Abstract

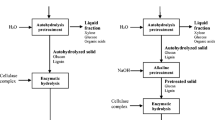

In this work, an alkaline delignification was investigated for several industrially relevant hardwoods to understand the kinetics of xylan solubilization and degradation and the role of residual lignin content in setting cell wall recalcitrance to enzymatic hydrolysis. Between 34 and 50 % of the xylan was solubilized during the heat-up stage of the pretreatment and undergoes degradation, depolymerization, as well as substantial disappearance of the glucuronic acid substitutions on the xylan during the bulk delignification phase. An important finding is that substantial xylan is still present in the liquor without degradation. Cellulose hydrolysis yields in the range of 80 to 90 % were achievable within 24–48 h for the diverse hardwoods subjected to delignification by alkali at modest enzyme loadings. It was found that substantial delignification was not necessary to achieve these high hydrolysis yields and that hybrid poplar subjected to pretreatment removing only 46 % of the lignin was capable of reaching yields comparable to hybrid poplar pretreated to 67 or 86 % lignin removal. Decreasing the lignin content was found to increase the initial rate of cellulose hydrolysis to glucose while lignin contents under approximately 70 mg/g original biomass were found to slightly decrease the maximum extent of hydrolysis, presumably due to drying-induced cellulose aggregation and pore collapse. Pretreatments were performed on woodchips, which necessitated a “disintegration” step following pretreatment. This allowed the effect of comminution method to be investigated for the three hardwoods subjected to the highest level of delignification. It was found that additional knife-milling following distintegration did not impact either the rate or extent of glucan and xylan hydrolysis.

Similar content being viewed by others

References

Balan V, Chiaramonti D, Kumar S (2013) Review of US and EU initiatives toward development, demonstration, and commercialization of lignocellulosic biofuels. Biofuels Bioprod Biorefin 7:732–759. doi:10.1002/bbb.1436

Hess JR, Kenney K, Wright C, Perlack R, Turhollow A (2009) Corn stover availability for biomass conversion: situation analysis. Cellulose 16:599–619. doi:10.1007/s10570-009-9323-z

Stoklosa RJ, Hodge DB (2014) Integration of (Hemi)-cellulosic biofuels technologies with chemical pulp production. In: Qureshi N, Hodge DB, Vertès A (eds) Biorefineries: integrated biochemical processes for liquid biofuels. Elsevier Press, Amsterdam

Perlack RD, Stokes BJ (2011) Billion-ton update: biomass supply for a bioenergy and bioproducts industry. Oak Ridge National Laboratory, Oak Ridge

Huang HJ, Lin WL, Ramaswamy S, Tschirner U (2009) Process modeling of comprehensive integrated forest biorefinery—an integrated approach. Appl Biochem Biotechnol 154:205–216. doi:10.1007/s12010-008-8478-7

Zhu JY, Pan XJ (2010) Woody biomass pretreatment for cellulosic ethanol production: technology and energy consumption evaluation. Bioresour Technol 101:4992–5002. doi:10.1016/j.biortech.2009.11.007

Pan X, Gilkes N, Kadla J, Pye K, Saka S, Gregg D, Ehara K, Xie D, Lam D, Saddler J (2006) Bioconversion of hybrid poplar to ethanol and co-products using an organosolv fractionation process: optimization of process yields. Biotechnol Bioeng 94:851–861. doi:10.1002/bit.20905

Tucker M, Farmer J, Keller F, Schell D, Nguyen Q (1998) Comparison of yellow poplar pretreatment between NREL digester and Sunds hydrolyzer. Appl Biochem Biotechnol 70–72:25–35

Kim Y, Kreke T, Mosier NS, Ladisch MR (2014) Severity factor coefficients for subcritical liquid hot water pretreatment of hardwood chips. Biotechnol Bioeng 111:254–263. doi:10.1002/bit.25009

Allen SG, Schulman D, Lichwa J, Antal MJ, Jennings E, Elander R (2001) A comparison of aqueous and dilute-acid single-temperature pretreatment of yellow poplar sawdust. Ind Eng Chem Res 40(10):2352–2361

Liu T, Williams DL, Pattathil S, Li M, Hahn MG, Hodge DB (2014) Coupling alkaline pre-extraction with alkaline-oxidative post-treatment of corn stover to enhance enzymatic hydrolysis and fermentability. Biotechnol Biofuels 7:48

Oka D, Kobayashi K, Isobe N, Ogawa Y, Yokoyama T, Kimura S, Kim UJ, Tokuyasu K, Wada M (2013) Enzymatic hydrolysis of wood with alkaline treatment. J Wood Sci 59:484–488. doi:10.1007/s10086-013-1359-x

Fornell R, Berntsson T, Åsblad A (2012) Process integration study of a kraft pulp mill converted to an ethanol production plant—part B: techno-economic analysis. Appl Therm Eng 42:179–190. doi:10.1016/j.applthermaleng.2012.02.043

Francis RC, Bolton TS, Abdoulmoumine N, Lavrykova N, Bose SK (2008) Positive and negative aspects of soda/anthraquinone pulping of hardwoods. Bioresour Technol 99:8453–8457. doi:10.1016/j.biortech.2008.02.055

Stoklosa RJ, Velez J, Kelkar S, Saffron CM, Thies MC, Hodge DB (2013) Correlating lignin structural features to phase partitioning behavior in a novel aqueous fractionation of softwood Kraft black liquor. Green Chem 15:2904–2912

Lora J, Glasser W (2002) Recent industrial applications of alignin: a sustainable alternative to nonrenewable materials. J Polym Environ 10:39–48. doi:10.1023/a:1021070006895

Doherty B, Rainey T (2006) Bagasse fractionation by the soda process. In: Hogarth D (ed) Proceedings of the Australian Society of Sugar Cane Technologists 2006, 2-5 May 2006, Mackay, Queensland, Australia

Dale VH, Kline KL, Wright LL, Perlack RD, Downing M, Graham RL (2011) Interactions among bioenergy feedstock choices, landscape dynamics, and land use. Ecol Appl 21:1039–1054. doi:10.1890/09-0501.1

Li M, Foster C, Kelkar S, Pu Y, Holmes D, Ragauskas A, Saffron CM, Hodge DB (2012) Structural characterization of alkaline hydrogen peroxide pretreated grasses exhibiting diverse lignin phenotypes. Biotechnol Biofuels 5:38

Stoklosa RJ, Hodge DB (2012) Extraction, recovery, and characterization of hardwood and grass hemicelluloses for integration into biorefining processes. Ind Eng Chem Res 51:11045–11053

Schädel C, Blöchl A, Richter A, Hoch G (2010) Quantification and monosaccharide composition of hemicelluloses from different plant functional types. Plant Physiol Biochem 48:1–8

Lan T, Lou H, Zhu J (2013) Enzymatic saccharification of lignocelluloses should be conducted at elevated pH 5.2–6.2. Bioenerg Res 6:476–485

Williams DL, Hodge DB (2014) Impacts of delignification and hot water pretreatment on the water induced cell wall swelling behavior of grasses and its relation to cellulolytic enzyme hydrolysis and binding. Cellulose 21:221–235

Sato TK, Liu T, Parreiras LS, Williams DL, Wohlbach DJ, Bice BD, Ong IM, Breuer RJ, Qin L, Busalacchi D (2014) Harnessing genetic diversity in Saccharomyces cerevisiae for fermentation of xylose in hydrolysates of alkaline hydrogen peroxide-pretreated biomass. Appl Environ Microbiol 80:540–554

Schild G, Sixta H, Testova L (2010) Multifunctional alkaline pulping. Delignification and hemicellulose extraction. Cellul Chem Technol 44:35

Pinto P, Evtuguin D, Neto CP (2005) Structure of hardwood glucuronoxylans: modifications and impact on pulp retention during wood kraft pulping. Carbohydr Polym 60(4):489–497

Sixta H, Potthast A, Krotschek AW (2008) Chemical pulping processe: sections 4.1–4.2.5. In: Handbook of pulp. Wiley-VCH Verlag GmbH, pp 109-229. doi:10.1002/9783527619887.ch4a

Kudahettige-Nilsson RL, Helmerius J, Nilsson RT, Sjöblom M, Hodge DB, Rova U (2014) Biobutanol production by Clostridium acetobutylicum using xylose recovered from birch Kraft black liquor. Bioresour Technol. doi:10.1016/j.biortech.2014.11.012

Käkölä J, Alén R, Pakkanen H, Matilainen R, Lahti K (2007) Quantitative determination of the main aliphatic carboxylic acids in wood Kraft black liquors by high-performance liquid chromatography–mass spectrometry. J Chromatogr A 1139(2):263–270

Linder Å, Bergman R, Bodin A, Gatenholm P (2003) Mechanism of assembly of xylan onto cellulose surfaces. Langmuir 19(12):5072–5077

Ebringerová A (2005) Structural diversity and application potential of hemicelluloses. Macromol Symp 232:1–12. doi:10.1002/masy.200551401

Mozdyniewicz D, Nieminen K, Sixta H (2013) Alkaline steeping of dissolving pulp. Part I: cellulose degradation kinetics. Cellulose 20:1437–1451. doi:10.1007/s10570-013-9926-2

Dahlman O, Jacobs A, Sjöberg J (2003) Molecular properties of hemicelluloses located in the surface and inner layers of hardwood and softwood pulps. Cellulose 10:325–334. doi:10.1023/a:1027316926308

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenerg Res 6:405–415. doi:10.1007/s12155-012-9276-1

Rockwood DL, Kirst M, Isebrands JG, Zhu JY (2012) Forest trees. In: Kole C, Joshi CP, Shonnard DR (eds) Handbook of bioenergy crop plants. CRC Press, Boca Raton

Saka S, Thomas RJ (1982) Fiber surface structure and fiber liberation in soda-anthraquinone kraft and soda pulps as determined by conventional electron microscopy. Wood Fiber Sci 14:144–158

Wang QQ, He Z, Zhu Z, Zhang YHP, Ni Y, Luo XL, Zhu JY (2012) Evaluations of cellulose accessibilities of lignocelluloses by solute exclusion and protein adsorption techniques. Biotechnol Bioeng 109:381–389. doi:10.1002/bit.23330

Schwald W, Brownell HH, Saddler JN (1988) Enzymatic hydrolysis of steam rreated aspen wood: Influence of partial hemicellulose and lignin removal prior to pretreatment. J Wood Chem Technol 8:543–560. doi:10.1080/02773818808070700

Ishizawa C, Jeoh T, Adney W, Himmel M, Johnson D, Davis M (2009) Can delignification decrease cellulose digestibility in acid pretreated corn stover? Cellulose 16:677–686. doi:10.1007/s10570-009-9313-1

Hult EL, Larsson PT, Iversen T (2001) Cellulose fibril aggregation — an inherent property of Kraft pulps. Polymer 42:3309–3314. doi:10.1016/S0032-3861(00)00774-6

Luo XL, Zhu JY (2011) Effects of drying-induced fiber hornification on enzymatic saccharification of lignocelluloses. Enzym MicrobTechnol 48:92–99. doi:10.1016/j.enzmictec.2010.09.014

Klein-Marcuschamer D, Oleskowicz‐Popiel P, Simmons BA, Blanch HW (2012) The challenge of enzyme cost in the production of lignocellulosic biofuels. Biotechnol Bioeng 109:1083–1087

Miao Z, Grift T, Hansen A, Ting K (2011) Energy requirement for comminution of biomass in relation to particle physical properties. Ind Crops Prod 33:504–513

Sundholm J, Gullichsen J, Paulerpo H, Pulping M (1999) Papermaking science and technology. Fapet Oy, Helsinki

Garlock RJ, Wong YS, Balan V, Dale BE (2012) AFEX pretreatment and enzymatic conversion of black locust (Robinia pseudoacacia L.) to soluble sugars. Bioenerg Res 5:306–318

Jones BW, Venditti R, Park S, Jameel H, Koo B (2013) Enhancement in enzymatic hydrolysis by mechanical refining for pretreated hardwood lignocellulosics. Bioresour Technol 147:353–360. doi:10.1016/j.biortech.2013.08.030

Zhu W, Zhu JY, Gleisner R, Pan XJ (2010) On energy consumption for size-reduction and yields from subsequent enzymatic saccharification of pretreated lodgepole pine. Bioresour Technol 101:2782–2792

Acknowledgments

Ryan Stoklosa was supported in part by funding from the Northeast Sun Grant Initiative. Natassa Christides (Michigan State University Department of Chemical Engineering and Materials Science) provided laboratory assistance and was supported by an NSF Due Grant (#0757020).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stoklosa, R.J., Hodge, D.B. Fractionation and Improved Enzymatic Deconstruction of Hardwoods with Alkaline Delignification. Bioenerg. Res. 8, 1224–1234 (2015). https://doi.org/10.1007/s12155-015-9579-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-015-9579-0