Abstract

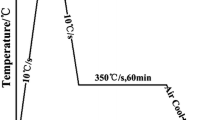

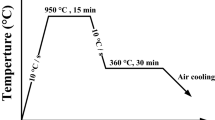

In the free-cutting field, Bi-bearing steel is widely concerned because it supplies the parts for instruments. This work aims to explore the forms of Bi particles existing in 1215MS steel and to detect the effect of Bi on the grain size and thermal expansion performance of steel by heat treatment and thermal expansion experiments with a thermal expansion instrument and a box type electric resistance furnace. Results show that both co-existence of the Bi-MnS inclusions and the isolated Bi particles merely existed in the austenite grain boundary of steel. The higher Bi content in steel is helpful to refine the austenite grain size of as-cast steel. When the austenite grain sizes were in the range of 0~5 μm, the normalized frequency of grains in 0, 130, 240 and 760 ppm Bi content steels was 0.014~0.042, while the normalized frequency in 1200 and 2300 ppm Bi content steels was 0.45 and 0.23, respectively. With adding Bi to steel, the net elongation curves of the Bi-bearing steels showed the upward convex peaks in cooling process. Liquid Bi inhibited the volume shrinkage of heated steel, showing the abnormal expansion phenomenon of Bi.

Similar content being viewed by others

Change history

07 February 2022

A Correction to this paper has been published: https://doi.org/10.1007/s11665-021-06509-2

References

N.E. Luiz and R. Machado, Development Trends and Review of Free-Machining Steels, J. Eng. Manuf., 2008, 222(2), p 347–360.

G. Bernsmann, M. Bleymeh and R. Ehl, Making of Free-Cutting Steels with Additions of Lead, Bismuth, Tellurium, Selenium Tin. Stahl Eisen, 2001, 12(2), p 87–91.

F.Y. Huang, Y.H. Frank and J.C. Kuo, High-Temperature Deformation Behavior of MnS in 1215MS Steel, Met. Mater. Int., 2018, 24(6), p 1333–1345.

H. Pray, H. Peoples and F.W. Fink, Addition of Bismuth for Producing Free-Machining Stainless Steel, Proc. ASTM, 1941, 41, p 646–655.

Chinese Official Baidu Bai-ke Website: https://baike.baidu.com/item/%E5%8F%8D%E5%B8% B8%E8%86%A8%E8%83%80/868743?fr=aladdin

T. Akasawa, H. Sakurai and M. Nakamura, Effects of Free-Cutting Additives on the Machinability of Austenitic Stainless Steels, J. Mater. Process. Technol., 2003, 143–144(8), p 66–71.

H. Yaguchi, Effect of Soft Additives (Pb/Bi) on Machinability of Low Carbon Re-sulfurized Free Machining Steels, Mater. Sci. Technol., 1989, 5(3), p 255–267.

J.B. Xie, J. Li, Z.W. Li and J.X. Fu, Forms of Bi Sulphide in 1215MS Steel Related to Machining and Mechanical Performance, Ironmak. Steelmak., 2020, p 1–10.

J.B. Xie, T. Fan, Z.Q. Zeng and J.X. Fu, Bi-Sulfide Existence in 0Cr18Ni9 Steel: Correlation with Machinability and Mechanical Properties, J. Mater. Res. Technol., 2020, 9(4), p 9142–9152.

Z. Li and D. Wu, Effect of Free-Cutting Additives on Machining Characteristics of Austenitic Stainless Steels, J. Mater. Sci. Technol., 2010, 26(9), p 839–844.

J.H. Wang, J.L. Li and X.P. Su, Influence of Melting Temperature and Cooling Rate on Microstructure of a Bismuth-Manganese-Iron Alloy, Mater. Manuf. Process., 2014, 29(2), p 175–183.

H.B. Peng, Y. Tang and Y.M. Zhang, Effect of MnS and Its Size on the Heterogeneous Nucleation and Precipitation of Bismuth in Steel, Trans. Indian Ins. Met., 2020, 73, p 873–879.

H.T. Liu and W.Q. Chen, Research on Recovery for Adding Low-Melting Point Metal Bismuth to Eco-Friendly Bi-S Based Free Cutting Steel, Ironmak. Steelmak., 2014, 41(5), p 355–359.

H.T. Liu and W.Q. Chen, Hot Ductility of Eco-Friendly Low Carbon Resulphurised Free Cutting Steel with Bismuth, Ironmak. Steelmak., 2014, 41(1), p 19–25.

Z.X. Li, C.S. Li, S.H. Kim, S.H. Kim and D.W. Suh, Influence of Initial Pearlite Morphology on the Microstructure Evolution during Heat Treatment of 1.0C–1.5Cr Steel, Met. Mater. Int., 2019, 25, p 9–17.

J.B. Xie, L.P. Wu, X.Y. Wu and J.X. Fu, Morphology and Composition Characteristics of Solid Solution in Te-Treated Y1Cr17 Steel, Emerg. Mater. Res., 2020, 9(4), p 1145–1153.

J.B. Xie, D. Zhang, Q.K. Yang, Z.Z. Huang, J.M. An and J.X. Fu, Exploration of Morphology Evolution of the Inclusions in Mg-Treated 16MnCrS5 Steel, Ironmak. Steelmak., 2019, 46(6), p 564–573.

J.B. Xie, D.L. Hu, H. Liu and J.X. Fu, Numerical Analysis of Effect of the Solutes on Formation of MnS in Non-tempered Steel, Ironmak. Steelmak., 2019, 46(6), p 542–549.

F. Tsukihashi, A. Suzuki and N. Sano, Activity Coefficient of Bismuth and Lead in Carbon Saturated Iron, Steel Res. Int., 1996, 67(2), p 35–38.

S. Dinda and W.R. Warke, Effect of Grain Boundary Segregation on Liquid Metal Induced Embrittlement of Steel, Mater. Sci. Eng., 1976, 24, p 199–208.

J.R. Weeks, The Solubility of Fe in Liquid Bi, Trans. ASM, 1965, 58, p 302–305.

O. Kubaschewski, Iron-Binary Phase Diagrams, Springer, Berlin Heidelberg GmbH, 1982.

S.A. Chaus, Application of Bismuth for Solidification Structure Refinement and Properties Enhancement in As-Cast High-Speed Steels, Trans. Iron Steel Ins. Jpn., 2006, 45(9), p 1297–1306.

Acknowledgments

This work appreciates the fund of National Natural Science Foundation of China (52074179).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: In the originally published article, the Al and O contents in Table 1 were listed incorrectly.

Rights and permissions

About this article

Cite this article

Xie, Jb., Hu, T., Zhong, Lm. et al. Bismuth Existing in 1215MS Steel Affecting Grain Size and Thermal Expansion. J. of Materi Eng and Perform 30, 7943–7949 (2021). https://doi.org/10.1007/s11665-021-06036-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06036-0