Abstract

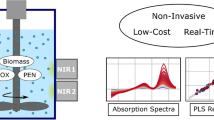

This paper presents a noninvasive optical sensor system for monitoring cell growth in shaker flasks commonly used in biological laboratories. The system uses an open-source microprocessor board to monitor concentration of Escherichia coli host cells. To allow measurement for a range of filling degrees and shaker speeds, the backscattering angle is chosen to minimize interference from surface reflections and the measurement window is synchronized to the position of the shaker flask. A nonlinear calibration model of scattered light can predict offline optical density with a mean relative error of 5.2%, an accuracy which is comparable to the classical offline method and sufficient for biotechnology applications.

Similar content being viewed by others

References

Zhang, H., W. Williams-Dalson, E. Keshavarz-Moore, and P. A. Shamlou (2005) Computational fluid dynamics (CFD) analysis of mixing and gas–liquid mass transfer in shake flasks. Biotechnol. Appl. Biochem. 41: 1–8.

Buchs, J. (2001) Introduction to advantages and problems of shaken cultures. Biochem. Eng. J. 7: 91–98.

Christian, U., J. Schmidt-Hager, M. Findeis, G. T. John, T. Scheper, and S. Beutel (2014) Application of an online-biomass sensor in an optical multisensory platform prototype for growth monitoring of biotechnical relevant microorganism and cell lines in single-use shake flasks. Sensors 14: 17390–17405.

Matanguihan, B. M., K. B. Konstantinov, and T. Yoshida (1994) Dielectric measurement to monitor the growth and the physiological state of biological cells. Bioproc. Eng. 11: 213–222.

Schmidt-Hager, J., U. Christian, M. Findeis, G. T. John, T. Scheper, and S. Beutel (2014) Noninvasive online biomass detector system for cultivation in shake flasks. Eng. Life Sci. 14: 467–476.

Chattopadhyay, S., V. S. Bisaria, T. Scheper, and A. K. Srivastava (2002) Non-invasive methods for determination of cellular growth in Podophyllum hexandrum suspension cultures. Biotech. Bioproc. Eng. 7: 331–334.

Lam, H. and Y. Kostov (2009) Optical instrumentation for bioprocess monitoring. Adv. Biochem. Eng. Biotechnol. 116: 1–28.

Ulber, R., J. G. Frerichs, and S. Beutel (2003) Optical sensor systems for bioprocess monitoring. Anal. Bioanal. Chem. 376: 342–348.

Gregory, M. E. and N. F. Thornhill (1997) The effects of aeration and agitation on the measurement of yeast biomass using a laser turbidity probe. Bioproc. Eng. 16: 339–344.

Matanguihan, R. M., K. B. Konstantinov, and T. Yoshida (1994) Dielectric measurement to monitor the growth and the physiological states of biological cells. Bioproc. Eng. 11: 213–222.

Kiviharju, K., K. Salonen, U. Moilanen, and T. Eerikainen (2008) Biomass measurement online: the performance of in situ measurements and software sensors. J. Ind. Microbiol. Biotech. 35: 657–665.

Griffiths, M. J., C. Garcin, R. P. van Hille, and S. T. L. Harrison (2011) Interference by pigment in the estimation of microalgal biomass concentration by optical density. J. Microbiol. Meth. 85: 119–123.

Hopfner, T., A. Bluma, G. Rudolph, P. Lindner, and T. Scheper (2010) A review of non-invasive optical-based image analysis systems for continuous bioprocess monitoring. Bioproc. Biosys. Eng. 33: 247–256.

Zhong, N. B., Q. Liao, X. Zhu, and M. F. Zhao (2015) Fiber-optic differential absorption sensor for accurately monitoring biomass in a photobioreactor. Appl. Opt. 54: 228–235.

Schneider, K., V. Schutz, G. John, and E. Heinzle (2010) Optical device for parallel on-line measurement of dissolved oxygen and PH in shake flask cultures. Bioproc. Biosys. Eng. 33: 541–547.

Kensy, F., E. Zang, C. Faulhammer, R. K. Tan, and J. Buchs (2009) Validation of a high-throughput fermentation system based on online monitoring of biomass and fluorescence in continuously shaken microtiter plates. Microb. Cell Fact. 8: 1–30.

Samorski, M., G. Muller-Newen, and J. Buchs (2005) Quasi-continuous combined scattered light and fluorescence measurements: A novel measurement technique for shaken microtiter plates. Biotech. Bioeng. 92: 61–68.

Peng, H. (2008) Apparatus and method for monitoring biological cell culture. US Patent 7,339,671.

Li, J., X. B. Zhan, T. Z. Liu, Z. Y. Zheng, and X. M. Qi (2009) Numerical simulation of fluid flow in Erlenmeyer shake flask with computational fluid dynamics. J. Chem. Industry Eng. 60: 878–885.

Li, C., J. Y. Xia, J. Chu, Y. H. Wang, Y. P. Zhuang, and S. L. Zhang (2013) CFD analysis of the turbulent flow in baffled shake flasks. Biochem. Eng. J. 70: 140–150.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Mao, J., Yan, Y., Eichstädt, O. et al. A noninvasive online system for biomass monitoring in shaker flasks using backward scattered light. Biotechnol Bioproc E 22, 161–169 (2017). https://doi.org/10.1007/s12257-016-0338-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-016-0338-7