Abstract

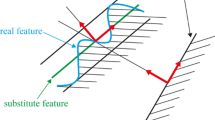

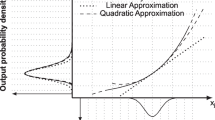

Tolerance analysis methods, which are important to achieve a balance between manufacturing costs and functional requirements, have been studied and improved over the last 30 years. This paper proposes a new method to improve the precision of assembly simulation for statistical assembly simulation; by investigating the effect of the geometric deviations and mechanical behaviors of assembly contact on the stack-up assembly deviation by combining the recent theories on the tolerance analysis of rigid bodies and local contact deformation. To improve the precision of the tolerance analysis, real parts with form defects were simulated with the help of non-nominal skin model shapes. The SMSs were first considered to be rigid, and a quadratic optimization-based method for the rigid body displacement was used to calculate the initial contact points of all the SMSs. Next, contact deformation, following Hertzian contact theory, occurred at the initial contact points, which changed the relative positions of the SMSs in the subsequent interactions. The iteration process was convergent, and the final simulation for tolerance analysis could be generated after several iterations. Case studies demonstrated the practicality of the proposed method. Their actual assembly deviations were simulated by combining the effects of geometric deviations and local surface deformations. Since the proposed tolerance analysis framework based on statistical assembly simulation, it is expected to control the functional requirements of mechanical assemblies with much rough tolerance design and help optimize the tolerance in the future.

Similar content being viewed by others

References

Kannan, S. M., & Pandian, G. R. (2020). A new selective assembly model for achieving specified tolerance in high precision assemblies. International Journal of Precision Engineering and Manufacturing, 21(7), 1217–1230.

Schleich, B., Anwer, N., Mathieu, L., & Wartzack, S. (2014). Skin model shapes: A new paradigm shift for geometric variations modelling in mechanical engineering. Computer-Aided Design, 50, 1–15. https://doi.org/10.1016/j.cad.2014.01.001

Polini, W. (2011). Geometric Tolerance Analysis. In B. M. Colosimo & N. Senin (Eds.), Geometric tolerances: Impact on product design, quality inspection and statistical process monitoring (pp. 39–68). London: Springer, London.

Yan, X., & Ballu, A. (2018). Review and comparison of form error simulation methods for computer-aided tolerancing. Journal of Computing and Information Science in Engineering. https://doi.org/10.1115/1.4041476

Requicha, A. A. G. (1983). Toward a theory of geometric tolerancing. The International Journal of Robotics Research, 2(4), 45–60. https://doi.org/10.1177/027836498300200403

Desrochers, A., & Clement, A. (1994). A dimensioning and tolerancing assistance model for CAD/CAM systems. The International Journal of Advanced Manufacturing Technology, 9(6), 352–361. https://doi.org/10.1007/BF01748479

Chase, K. W., Magleby, S. P., & Glancy, C. G. (1998). A comprehensive system for computer-aided tolerance analysis of 2-D and 3-D mechanical assemblies. In H. A. ElMaraghy (Ed.), Geometric design tolerancing: Theories, standards and applications (pp. 294–307). Boston, MA: Springer.

Mujezinović, A., Davidson, J. K., & Shah, J. J. (2002). A new mathematical model for geometric tolerances as applied to round faces. Journal of Mechanical Design, 124(4), 609–622. https://doi.org/10.1115/1.1497362

Bourdet, P., & Clement, A. (1988). A study of optimal-criteria identification based on the small-displacement screw model. Cirp Annals, 37(1), 503–506. https://doi.org/10.1016/S0007-8506(07)61687-4

Teissandier, D., Couétard, Y., & Gérard, A. (1999). A computer aided tolerancing model: Proportioned assembly clearance volume. Computer Aided Design, 31(13), 805–817. https://doi.org/10.1016/S0010-4485(99)00055-X

Giordano, M., Samper, S., & Petit, J.-P. (2007). Tolerance analysis and synthesis by means of deviation domains, Axi-Symmetric Cases. In J. K. Davidson (Ed.), Models for computer aided tolerancing in design and manufacturing. Dordrecht: Springer.

Homri, L., Goka, E., Levasseur, G., & Dantan, J. Y. (2017). Tolerance analysis — Form defects modeling and simulation by modal decomposition and optimization☆. Computer Aided Design, 91, 46–59. https://doi.org/10.1016/J.CAD.2017.04.007

Wilma, P., & Giovanni, M. (2015). Manufacturing signature for tolerance analysis. Journal of Computing and Information Science Engineering. https://doi.org/10.1115/1.4028937

Schleich, B., Anwer, N., Mathieu, L., & Wartzack, S. (2015). Contact and mobility simulation for mechanical assemblies based on skin model shapes. Journal of Computing and Information Science in Engineering. https://doi.org/10.1115/1.4029051

Schleich, B., & Wartzack, S. (2018). Novel approaches for the assembly simulation of rigid skin model shapes in tolerance analysis. Computer Aided Design, 101, 1–11.

Zhu, Z., Qiao, L., & Anwer, N. (2016). An improved tolerance analysis method based on skin model shapes of planar parts. Procedia Cirp, 56, 237–242. https://doi.org/10.1016/J.PROCIR.2016.10.072

Gupta, S., & Turner, J. U. (1993). Variational solid modeling for tolerance analysis. Ieee Computer Graphics and Applications, 13(3), 64–67. https://doi.org/10.1109/38.210493

Boyer, M., & Stewart, N. F. (1991). Modeling spaces for toleranced objects. The International Journal of Robotics Research, 10(5), 570–582. https://doi.org/10.1177/027836499101000512

Jeevanantham, A. K., Chaitanya, S. V., & Rajeshkannan, A. (2019). Tolerance analysis in selective assembly of multiple component features to control assembly variation using matrix model and genetic algorithm. International Journal of Precision Engineering and Manufacturing, 20(10), 1801–1815. https://doi.org/10.1007/s12541-019-00194-x

Sun, Y., Guo, J., Hong, J., Liu, G., Wu, W., & Yue, C. (2019). Repair decision based on sensitivity analysis for aero-engine assembly. International Journal of Precision Engineering and Manufacturing, 20(3), 347–362. https://doi.org/10.1007/s12541-019-00094-0

Chase, K. W., Gao, J., Magleby, S. P., & C D, . (1996). Sorensen including geometric feature variations in tolerance analysis of mechanical assemblies. Iie Transactions, 28(10), 795–807. https://doi.org/10.1080/15458830.1996.11770732

Wittwer, J. W., Chase, K. W., & Howell, L. L. (2004). The direct linearization method applied to position error in kinematic linkages. Mechanism and Machine Theory, 39(7), 681–693. https://doi.org/10.1016/J.MECHMACHTHEORY.2004.01.001

Salomons, O. W., Haalboom, F. J., Poerink, H. J. J., & F v Slooten F J A M v Houten H J J Kals, . (1996). A computer aided tolerancing tool II tolerance analysis. Computers In Industry, 31(2), 175–186. https://doi.org/10.1016/0166-3615(96)00047-4

Zeng, W., Rao, Y., Wang, P., & Yi, W. (2017). A solution of worst-case tolerance analysis for partial parallel chains based on the Unified Jacobian-Torsor model. Precision Engineering Journal of the International Societies for Precision Engineering and Nanotechnology, 47, 276–291. https://doi.org/10.1016/J.PRECISIONENG.2016.09.002

Laperrière, L., Ghie, W., & Desrochers, A. (2002). Statistical and deterministic tolerance analysis and synthesis using a unified Jacobian-Torsor model. Cirp Annals, 51(1), 417–420. https://doi.org/10.1016/S0007-8506(07)61550-9

Singh, G., Ameta, G., Davidson, J. K., & Shah, J. J. (2013). Tolerance analysis and allocation for design of a self-aligning coupling assembly using tolerance-maps. Journal of Mechanical Design. https://doi.org/10.1115/1.4023279

Homri, L., Teissandier, D., & Ballu, A. (2015). Tolerance analysis by polytopes: Taking into account degrees of freedom with cap half-spaces. Computer-Aided Design, 62, 112–130. https://doi.org/10.1016/j.cad.2014.11.005

Hong, Y. S., & Chang, T. C. (2002). A comprehensive review of tolerancing research. International Journal of Production Research, 40(11), 2425–2459. https://doi.org/10.1080/00207540210128242

Ameta, G., Serge, S., & Giordano, M. (2011). comparison of spatial math models for tolerance analysis: Tolerance-maps, deviation domain, and TTRS. Journal of Computing and Information Science in Engineering. https://doi.org/10.1115/1.3593413

Sun, Q., Zhao, B., Liu, X., Mu, X., & Zhang, Y. (2019). Assembling deviation estimation based on the real mating status of assembly. Computer Aided Design, 115, 244–255. https://doi.org/10.1016/J.CAD.2019.06.001

Zhang, Z., Zhang, Z., Jin, X., & Zhang, Q. (2018). A novel modelling method of geometric errors for precision assembly. The International Journal of Advanced Manufacturing Technology, 94, 1139–1160. https://doi.org/10.1007/S00170-017-0936-3

Jbira, I., Tlija, M., Louhichi, B., & Tahan, A. (2017). CAD/Tolerancing integration: Mechanical assembly with form defects. Advances in Engineering Software, 114, 312–324. https://doi.org/10.1016/J.ADVENGSOFT.2017.07.010

Liu, T., Pierre, L., Anwer, N., Cao, Y., & Yang, J. (2018). Form defects consideration in polytope based tolerance analysis. Journal of Mechanical Design. https://doi.org/10.1115/1.4041784

Korbi, A., Tlija, M., Louhichi, B., & BenAmara, A. (2018). CAD/tolerancing integration: A new approach for tolerance analysis of non-rigid parts assemblies. The International Journal of Advanced Manufacturing Technology, 98(5), 2003–2013. https://doi.org/10.1007/S00170-018-2347-5

Corrado, A., & Polini, W. (2018). FEA integration in the tolerance analysis using skin model shapes. Procedia Cirp, 75(1), 285–290. https://doi.org/10.1016/J.PROCIR.2018.04.055

Guo, J., Li, B., Liu, Z., Hong, J., & Wu, X. (2016). Integration of geometric variation and part deformation into variation propagation of 3-D assemblies. International Journal of Production Research, 54(19), 5708–5721. https://doi.org/10.1080/00207543.2016.1158881

Liu, J., Zhang, Z., Ding, X., & Shao, N. (2018). Integrating form errors and local surface deformations into tolerance analysis based on skin model shapes and a boundary element method. Computer Aided Design, 104, 45–59. https://doi.org/10.1016/J.CAD.2018.05.005

Shao, N., Ding, X., & Liu, J. (2020). Tolerance analysis of spur gears based on skin model shapes and a boundary element method. Mechanism and Machine Theory, 144, 103658. https://doi.org/10.1016/j.mechmachtheory.2019.103658

Yan, X., & Ballu, A. (2018). Tolerance analysis using skin model shapes and linear complementarity conditions. Journal of Manufacturing Systems, 48, 140–156. https://doi.org/10.1016/J.JMSY.2018.07.005

Zeng, W., & Rao, Y. (2019). Modeling of assembly deviation with considering the actual working Conditions. International Journal of Precision Engineering and Manufacturing, 20(5), 791–803. https://doi.org/10.1007/s12541-019-00014-2

Ballu, A., Mathieu, L., & Dantan, J.-Y. (2015). Formal language for geospelling. Journal of Computing and Information Science Engineering. https://doi.org/10.1115/1.4029216

Zhang, M. (2011). Discrete shape modeling for geometrical product specification: Contributions and applications to skin model simulation, École normale supérieure de Cachan - ENS Cachan, 10/17/2011.

Zhang, M., Anwer, N., Stockinger, A., Mathieu, L., & Wartzack, S. (2013). Discrete shape modeling for skin model representation. In: Proceedings of the institution of mechanical engineers, Part B: Journal of Engineering Manufacture. 227(5), 672–680.

Lorin, S. C., Lindkvist, L., & Söderberg, R. (2012). Simulating part and assembly variation for injection molded parts. In: Proceedings of the ASME 2012 international design engineering technical conferences and computers and information in engineering conference. Volume 5: 6th international conference on micro- and nanosystems; 17th design for manufacturing and the life cycle conference. Chicago, Illinois, USA. August 12–15, 2012. pp. 487–496.

Lindau, B., Andersson, A., Lindkvist, L., & Söderberg, R. (2012). Using forming simulation results in virtual assembly analysis. In: Proceedings of the ASME 2012 international mechanical engineering congress and exposition. Volume 3: Design, materials and manufacturing, Parts A, B, and C. Houston, Texas, USA. November 9–15, 2012. pp. 31–38.

Schleich, B., & Wartzack, S. (2015). Evaluation of geometric tolerances and generation of variational part representatives for tolerance analysis. The International Journal of Advanced Manufacturing Technology, 79(5), 959–983. https://doi.org/10.1007/S00170-015-6886-8

Yan, X., & Ballu, A. (2017). Generation of consistent skin model shape based on FEA method. The International Journal of Advanced Manufacturing Technology, 92(1), 789–802. https://doi.org/10.1007/S00170-017-0177-5

Johnson, K. L. (1987). Contact Mechanics. Cambridge: Cambridge University Press.

Yuan, Y., Xu, K., & Zhao, K. (2020). The loading-unloading model of contact between fractal rough surfaces. International Journal of Precision Engineering and Manufacturing, 21, 1047–1063.

Yastrebov, V. A., Anciaux, G., & Molinari, J.-F. (2015). From infinitesimal to full contact between rough surfaces: Evolution of the contact area. International Journal of Solids and Structures, 52, 83–102. https://doi.org/10.1016/J.IJSOLSTR.2014.09.019

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51505254, 51975326), the Science, Technology and Innovation Commission of Shenzhen Municipality (JCYJ20180301171337648) and the Fundamental Research Funds of Shandong University (2018JC041).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, S., Hu, T. & Xiong, Z. Precision Assembly Simulation of Skin Model Shapes Accounting for Contact Deformation and Geometric Deviations for Statistical Tolerance Analysis Method. Int. J. Precis. Eng. Manuf. 22, 975–989 (2021). https://doi.org/10.1007/s12541-021-00505-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-021-00505-1