Abstract

Foodborne illnesses occur due to contamination by pathogenic microorganisms. Therefore, decontaminating food is vital before marketing and circulation. Radio frequency (RF) heating stands out in several branches of industry, mainly food processing, as an alternative method to conventional pasteurization which takes long process times and overheating. RF heating functions without relying on heat conduction. It generates internal heat by inducing the rotation of polar molecules and the motion of ions. The advantages of dielectric heating with greater wave penetration include rapid, uniform and volumetric heating, presenting high energy efficiency. Furthermore, it is an effective, validated method for eliminating pathogens in agricultural products and is free from chemical residues. Although many reviews have discussed this technology, few reviews have covered the research trends in this field in the recent years, during which the number of studies discussing RF treatment of foods have increased. Therefore, this review focuses on the RF applications in the food industry for pest control, microbial and enzymatic inactivation of solid, liquid, and powdered foods in the last five years. Besides covering the fundamental aspects of RF technology, we also examine its benefits and drawbacks, address the challenges it presents, and explore future prospects

Graphical Abstract

Similar content being viewed by others

Introduction

The expansion of formulation engineering within the food processing industry, coupled with the demand for diversified food products, has spurred significant advancements in the food ingredients market. Many of these ingredients are manufactured in a powdered form, underscoring the vital role of powder processing technology for both food producers and food ingredient manufacturers [1]. Powdered foods have low bulk weight, making transportation and storage easier [2]. Furthermore, reducing moisture content reduces the rate of quality degradation. Food powders have low water activity (aw) with values equal to or less than 0.7 [3]. In this sense, it was expected that powdered foods would be safe from a microbiological point of view. Later, researchers reported that rehydrating powdered foods contaminated with microorganisms helped repair lesions from the spores resulting in deadly Enterococcus outbreaks in powdered milk [4]. Contaminated food powder retards microbial growth. However, microorganisms survive for a long time. Thus, sterilization techniques aimed to inactivate microbial cells in solid and liquid foods through denaturation of DNA at 71.06 °C for 15 s followed by drying with hot air at 135 to 205 °C for 5–6 s [5]. Nevertheless, the elevated temperatures used in traditional treatments, while effective in deactivating microorganisms, can result in changes to the sensory qualities and nutritional attributes of powdered substances. These alterations may include the degradation of vitamins, flavor, volatile oils, and bioactive properties.

Commercial pasteurization by conventional heating for liquid foods reduces microorganism counts and inactivates undesirable enzymes [6]. Through the mechanisms of conduction and convection, heat is transferred from the external environment to the interior of the food. However, the treatment requires long process times and can cause overheating [7]. Furthermore, fouling in the heat exchanger due to high temperature impacts to a reduction in food quality. Therefore, avoiding fouling in equipment that leads to overheating or insufficient heating is a disadvantage of pasteurization process.

For solid and semi-solid foods, conventional heat treatments based on exposure to hot air and humidity transmit insufficient thermal energy to reach the core of the product. Surface exposure of food to heat causes cracks in addition to ineffective treatment of the core, leading to degradation of product quality [8]. Particulate foods such as grains and seeds (oilseeds, cereals, and nuts) are heat treated using dry heat, hot water, or steam. However, the short period of time can be ineffective, damaging the vigor of the seeds. On the other hand, the long heating time reduces the sensory quality of the food [9]. Seeds treated by chemical methods, including fungicides such as methyl bromide and phosphine may contain residues of these reagents. Furthermore, the use of fungicides can lead to increased resistance of the pest or pathogen [10]. Additionally, gases originating from the chemical method damage electrical equipment and destroy the ozone layer when in contact with the atmosphere. In this sense, the search for food decontamination technologies that maintain nutritional quality and sensory properties has become the focus of research in recent decades. Furthermore, issues related to food safety have triggered several emerging technologies, such as pulsed electric field [11], ozone processing [12], cold plasma [13], pulsed light [14], high pressure processing [15], microwave heating [16], infrared heating [17], ohmic heating [18], and radio frequency (RF) heating [19].

RF technology involves dielectric and electromagnetic heating with longer wavelength, resulting in deeper penetration [20]. The coupling of electromagnetic waves in food generates heat [21]. The alternating electric field applied to the dielectric material causes friction between the molecules due to the movement of ions and rotation of polarized molecules [22]. This friction generates heat inside the product and avoids limitations on the heat transfer rate. In RF heating, ionic conduction predominates, with charged ions exerting more influence on heat generation than water molecules. In food processing, RF applications include defrosting [23], disinfestation [10, 24], pasteurization/sterilization [25], drying [26], enzyme inactivation [27], improving gelling properties in foods [28], and modification of the internal structure of starch [29]. Additionally, volumetric heating caused by RF can substantially reduce the heat spent during food blanching [30, 31]. Moisture content influences the material behavior under RF processing: cellular tissues with higher humidity absorb more energy compared to tissues with lower humidity. In this way, moisture leveling through RF heating promotes uniform drying [32].

Although some recent reviews have widely discussed the RF technology [33,34,35,36], to the authors’ knowledge there are no reviews addressing trends in the last five years on the RF applications in the food industry for pest control, microbial and enzymatic inactivation of solid, liquid, and powdered foods. In this context, the aim of this review is to outline the foundational aspects of RF technology and its evolving applications in food decontamination, addressing its advantages and disadvantages, along with the challenges and prospects for expanding the technology.

Fundamentals of Radio Frequency Technology

The application of RF is a widely disseminated technology in the telecommunications area. Its use in the heating field began at the end of the 19th century. Exploration in the food processing sector for blanching, dehydrating, defrosting, and cooking began in the mid-20th century [25]. In the 1960s, industrial production lines for defrosting vegetables and meat products began to spread RF technology [37]. Advancements in thermal processing studies are increasingly apparent due to the progress in computational technology and the enhancement of dielectric performance and temperature sensors, all contributing to the evolution of RF applications.

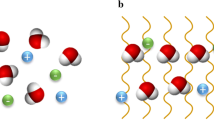

RF is defined as a non-ionizing wave that acts at specific frequencies of 13.56, 27.12, and 40.68 MHz with a wavelength of 22.1, 11.1, and 7.4 m respectively. Industrial, scientific, and medical use requires specific frequencies. The Federal Communications Commission has permitted the use of radio frequencies for heating at 13.56, 27.12 and 40.68 MHz to prevent RF interference in other areas, such as cellular telecommunications [7]. The thermal and electrical properties of a material placed in contact with an alternating electric field change due to this interaction [38]. The positive ions will move close to the negative pole of the electromagnetic field and vice versa, resulting in the phenomenon of ionic migration or conduction as illustrated in Fig. 1a. Furthermore, the effects of friction will generate heat in the dipole molecules that are rotating. These inverted movements occur thousands of times per second during the oscillation of the magnetic field. The collision of ions inside the material and the friction between the dipole molecules reflect on RF heating, as shown in Fig. 1b, c.

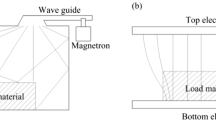

Figure 2 displays a schematic representation of an RF emitting equipment. The electromagnetic waves have the ability to penetrate dielectric materials and induce heating throughout space, through polarization processes ionic or dipole rotation [10, 39]. Compared to microwaves, radio waves have greater penetration depth due to their long wavelength. RF heating is generated by a standard oscillatory circuit and an automatic impedance matching system can assist in maintaining the circuit impedance [9]. Consequently, coupling power stability can be maintained during warm-up while maintaining a fixed frequency and controlling feedback. It is important to highlight that the moisture content of the material is the factor that most influences the dielectric properties [40]. Likewise, it contributes to improving heating uniformity during the RF process.

The dielectric properties of materials describe their interaction with an alternating electric field and quantify their ability to reflect, store, and transmit electromagnetic energy. They are expressed as the complex permittivity, ε = ε′ − jε″. The real component, ε′, corresponds to the dielectric constant, representing the energy storage capacity of the electric field by the material. The imaginary component, ε″, represents the dielectric loss factor, which is related to the dissipation of electric field energy in the form of heat [41]. The penetration depth comprises the distance from the surface of a dielectric material, at which the incident power is reduced to 1/e (e ≈ 2.718) of the original power, while electromagnetic waves propagate through this dielectric material [25]. Equation (1) describes the depth of penetration.

where dp - depth of penetration (m), c - Speed of light in vacuum (3 × 108 m s−1), and f - Frequency (Hz).

A signal analyzer connected to a sample holder by a probe provides the real and imaginary impedance values from which the dielectric properties of the material are computed [42]. When measuring dielectric properties using LCR [(Inductance (L), Capacitance (C), Resistance (R)] meters and impedance analyzers, a small voltage is applied to the ends of the target sample, which allows detection of the current passing through the food [43]. For values in the range 1–300 MHz, an LCR meter (5 Hz–3 GHz) [44] or impedance analyzer (20 Hz–3 GHz) [45] can provide accurate results. Spectrum/lattice/vector analyzers determine dielectric properties for high frequencies, in the range 30 kHz–8.5 GHz [46]. However, there is lower accuracy for products with low moisture content. These analyzers record the phase and amplitude of a reflected wave signal coming from a sample of material. The attenuation and phase change of the signal are measured and interpreted to obtain the dielectric properties of the material [47,48,49]. Dielectric properties can be determined by transmission and resonance. Transmission using an open coaxial probe sweeps microwave frequency. However, the technique lacks precision in measuring low loss factors [50]. The technique involves immersing the probe in a liquid or in contact with the flat face of the solid material (or powder). The measurement of the reflected signal is related to complex permittivity. A typical measurement system involves a vector network analyzer, a coaxial probe, and permittivity determination software. On the other hand, the resonance technique presents greater precision in determining dielectric properties and dielectric loss [51, 52]. Resonance can be promoted by the metal walls of a cavity or achieved by the dielectric sample. A dielectric sample inside a cavity disturbs its electromagnetic field, changing the resonance frequency and quality factor. The advantages of the technique involve easy preparation, measurement, and calculation of dielectric properties [50]. As disadvantages, the reproducibility of the test may be compromised due to the small size of the sample in relation to the cavity, as well as each frequency evaluated requires a different cavity [53].

Applications in Food Processing

This section covers the application of the RF technology to control pest in food grains, reduce microbial populations in liquids and powders, and inactivate enzymes in solid, liquid, and powdered foods, although RF energy also has other applications such as cooking [54], thawing [55], drying [56], roasting [57], and pre-treatment for vegetable oil extraction [58].

Pest Control

Pest cause post-harvest losses of up to 20% in oilseeds worldwide [59]. In this sense, RF heating is an alternative to chemical fumigations, helping to control pest in food grains [60]. Furthermore, environmental concerns, the organic food market and pest resistance to chemicals have pressured the industry to develop non-chemical treatments to promote disinfestation. Additionally, synthetic chemicals carry risks to human health through product contamination.

Table 1 presents studies of food grain disinfections by RF heating. Appugol et al. [59] reported the effect of RF on peanut quality and peanut oil to promote complete mortality of Caryedon serratus. Treatment at 89.96 °C reduced the moisture content from 7.45 to 2.11% and the protein content from 22.17 to 20.94% without changing the color of the product. Furthermore, the oil extraction yield increased by 18.97% after treatment, with improved composition through the reduction of saturated fatty acids and an increase in unsaturated fatty acids. Similarly, Indumathi et al. [61] evaluated the disinfestation of Tribolium castaneum (Herbst) semolina using 40.68 MHz, 10 kW RF heating. Treatment with 8 min of exposure was sufficient to disinfest 100% of T. castaneum in semolina, achieving 100% mortality at 64.4 °C. To the authors, RF technology is a promising and ecological technology for promoting grain disinfestation.

Weevil mortality at 50 °C was investigated using pilot-scale RF at 12 kW and 27.12 MHz [62]. The 10 kg batch was heated in 2.72 min, while the 20 kg batch only took 1.29 min to reach 50 °C, demonstrating rapid heating volumetric. Uniform indices close to zero were obtained for both batches. Similarly Hou et al. [63] reported RF technology as a post-harvest physical insecticide for eliminating Rhyzopertha dominica insects in coix seeds. The authors studied different temperatures and times of the sample kept in ambient air inside the RF cavity. Energy efficiency occurred by heating the sample 50 °C by RF, keeping it 56.9 min in ambient air. Aiming for a short time process, just heating to 59 °C was sufficient without exposure to ambient air. The RF commercial system has been effective in eliminating R. dominica from rice. Hou et al. [64] reported that heating at 54 °C for 11 min was enough for pest mortality. The process yield was 594.8 kg h−1 with an electrical cost of US$ 2.53 per ton. Thus, these positive findings highlight RF as a non-chemical pest disinfectant in post-harvest grains.

Microbial Inactivation

Microbial decontamination by RF heating is based on the diffusion of heat at a faster rate within the cell of the microorganism compared to other means. The cells are thermally destroyed with a low heating rate [70]. The mode of RF heat transfer is radiation. In this way, microbial DNA and essential proteins absorb this energy, physically modifying the cellular structure and function of the microorganism [2]. The effect of RF heat treatment to reduce microbial population depends on the species, cell wall structure, RF frequency, and heating uniformity.

Table 2 shows the population reduction of microorganisms for various foods using RF technology. Liu et al. [71] studied low-temperature, long-term RF pasteurization of onion powder to evaluate the inactivation of Salmonella enterica. RF heating reached 66 °C in 180 s. After 38 h of treatment, there was a reduction in the microbial population of 3.4 log. Furthermore, the quality of the onion powder was not changed after the process. Although Salmonella is the indicator microorganism validating thermal pasteurization, several studies have reported Enterococcus faecium as a suitable substitute for pasteurizing spices and herbs [72,73,74]. In this sense, Wason et al. [75] evaluated RF pasteurization in packaging containing dried basil leaves for inactivation of Salmonella enterica and E. faecium. The Salmonella population was reduced by 4.58 ± 0.14 log, while E. faecium by 2.59 ± 0.46 log using RF treatment for 105 s vertically. After the process, the quality analysis demonstrated that there was no change in the color, total phenolic content and antioxidants of the product. In this context, RF pasteurization of a packaged product together with steam ventilation eliminates cross-contamination, improves heating uniformity, avoiding impacts on product quality.

Jeong et al. [76] reported the effect of rice milling degree on RF heating rate, inactivation of Salmonella Typhimurium and Staphylococcus aureus and change in color. Samples were heated from 0 to 75 s. The highest heating rate was observed for the 2% grinding grade. High values of pathogen reduction with the same degree of grinding and 75 s of treatment resulted in logarithmic reductions of > 6.09 and > 7.90 for Salmonella Typhimurium and Staphylococcus aureus, respectively. The color of the samples was not deteriorated by RF heating, regardless of the degree of grinding, with no significant effect. In another study, RF technology was evaluated in the pasteurization of egg white powder in continuous mode [77]. Thermal processing for 2 h at 80 °C showed a logarithmic reduction of > 6.69 for Salmonella and > 6.78 for E. faecium. The greater resistance and similar kinetics to Salmonella make E. faecium a potential surrogate microorganism for pathogen evaluation. For the authors, the validated thermal process can be expanded to the egg industry. Furthermore, the continuous process could process a larger quantity of products in a shorter time compared to stationary RF heating. Hot air, intermittent stirring, or electrode modifications can help improve the uniformity of continuous heating [92, 93].

Enzyme Inactivation

Enzymes are like biocatalysts that act in reactions in the metabolism and physiology of plants. However, their activities after harvest lead to food deterioration, through color change, generation of odors and nutritional loss [94]. In food grains, the most relevant enzyme is related to color change and the development of strange flavors due to contact with substrates such as lipids, polyphenols, and proteins [95]. Compared to disinfestation and pasteurization treatments, RF heating is rarely reported for enzyme inactivation.

Table 3 displays studies on enzyme inactivation by RF and their main findings. In general, studies compare RF with conventional hot water blanching and evaluate enzyme inactivation, texture, weight, vitamin C content, and electrolyte leakage. Yao et al. [96] observed a drop from 66.03 to 6.46% in the activity of the peroxidase enzyme by increasing the RF heating temperature from 65 to 85 °C in the treatment of lettuce stems. In another study, Yao et al. [97] combined steam-assisted RF blanching for application to lettuce cuboids. RF treatment at 80 °C followed by steam application for 1 min demonstrated excellent heating uniformity and sample quality, with a 95% reduction in peroxidase activity and retention of almost 80% of vitamin C.

Sun et al. [99] reported the effects of RF blanching and boiling water on the inactivation of the lipoxygenase enzyme, nutritional content, and grain morphology of sweet corn. RF heating from 50 to 80 °C reduced enzyme activity to 4.68%. Physicochemical properties such as color, texture, and nutrient content were better preserved compared to blanching in boiling water. According to the micrographs in Fig. 3, the increase in temperature during RF bleaching damaged the cells. On the other hand, hot water bleaching damaged cells more severely. Disruption of the cell wall exposed the cystic surfaces of the cells. This phenomenon is known as pectin depolymerization, responsible for the deterioration of the texture of foods and the softening of plant tissue during heat treatment [106, 107]. Yarrakula et al. [100] investigated lipase inactivation from pearl millet (Pennisetum glaucum L.) grains by combining hot air-assisted RF technology. Lipase activity was reduced to 2.7% with the sample 15% hydrated and processed for 15 min using a heating rate of 5.2 °C min−1. A longer period of exposure to the treatment as well as greater sample humidity improved the bonding properties. For the authors, the study adds value and promotes the use of underused gluten-free cereals due to rapid rancidity. Furthermore, pearl millet grains present nutritional and therapeutic benefits.

Adapted from Sun et al. [99], with permission from Elsevier

Micrographs of untreated and treated sweet corn by RF and boiling-water (BW).

Advantages and Disadvantages of Radio Frequency Technology

The use of RF has several distinct characteristics in contrast to conventional heat transfer and diffusion methods. To prevent Ohmic heating, it is crucial to ensure that the electrodes do not make direct contact with the food when employing RF heating units. This technology is suitable for both liquid and solid food products, and its wavelength exceeds that of microwave frequencies. Due to their greater power capacity, RF waves penetrate deeper into the material compared to conventional microwaves. Thus, heat is internally generated within the material, leading to a more even distribution. Furthermore, the construction of large-scale RF units is more convenient and contributes to improving the quality of the final product. Other notable advantages of this sustainable technology include increased energy efficiency, moisture leveling, contactless heating, and faster drying and curing times [108]. The operating and equipment costs compared to conventional heating systems are the disadvantages of the technology. The total costs of implementing RF technology can vary between 2500 and 6000 euros per installed kilowatt of RF power. The capital costs involved can be divided into: (1) energy generator – 20–30%; (2) applicator – >35%; (3) power transmission – 5–10%; (4) auxiliary instrumentation – 5–30%; (5) installation and startup – 5–15% [109]. However, considering that the cost per installed kilowatt of RF power decreases when the nominal plant power exceeds 12 kW, and considering that electricity to run a RF power can come from renewable sources at a competitive price, and taking into account the minimization of handling, RF technology is an attractive choice.

Challenges and Future Perspectives

Despite being in the market for an extended period, the adoption of the RF technology within the industry has progressed at a relatively modest pace. The design of RF heating systems is made complex by the requirement for comprehensive data on the dielectric properties of food products, as well as the dimensions, configurations, and placements of RF electrodes to achieve uniform temperature distribution [70]. Furthermore, the high intensity of the electric field in the sample causes a dielectric breakdown, causing destruction of the product or rupture of the packaging [110]. Moist foods with high salt content may exhibit non-uniform heating at the RF frequency, leading to product loss [111]. Controlled food thawing is difficult to achieve without other heat exchange mechanism able to mitigate possible run away heating zones [23]. Additionally, there are still some challenges such as analysis in real time, lack of data for comparison, high cost due to electricity, and difficulty in measuring temperature without contact in order to avoid interaction with the electromagnetic field [112].

A future of RF technology in the food industry cannot be imagined without the implementation of key-enabling technologies in this sector. Future research should focus on introducing in industrial applications the use of digital technology, computer simulation, and parameter evaluation. As variations in temperature, humidity, and electric field intensity inside materials are complex during RF drying, the use of online digital solutions for monitoring, and measurement is recommended. Computer simulation allows a quick and low-cost analysis, without environmental limitations. It helps in simulating and optimizing parameters to improve heating uniformity, often eliminating the need for a series of experiments [113].

Among the commercially accessible software for heat transfer and/or electromagnetic field displacement, many are based on finite element method, such as COMSOL Multiphysics [114] (an update of an early version called FEMLAB, which was used to develop and solve the first model of RF heating of food [115]), High-Frequency Structure Simulator (HFSS-ANSYS) [116], Quickwave 3D (QW3D) [117], and TLM-FOOD HEATING [118]. COMSOL Multiphysics software allows coupling different physical phenomena and it has been used to simulate RF heating behaviors through the concurrent solution of electromagnetic and heat transfer equations [119]. Model parameters such as top electrode voltage, thermal conductivity, heat transfer coefficients, and dielectric properties are entered before simulation. For each simulation, the model geometry is based on the sample and the RF heating unit. After solving the simulation, the average temperature and heating uniformity index are determined considering the volume, surface, and target point. Subsequently, validating the simulation model and its solution involves heating the samples at predetermined locations within the RF unit. Thus, there is an understanding of the influence of the shape and size of granular particles on the uniformity of RF heating [120]. Additionally, the simulation helps in selecting the packaging shape [121]. Huang et al. [122] used COMSOL software to simulate RF heating of insects in soybeans in the upper, middle, and lower layers of the container. Experimental validation using Indian moth larvae indicated a differential heating of 5.9–6.6 °C more than the host soybean when RF treatment occurred from 25 to 50 °C, demonstrating that the heating rate for insects was 1.4 times higher than for soybeans. The orientation of the insect body in the cold point of the layers, combined with its size, influences the heating inside its body.

Regarding industrial application, the ultimate objective of the research groups is the dissemination of the technology on a large scale. Efforts should/could be spent to integrate RF processing systems in power grid supplied by renewable energy, eventually to design and place on the market integrated RF systems, to be mounted on vehicles and transported and used even in rural areas, where eventually fast and reliable inactivation method is needed to prevent spoilage of agricultural products, preventing their possible infestations before selling the products. However, there are gaps between fundamental and industrial-scale research. Equipment maintenance is still a bottleneck for the adoption of RF technology. Additionally, service and maintenance contracts for RF equipment are expensive. The electric arc is another barrier found in industrial processing. Arcing in RF treatment is very common and several methods/algorithms have been implemented in hardware to avoid this phenomenon. However, most of them end up shutting down the RF system after a certain number of arcing events are encountered. This division makes it difficult to verify the integrity of the process.

Most studies have focused on the aspect of RF heating uniformity and electrode placement, etc. However, the area of dynamic impedance matching has not received as much attention, demonstrating opportunities to improve the technology. Likewise, future research should seek to simplify the structural design of RF generation and the cavity, aiming to reduce costs on an industrial scale [123]. The energy consumption and economic costs of an industrial technology are crucial factors and are ignored in fundamental research. Furthermore, the variation in sample volume alters the uniformity of heating and subsequent drying. Therefore, laboratory or pilot scale tests must be validated according to protocols to promote application, for example in the food industry.

Conclusion

In recent decades, researchers have explored emerging RF technology as a potential substitute for traditional heat treatment. Furthermore, there has been extensive documentation of the dielectric properties of various products. The non-uniformity of the product can often be the main limitation of the treatment as it reduces the quality of the product and reduces food safety, favoring the development of microorganisms. In this context, this review addressed application trends over the last five years, considering RF heating as a promising alternative for the food industry. Studies are focused on simulations, equipment designs, and process optimization to overcome this obstacle. RF technology has been reported for liquid, solid, and powdered foods, as well as pre-packaged foods. The advantage of RF heating a packaged product is the reduced risk of cross-contamination. The physical state of food represents a particularity in studies due to different sizes and chemical composition. According to the objectives of the studies, RF proved to be a green technology for pest disinfestation, enzymatic and microorganisms inactivation, achieving food safety goals without changing the quality of the product. Additionally, it has the capacity to maintain nutritional, physicochemical, and sensory attributes due to shorter processing time. Published experimental results are mostly referred to 27.12 MHz: there is still room to explore the benefit of this technology at higher or lower frequency, considering the different penetration depths that can be achieved. Considering the complexity of an optimal design of such processes and equipment, the use of computer-aided food engineering methodology could definitely contribute to expand the use of RF-assisted processes for a more sustainable food industry.

Data Availability

No datasets were generated or analysed during the current study.

References

Hickey AJ, Giovagnoli S (2018) Powder and particle-dependent traditional manufacturing processes (Unit Operations). In: Hickey AJ, Giovagnoli S (eds) Pharmaceutical powder and particles. Springer International Publishing, Cham, pp 61–71. https://doi.org/10.1007/978-3-319-91220-2_8

Rifna EJ, Singh SK, Chakraborty S, Dwivedi M (2019) Effect of thermal and non-thermal techniques for microbial safety in food powder: recent advances. Food Res Int 126:108654. https://doi.org/10.1016/j.foodres.2019.108654

Blessington T, Theofel CG, Harris LJ (2013) A dry-inoculation method for nut kernels. Food Microbiol 33:292–297. https://doi.org/10.1016/j.fm.2012.09.009

Pal M, Alemu J, Mulu S, Karanfil O, Parmar B, Nayak JB (2016) Microbial and hygienic aspects of dry milk powder. Beverage Food World 43:28–31

Li X, Farid M (2016) A review on recent development in non-conventional food sterilization technologies. J Food Eng 182:33–45. https://doi.org/10.1016/j.jfoodeng.2016.02.026

Zhu X, Guo W, Jia Y (2014) Temperature-dependent Dielectric properties of raw cow’s and Goat’s milk from 10 to 4,500 MHz relevant to radio-frequency and microwave pasteurization process. Food Bioprocess Technol 7:1830–1839. https://doi.org/10.1007/s11947-014-1255-4

Di Rosa AR, Bressan F, Leone F, Falqui L, Chiofalo V (2019) Radio frequency heating on food of animal origin: a review. Eur Food Res Technol 245:1787–1797. https://doi.org/10.1007/s00217-019-03319-8

Dewan A, Panghal A, Dabaghiannejad B, Ranga V, Kumar N, Chhikara N (2023) Radio-frequency technology in food processing. In: Novel technologies in food science. pp 271–306. https://doi.org/10.1002/9781119776376.ch7

Ling B, Cheng T, Wang S (2020) Recent developments in applications of radio frequency heating for improving safety and quality of food grains and their products: a review. Crit Rev Food Sci Nutr 60:2622–2642. https://doi.org/10.1080/10408398.2019.1651690

Hou L, Johnson JA, Wang S (2016) Radio frequency heating for postharvest control of pests in agricultural products: a review. Postharvest Biol Technol 113:106–118. https://doi.org/10.1016/j.postharvbio.2015.11.011

Soni A, Oey I, Silcock P, Ross IK, Bremer PJ (2020) Effect of pulsed electric field with moderate heat (80 °C) on inactivation, thermal resistance and differential gene expression in B. cereus spores. J Food Process Preserv 44:e14503. https://doi.org/10.1111/jfpp.14503

Tanaka MS, Albergaria FC, Oliveira DCF, Ramos EM, Murgas LDS, Gomes MES, Ramos ALS (2023) Microbiological and physicochemical quality of tilapia fillets treated with ozone and chlorine solution and stored under refrigeration. Food Chem Adv 3:100371. https://doi.org/10.1016/j.focha.2023.100371

Chen Y, Chen Y, Fang Y, Pei Z, Zhang W (2024) Coconut milk treated by atmospheric cold plasma: effect on quality and stability. Food Chem 430:137045. https://doi.org/10.1016/j.foodchem.2023.137045

Li X, Gu N, Ye Y, Lan H, Peng F, Peng G (2023) Intense pulsed light for inactivating planktonic and biofilm molds in food. Front Microbiol 13:1104875 https://doi.org/10.3389/fmicb.2022.1104875

Chang Y-H, Wu S-J, Chen B-Y, Huang H-W, Wang C-Y (2017) Effect of high-pressure processing and thermal pasteurization on overall quality parameters of white grape juice. J Sci Food Agric 97:3166–3172. https://doi.org/10.1002/jsfa.8160

Tarrah A et al (2022) Thermal resistance and high-performance microwave decontamination assessment of Bacillus endospores isolated from food-grade herbal extracts. PLoS One 16:e0261988. https://doi.org/10.1371/journal.pone.0261988

Mohammadi Shad Z, Venkitasamy C, Kuelbs E, Buren L, Watrelot AA (2023) Effect of infrared drying on chemical and microbial properties of cold-hardy grape pomace (Edelweiss and Marquette). Food Sci Nutr 11:1826–1835. https://doi.org/10.1002/fsn3.3215

Jia L, Shao L, Zhao Y, Sun Y, Li X, Dai R (2023) Inactivation effects and mechanism of ohmic heating on Bacillus cereus. Int J Food Microbiol 390:110125. https://doi.org/10.1016/j.ijfoodmicro.2023.110125

Cui B, Sun Y, Wang K, Liu Y, Fu H, Wang Y, Wang Y (2022) Pasteurization mechanism on the cellular level of radio frequency heating and its possible non-thermal effect. Innov Food Sci Emerg Technol 78:103026. https://doi.org/10.1016/j.ifset.2022.103026

Bedane TF, Erdogdu F, Lyng JG, Marra F (2021) Effects of geometry and orientation of food products on heating uniformity during radio frequency heating. Food Bioprod Process 125:149–160. https://doi.org/10.1016/j.fbp.2020.11.010

Skåra T, Løvdal T, Skipnes D, Nwabisa Mehlomakulu N, Mapengo CR, Otema Baah R, Emmambux MN (2023) Drying of vegetable and root crops by solar, infrared, microwave, and radio frequency as energy efficient methods: a review. Food Rev Int 39:7197–7217. https://doi.org/10.1080/87559129.2022.2148688

Zhou X, Wang S (2019) Recent developments in radio frequency drying of food and agricultural products: a review. Drying Technol 37:271–286. https://doi.org/10.1080/07373937.2018.1452255

Bedane TF, Altin O, Erol B, Marra F, Erdogdu F (2018) Thawing of frozen food products in a staggered through-field electrode radio frequency system: a case study for frozen chicken breast meat with effects on drip loss and texture. Innov Food Sci Emerg Technol 50:139–147. https://doi.org/10.1016/j.ifset.2018.09.001

Zhou L, Ling B, Zheng A, Zhang B, Wang S (2015) Developing radio frequency technology for postharvest insect control in milled rice. J Stored Prod Res 62:22–31. https://doi.org/10.1016/j.jspr.2015.03.006

Jiao Y, Tang J, Wang Y, Koral TL (2018) Radio-frequency applications for food processing and safety. Annual Rev Food Sci Technol 9:105–127. https://doi.org/10.1146/annurev-food-041715-033038

Zhou X, Gao H, Mitcham EJ, Wang S. (2018) Comparative analyses of three dehydration methods on drying characteristics and oil quality of in-shell walnuts, Drying Technol 36:477–490. https://doi.org/10.1080/07373937.2017.1351452

Ling B, Ouyang S, Wang S (2019) Radio-frequency treatment for stabilization of wheat germ: Storage stability and physicochemical properties. Innov Food Sci Emerg Technol 52:158–165. https://doi.org/10.1016/j.ifset.2018.12.002

Liu L, Guan X, Jiao Q, Xu J, Li R, Erdogdu F, Wang S (2023) Developing combined radio frequency with water bath treatments to improve gel properties of minced chicken breast. Food Bioprocess Technol. https://doi.org/10.1007/s11947-023-03127-9

Zhou D, Yang G, Tian Y, Kang J, Wang S (2023) Different effects of radio frequency and heat block treatments on multi-scale structure and pasting properties of maize, potato, and pea starches. Food Hydrocoll 136:108306. https://doi.org/10.1016/j.foodhyd.2022.108306

Gong C, Zhang H, Yue J, Miao Y, Jiao S (2019) Investigation of hot air-assisted radio frequency heating as a simultaneous dry-blanching and pre-drying method for carrot cubes. Innov Food Sci Emerg Technol 56:102181. https://doi.org/10.1016/j.ifset.2019.102181

Gong C, Zhao Y, Zhang H, Yue J, Miao Y, Jiao S (2019) Investigation of radio frequency heating as a dry-blanching method for carrot cubes. J Food Eng 245:53–56. https://doi.org/10.1016/j.jfoodeng.2018.10.004

Huang Z, Marra F, Subbiah J, Wang S (2018) Computer simulation for improving radio frequency (RF) heating uniformity of food products: a review. Crit Rev Food Sci Nutr 58:1033–1057. https://doi.org/10.1080/10408398.2016.1253000

Dag D, Singh RK, Kong F (2022) Developments in radio frequency pasteurization of food powders. Food Rev Int 38:1197–1214. https://doi.org/10.1080/87559129.2020.1775641

Guan X et al (2022) Recent developments in pasteurising seeds and their products using radio frequency heating: a review. Int J Food Sci Technol 57:3223–3243. https://doi.org/10.1111/ijfs.15497

Soto-Reyes N, Sosa-Morales ME, Rojas-Laguna R, López-Malo A (2022) Advances in radio frequency pasteurisation equipment for liquid foods: a review. Int J Food Sci Technol 57:3207–3222. https://doi.org/10.1111/ijfs.15662

Zhang Y et al (2022) Impact of radio frequency treatment on textural properties of food products: an updated review. Trends Food Sci Technol 124:154–166. https://doi.org/10.1016/j.tifs.2022.04.014

Altemimi A, Aziz SN, Al-HiIphy ARS, Lakhssassi N, Watson DG, Ibrahim SA (2019) Critical review of radio-frequency (RF) heating applications in food processing. Food Qual Saf 3:81–91. https://doi.org/10.1093/fqsafe/fyz002

Bermudez-Aguirre D, Niemira BA (2023) Radio frequency treatment of food: a review on pasteurization and disinfestation. Foods 12:3057. https://doi.org/10.3390/foods12163057

Hassan AB, von Hoersten D, Mohamed Ahmed IA (2019) Effect of radio frequency heat treatment on protein profile and functional properties of maize grain. Food Chem 271:142–147. https://doi.org/10.1016/j.foodchem.2018.07.190

Sacilik K, Colak A (2010) Determination of dielectric properties of corn seeds from 1 to 100 MHz. Powder Technol 203:365–370. https://doi.org/10.1016/j.powtec.2010.05.031

Guo WC, Nelson SO, Trabelsi S, Kays SJ (2007) 10–1800-MHz dielectric properties of fresh apples during storage. J Food Eng 83:562–569. https://doi.org/10.1016/j.jfoodeng.2007.04.009

Zhang L, Lyng JG, Brunton N, Morgan D, McKenna B (2004) Dielectric and thermophysical properties of meat batters over a temperature range of 5–85 °C. Meat Sci 68:173–184. https://doi.org/10.1016/j.meatsci.2004.02.009

Jiao Y (2019) 23 - Measurement techniques of electrical properties for food quality evaluation. In: Zhong J, Wang X (eds) Evaluation technologies for food quality. Woodhead Publishing, pp 595–616. https://doi.org/10.1016/B978-0-12-814217-2.00023-8

Ozturk S, Kong F, Trabelsi S, Singh RK (2016) Dielectric properties of dried vegetable powders and their temperature profile during radio frequency heating. J Food Eng 169:91–100. https://doi.org/10.1016/j.jfoodeng.2015.08.008

Boreddy SR, Subbiah J (2016) Temperature and moisture dependent dielectric properties of egg white powder. J Food Eng 168:60–67. https://doi.org/10.1016/j.jfoodeng.2015.07.023

Zhang S, Zhou L, Ling B, Wang S (2016) Dielectric properties of peanut kernels associated with microwave and radio frequency drying. Biosyst Eng 145:108–117. https://doi.org/10.1016/j.biosystemseng.2016.03.002

Castro-Giráldez M, Dols L, Toldrá F, Fito P (2011) Development of a dielectric spectroscopy technique for the determination of key biochemical markers of meat quality. Food Chem 127:228–233. https://doi.org/10.1016/j.foodchem.2010.12.089

Jha S, Narsaiah K, Basediya AL, Sharma R, Jaiswal P, Kumar R, Bhardwaj R (2011) Measurement techniques and application of electrical properties for nondestructive quality evaluation of foods—a review. J Food Sci Technol 48:387–411. https://doi.org/10.1007/s13197-011-0263-x

McKeown MS, Trabelsi S, Tollner EW, Nelson SO (2012) Dielectric spectroscopy measurements for moisture prediction in Vidalia onions. J Food Eng 111:505–510. https://doi.org/10.1016/j.jfoodeng.2012.02.034

Frabetti ACC, Garnault T, Curto H, Thillier A, Boillereaux L, Rouaud O, Curet S (2023) Dielectric properties of low moisture foods measured by open-ended coaxial probe and cavity perturbation technique. Eur Food Res Technol 249:2861–2873. https://doi.org/10.1007/s00217-023-04333-7

Sheen J (2005) Study of microwave dielectric properties measurements by various resonance techniques. Measurement 37:123–130. https://doi.org/10.1016/j.measurement.2004.11.006

Sheen J (2006) Amendment of cavity perturbation technique for loss tangent measurement at microwave frequencies. In: 2006 7th International Symposium on Antennas, Propagation & EM Theory, 26–29 Oct. 2006. pp 1–3. https://doi.org/10.1109/ISAPE.2006.353221

Ohlsson T, Bengtsson NE, Risman PO (1974) The frequency and temperature dependence of dielectric food data as determined by a cavity perturbation technique. J Microw Power 9:129–145. https://doi.org/10.1080/00222739.1974.11688910

Singh RK, Deshpande D (2019) Functional properties of marinated chicken breast meat during heating in a pilot-scale radio-frequency oven. Int J Food Prop 22:1985–1997. https://doi.org/10.1080/10942912.2019.1698604

Yang H, Chen Q, Cao H, Fan D, Huang J, Zhao J, Yan B, Zhou W, Zhang W, Zhang H(2019) Radiofrequency thawing of frozen minced fish based on the dielectric response mechanism. Innov Food Sci Emerg Technol 52:80–88. https://doi.org/10.1016/j.ifset.2018.10.013

Mahmood N, Liu Y, Saleemi MA, Munir Z, Zhang Y, Saeed R (2023) Investigation of physicochemical and textural properties of brown rice by hot air assisted radio frequency drying. Food Bioprocess Technol 16:1555–1569. https://doi.org/10.1007/s11947-023-03001-8

Liao M, Zhao Y, Gong C, Zhang H, Jiao S (2018) Effects of hot air-assisted radio frequency roasting on quality and antioxidant activity of cashew nut kernels. LWT - Food Sci Technol 93:274–280. https://doi.org/10.1016/j.lwt.2018.03.047

Fan L, Xu J, Guan X, Li R, Wang S (2023) Developing radio frequency pretreatment technology for improving yield and quality of flaxseed oil extractions. Innov Food Sci Emerg Technol 86:103363. https://doi.org/10.1016/j.ifset.2023.103363

Appugol KA, Mangang IB, Shanmugasundaram S, Manickam L (2022) Radiofrequency heating: a novel thermal treatment on the quality of peanut during disinfestation of Caryedon serratus and its potential in reducing aflatoxin. J Food Process Preserv 46:e17029. https://doi.org/10.1111/jfpp.17029

Wang S, Llave Y, Kong F, Marra F, Erdoğdu F (2022) 9 - Update on emerging technologies including novel applications: radio frequency. In: Juliano P, Buckow R, Nguyen MH, Knoerzer K, Sellahewa J (eds) Food engineering innovations across the food supply chain. Academic Press, pp 163–186. https://doi.org/10.1016/B978-0-12-821292-9.00013-3

Indumathi C, Manoj D, Loganathan M, Shanmugasundaram S (2023) Radio frequency disinfestation of Tribolium castaneum (Herbst) in Semolina: an emerging thermal technique. J Food Process Eng 46:e14443. https://doi.org/10.1111/jfpe.14443

Carbajal-Padilla D, Cerón-García A, Gómez-Salazar JA, Rojas-Laguna R, Sosa-Morales ME (2022) Postharvest treatments with radio frequency for 10 and 20 kg batches of black beans (Phaseolus vulgaris L). Int J Food Sci Technol 57:3244–3250. https://doi.org/10.1111/ijfs.15584

Hou L, Wu Y, Kou X, Li R, Wang S (2022) Developing high-temperature-short-time radio frequency disinfestation treatments in coix seeds: insect mortality, product quality and energy consumption. Biosyst Eng 215:262–270. https://doi.org/10.1016/j.biosystemseng.2022.01.018

Hou L, Liu Q, Wang S (2019) Efficiency of industrial-scale radio frequency treatments to control Rhyzopertha dominica (Fabricius) in rough, brown, and milled rice. Biosyst Eng 186:246–258. https://doi.org/10.1016/j.biosystemseng.2019.08.009

Mangang IB, Minj R, Manickam L, Rangarajan J, Shanmugasundaram S (2022) Turmeric—a super food—prevention of post-harvest losses using radio frequency disinfestation. Arch Phytopathol Plant Prot 55:1450–1463. https://doi.org/10.1080/03235408.2022.2104583

Indumathi C, Manoj D, Loganathan M, Shanmugasundaram S (2021) Impact of radiofrequency disinfestation on Tribolium castaneum (Herbst) in wheat flour and its influence on the functional characteristics of wheat flour. J Food Process Preserv 45:e15770. https://doi.org/10.1111/jfpp.15770

Li R, Song X, Guan X, Ni B, Gao Y, Hou L, Kou X, Wang S (2022) New strategy for improving heating uniformity and insect mortality in radio frequency treated mung beans. Int J Agricultural Biol Eng 15:229–235. https://doi.org/10.25165/j.ijabe.20221505.7176

Song X, Ma B, Kou X, Li R, Wang S (2020) Developing radio frequency heating treatments to control insects in mung beans. J Stored Prod Res 88:101651. https://doi.org/10.1016/j.jspr.2020.101651

Yang C, Zhao Y, Tang Y, Yang R, Yan W, Zhao W (2018) Radio frequency heating as a disinfestation method against Corcyra cephalonica and its effect on properties of milled rice. J Stored Prod Res 77:112–121. https://doi.org/10.1016/j.jspr.2018.04.004

Marra F, Zhang L, Lyng JG (2009) Radio frequency treatment of foods: review of recent advances. J Food Eng 91:497–508. https://doi.org/10.1016/j.jfoodeng.2008.10.015

Liu S, Xiong H, Qiu Y, Dai J, Zhang Q, Qin W (2022) Radiofrequency-assisted low-temperature long-time (LTLT) pasteurization of onion powder. LWT - Food Sci Technol 170:114002. https://doi.org/10.1016/j.lwt.2022.114002

Chen L, Wei X, Irmak S, Chaves BD, Subbiah J (2019) Inactivation of Salmonella enterica and Enterococcus faecium NRRL B-2354 in cumin seeds by radiofrequency heating. Food Control 103:59–69. https://doi.org/10.1016/j.foodcont.2019.04.004

Ozturk S, Kong F, Singh RK (2020) Evaluation of Enterococcus faecium NRRL B-2354 as a potential surrogate of Salmonella in packaged paprika, white pepper and cumin powder during radio frequency heating. Food Control 108:106833. https://doi.org/10.1016/j.foodcont.2019.106833

Verma T, Chaves BD, Howell T, Subbiah J (2021) Thermal inactivation kinetics of Salmonella and Enterococcus faecium NRRL B-2354 on dried basil leaves. Food Microbiol 96:103710. https://doi.org/10.1016/j.fm.2020.103710

Wason S, Verma T, Irmak S, Subbiah J (2022) In-package pasteurization of dried basil leaves using radiofrequency heating. Food Control 141:109179. https://doi.org/10.1016/j.foodcont.2022.109179

Jeong KO, Kim SS, Park SH, Kang DH (2022) Inactivation of Salmonella enterica serovar Typhimurium and Staphylococcus aureus in rice by radio frequency heating. J Food Prot 85:380–383. https://doi.org/10.4315/JFP-21-275

Wei X, Lau SK, Reddy BS, Subbiah J (2020) A microbial challenge study for validating continuous radio-frequency assisted thermal processing pasteurization of egg white powder. Food Microbiol 85:103306. https://doi.org/10.1016/j.fm.2019.103306

Jeong KO, Kim SS, Park SH, Kang DH (2020) Inactivation of Escherichia coli, Salmonella enterica Serovar Typhimurium, and Bacillus cereus in roasted grain powder by radio frequency heating. J Appl Microbiol 129:1227–1237. https://doi.org/10.1111/jam.14705

Jantapirak S, Takahashi C, Uemura K (2021) Effect of radiofrequency heating of vacuum-packed nitrite-free sausage on quality properties and microorganism inactivation. Biosci Biotechnol Biochem 85:907–915. https://doi.org/10.1093/bbb/zbaa099

Yang Y, Geveke DJ, Brunkhorst CD, Sites JE, Geveke NJ, Tilman ED (2019) Optimization of the radio frequency power, time and cooling water temperature for pasteurization of Salmonella Typhimurium in shell eggs. J Food Eng 247:130–135. https://doi.org/10.1016/j.jfoodeng.2018.12.004

Yang Y, Geveke DJ (2020) Shell egg pasteurization using radio frequency in combination with hot air or hot water. Food Microbiology 85:103281. https://doi.org/10.1016/j.fm.2019.103281

Geveke DJ, Bigley ABW, Brunkhorst CD, Jones DR, Tilman ED (2018) Improvement in the radio frequency method to pasteurise shell eggs by automation and cost reduction. Int J Food Sci Technol 53:2500–2508. https://doi.org/10.1111/ijfs.13843

Rezaeimotlagh A, Tang KSC, Resch M, Cullen PJ, Trujillo FJ (2018) Inactivation kinetics of Escherichia coli in cranberry juice during multistage treatment by electric fields. Food Res Int 106:780–790. https://doi.org/10.1016/j.foodres.2018.01.049

Wei X, Lau SK, Stratton J, Irmak S, Subbiah J (2019) Radiofrequency pasteurization process for inactivation of Salmonella spp. and Enterococcus faecium NRRL B-2354 on ground black pepper. Food Microbiol 82:388–397. https://doi.org/10.1016/j.fm.2019.03.007

Cao X, Zhang M, Chitrakar B, Mujumdar AS, Zhong Q, Wang Z, Wang L (2019) Radiofrequency heating for powder pasteurization of barley grass: antioxidant substances, sensory quality, microbial load and energy consumption. J Sci Food Agric 99:4460–4467. https://doi.org/10.1002/jsfa.9683

Xu J, Yang R, Jin Y, Barnett G, Tang J (2020) Modeling the temperature-dependent microbial reduction of Enterococcus faecium NRRL B-2354 in radio-frequency pasteurized wheat flour. Food Control 107:106778. https://doi.org/10.1016/j.foodcont.2019.106778

Liu S, Ozturk S, Xu J, Kong F, Gray P, Zhu M-J, Sablani SS, Tang J (2018) Microbial validation of radio frequency pasteurization of wheat flour by inoculated pack studies. J Food Eng 217:68–74. https://doi.org/10.1016/j.jfoodeng.2017.08.013

Molnár H et al (2018) The effect of different decontamination methods on the microbial load, bioactive components, aroma and colour of spice paprika. Food Control 83:131–140. https://doi.org/10.1016/j.foodcont.2017.04.032

Hu S, Zhao Y, Hayouka Z, Wang D, Jiao S (2018) Inactivation kinetics for Salmonella typhimurium in red pepper powders treated by radio frequency heating. Food Control 85:437–442. https://doi.org/10.1016/j.foodcont.2017.10.034

Xu J, Xu Y, Guan X, Yang G, Wang S (2023) Effects of sequential treatments using radio frequency energy and ultraviolet light on inactivation of Bacillus cereus spores and quality attributes of buckwheat. Int J Food Microbiol 385:109997 https://doi.org/10.1016/j.ijfoodmicro.2022.109997

Zhang L, Lyng JG, Xu R, Zhang S, Zhou X, Wang S (2019) Influence of radio frequency treatment on in-shell walnut quality and Staphylococcus aureus ATCC 25923 survival. Food Control 102:197–205. https://doi.org/10.1016/j.foodcont.2019.03.030

Chen L, Huang Z, Wang K, Li W, Wang S (2016) Simulation and validation of radio frequency heating with conveyor movement. J Electromagn Waves Appl 30:473–491. https://doi.org/10.1080/09205071.2015.1121841

Jiao Y, Shi H, Tang J, Li F, Wang S (2015) Improvement of radio frequency (RF) heating uniformity on low moisture foods with polyetherimide (PEI) blocks. Food Res Int 74:106–114. https://doi.org/10.1016/j.foodres.2015.04.016

Terefe NS, Buckow R, Versteeg C (2014) Quality-related enzymes in fruit and vegetable products: effects of novel food processing technologies, part 1: high-pressure processing critical reviews in food. Sci Nutr 54:24–63. https://doi.org/10.1080/10408398.2011.566946

Doblado-Maldonado AF, Pike OA, Sweley JC, Rose DJ (2012) Key issues and challenges in whole wheat flour milling and storage. J Cereal Sci 56:119–126. https://doi.org/10.1016/j.jcs.2012.02.015

Yao Y, Wei X, Pang H, Wang K, Liu Q, Fu H, Chen X, Wang Y (2020) Effects of radio-frequency energy on peroxidase inactivation and physiochemical properties of stem lettuce and the underlying cell-morphology mechanism. Food Chem 322:126753. https://doi.org/10.1016/j.foodchem.2020.126753

Yao Y, Zhang B, Zhou L, Wang Y, Fu H, Chen X, Wang Y (2022) Steam-assisted radio frequency blanching to improve heating uniformity and quality characteristics of stem lettuce cuboids. Food Bioprocess Technol 15:1907–1917. https://doi.org/10.1007/s11947-022-02856-7

Kravets M, Cedeño-Pinos C, Abea A, Guàrdia MD, Muñoz I, Bañón S (2023) Validation of pasteurisation temperatures for a tomato-oil homogenate (salmorejo) processed by radiofrequency or conventional continuous heating. Foods 12:2837. https://doi.org/10.3390/foods12152837

Sun Y et al (2022) Effects of radiofrequency blanching on lipoxygenase inactivation, physicochemical properties of sweet corn (Zea mays L.), and its correlation with cell morphology. Food Chem 394:133498. https://doi.org/10.1016/j.foodchem.2022.133498

Yarrakula S, Mummaleti G, Pare A, Vincent H, Saravanan S (2022) Hot air–assisted radio frequency hybrid technology for inactivating lipase in pearl millet. J Food Process Preserv 46:e16178. https://doi.org/10.1111/jfpp.16178

Zhang C, Hu C, Sun Y, Zhang X, Wang Y, Fu H, Chen X, Wang Y (2021) Blanching effects of radio frequency heating on enzyme inactivation, physiochemical properties of green peas (Pisum sativum L.) and the underlying mechanism in relation to cellular microstructure. Food Chem 345:128756. https://doi.org/10.1016/j.foodchem.2020.128756

Yao Y, Sun Y, Cui B, Fu H, Chen X, Wang Y (2021) Radio frequency energy inactivates peroxidase in stem lettuce at different heating rates and associate changes in physiochemical properties and cell morphology. Food Chem 342:128360. https://doi.org/10.1016/j.foodchem.2020.128360

Jiang Y, Wang S, He F, Fan Q, Ma Y, Yan W, Tang Y, Yang R, Zhao W (2018) Inactivation of lipoxygenase in soybean by radio frequency treatment. Int J Food Sci Technol 53:2738–2747. https://doi.org/10.1111/ijfs.13885

Jiang H, Ling B, Zhou X, Wang S (2020) Effects of combined radio frequency with hot water blanching on enzyme inactivation, color and texture of sweet potato. Innov Food Sci Emerg Technol 66:102513. https://doi.org/10.1016/j.ifset.2020.102513

Ling B, Lyng JG, Wang S (2018) Effects of hot air-assisted radio frequency heating on enzyme inactivation, lipid stability and product quality of rice bran. LWT - Food Sci Technol 91:453–459. https://doi.org/10.1016/j.lwt.2018.01.084

Ando Y, Maeda Y, Mizutani K, Wakatsuki N, Hagiwara S, Nabetani H (2016) Impact of blanching and freeze-thaw pretreatment on drying rate of carrot roots in relation to changes in cell membrane function and cell wall structure. LWT - Food Sci Technol 71:40–46. https://doi.org/10.1016/j.lwt.2016.03.019

Sila DN, Van Buggenhout S, Duvetter T, Fraeye I, De Roeck A, Van Loey A, Hendrickx M (2009) Pectins in processed fruits and vegetables: part II—structure–function relationships. Compr Rev Food Sci Food Saf 8:86–104. https://doi.org/10.1111/j.1541-4337.2009.00071.x

Sirohi R et al (2021) Technologies for disinfection of food grains: advances and way forward. Food Res Int 145:110396. https://doi.org/10.1016/j.foodres.2021.110396

Marra F (2012) Microwave and radio-frequency heating processes for food. In: Handbook of food process design. pp 1031–1056. https://doi.org/10.1002/9781444398274.ch35

Zhao Y, Ling Q (2012) Radio frequency dielectric heating. In: Sun DW (ed) Thermal food processing, 2nd edn. CRC Press, Boca Raton, p 28

Tang J, Chan T (2007) Microwave and radio frequency in sterilization and pasteurization applications. pp 101–157. https://doi.org/10.2495/978-1-85312-932-2/04

Marra F (2023) Combining computer aided food engineering and electro-heating applications as contribution to food processing sustainability. Front Sustain. 4. https://doi.org/10.3389/frsus.2023.1170467

Goñi SM, d’Amore M, Della Valle M, Olivera DF, Salvadori VO, Marra F (2022) Effect of load spatial configuration on the heating of chicken meat assisted by radio frequency at 40.68 MHz. Foods 11:1096. https://doi.org/10.3390/foods11081096

Guan X, Wang Z, Xu J, Lin B, Li R, Wang S (2022) Computer simulation analyses to improve radio frequency heating uniformity for watermelon seeds by inserting horizontal aluminum and polypropylene (PP) plates in a rectangular PP container. Innov Food Sci Emerg Technol 81:103118. https://doi.org/10.1016/j.ifset.2022.103118

Marra F, Lyng J, Romano V, McKenna B (2007) Radio-frequency heating of foodstuff: solution and validation of a mathematical model. J Food Eng 79:998–1006. https://doi.org/10.1016/j.jfoodeng.2006.03.031

Wu Q, Guo H, Liu Q, Zhu G, Wang J, Cao Y, Li M (2023) Design and fabrication of a series contact RF MEMS switch with a novel top electrode. Nanatechnol Precis Eng 6:013006. https://doi.org/10.1063/10.0016903

Quickwave (2018) Software for electromagnetic design and simulations. Available on https://www.qwed.eu/QuickWave_2018.pdf. Accessed 20 Oct 2023

Yang JUN, Zhao Y, Wells JH (2003) Computer simulation of capacitive radio frequency (RF) dieletric heating on vegetable sprout seeds. J Food Process Eng 26:239–263. https://doi.org/10.1111/j.1745-4530.2003.tb00600.x

Uyar R, Bedane TF, Erdogdu F, Koray Palazoglu T, Farag KW, Marra F (2015) Radio-frequency thawing of food products – a computational study. J Food Eng 146:163–171. https://doi.org/10.1016/j.jfoodeng.2014.08.018

Zhou B, Zuo Y, Yang H, Wang S, Hou L (2023) Modelling radio frequency heating of randomly stacked walnut kernels with different particle size. Biosyst Eng 228:56–66. https://doi.org/10.1016/j.biosystemseng.2023.02.011

Cui Y, Wang X, Jiang S, Wang S, Hou L (2023) Improving radio frequency heating uniformity in milled rice with different packaging shapes by changing temperature of forced air. Innov Food Sci Emerg Technol 84:103280. https://doi.org/10.1016/j.ifset.2023.103280

Huang Z, Chen L, Wang S (2015) Computer simulation of radio frequency selective heating of insects in soybeans. Int J Heat Mass Transf 90:406–417. https://doi.org/10.1016/j.ijheatmasstransfer.2015.06.071

Gao J, Wu M, Du S, Zhang H, Wang S, Ling B (2023) Recent advances in food processing by radio frequency heating techniques: a review of equipment aspects. J Food Eng 357:111609. https://doi.org/10.1016/j.jfoodeng.2023.111609

Funding

Open access funding provided by Università degli Studi di Salerno within the CRUI-CARE Agreement. No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

Josiel Martins Costa: Conceptualization; Investigation; Formal analysis; Writing – original draft; Figure design. Francesco Marra: Investigation, Writing – review & editing.

Corresponding authors

Ethics declarations

Ethical Approval

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Trends in RF-assisted processes for pest control, microbial and enzyme inactivation were reviewed.

• Challenges and prospects for the development of RF technology were discussed.

• RF processing can be considered mature to achieve pest control, microbial and enzyme inactivation at industrial scale.

• Properly designed RF processes allow treated foods to maintain color, texture, and nutrients.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Costa, J.M., Marra, F. Advances in Food Processing Through Radio Frequency Technology: Applications in Pest Control, Microbial and Enzymatic Inactivation. Food Eng Rev (2024). https://doi.org/10.1007/s12393-024-09372-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12393-024-09372-8