Abstract

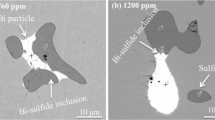

This work aims to comprehensively summarize the types and distribution of the isolated Bi particles and MnS inclusions in the Bi-bearing steels, to study the precipitated behavior of sulfide, and to study the effect of Bi particles on grain sizes and the volume thermal expansion coefficients of the steels. Results show that the average percentage of the isolated Bi particles, semi-encapsulation, complete encapsulation, back-bridge, tiny encapsulation, cavity bridge Bi–MnS inclusions in the Bi-bearing steels was 16.89%, 20.49%, 3.44%, 16.89%, 31.63%, 10.66%, respectively. The average equivalent diameters of the grains in the 0 ppm, 130 ppm, 240 ppm, 760 ppm, 1200 ppm and 2300 ppm Bi content steels were 20.88, 20.17, 19.54, 18.13, 13.98 and 13.25 μm, respectively. The precipitated equilibrium mass concentration product of the MnS (w[Mn]·w[S]) was calculated to be 1.07, and the solid fraction fS value was 0.61. At 950 °C, the volume thermal expansion coefficient change (ΔVE) in 760 ppm Bi content steel was minimum 4 × 10–10%, while at 461.6 °C the ΔVE was maximum, 0.09%, which means that Bi affected the volume thermal expansion of the steel strongest in this temperature range.

Graphic Abstract

Similar content being viewed by others

Change history

16 December 2021

A Correction to this paper has been published: https://doi.org/10.1007/s12540-021-01150-z

References

F.Y. Huang, Y.H. Frank, J.C. Kuo, Met. Mater. Int. 24, 1333 (2018)

J.B. Xie, J. Li, Z.W. Li, L.P. Wu, P.P. Zhang, J.X. Fu, Ironmak. Steelmak. (2020) https://doi.org/10.1080/03019233.2020.1845566

H. Yaguchi, Mater. Sci. Technol. 5, 255 (1989)

T. Akasawa, H. Sakurai, M. Nakamura, T. Tanaka, K. Takano, J. Mater. Process. Tech. 143–144, 66 (2003)

N.E. Luiz, R. Machado, P. I. Mech. Eng. B J. Eng. 222, 347 (2008)

G. Bernsmann, M. Bleymeh, R. Ehl, A. Hassler, Stahl Eisen 12, 87 (2001)

H. Pray, H. Peoples, F.W. Fink, Proc. ASTM 41, 646 (1941)

J.B. Xie, T. Fan, Z.Q. Zeng, H. Sun, J.X. Fu, J. Mater. Res. Technol. 9, 9142(2020)

Z. Li, D. Wu, J. Mater. Sci. Technol. 26, 839 (2010)

H.B. Peng, Y. Tang, Y.M. Zhang, X. Wang, C. Zhou, T. Indian I. Metals 73, 873 (2020)

H.T. Liu, W.Q. Chen, Ironmak. Steelmak. 41, 355 (2014)

H.T. Liu, W.Q. Chen, Ironmak. Steelmak. 41, 19 (2014)

H.T. Liu, W.Q. Chen, W. Li, Y. Yu, High Temp. Mater. Proc. 33, 187 (2014)

J.B. Xie, D.L. Hu, J.X. Fu, H. Liu, Ironmak. Steelmak. 46, 542 (2019)

J.B. Xie, L.P. Wu, X.Y. Wu, J.X. Fu, Emerg. Mater. Res. 9, 1145 (2020)

J.B. Xie, D. Zhang, Q.K. Yang, J.M. An, Z.Z. Huang, J.X. Fu, Ironmak. Steelmak. 46, 564 (2019)

Z.X. Li, C.S. Li, S.H. Kim, D.W. Suh, Met. Mater. Int. 25, 9 (2019)

J.R. Weeks, Am. Soc. Metals, Trans. Quant. 58, 302 (1965)

O. Kubaschewski, Iron-Binary Phase Diagrams (Springer, Berlin, 1982)

A.S. Chaus, ISIJ Int. 45, 1297 (2005)

Acknowledgements

This work appreciates the fund of National Natural Science Foundation of China (52074179).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: In the original publication of the article, in Table 1 the Al and O contents are incorrect and they have been corrected.

Rights and permissions

About this article

Cite this article

Xie, Jb., Liu, Bb., Wu, Xy. et al. Distribution of Bi–MnS Inclusions Existing in 1215MS Steels: Correlation with Thermal Physical Coefficient. Met. Mater. Int. 28, 1306–1313 (2022). https://doi.org/10.1007/s12540-021-01097-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01097-1