Abstract

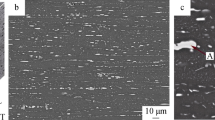

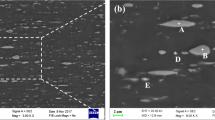

The effects of solution temperature and holding time on the microstructure, mechanical properties and surface morphology of 2A12 aluminum alloy sheets were discussed in this paper. The universal tensile tester was used to test the tensile strength and yield strength of aluminum alloy sheets with different treatment systems. The surface morphology of the alloy sheets was characterized by a white light interference profile scanner, and the microstructure of the sheets was characterized by optical microscope (OM), scanning electron microscope (SEM) and electron backscattered diffraction (EBSD). The results showed that the mechanical properties of the sheets could not satisfy GBT228.1-2010 national standard when the holding time was 10 min and the holding temperature was 475 °C. However, under the other heat treatment systems, the alloy could reach the GBT228.1-2010 national standard. Moreover, with the extension of the holding time, the part of the matrix gradually diffused into the aluminum-clad layer. When the holding time was shorter than 25 min, the boundary between the matrix and the aluminum-clad layer was relatively obvious. And the diffusion gradually became obvious when the holding time was over 25 min. Thereby, the boundary became blurry. The further investigation suggested that the solution temperature of 495 °C and the holding time of 35 min showed better mechanical properties and better surface morphology.

Graphic abstract

Similar content being viewed by others

References

Cam G, Selcuk M. Recent developments in friction stir welding of al-alloys. J Mater Eng Perform. 2014;23(6):1936.

Sanders RE. Technology innovation in aluminum products. JOM. 2001;53(2):21.

Liu CY, Teng GB, Ma ZY, Wei LL, Zhou WB, Huang HF, Qi HQ. Mechanical properties and thermal stability of 7055 Al alloy by minor Sc addition. Rare Met. 2020;39(6):725.

Kahveci AI. Processing and Properties of Spray Formed 2xxx Aluminum Alloys. Science and Technology of Rapid Solidification and Processing. Netherlands: Springer; 1995.

Poltavtseva M, Heyn A, Boese E. Long term corrosion behavior of clad aluminum materials under different atmospheric conditions. Mater Corros. 2013;64(8):723.

Masahashi N, Oku M, Watanabe S, Hanada S. Fabrication and corrosion properties of iron aluminum alloy/steel laminated composite prepared by clad rolling. Mater Sci Forum. 2007;539–543:866.

Jeong EW, Hui KN, Bae DH, Bae DS, Cho YR. Identification of the intermetallic compound layer formed at the interface of roll-bonded aluminum-clad steel by thermal annealing. Met Mater Int. 2014;20(3):499.

Hashimoto T, Zhang X, Zhou X, Skeldon P, Haigh SJ, Thompson GE. Investigation of dealloying of S phase (Al2CuMg) in AA 2024-T3 aluminium alloy using high resolution 2D and 3D electron imaging. Corros Sci. 2016;103:157.

Manurung CS, Napitupulu RA. In shielding gas effect to diffusion activities of magnesium and copper on aluminum clad. In: Materials Science and Engineering Conference Series, 2017; 012046.

Yamashita M, Mimaki T, Hashimoto S, Miura S. Intergranular corrosion of copper and α-Cu–Al alloy bicrystals. Philos Mag A. 1991;63(63):695.

Wang XD, Lin SP, Yang JJ, Tang ZL, Nie ZR. Microstructure and mechanical properties of Al–Mg–Mn alloy with erbium. Rare Met. 2012;31(3):237.

Shih HC, Ho NJ, Huang JC. Precipitation behaviors in Al–Cu–Mg and 2024 aluminum alloys. Metall Mater Trans A. 1996;27(9):2479.

Khan MK, Fitzpatrick ME, Hainsworth SV, Edwards L. Effect of tool profile and fatigue loading on the local hardness around scratches in clad and unclad aluminium alloy 2024. Mater Sci Eng A. 2009;527(1):297.

Khan MK, Hainsworth SV, Fitzpatrick ME, Edwards L. Application of the work of indentation approach for the characterization of aluminium 2024-T351 and Al cladding by nanoindentation. J Mater Sci. 2009;44(4):1006.

Sun S, Zhao Y, Zheng Q. Evolution mechnism of pitting of al clad 7075 and 2024 aluminium alloy in coastal environment. J Chin Soc Corros Protect. 2012;32(3):195.

Duquesnay DL, Underhill PR, Britt HJ. Fatigue failure of adhesively patched 2024-T3 and 7075-T6 clad and bare aluminium alloys. Fatigue Fract Eng Mater Struct. 2010;28(4):381.

Zhu BH, Xiong BQ, Zhang YA, Zhang JB, Wang F, Li ZH. Microstructure and properties characteristic during interrupted multi-step aging in Al–Cu–Mg–Ag–Zr alloy. Rare Metals. 2011;30(4):419.

Hinder SJ, Grilli R, Rustame M, Santos WIA, Costa I. A surface analytical investigation of cerium-based conversion coatings deposited onto an AA2024-T3 aluminium alloy cladding layer. Surf Interface Anal. 2015;46(10–11):735.

Huang HG, Dong YK, Yan M, Du FS. Evolution of bonding interface in solid–liquid cast-rolling bonding of Cu/Al clad strip. Trans Nonferrous Met Soc China. 2017;27(5):1019.

Liao B, Wu XD, Yan C-J, Liu Z, Ji YL, Cao LF, Huang GJ, Liu Q. Microstructure characterization of Al-cladded Al–Zn–Mg–Cu sheet in different hot deformation conditions. Trans Nonferrous Met Soc China. 2017;27(8):1689.

Huang CH, Wan MP, Yang M, Liang YL, Wen X, Zhao F. Effect of solid solution process on microstructure and properties of high strength and tough 211Z.X aluminum alloy. Chin J Rare Metals. 2019;43(8):816.

Halkaci HS, Turkoz M, Yiğit O. Effects of heat treatment conditions on the mechanical properties of AA 2024 alloy. Appl Mech Mater. 2012;217–219:1225.

Reis DAP, Couto AA, Domingues NI, Hirschmann AC, Zepka S, de Moura Neto C. Effect of artificial aging on the mechanical properties of an aerospace aluminum alloy 2024. Defect Diffus Forum. 2012;326–328:193.

Goodarzy MH, Arabi H, Boutorabi MA, Seyedein SH, Najafabadi SH. The effects of room temperature ECAP and subsequent aging on mechanical properties of 2024 Al alloy. J Alloys Compd. 2014;585:753.

Li YY, Zhang WW, Fei J, Zhang DT, Chen WP. Heat treatment of 2024/3003 gradient composite and diffusion behavior of the alloying elements. Mater Sci Eng A. 2005;391(1):124.

Khan MS, Salam A, Ikram N. Effect of cold work on the age hardening behaviour of 2014 Al alloy. Techn J Univ Eng Technol (UET). 2015;20:76.

Zhou J, Xu S, Huang S, Meng X, Sheng J, Zhang H, Li J, Sun Y, Boateng EA. Tensile properties and microstructures of a 2024-T351 aluminum alloy subjected to cryogenic treatment. Metals. 2016;6(11):279.

Wang GJ, Xiong BQ, Zhang YA, Li ZH. Elevated temperature endurance and creep properties of extruded 2D70 Al alloy rods. Rare Met. 2011;30(3):310.

De Groot P. The meaning and measure of vertical resolution in optical surface topography measurement. Appl Sci. 2017;7(1):54.

Abbasi M, Kheirandish S, Kharrazi Y, Hejazi J. The fracture and plastic deformation of aluminum alloyed Hadfield steels. Mater Sci Eng A. 2009;513–514:72.

Nakai M, Eto T. New aspect of development of high strength aluminum alloys for aerospace applications. Mater Sci Eng A. 2000;285(1):62.

Acknowledgements

This study was financially supported by the National Key R&D Program of China (No. 2016YFB0300800).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, S., Zhang, YA., Yan, LZ. et al. Microstructure and surface of 2A12 aluminum alloy cladded with pure aluminum after solution treatment. Rare Met. 40, 2937–2946 (2021). https://doi.org/10.1007/s12598-020-01521-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01521-2