Abstract

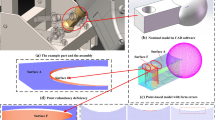

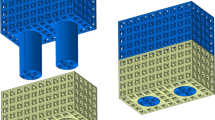

Controlling product geometric quality is an important issue, because real parts deviate from their nominal value (e.g., in form, orientation, and position error of features, size of part, etc.). To analyze the influence of these deviations on final product, one solution is to consider the nonnominal Skin Model Shape to simulate assembly, manufacturing, or metrology. The modeling of nonnominal parts is still in its initial phases. First, methods of generating a single feature with deviations are reviewed and classified. With the combination of the single nonideal features to obtain the complete nonideal model of the part, geometrical issues appear, such as gaps and self-intersections. These can be influenced by acute and obtuse angles and the ratio between mesh size and deviation value. From an analysis of these issues, two deviation combination methods are proposed to preserve the manufacturing deviation of features and consistency of the model. These methods are qualified as local and global methods. The local method is based on the iterative calculation of mesh regularization. The global method is based on finite element analysis, with manufacturing deviations added to the nominal model by the penalty function approach. The effectiveness and efficiency of both kinds of method are compared on a trial geometry. The global method is preferred as it needs no iterative calculation, no stop criteria and gives better results. Finally, the proposed method is validated on a more complex mechanical part: a cutter body.

Similar content being viewed by others

Reference

Chen H, Jin S, Li Z, Lai X (2014) A comprehensive study of three dimensional tolerance analysis methods. Comput Aided Des 53:1–13. doi:10.1016/j.cad.2014.02.014

Ameta G, Serge S, Giordano M (2011) Comparison of spatial math models for tolerance analysis: tolerance-maps, deviation domain, and TTRS. J Comput Inf Sci Eng 11:21004

Requicha AAG (1983) Toward a theory of geometric tolerancing. Int J Robot Res 2:45–60. doi:10.1177/027836498300200403

Wirtz A (1993) Vectorial tolerancing: a basic element for quality control. 3rd CIRP

Geis A, Husung S, Oberänder A et al (2015) Use of vectorial tolerances for direct representation and analysis in CAD-systems. Procedia CIRP 27:230–240. doi:10.1016/j.procir.2015.04.071

Desrochers A, Clément A (1994) A dimensioning and tolerancing assistance model for CAD/CAM systems. Int J Adv Manuf Technol 9:352–361

Clément A, Desrochers A, Riviere A (1991) Theory and Practice of 3-D Tolerancing for Assembly. École de technologie supérieure

Teissandier D, Couetard Y, Gérard A (1999) A computer aided tolerancing model: proportioned assembly clearance volume. Comput Aided Des 31:805–817

Teissandier D, Couetard Y, Delos V (1999) Operations on polytopes: application to tolerance analysis. Glob. Consistency Toler. Springer, In, pp 425–434

Davidson JK, Mujezinović A, Shah JJ (2002) A new mathematical model for geometric tolerances as applied to round faces. J Mech Des 124:609. doi:10.1115/1.1497362

Schleich B, Anwer N, Zhu Z, et al (2014) Comparative Study on Tolerance Analysis Approaches. Int. Symp. Robust Des. ISoRD14

Mathieu L, Ballu A (2007) A model for a coherent and complete tolerancing process. In: Davidson JK (ed) Models Comput. Aided Toler. Des. Manuf. Springer Netherlands, Dordrecht, pp 35–44

Ballu A, Mathieu L, Dantan J-Y (2015) Formal language for GeoSpelling. J Comput Inf Sci Eng 15:21009. doi:10.1115/1.4029216

Hu YZ, Tonder K (1992) Simulation of 3-D random rough surface by 2-D digital filter and fourier analysis. Int J Mach Tools Manuf 32:83–90. doi:10.1016/0890-6955(92)90064-N

Yastrebov VA, Anciaux G, Molinari J-F (2015) From infinitesimal to full contact between rough surfaces: evolution of the contact area. Int J Solids Struct 52:83–102. doi:10.1016/j.ijsolstr.2014.09.019

Wilma P, Giovanni M (2015) Manufacturing signature for tolerance analysis. J Comput Inf Sci Eng 15:21005

Yanlong C, Bo L, Xuefeng Y et al (2015) Geometrical simulation of multiscale Toleranced surface with consideration of the tolerancing principle. J Comput Inf Sci Eng 15:21006

Franciosa P, Gerbino S, Patalano S (2011) Simulation of variational compliant assemblies with shape errors based on morphing mesh approach. Int J Adv Manuf Technol 53:47–61. doi:10.1007/s00170-010-2839-4

Huang W, Kong Z (2008) Simulation and integration of geometric and rigid body kinematics errors for assembly variation analysis. J Manuf Syst 27:36–44. doi:10.1016/j.jmsy.2008.06.004

Ballu A, Mathieu L (1996) Univocal expression of functional and geometrical tolerances for design, manufacturing and inspection. In: Kimura F (ed) Comput.-aided Toler. Springer Netherlands, Dordrecht, pp 31–46

ISO 17450–1:2011 Geometric product specification—general concepts—part 1: model for geometrical specification and verification

Anwer N, Ballu A, Mathieu L (2013) The skin model, a comprehensive geometric model for engineering design. CIRP Ann-Manuf Technol 62:143–146

Schleich B, Anwer N, Mathieu L, Wartzack S (2014) Skin model shapes: a new paradigm shift for geometric variations modelling in mechanical engineering. Comput Aided Des 50:1–15. doi:10.1016/j.cad.2014.01.001

Zhang M, Anwer N, Stockinger A et al (2013) Discrete shape modeling for skin model representation. Proc Inst Mech Eng Part B J Eng Manuf 227:672–680. doi:10.1177/0954405412466987

Henke RP, Summerhays KD, Baldwin JM et al (1999) Methods for evaluation of systematic geometric deviations in machined parts and their relationships to process variables. Precis Eng 23:273–292

Schleich B, Wartzack S, Anwer N, Mathieu L (2015) Skin model shapes: offering new potentials for modelling product shape variability. In: ASME 2015 Int. Des. Eng. Tech. Conf. Comput. Inf. Eng. Conf. American Society of Mechanical Engineers, p V01AT02A015–V01AT02A015

Wang H, Li G, Zhong Z (2008) Optimization of sheet metal forming processes by adaptive response surface based on intelligent sampling method. J Mater Process Technol 197:77–88. doi:10.1016/j.jmatprotec.2007.06.018

Hu M, Lin Z, Lai X, Ni J (2001) Simulation and analysis of assembly processes considering compliant, non-ideal parts and tooling variations. Int J Mach Tools Manuf 41:2233–2243

Blackmore D, Leu M, Wang LP (1997) The sweep-envelope differential equation algorithm and its application to NC machining verification. Comput Aided Des 29:629–637. doi:10.1016/S0010-4485(96)00101-7

Lee S-K, Ko S-L (2002) Development of simulation system for machining process using enhanced Z map model. J Mater Process Technol 130:608–617

Lin Y, Shen Y-L (2004) Enhanced virtual machining for sculptured surfaces by integrating machine tool error models into NC machining simulation. Int J Mach Tools Manuf 44:79–86. doi:10.1016/j.ijmachtools.2003.08.003

Movahhedy M, Gadala MS, Altintas Y (2000) Simulation of the orthogonal metal cutting process using an arbitrary Lagrangian–Eulerian finite-element method. J Mater Process Technol 103:267–275

Soori M, Arezoo B, Habibi M (2014) Virtual machining considering dimensional, geometrical and tool deflection errors in three-axis CNC milling machines. J Manuf Syst 33:498–507. doi:10.1016/j.jmsy.2014.04.007

Spence AD, Abrari F, Elbestawi MA (2000) Integrated solid modeller based solutions for machining. Comput Aided Des 32:553–568. doi:10.1016/S0010-4485(00)00042-7

Altintas Y, Kersting P, Biermann D et al (2014) Virtual process systems for part machining operations. CIRP Ann - Manuf Technol 63:585–605. doi:10.1016/j.cirp.2014.05.007

Zhang M, Anwer N, Mathieu L, Zhao H (2011) A discrete geometry framework for geometrical product specifications. Proc. 21st CIRP Des. Conf. Kaist MK Thompson Ed Pap

Wagersten O, Lindau B, Lindkvist L, Söderberg R (2014) Using morphing techniques in early variation analysis. J Comput Inf Sci Eng 14:11007

Das A, Franciosa P, Williams D, Ceglarek D (2016) Physics-driven shape variation modelling at early design stage. Procedia CIRP 41:1072–1077. doi:10.1016/j.procir.2016.01.031

Formosa F, Samper S (2007) Modal expression of form defects. In: Models Comput. Aided Toler, Des. Manuf. Springer, pp 13–22

Kingslake R, Shannon RR (1992) Basic wavefront aberration theory for optical metrology. Appl. Opt. Opt. Eng. Vol 11

Yan X, Ballu A (2016) Toward an automatic generation of part models with form error. Procedia CIRP 43:23–28. doi:10.1016/j.procir.2016.02.109

Jin S, Lewis RR, West D (2005) A comparison of algorithms for vertex normal computation. Vis Comput 21:71–82. doi:10.1007/s00371-004-0271-1

Chen C-Y, Cheng K-Y (2008) A sharpness-dependent filter for recovering sharp features in repaired 3D mesh models. Vis Comput Graph IEEE Trans On 14:200–212

Ju T (2009) Fixing geometric errors on polygonal models: a survey. J Comput Sci Technol 24:19–29

Yang L, Yan Q, Xiao C (2016) Shape-controllable geometry completion for point cloud models. Vis Comput. doi:10.1007/s00371-016-1208-1

Ballu A, Yan X, Blanchard A et al (2016) Virtual metrology laboratory for e-learning. Procedia CIRP 43:148–153. doi:10.1016/j.procir.2016.02.110

Ohtake Y, Belyaev A, Bogaevski I (2001) Mesh regularization and adaptive smoothing. Comput Aided Des 33:789–800. doi:10.1016/S0010-4485(01)00095-1

Riehl S, Steinmann P (2015) A staggered approach to shape and topology optimization using the traction method and an evolutionary-type advancing front algorithm. Comput Methods Appl Mech Eng 287:1–30. doi:10.1016/j.cma.2015.01.007

Yamauchi H, Lee S, Lee Y, et al (2005) Feature sensitive mesh segmentation with mean shift. In: Shape Model. Appl. 2005 Int. Conf. IEEE, pp 236–243

Kobbelt L, Campagna S, Vorsatz J, Seidel H-P (1998) Interactive multi-resolution modeling on arbitrary meshes. In: Proc. 25th Annu. Conf. Comput. Graph. Interact. Tech. ACM, pp 105–114

Ait-Ali-Yahia D, Baruzzi G, Habashi WG et al (2002) Anisotropic mesh adaptation: towards user-independent, mesh-independent and solver-independent CFD. Part II. Structured grids. Int J Numer Methods Fluids 39:657–673

Blom FJ (2000) Considerations on the spring analogy. Int J Numer Methods Fluids 32:647–668. doi:10.1002/(SICI)1097-0363(20000330)32:6<647::AID-FLD979>3.0.CO;2-K

Zeng D, Ethier CR (2005) A semi-torsional spring analogy model for updating unstructured meshes in 3D moving domains. Finite Elem Anal Des 41:1118–1139. doi:10.1016/j.finel.2005.01.003

Amirante D, Hills NJ, Barnes CJ (2012) A moving mesh algorithm for aero-thermo-mechanical modelling in turbomachinery. Int J Numer Methods Fluids 70:1118–1138

Hsu S-Y, Chang C-L (2007) Mesh deformation based on fully stressed design: the method and 2-D examples. Int J Numer Methods Eng 72:606–629

Zienkiewicz OC, Taylor RL, Zienkiewicz OC, Taylor RL (1977) The finite element method. McGraw-hill London

Zeng P (2007) Fundamentals of finite element analysis. Tsinghua University Press, Beijing

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This work was supported by the China Scholarship Council.

Rights and permissions

About this article

Cite this article

Yan, X., Ballu, A. Generation of consistent skin model shape based on FEA method. Int J Adv Manuf Technol 92, 789–802 (2017). https://doi.org/10.1007/s00170-017-0177-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0177-5