δ-MnOx on carbon nanotube. Chemsuschem 10(22), 4472–4478 (2017). https://doi.org/10.1002/cssc.201700824

X. Long, Z. Chen, M. Ju, M. Sun, L. Jin et al., TM LDH meets birnessite: a 2D–2D hybrid catalyst with long-term stability for water oxidation at industrial operating conditions. Angew. Chem. Int. Ed. 60(17), 9699–9705 (2021). https://doi.org/10.1002/anie.202016064

N.K. Chaudhari, H. Jin, B. Kim, K. Lee, Nanostructured materials on 3D nickel foam as electrocatalysts for water splitting. Nanoscale 9(34), 12231–12247 (2017). https://doi.org/10.1039/C7NR04187J

N. Jiang, Q. Tang, M. Sheng, B. You, D. Jiang et al., Nickel sulfides for electrocatalytic hydrogen evolution under alkaline conditions: a case study of crystalline NiS, NiS2, and Ni3S2 nanoparticles. Catal. Sci. Technol. 6(4), 1077–1084 (2016). https://doi.org/10.1039/C5CY01111F

L. Zhang, Y. Zheng, J. Wang, Y. Geng, B. Zhang et al., Ni/Mo bimetallic-oxide-derived heterointerface-rich sulfide nanosheets with Co-doping for efficient alkaline hydrogen evolution by boosting volmer reaction. Small 17(10), 2006730 (2021). https://doi.org/10.1002/smll.202006730

J. Yuan, X. Cheng, H. Wang, C. Lei, S. Pardiwala et al., A superaerophobic bimetallic selenides heterostructure for efficient industrial-level oxygen evolution at ultra-high current densities. Nano-Micro Lett. 12, 104 (2020). https://doi.org/10.1007/s40820-020-00442-0

X. Luo, P. Ji, P. Wang, R. Cheng, D. Chen et al., Interface engineering of hierarchical branched Mo-doped Ni3S2/NixPy hollow heterostructure nanorods for efficient overall water splitting. Adv. Energy Mater. 10(17), 1903891 (2020). https://doi.org/10.1002/aenm.201903891

J. Li, W. Xu, J. Luo, D. Zhou, D. Zhang et al., Synthesis of 3D hexagram-like cobalt-manganese sulfides nanosheets grown on nickel foam: a bifunctional electrocatalyst for overall water splitting. Nano-Micro Lett. 10, 6 (2017). https://doi.org/10.1007/s40820-017-0160-6

M.P. Suryawanshi, U.V. Ghorpade, S.W. Shin, U.P. Suryawanshi, H.J. Shim et al., Facile, room temperature, electroless deposited (Fe1-x, Mnx)OOH nanosheets as advanced catalysts: the role of Mn incorporation. Small 14(30), 1801226–1801233 (2018). https://doi.org/10.1002/smll.201801226

H. Abe, A. Murakami, S. Tsunekawa, T. Okada, T. Wakabayashi et al., Selective catalyst for oxygen evolution in neutral brine electrolysis: an oxygen-deficient manganese oxide film. ACS Catal. 11(11), 6390–6397 (2021). https://doi.org/10.1021/acscatal.0c05496

B. Ravel, M. Newville, Athena, artemis, hephaestus: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Rad. 12, 537–541 (2005). https://doi.org/10.1107/S0909049505012719

F. Hartmann, M. Etter, G. Cibin, L. Liers, H. Terraschke et al., Superior sodium storage properties in the anode material NiCr2S4 for sodium-ion batteries: an X-ray diffraction, pair distribution function, and X-ray absorption study reveals a conversion mechanism via nickel extrusion. Adv. Mater. 33(44), 2101576 (2021). https://doi.org/10.1002/adma.202101576

H. Funke, A.C. Scheinost, M. Chukalina, Wavelet analysis of extended X-ray absorption fine structure data. Phys. Rev. B 71, 094110 (2005). https://doi.org/10.1103/PhysRevB.71.094110

Y. Wang, L. Yan, K. Dastafkan, C. Zhao, X. Zhao et al., Lattice matching growth of conductive hierarchical porous MOF/LDH heteronanotube arrays for highly efficient water oxidation. Adv. Mater. 33(8), 2006351–2006362 (2021). https://doi.org/10.1002/adma.202006351

S. Wang, P. Yang, X. Sun, H. Xing, J. Hu et al., Synthesis of 3D heterostructure Co-doped Fe2P electrocatalyst for overall seawater electrolysis. Appl. Catal. B Environ. 297, 120386–120396 (2021). https://doi.org/10.1016/j.apcatb.2021.120386

Z. Xu, S. Jin, M.H. Seo, X. Wang, Hierarchical Ni-Mo2C/N-doped carbon mott-schottky array for water electrolysis. Appl. Catal. B Environ. 292, 120168 (2021). https://doi.org/10.1016/j.apcatb.2021.120168

Acknowledgements

This work is supported by the Guangdong Basic and Applied Basic Research Foundation (2021A1515110859), the Research Fund Program of Key Laboratory of Fuel Cell Technology of Guangdong Province, the Natural Sciences and Engineering Research Council of Canada (NSERC), and Institut National de la Recherche Scientifique (INRS). The synchrotron research described in this paper was performed at the HXMA, SXRMB, and SGM beamline at the Canadian Light Source, which is financially supported by NSERC, CFI, the University of Saskatchewan, the Government of Saskatchewan, Western Economic Diversification Canada, the National Research Council of Canada, and the Canadian Institutes of Health Research. The authors thank Dr. N. Chen, Dr. M. Shakouri, and Dr. T. Regier at Canadian Light Source for their technical support.

Funding

Open access funding provided by Shanghai Jiao Tong University.

Author information

Authors and Affiliations

Corresponding authors

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, P., Luo, Y., Zhang, G. et al. Interface Engineering of NixSy@MnOxHy Nanorods to Efficiently Enhance Overall-Water-Splitting Activity and Stability. Nano-Micro Lett. 14, 120 (2022). https://doi.org/10.1007/s40820-022-00860-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40820-022-00860-2