Abstract

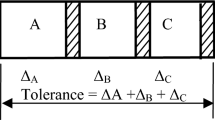

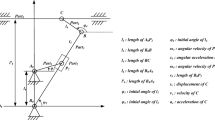

A product may consist of two or more components being assembled together. The geometrical and dimensional tolerances (GDT) present in each feature of the components influence the performance of the assembly. Their accumulation and propagation on assembly fit can be investigated by tolerance analysis. However, during the high precision assembly manufacturing, especially in the selective assembly process, only the dimensional deviations of mating components are considered to evaluate the assembly fit. In this paper, the assembly fits in selective assembly due to GDT of an individual feature of components, is modelled by the matrix method of tolerance analysis. Based on the principles of Technologically and Topologically Related Surfaces and Minimum Geometric Datum Elements, a worst case tolerance analysis is applied into the selective assembly. The conventional method of dividing the components into groups (bins) by dimensional deviation is replaced by integrated GDT. The best combination of components to obtain minimum assembly variation is achieved through a genetic algorithm. The proposed method is demonstrated using a two-dimensional valvetrain assembly that consists of camshaft, tappet, and valve-stem. The effect of considering and annulling the GDT in selective assembly is verified up to 20 numbers of group size.

Similar content being viewed by others

References

Fischer, B. R. (2011). Mechanical tolerance stackup and analysis. Boca Raton: CRC Press.

Schleich, B., & Wartzack, S. (2016). A quantitative comparison of tolerance analysis approaches for rigid mechanical assemblies. Procedia CIRP, 43, 172–177.

Zhu, Z., & Qiao, L. (2015). Analysis and control of assembly precision in different assembly sequences. Procedia CIRP, 27, 117–123.

Corrado, A., & Polini, W. (2017). Manufacturing signature in jacobian and torsor models for tolerance analysis of rigid parts. Robotics and Computer-Integrated Manufacturing, 46, 15–24.

Schleich, B., Anwer, N., Mathieu, L., & Wartzack, S. (2014). Skin model shapes: A new paradigm shift for geometric variations modelling in mechanical engineering. CAD Computer-Aided Design, 50, 1–15.

Colosimo, B. M., & Senin, N. (2010). Geometric tolerances: Impact on product design, quality inspection and statistical process monitoring. London: Springer.

Armillotta, A. (2013). A method for computer-aided specification of geometric tolerances. CAD Computer-Aided Design, 45(12), 1604–1616.

Schleich, B., & Wartzack, S. (2015). Evaluation of geometric tolerances and generation of variational part representatives for tolerance analysis. International Journal of Advanced Manufacturing Technology, 79(5–8), 959–983.

Wang, W. M., Li, D. B., He, F., & Tong, Y. F. (2018). Modelling and optimization for a selective assembly process of parts with non-normal distribution. International Journal of Simulation Modelling, 17(1), 133–146.

Glukhov, V. I., & Shalay, V. V. (2017). The provision of clearances accuracy in piston—Cylinder mating. AIP Conference Proceedings, 1876(1), 20078.

Chu, X., Xu, H., Wu, X., Tao, J., & Shao, G. (2018). The method of selective assembly for the RV reducer based on genetic algorithm. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 232(6), 921–929.

Liu, S., & Liu, L. (2017). Determining the number of groups in selective assembly for remanufacturing engine. Procedia Engineering, 174, 815–819.

Bartkowiak, T., & Gessner, A. (2016). Coordinate measurement-based mating surfaces model and its application for selective assembly of machine tools. In Proceedings of the sixth international conference on structural engineering, mechanics and computation, 5–7 September 2016, Cape Town, South Africa, 2016, no. September (pp. 1790–1796).

Lu, C., & Fei, J.-F. (2014). An approach to minimizing surplus parts in selective assembly with genetic algorithm. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 229(3), 508–520.

Tan, M. H. Y., & Wu, C. F. J. (2012). Generalized selective assembly. IIE Transactions, 44(1), 27–42.

Mease, D., Nair, V. N., & Sudjianto, A. (2004). Selective assembly in manufacturing: Statistical issues and optimal binning strategies. Technometrics, 46(2), 165–175.

Marziale, M., & Polini, W. (2011). Review of variational models for tolerance analysis of an assembly. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 225(3), 305–318.

Peng, H., & Lu, W. (2017). Three-dimensional assembly tolerance analysis based on the Jacobian–Torsor statistical model. In 3 rd international conference on mechatronics mechanical engineering (ICMME 2016). Shanghai, China, Oct. 21–23, 2016 (Vol. 07007, pp. 1–5).

Wu, Y. (2015). Assembly tolerance analysis method based on the real machine model with three datum planes location. Procedia CIRP, 27, 47–52.

Corrado, A., Polini, W., & Moroni, G. (2017). Manufacturing signature and operating conditions in a variational model for tolerance analysis of rigid assemblies. Research in Engineering Design, 28(4), 529–544.

Zeng, W., Rao, Y., Wang, P., & Yi, W. (2017). A solution of worst-case tolerance analysis for partial parallel chains based on the unified Jacobian–Torsor model. Precision Engineering, 47, 276–291.

Marziale, M., & Polini, W. (2009). A review of two models for tolerance analysis of an assembly: Vector loop and matrix. International Journal of Advanced Manufacturing Technology, 43(11–12), 1106–1123.

Marziale, M., & Polini, W. (2010). Tolerance analysis: A new model based on variational solid modelling. In ASME 10th biennial conference on engineering systems design and analysis, 2010 (pp. 383–392).

Marziale, M., & Polini, W. (2011). A review of two models for tolerance analysis of an assembly: Jacobian and torsor. International Journal of Computer Integrated Manufacturing, 24(1), 74–86.

Polini, W. (2011). Geometric tolerance analysis. In B. M. Colosimo & N. Senin (Eds.), Geometric tolerances: Impact on product design, quality inspection and statistical process monitoring (pp. 39–68). London: Springer.

Polini, W. (2012). Taxonomy of models for tolerance analysis in assembling. International Journal of Production Research, 50(7), 2014–2029.

Polini, W., & Corrado, A. (2016). Geometric tolerance analysis through Jacobian model for rigid assemblies with translational deviations. Assembly Automation, 36(1), 72–79.

Schleich, B., Anwer, N., Zhu, Z., Qiao, L., Mathieu, L., & Wartzack, S. (2014). A comparative study on tolerance analysis approaches. In Proceedings international symposium on robust design—ISoRD14 (pp. 29–39).

Prisco, U., & Giorleo, G. (2002). Overview of current CAT systems: Review article. Integrated Computer-Aided Engineering, 9(4), 373–387.

Shen, Z., Ameta, G., Shah, J. J., & Davidson, J. K. (2005). A comparative study of tolerance analysis methods. Journal of Computing and Information Science in Engineering, 5(3), 247–256.

Yan, H., Wu, X., & Yang, J. (2015). Application of Monte Carlo method in tolerance analysis. Procedia CIRP, 27, 281–285.

Kannan, S. M., Jeevanantham, A. K., & Jayabalan, V. (2008). Modelling and analysis of selective assembly using Taguchi’s loss function. International Journal of Production Research, 46(15), 4309–4330.

Zhang, Y., & Fang, X. D. (1999). Predict and assure the matchable degree in selective assembly via PCI-based tolerance. Journal of Manufacturing Science and Engineering, 121(3), 494–500.

Salomons, O. W., Haalboom, F. J., Jonge Poerink, H. J., Van Slooten, F., Van Houten, F. J. A. M., & Kals, H. J. J. (1996). A computer aided tolerancing tool II: Tolerance analysis. Computers in Industry, 31(2), 175–186.

Desrochers, A., & Maranzana, R. (1996). Constrained dimensioning and tolerancing assistance for mechanisms. In Computer-aided tolerancing, 1996 (pp. 17–30).

Desrochers, A., & Rivibret, A. (1997). A matrix approach to the representation of tolerance zone and clearances. The International Journal of Advanced Manufacturing Technology, 13, 630–636.

ISO 8015. (2011). Geometrical product specifications (GPS)—Fundamentals—Concepts, principles and rules.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jeevanantham, A.K., Chaitanya, S.V. & Rajeshkannan, A. Tolerance Analysis in Selective Assembly of Multiple Component Features to Control Assembly Variation Using Matrix Model and Genetic Algorithm. Int. J. Precis. Eng. Manuf. 20, 1801–1815 (2019). https://doi.org/10.1007/s12541-019-00194-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00194-x