Abstract

Here, we present a quasi-universal correlation for the friction factor in 90-degree and 180-degree bend pipes using the ensemble of metamodels (EOM). Using computational simulations, we obtain frictional losses at curvature ratios from 0.01 to 0.2 and Reynolds numbers up to 0.1 million. With the help of this data, we develop the EOM based correlation. The extensive window of parameters considered in the present study encompasses a vast design and operating conditions of 90-degree and 180-degree bend pipes. The large parametric space considered here essentially represents a variety of hydrodynamic scenarios. We use a sufficient yet nominal set of parameters representative of the variation and perform numerical simulations over the sampled set. Using the simulation data, we then train and validate the EOM to develop the required correlation. The k-fold cross-validation technique is employed to the EOM to optimize the model’s predictive capabilities over the changing flow regimes. We believe that this modeling strategy, along with the database, may act as a base framework towards the further development of data augmentation techniques in pipes of various configurations, in general. Using this EOM based correlation, we further generate a large database for the friction factor in the two smooth bend pipe configurations at various curvature ratio and different Reynolds number. This approach can be viewed as an alternative to the Moody chart, however, for pipe bends.

Similar content being viewed by others

Data availability

The data obtained from the numerical analysis and the optimization using ensemble of metamodels, is available in the Mendeley Data repository (https://doi.org/10.17632/wcfj8byjw6.1).

Abbreviations

- \(C\) :

-

Correlation function

- \({\varvec{C}}\) :

-

Correlation matrix

- \(d\) :

-

Pipe diameter

- \(De\) :

-

Dean number

- \(E\) :

-

Metamodel

- \(\overline{E }\) :

-

Ensemble of metamodels

- \(F\) :

-

Sigmoidal function

- \(f\) :

-

Darcy friction factor

- \(k\) :

-

Turbulent kinetic energy

- \({O}_{j}\) :

-

Output of neuron

- \(p\) :

-

Pressure

- \(Po\) :

-

Pouiselle number

- \(R\) :

-

Radius of curvature

- \(Re\) :

-

Reynolds Number

- \(R{e}_{t}\) :

-

Turbulent Reynolds number

- \({r}_{s}\) :

-

Spearman’s rank coefficient

- \(S\) :

-

Training sample

- \({u}_{m}\) :

-

Cross-section averaged velocity

- \(w\) :

-

Weight of metamodels

- \({w}_{ij}\) :

-

Intermediate weights of neuron

- \({X}_{i}\) :

-

Input parameter of neuron

- \({y}^{+}\) :

-

Non-dimensional length scale

- \(Z\) :

-

Stochastic component

- \(\alpha \) :

-

Momentum factor

- \(\beta \) :

-

Regression weight

- \(\varepsilon \) :

-

Random error vector

- \(\epsilon \) :

-

Turbulent dissipation

- \(\eta \) :

-

Learning rate

- \({\theta }^{*}\) :

-

Kriging function parameter

- \({\theta }_{b}\) :

-

Bend angle

- \({\theta }_{j}\) :

-

Bias of neuron weights

- \(\kappa \) :

-

Curvature ratio of pipe

- \(\mu \) :

-

Dynamic viscosity of fluid

- \(\rho \) :

-

Density of fluid

- \({\sigma }^{2}\) :

-

Variance

- \({\sigma }_{i}\) :

-

Width of hidden neuron

- \({\tau }_{w}\) :

-

Wall shear stress

- \({\psi }_{i}\) :

-

Gaussian function activation unit

- \(\omega \) :

-

Rate of turbulent dissipation

References

Eustice J 1911 Experiments on stream-line motion in curved pipes. Proceedings of the Royal Society of London Series A Containing Papers of a Mathematical and Physical Character. 85: 119–131. https://doi.org/10.1098/rspa.1911.0026

Dean W R 1927 XVI Note on the motion of fluid in a curved pipe. The London Edinburgh and Dublin Philosophical Magazine and Journal of Science. 4: 208–223. https://doi.org/10.1080/14786440708564324

Dean W R 1928 LXXII The stream-line motion of fluid in a curved pipe (Second paper). The London Edinburgh and Dublin Philosophical Magazine and Journal of Science. 5: 673–695. https://doi.org/10.1080/14786440408564513

Itō H 1959 Friction Factors for Turbulent Flow in Curved Pipes. Journal of Basic Engineering. 81: 123–132. https://doi.org/10.1115/14008390

Soh W Y and Berger S A 1987 Fully developed flow in a curved pipe of arbitrary curvature ratio. Int. J. Numer. Methods Fluids. 7: 733–755. https://doi.org/10.1002/fld.1650070705

Vashisth S, Kumar V and Nigam K D P 2008 A review on the potential applications of curved geometries in process industry. Ind. Eng. Chem. Res. 47: 3291–3337. https://doi.org/10.1021/ie701760h

Acar E and Rais-Rohani M 2009 Ensemble of metamodels with optimized weight factors. Structural and Multidisciplinary Optimization. 37: 279–294. https://doi.org/10.1007/s00158-008-0230-y

Patankar S V, Pratap V S and Spalding D B 1975 Prediction of Turbulent Flow in Curved Pipes. Numerical Prediction of Flow Heat Transfer Turbulence and Combustion. Elsevier, pp. 147–159 doi: 101016/b978-0-08-030937-850019-2

Rathore M K, Mondloe D S and Upadhyay S 2017 Computational Investigation of Fluid Flow Bend Pipe Using Finite Volume Approach. International Research Journal of Engineering and Technology (IRJET). 4 [Online] Available: https://irjet.net/archives/V4/i6/IRJET-V4I6349.pdf

Dutta P and Nandi N 2015 Effect of Reynolds number and curvature ratio on single phase turbulent flow in pipe bends. Mechanics and Mechanical Engineering. 19: 5–16

Röhrig R, Jakirlić S and Tropea C 2015 Comparative computational study of turbulent flow in a 90° pipe elbow. Int. J. Heat Fluid Flow. 55: 120–131. https://doi.org/10.1016/jijheatfluidflow201507011

Chowdhury R R, Alam M M and Islam A K M S 2016 Numerical modeling of turbulent flow through bend pipes. Environment. 6: 7

Venkataraman S and Haftka R T 2004 Structural optimization complexity: What has Moore’s law done for us? Structural and Multidisciplinary Optimization. 28: 375–387. https://doi.org/10.1007/s00158-004-0415-y

Booker A J 1998 Design and analysis of computer experiments. 7th AIAA/USAF/NASA/ISSMO Symposium on Multidisciplinary Analysis and Optimization, pp. 118–128 doi: 102514/61998-4757

Lophaven S, Nielsen H B and Sondergaard J 2002. DACE - A Matlab Kriging Toolbox (auch für Scilab). 2 Citeseer [Online] Available: http://www.2imm.dtu.dk/~hbn/dace/dace.pdf%5C

Martin J D and Simpson T W 2005 Use of kriging models to approximate deterministic computer models. AIAA Journal. 43: 853–863. https://doi.org/10.2514/18650

Addelman S, Box G E P, Hunter W G and Hunter J S 1979. Statistics for Experimenters. 21: 3 John Wiley and sons New York doi: 102307/1267766

Gunst R F, Myers R H and Montgomery D C 1996 Response Surface Methodology: Process and Product Optimization Using Designed Experiments. Technometrics. 38: 285. https://doi.org/10.2307/1270613

Dyn N, Levin D and Rippa S 1986 Numerical Procedures for Surface Fitting of Scattered Data by Radial Functions. SIAM Journal on Scientific and Statistical Computing. 7: 639–659. https://doi.org/10.1137/0907043

Mullur A A and Messac A 2005 Extended radial basis functions: More flexible and effective metamodeling. AIAA Journal. 43: 1306–1315. https://doi.org/10.2514/111292

Murtagh F M 1991. Neural networks for statistical and economic data. 3 Thomson Learning doi: 101016/0925-2312(91)90019-8

Cheng B and Titterington D M 1994 Neural networks: A review from a statistical perspective. Statistical Science. 9: 2–30. https://doi.org/10.1214/ss/1177010638

MacKay D 1998 Introduction to Gaussian Processes. Book Neural Networks and Machine Learning Springer-Verlag. 168: 84–92

Smola A J and Schölkopf B 2004 A tutorial on support vector regression. Stat. Comput. 14: 199–222. https://doi.org/10.1023/B:STCO00000353014954988

Clarke S M, Griebsch J H and Simpson T W 2005 Analysis of support vector regression for approximation of complex engineering analyses. Journal of Mechanical Design Transactions of the ASME. American Society of Mechanical Engineers Digital Collection, pp. 1077–1087 doi: 101115/11897403

Goel T, Haftka R T, Shyy W and Queipo N V 2007 Ensemble of surrogates. Structural and Multidisciplinary Optimization. 33: 199–216. https://doi.org/10.1007/s00158-006-0051-9

Zerpa L E, Queipo N V, Pintos S and Salager J L 2004 An optimization methodology of alkaline-surfactant-polymer flooding processes using field scale numerical simulation and multiple surrogates. Proceedings - SPE Symposium on Improved Oil Recovery. 2004-April 3–4: 197–208 doi: 102523/89387-ms

Viana F A C, Haftka R T and Steffen V 2009 Multiple surrogates: How cross-validation errors can help us to obtain the best predictor. Structural and Multidisciplinary Optimization. 39: 439–457. https://doi.org/10.1007/s00158-008-0338-0

Husain A and Kim K Y 2010 Enhanced multi-objective optimization of a microchannel heat sink through evolutionary algorithm coupled with multiple surrogate models. Appl. Therm. Eng. 30: 1683–1691. https://doi.org/10.1016/japplthermaleng201003027

Bellary S A I, Adhav R, Siddique M H, Chon B H, Kenyery F and Samad A 2016 Application of computational fluid dynamics and surrogate-coupled evolutionary computing to enhance centrifugal-pump performance. Engineering Applications of Computational Fluid Mechanics. 10: 172–182. https://doi.org/10.1080/1994206020151128359

Heo M W, Kim K Y, Kim J H and Choi Y S 2016 High-efficiency design of a mixed-flow pump using a surrogate model. Journal of Mechanical Science and Technology. 30: 541–547. https://doi.org/10.1007/s12206-016-0107-8

Samad A and Kim K-Y 2009 Surrogate Based Optimization Techniques for Aerodynamic Design of Turbomachinery. International Journal of Fluid Machinery and Systems. 2: 179–188. https://doi.org/10.5293/ijfms200922179

Shi H-ning, Ma T, Chu W-xiao and Wang Q-wang 2017 Optimization of inlet part of a microchannel ceramic heat exchanger using surrogate model coupled with genetic algorithm. Energy Conversion and Management. 149: 988–996. https://doi.org/10.1016/j.enconman.2017.04.035

Mak S, Sung C-Li, Wang X, Yeh S-Ting, Chang Y-Hung, Joseph V R, Yang V and Wu C F J 2018 An efficient surrogate model for emulation and physics extraction of large eddy simulations. Journal of the American Statistical Association. 113: 1443–1456. https://doi.org/10.1080/01621459.2017.1409123

Sun L, Gao H, Pan S and Wang J X 2020 Surrogate modeling for fluid flows based on physics-constrained deep learning without simulation data. Comput Methods Appl. Mech. Eng. 361: 112732 doi: 101016/jcma2019112732

Narayanan G, Joshi M, Dutta P and Kalita K 2020 PSO-tuned support vector machine metamodels for assessment of turbulent flows in pipe bends. Engineering Computations (Swansea Wales). 37: 981–1001. https://doi.org/10.1108/EC-05-2019-0244

Ganesh N, Dutta P, Ramachandran M, Bhoi A K and Kalita K 2020 Robust metamodels for accurate quantitative estimation of turbulent flow in pipe bends. Eng. Comput. 36: 1041–1058. https://doi.org/10.1007/s00366-019-00748-7

McKeon B J, Swanson C J, Zagarola M V, Donnelly R J and Smits A J 2004 Friction factors for smooth pipe flow. J. Fluid Mech. 511: 41–44. https://doi.org/10.1017/S0022112004009796

Keulegan G H and Beij K H 1937. Pressure losses for fluid flow in curved pipes. 18 1 US Government Printing Office doi: 106028/jres018049

Berger S A, Talbot L and Yao L S 1983 Flow in Curved Pipes. Annu. Rev. Fluid Mech. 15: 461–512. https://doi.org/10.1146/annurevfl15010183002333

Austin L R and Seader J D 1973 Fully developed viscous flow in coiled circular pipes. AIChE Journal. 19: 85–94. https://doi.org/10.1002/aic690190113

White C M 1932 Fluid friction and its relation to heat transfer. Transactions of the Institutions of Chemical Engineers. 10: 66–86

Brown G O 2002 The history of the Darcy-Weisbach equation for pipe flow resistance. Proceedings of the Environmental and Water Resources History, pp. 34–43 doi: 101061/40650(2003)4

Churchill S W 1977 Friction-Factor Equation Spans All Fluid-Flow Regimes. Chemical Engineering (New York) 84: 91–92

Colebrook C F and White C M 1937 Experiments with fluid friction in roughened pipes. Proc. R. Soc. London A Math. Phys. Sci. 161: 367–381. https://doi.org/10.1098/rspa19370150

Pope S B 2001 Turbulent Flows. Meas. Sci. Technol. 12: 2020–2021. https://doi.org/10.1088/0957-0233/12/11/705

Lambert J 1758 Observationes variae in mathesin puram. Acta Helvetica physico-mathematico-anatomico-botanico-medica. 3: 128–168

Skalak R and Sutera S P 1993 The history of Poiseuille’s Law. Annu. Rev. Fluid Mech. 25: 1

Bernard P S and Wallace J M 2003 Turbulent Flows. IOP Publishing. https://doi.org/10.1002/3527600434eap544

Vasa A and Chaudhury K 2022 The vortex structures of the mean turbulent flow field in a 90-degree bend pipe. European Journal of Mechanics - B/Fluids. 98: 21–31. https://doi.org/10.1016/jeuromechflu202211004

Loulou P, Moser R D, Mansour N N and Cantwell B J 1997 Direct numerical simulation of incompressible pipe flow using a B-spline spectral method

Wu X and Moin P A 2008 direct numerical simulation study on the mean velocity characteristics in turbulent pipe flow. J. Fluid Mech. 608: 81–112

Singh S P and Mittal S 2005 Flow past a cylinder: Shear layer instability and drag crisis. Int. J. Numer. Methods Fluids. 47: 75–98. https://doi.org/10.1002/fld807

Vasa A and Chaudhury K 2022 Frictional loss in bend pipes: numerical simulation and data driven modelling. Mendeley Data. V1 doi: 1017632/wcfj8byjw61

Hüttl T J and Friedrich R 2000 Influence of curvature and torsion on turbulent flow in helically coiled pipes in. International Journal of Heat and Fluid Flow. Elsevier Science Inc, pp. 345–353 doi: 101016/S0142-727X(00)00019-9

Rowe M 1970 Measurements and computations of flow in pipe bends. J. Fluid Mech. 43: 771–783. https://doi.org/10.1017/S0022112070002732

Kothari S C and Oh H 1993. Neural Networks for Pattern Recognition. 37 Oxford university press doi: 101016/S0065-2458(08)60404-0

Myers J L, Well A D and Lorch R F 2013. Research design and statistical analysis third edition. 9780203726 Routledge doi: 104324/9780203726631

Box G E P and Wilson K B 1951 On the Experimental Attainment of Optimum Conditions. Journal of the Royal Statistical Society: Series B (Methodological). 13: 1–38. https://doi.org/10.1111/j2517-61611951tb00067x

Sobieszczanski-Sobieski J and Haftka R T 1996 Multidisciplinary aerospace design optimization: Survey of recent developments. 34th Aerospace Sciences Meeting and Exhibit. 14: 1–23 doi: 102514/61996-711

Rosenblatt F 1957 The Perceptron - A Perceiving and Recognizing Automaton. Cornell Aeronautical Laboratory

Hecht-Nielsen R 1987 Kolmogorov’s Mapping Neural Network Existence Theorem in. Proceedings of the International Conference on Neural Networks, pp. 11–14

Rogers L L and Dowla F U 1994 Optimization of groundwater remediation using artificial neural networks with parallel solute transport modelling. Water Resour Res. 30: 457–481. https://doi.org/10.1029/93WR01494

Hecht-Nielsen R 1989 Theory of the backpropagation neural network in. Neural networks for perception. Elsevier, pp. 593–605 doi: 101109/ijcnn1989118638

Samadi M, Jabbari E, Azamathulla H M and Mojallal M 2015 Estimation of scour depth below free overfall spillways using multivariate adaptive regression splines and artificial neural networks. Engineering Applications of Computational Fluid Mechanics. 9: 291–300. https://doi.org/10.1080/1994206020151011826

Viana F A C 2010 SURROGATES Toolbox User’s Guide Version 21. [Online] Available: http://sites.google.com/site/fchegury/surrogatestoolbox

Myers R H, Montgomery D C, Geoffrey G, Borror Vining C M and Kowalski S M 2004 Response Surface Methodology: A Retrospective and Literature Survey. Journal of Quality Technology. 36: 53–78. https://doi.org/10.1080/00224065200411980252

Couckuyt I, Dhaene T and Demeester P 2014 OoDACE toolbox: A flexible object-oriented kriging implementation. Journal of Machine Learning Research. 15: 3183–3186

Bishop C M 1995. Neural networks for pattern recognition. Clarendon Press Accessed: Jul 02 2021 [Online] Available: https://globaloup.com/academic/product/neural-networks-for-pattern-recognition-9780198538646#YN9yJeRHgm4mendeley

Eisfeld B, Rumsey C and Togiti V 2016 Verification and Validation of a Second-Moment-Closure Model. AIAA Journal. 54: 1524–1541. https://doi.org/10.2514/1J054718

Chou P Y 1945 On velocity correlations and the solutions of the equations of turbulent fluctuation. Q. Appl. Math. 3: 38–54. https://doi.org/10.1090/qam/11999

Rotta J 1951 Statistische Theorie nichthomogener Turbulenz. Zeitschrift für Physik. 129: 547–572. https://doi.org/10.1007/BF01330059

Daly B J and Harlow F H 1970 Transport equations in turbulence. Physics of Fluids. 13: 2634–2649. https://doi.org/10.1063/11692845

Launder B E and Spalding D B 1983 The Numerical Computation of Turbulent Flows. Numerical Prediction of Flow Heat Transfer Turbulence and Combustion. Elsevier, pp. 96–116 doi: 101016/b978-0-08-030937-850016-7

Fu S, Launder B E and Leschziner M A 1987 Modeling strongly swirling recirculating jet flow with Reynolds stress transport closures. In: Symposium on Turbulent Shear Flows 6th Toulouse France, pp. 17-6–2 to 17-6–6

Launder B E 1989 Second-moment closure: present and future? Int. J. Heat Fluid Flow. 10: 282–300. https://doi.org/10.1016/0142-727X(89)90017-9

Launder B E and Shima N 1989 Second-moment closure for the near-wall sublayer: Development and application. AIAA Journal. 27: 1319–1325. https://doi.org/10.2514/310267

Acknowledgement

The present work was supported by a doctoral scholarship for AV from the Ministry of Education, India and through a seed grant for KC from the National Institute of Technology, Rourkela, India [vide letter number, NITR/RG/2018/M/0430, Dated: August 20,2018].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Appendix A: Reynolds Stress Model theory

Appendix A: Reynolds Stress Model theory

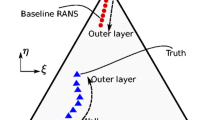

The steady RANS based Reynolds Stress closure model (RSM) is used in this analysis. The theory of this model is quite extensive. Therefore, we present only a brief overview of the model equations. Since the Fluent solver is used for our simulations, we greatly refer to the ANSYS documentation for this model. We also refer to the NASA turbulence modeling resource [70], for a more verified and up to date representation of the model. Furthermore, we attempt to represent the equations here in a structured manner, in tune with the NASA turbulence modeling resource. RSM is used in turbulent flow cases where anisotropy predominantly effects mean flow. This may include unbalances in axial flow due to curvature, pressure differences, mixing, and secondary flow. Modeling transport equations using RSM includes five additional equations in two-dimensional and seven additional equations in three-dimensional flows [71, 72]. The exact Reynolds stress transport equations for Reynolds stresses \(-\rho \overline{{u }_{i}^{\prime}{u}_{j}^{\prime}}\) is given by

Where, \(k\) is the turbulent kinetic energy and its dissipation is \(\epsilon \). The first term on the right-hand side \(-\partial /\partial {x}_{k}\left[\rho \overline{{u }_{i}^{\mathrm{^{\prime}}}{u}_{j}^{\mathrm{^{\prime}}}{u}_{k}\mathrm{^{\prime}}}+\stackrel{-}{p\left({\delta }_{kj}{u}_{i}^{\mathrm{^{\prime}}}+{\delta }_{ik}{u}_{j}\mathrm{^{\prime}}\right)}\right]\) describes turbulent diffusion \({(D}_{T,ij})\), which is modeled using a gradient-diffusion model [73] given by

Following the lead of Launder and Spalding [74], Fu et al [75] and Launder [76], the pressure strain term \(p\left(\partial {u}_{i}^{\prime}/\partial {x}_{j}+\partial {u}_{j}^{\prime}/\partial {x}_{i}\right)\) may be denoted as \({\phi }_{ij}\) given by

Where, \({\phi }_{ij,1}\) and \({\phi }_{ij,2}\) are pressure strain terms where 1 denotes slow and 2 denotes rapid. They are solved using Eqs. (A.4) and (A.5). \({\phi }_{ij,w}\) represents wall reflection.

Where, \(P=0.5{P}_{kk}\), \(G=0.5{G}_{kk}\) and \(C=0.5{C}_{kk}\). The equation for wall reflection is

Where, \({n}_{u}\) unit normal of wall, \({d}_{n}\) is distance normal of wall and \({C}_{l}={C}_{\mu }^{3/4}/k\), where \({C}_{\mu }=0.09\). A two-layer model with enhanced wall treatment is considered here. This approach divides the domain into two regions. Within these two regions, one may be dominated by turbulence and the other by viscosity. This division is determined by turbulent Reynolds number (\(R{e}_{t}\)), given by

Launder and Shima [77] state that \({C}_{1},{C}_{2},{C}_{1}^{\prime}\) and \({C}_{2}^{\prime}\) are functions of the resultant invariants and \(R{e}_{t}\). They are equated by

Where, \({A}_{2}\) and \({A}_{3}\) are the tensor invariants and \(A\) is the flatness invariant.

The anisotropy tensor (\({a}_{ij}\)) is given by

Rights and permissions

About this article

Cite this article

Vasa, A., Chaudhury, K. Frictional loss in bend pipes: numerical simulation and data driven modeling. Sādhanā 48, 186 (2023). https://doi.org/10.1007/s12046-023-02236-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-023-02236-7