Abstract

High biobased carbon content polyurethane dispersions (PUD) are a more sustainable alternative to conventional oil-derived waterborne dispersions in coatings. However, there are still many performance limitations from restricted availability of effective renewable monomers and oligomers. This work demonstrates the improvement of the properties of high biobased content PUD and derived coating by introducing a photo-reversibly crosslinkable coumarin as chain extender within the structure. The effect of partial substitution of 1,3-propanediol biobased by a di-hydroxy photo-reactive cyclic coumarin on the particle size and the stability was analyzed by dynamic light scattering (DLS) and multiple light scattering (MLS). The lateral and more rigid structure of coumarin involved a moderated increment in particle size without significant effect on the dispersion stability for at least 45 days. Associated improvement in hardness and toughness was also demonstrated by tensile test, pendulum hardness, pencil hardness and scratch resistance test. Furthermore, controlled UV irradiation of the polyurethane gave rise to a mechanical performance adjustment from reversible photo-crosslinking and scission of the coumarin molecules within the macromolecular structure. A 70% dimerization degree of the coumarin within the polyurethane film by UV light provided a partially reversible threefold higher tensile strength than that of the original biobased formulation as an effective tool to tune the response of biobased polyurethanes.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polyurethanes are one of the most popular classes of polymers for a large number of coating applications thanks to properties that can be tailored over a wide range.1 However, the environmental policies, the worldwide crude oil price fluctuations, the depletion of the fossil fuel reserves, as well as global warming, are pressing to achieve more sustainable products able to substitute the conventional solvent-based coatings. In the last decades, thus, waterborne polyurethane dispersions (PUDs) have gained major relevance because they successfully supersede their conventional solventborne counterparts.2,3,4

In this scenario, another natural step forward is to increase the biocontent in PUD from using biopolyols gradually becoming commercially available.5,6 Therefore, several studies have been published in recent years regarding waterborne polyurethane dispersions (PUDs) synthesized from polyols based on natural oils.7,8,9,10,11,12

Nevertheless, high biobased carbon content with suitable performance still remains a challenge for high-demanding polyurethane industries from certain limitations in properties.13 The higher the target technical performance, the more likely a manufacturer is not able to come up with suitable biobased compounds to be directly used.

Coumarins are characterized by different interesting physical, biological, photo-physical and photochemical properties from a wide range of chemical structures and side substituents, which turns them into molecules able to provide new functions to polyurethanes.14 Then, biobased solutions could also exploit those features to improve performance or to achieve new functions to enlarge their usefulness. Coumarin consists of a large family of benzo-α-pyrones characterized by fused benzene and pyrone rings that can be easily obtained from many species of plants, bacteria and fungi (Fig. 1). These molecules can be photo-reactive chemicals able to experience reversible [2π + 2π] cycloaddition reactions to cause a cyclobutane ring upon UV irradiation.15 In particular, cycloaddition reaction occurs at ≈365 nm, whereas photo-cleavage reaction at 254 nm renders the original coumarin moieties. It is clear that these reactions in the solid state can be extremely useful for surface coatings, although reversible photo-reactions show continuous cycle by cycle loss of efficiency, particularly for photo-scission processes.14

Coumarins have provided intrinsic healing features to polyurethanes (between 16 and 78% of damage recovery as a function of the structure).16,17 Besides, the photo-reactivity of coumarin has been studied to crosslink polyurethane linear chains18,19,20 (Fig. 2).

This current work studies a non-previously reported approach to enhance the performance of a high content of biogenic carbon PUD by incorporating a coumarin diol in the synthesis as a photo-reactive chain extender in a prepolymer mixing process. The results demonstrate the possibility of designing coatings derived from photo-crosslinkable biobased waterborne polyurethane dispersions with enhanced performance, which could find wide applications in sectors as textile, wood, or packaging, among others, where PUD are widely used.

Experimental

Materials

According to the synthesis process previously reported by the authors to obtain the coumarin monomer,18 2,2-bis(hydroxymethyl)propionic acid, 2,2-dimethoxypropane, p-toluenesulfonic acid monohydrate, 1,3-dicyclohexylcarbodiimide, resorcinol, ethyl acetoacetate, 2-bromoethanol (BrEtOH), anhydrous pyridine and dowex H + resin were supplied by Sigma-Aldrich and used as received. Priplast 3294 (Croda), a 100% biobased polyester polyol with an approximate molecular weight (Mw) of 2000 g mol–1, was used as polyol, whereas a 100% biobased 1,3 propanediol from Dupont was used as chain extender. Dimethylolpropionic acid (DMPA) as internal emulsifier, triethylamine (TEA) as the neutralizer, dibutyltin dilaurate (DBTDL) as the catalyst and N-methyl pyrrolidone (NMP) as a cosolvent were supplied by Sigma-Aldrich. Aliphatic diisocyanate for the synthesis of the polyurethane was isophorone diisocyanate (IPDI) (supplied by Merck).

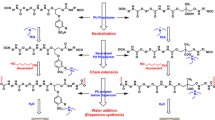

Synthesis of 2,2-bis(hydroxymethyl)propionate of 7-hydroxyethoxy-4-methylcoumarin (DHEOMC diol)

The synthesis process of the coumarin diol was previously published by the authors.18 Isopropylidene-2,2-bis-(methoxy)propionic anhydride (DMPAA) was synthesized according to literature.21,22 7-Hydroxyethoxy-4-methylcoumarin (HEOMC) was synthesized by reacting 7-hydroxy-4-methylcoumarin with BrEtOH and potassium carbonate in DMF. Afterwards, DMPAA and HEOMC were reacted to produce an ester. Finally, the deprotection of the hydroxyl groups was performed by introduced the protonated resin to obtain the target DHEOMC diol (Fig. 3). Solution liquid 1H NMR spectrum was recorded at room temperature in a Varian Unity Plus 400 instrument using deuterated chloroform (CDCl3) or deuterated dimethylsulfoxide (DMSO-d6) as solvent. Spectrum was referenced to the residual solvent protons at 7.26 or 2.50 ppm.

Synthesis of the waterborne polyurethane dispersions

Water polyurethane dispersions (PUD) were prepared by prepolymer mixing process.23 NMP cosolvent was used (12 wt%) to reduce the viscosity of the reaction media. The formulations used in the different reactions are summarized in Table 1.

The polymer was designed according to the following features: the ratio [NCO]/[OH] in prepolymer is 1.5, internal emulsifier, DMPA, was set to 7 wt% based on the weight of the prepolymer, and the corresponding carboxylic groups were 100% neutralized by the addition of TEA. The solid content in the final waterborne PUD was 30 wt%. In the synthesis of polyurethane with coumarin, this compound, DHEOMC, was introduced dissolved in NMP as chain extender substituting partially 1,3 propanediol. A 5 wt% content of coumarin was selected as effective enough modification with suitable dispersion quality.28,29 A low particle size distribution, with the associated long period stability of the dispersion, are imperative for useful suitable waterborne coatings. Therefore, coumarin content must be limited to avoid any undesirable effect on the dispersion but with enough photo-reactive effect to provide variations in polyurethane performance by irradiation.

Polyol, IPDI, DMPA, catalyst and cosolvent reacted in a 250 mL glass-jacketed reactor equipped with a mechanical stirrer at 80°C for 2.5 h, under nitrogen atmosphere, to synthesize the NCO-terminated prepolymer. TEA was added at lower temperature to perform the neutralization process for 0.5 h. Subsequently, the chain extender (1,3-propanediol or/and DHEOMC diol) was added, and the synthesis of the polyurethane occurred for 1.5 h. Dispersion was achieved by gradually incorporating water to the polyurethane at 30°C under vigorous stirring. The reaction scheme can be seen in Fig. 4.

Polyurethane films were prepared by casting 4 g of polyurethane dispersion in a mould and allowing evaporation of the water at room temperature for 7 days. Afterwards, the polyurethane was dried at 50°C for 24 h. Transparent films obtained were 0.3–0.5 mm thick.

Photo-dimerization of polyurethane

Irradiation for photo-dimerization/photo-cleavage of polyurethane film with coumarin in the hard segment was carried out in an ultraviolet crosslinker (ultraviolet products) equipped with two set of 5 (8 W) lamps for 354 nm or 254 nm irradiations (354 and 254 nm are the wavelengths on the maxima of the irradiation spectra of the lamps, respectively). Photo-dimerization of coumarin and the formation of cyclobutane to crosslink the polyurethane chains occur when irradiated at 354 nm. The light-triggered cyclobutane cleavage reaction occurs by irradiating again dimerized polyurethanes at 254 nm.

Characterization

Characterization of the polyurethane dispersions

Particle size and ζ-potential

The particle size distribution was evaluated by Dynamic Light Scattering (DLS) technique from measuring variations in the light scattered by the polyurethane dispersions. The zeta (ζ) potential was established by Phase Analysis Light Scattering from the electrophoretic mobility of the dispersions. Both parameters were measured with a Brookhaven ZetaPALS instrument. PUD samples were diluted with deionized water before measurement at 25°C.

Medium term stability

Medium term stability analysis was carried out with Turbiscan™ LAB Stability Analyser from Formulaction SA. The technology embedded in Turbiscan LAB™ is based on the Multiple Light Scattering (MLS) technique, which enables fast and sensitive identification of destabilization mechanisms (such as creaming, sedimentation, flocculation, coalescence, etc.). Turbiscan LAB calculates Turbiscan® Stability Index (TSI), which is a specific parameter developed to compare and characterize the physical stability of samples. TSI value can be associated to the destabilization kinetics analyzing its evolution over the time.

Stability of PUD was evaluated without dilution at different times to detect destabilization mechanisms and obtain destabilization kinetics curves.

Characterization of the polyurethane films

Molecular weight

The molecular mass distribution of the PUD films was determined by gel permeation chromatography, using GPC WATERS equipment, with refractive index detector 2414 and two columns TOSOH HR1 and HR3, calibrated with respect to polystyrene standards. Polymer were dissolved in tetrahydrofuran (THF) and 70 µL of the sample was injected with a volume rate of carrier solvent of 1 mL min−1 at 40°C temperature. The average molecular masses, Mn, Mw and polydispersity index were determined.

Photo-reactivity of polyurethanes

UV experiments were performed in a Perkin Elmer Lambda 35 UV/Vis spectrometer. Absorbance of the thin film was measured from 380 to 250 nm. The photo-reversibility of the synthesized polyurethane was characterized in the coatings by UV. During dimerization, the UV peak with maximum in absorbance at 320 nm in the polyurethane UV spectrum related to the conjugated π-system decreased due to the disappearance of the double bond in the coumarin with formation of a cyclobutane ring by [2π + 2π] cycloaddition. The maximum absorbance at 320 nm was used to describe the photo-reaction degree,24,25 where conversion is

At: absorbance at 320 nm at time t since start of UV radiation.

Ao: absorbance at 320 nm at time 0.

Raman technology was also used to study the photo-dimerization kinetic. Spectroscopy measurements were carried out by a Renishaw in Via Laser micro-Raman Spectrometer (Wotton-under-Edge, UK). A laser beam with wavelength of 785 nm served as the excitation light. The testing area on the film was about 1 μm2. Conversion quantification was done by taking the ratio of the peak related to the double bond at 1617 cm−1 and the peak at 1442 cm−1 related to methylene groups.18,24

The gel content (GC) of the resultant films was measured by gravimetrical analysis soaking the cured films in tetrahydrofuran (THF) for 24 h and drying the insoluble part in an oven at 40°C for 24 h to constant weight.26

Thermal properties

Modulated DSC experiments were carried out in Mettler Toledo DSC 1 instrument. All samples were heated and cooled for several times at the rate of 1°C min−1 in a nitrogen atmosphere. The reversible and non-reversible heat flow information can be simultaneously obtained in this modulated DSC experiment. The temperature of the midpoint of reversible heat flow, corresponding to the change in the specific heat, was taken as the glass transition temperature (tg).

Mechanical properties

Tensile properties were measured in a FTM-50 1000N testing machine (Techlab Systems, S.L.) equipped with a 500 N load cell. Test pieces were cut from the samples. A crosshead speed of 50 mm min−1 was used. Strain was measured from crosshead separation and referred to 10 mm initial length. A minimum of 5 samples were tested for each material.

Polyurethane coatings performance

Polyurethane dispersions were applied on poly(methyl methacrylate) (PMMA) substrate by automatic film applicator with a bar of 64 µm. Drying process was established in 7 days at ambient temperature before testing.

Surface morphology

The study of coatings surface topography was carried out using an PLu neox optical profiler from Sensofar. Confocal scanning technology was used to analyze the roughness. The surface topography obtained was treated and roughness parameters were calculated by Sensoview software according to ISO 25178.

Surface gloss

The gloss of the polyurethane coatings on PMMA pieces was measured according to ISO2813:1994 standard in a Micro-TRI-Gloss instrument (BYK-Gardner GmbH). Gloss was obtained by directing a constant intensity light beam at 60° on the coating surface and measuring the reflected light. The values obtained were the average of ten replicates.

Surface hardness

Pendulum hardness measures the number of oscillations of a pendulum on a coating surface until it stops. The König hardness of the polyurethane coatings on PMMA pieces was measured based on ISO 1522:2006 standard with König Pendulum Hardness Tester (Neurtek. Instruments S.L). The values obtained were the average of ten replicates. Scratch resistance was quantified by measurements of the Pencil Hardness. The pencil hardness scale extends from 9H (hard) to 9B (not hard). We followed ISO 15184, using a Wolf-Wilburn Pencil Hardness tester (BYK-Gardner, Geretsried, Germany).

Results and discussion

Synthesis of 2,2-bis(hydroxymethyl)propionate of 7-hydroxyethoxy-4-methylcoumarin (DHEOMC diol)

After the deprotection reaction of the acetonide group, the chemical composition of DHEOMC was determined by 1H NMR. Apart from target DHEOMC (coumarin diol with a molecular weight of 292 g mol−1), in the NMR spectrum of this product, a signal was detected at 3.74 ppm corresponding to the starting monofunctional product HEOMC. For the determination of the weight content of each product, the aromatic signals of the coumarin moiety (> 6.0 ppm) were used as a reference because they remain constant in both products.

From the ratio of areas between the signals located at 4.36 and 3.74 ppm, (Fig. 5) the molar ratio between both products is determined, considering that the first signal contained four hydrogens of DHEOMC, while the second signal came from two hydrogens of HEOMC. From this area ratio, it was obtained that there was 66.5% mole of DHEOMC and 33.5% mole of HEOMC. Then, from the molecular weights of both products (DHEOMC, 336.34 g mol−1 and HEOMC, 220.22 g mol−1), it was deduced that the weight ratio between both products was 75.21 wt% DHEOMC and 24.79 wt% HEOMC. Therefore, the photo-reactive coumarin monomer obtained was composed of a difunctional (75.21 wt%) and a monofunctional (24.79 wt%) species. In the synthesis of the polyurethane, thus, the effect of the monofunctional 7-hydroxyethoxy-4-methylcoumarin as end-capping agent in the chain extension stage should be considered. While it is true that the photo-reactivity of the functionalized polyurethane should keep proper from HEOMC demonstrating similar dimerization and cleavage conversions than DHEOMC.27 This monomer exhibited close to a 75% dimerization conversion in polyurethane films.19

Synthesis of the waterborne polyurethane dispersions

Photo-reactive PU was obtained by substituting part of biobased chain extender by the DHEOMC to obtain a 5 wt% concentration of coumarin in the final polyurethane, as it was detailed above.

As shown in Table 2, it was found that the average particle size of the biobased dispersion increased with the incorporation of the photo-reactive coumarin, as was observed in literature for petroleum based PUD.17 Steric impediments in particle formation mechanism by the voluminous coumarin side groups resulted in a significant increase in particle sizes. The same carboxyl content from DMPA in coumarin functionalized formulation provided enough electrostatic repulsion between these negatively charged bigger nanoparticles to achieve stable dispersions with a zeta potential well below − 30 mV, which is characteristic of electrostatically stable dispersions.30 The average particle size (d50) of both raw biobased formulation and coumarin based PUD barely increased a 3 and 5% after 45 days of storage, respectively. The dispersions, thus, kept stable with time, as demonstrated not only by the zeta potential, but also by the very slight evolution of TSI index (Fig. 6). The coumarin functionalized PUD just exhibited a slightly higher TSI than original biobased sample from higher initial particle size and slightly more pronounced increase with time. Dispersion remained stables for at least 45 days, no destabilization processes like sedimentation or creaming were detected.

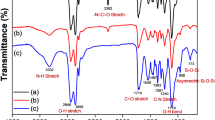

Photo-dimerization/photo-cleavage conversion

Obtained polymer film was exposed to UV radiation in an ultraviolet crosslinker oven during different irradiation times to promote the dimerization and cleavage of photo-active coumarin molecules in polyurethane, as shown in Fig. 7. Photo-dimerization/photo-cleavage reactions were studied by UV VIS spectroscopy and Raman spectroscopy.24 The crosslinking degree achieved was analyzed by gel content test.

UV–Vis spectroscopy revealed that photo-dimerization reaction achieved a conversion of 0.70 by irradiation at 354 nm. However, after excision process by 1.5 min irradiation at 254 nm, the coumarin dimerized conversion decreased until 0.18. That means that the photo-dimerization of polyurethane synthesized was not completely reversible, just the 74% of dimerized coumarin was cleaved by irradiation at 254 nm, see Fig. 8.

Regarding Ramam analysis, conversion quantification was calculated by ratioing the peak related to the double bond at 1617 cm−1 and the peak at 1442 cm−1 related to methylene groups, which remained constant during the UV radiation of polymer (Fig. 9). The photo-dimerization conversion calculated by Raman spectroscopy was 0.70 after 240 min irradiation at 354 nm. Subsequent irradiation at 254 nm for 1.5 min (photo-scission process) led to conversion decreased to 0.16 (which means a photo-cleavage yield of a 77%), Fig. 10. Generally, cleavage yield drops more sharply with irradiation from existing an equilibrium between coumarin and its dimers and from forming non-cleavable dimers when lactone ring opens.14,17 As observed previously in petrol based polyurethanes,18,20 higher conversions were not expected for longer exposure times once asymptotic behavior of conversion curve was observed.

The partial photo-dimerization reaction of DHEOMC in the hard segments (0.7 conversion of a 5 wt% of coumarin) caused the formation of some crosslinking points that promoted a low gel content (3% gel fraction). As described above, reduced content of coumarin preserved the properties of the dispersion and as will be shown, the final aesthetic properties of the coatings. However, this photo-induced lightly crosslinked structure may lead to tailor made improvement of the mechanical performance of elastomeric biobased polyurethanes for flexible applications like packaging or textile, among others.

Polyurethane properties

The analysis of the molecular weight confirmed the potential effect of the monofunctional coumarin specie (HEOMC identified by NMR) as an end-capping agent on the chain extension process. The 24.79% of monohydroxyl coumarin monomer entailed a reduction in the molecular weight of the polyurethane from partially stopping the polymer growth31,32 (Table 2).

The dynamic scan calorimetric revealed a single glass transition temperature indicating that the polymers did not show the characteristic phase separation of these materials. The irregularity structure of IPDI isocyanate along with the presence of coumarin lateral motif difficult the hard segments to segregate and the crystallization of the polyurethane.33

DSC analysis (Table 2 and Fig. 11) demonstrated that glass transition temperatures (tg) of the studied polymers were not significantly affected by the presence of the coumarin monomer. On the one hand, the effect of modifying the chain extender on the tg is really constrained in polyurethane structures with a balance ratio between hard and soft segments (moderate hard segment content), even further when soft segments are formed by high molecular weight polyols, like Priplast (2000 g mol−1) in this study.34 On the other hand, the glass transition temperature was not significantly altered by the low crosslinking degree33,35,36,37 when the 5 wt% fraction of DHEOMC within the hard segment was dimerized. As expected, the long chain biobased soft segment was bearing the greatest effect on tg if compared to chain extender or lightly crosslinked structure.

Different coating properties of the synthesized biobased polyurethanes were studied (Table 3). Side coumarin moieties within the polyurethane chain barely affected the film formation and the related aesthetic properties from surface morphology. The presence of voluminous coumarin species could have some adverse effect on the flow behavior and surface roughness during coalescing and drying of PUD. Then, significant raise in roughness would generate a gloss effect, i.e. enhanced microroughness increases diffusely reflected light and involves a matting effect. However, the sub-micron scale roughness of the biobased coating did not suffer any representative alteration from coumarin species (Table 4 and Fig. 12). Subsequent dimerization and scission also did not modify the surface morphology of the coatings. As a result, the surface gloss remained practically constant despite coumarin rings from excellent formation of a continuous film with very low roughness (much smaller than half the wavelength of visible light, approximately 0.3 μm).38

The results showed that the incorporation of DHEOMC in the biobased polyurethane structure improved the mechanical response of coatings without hindering the aesthetic response. A significant improvement in scratch resistance when DHEOMC was incorporated into the polymer was observed. Furthermore, photo-dimerization of the coating enhanced this resistance from slightly crosslinked structure. Surface hardness also suffered a significant enhancement with the presence of coumarin, though hard segment content was constant. However, in this latter case, the photo-dimerization did not cause a significant increment in surface hardness performance, see Table 4.

Tensile tests demonstrated that mechanical performance improved considerably by incorporating DHEOMC coumarin rings within the elastomeric matrix. The tensile stress grew by up to 200% from the rigid cyclic structures in the linear polyurethane,13 and the associated deformation at failure also increased a 70%. But the effect of the reversible photo-crosslinking on the mechanical performance of the biobased polyurethane is equally interesting from photo-crosslinking/photo-cleavage process of coumarin substantially increasing or decreasing the tensile response of the biopolyurethane (Table 5).

Coumarin crosslinking improved the tensile stress and the strain until 8.46 MPa and 487%, respectively, which supposed an outstanding increase of tensile properties of the biobased polyurethane. For its part, cleavage process at 254 nm partially recovered the tensile strength of the original polyurethane (PUD_BIO_DHEOMC) due to the partly photo-scission of cyclobutane ring when irradiated at 254 nm. As with photo-cleavage process achieved up to 0.70 conversion, full recovery of the mechanical properties of the original soft polyurethane was also not possible, remaining a partial crosslinked structure and associated higher mechanical response (Fig. 13).

Conclusions

Difunctional coumarin molecule (DHEOMC) was successfully introduced as partial substitute of biobased chain extender in renewable waterborne polyurethane dispersion without significant modifications of the synthesis pathway. In addition to an excellent dispersion of the coumarin modified polymer in water by mechanical stirring, the novel PUD demonstrated suitable stability although moderate increase in particle size (60% higher d50) when voluminous side coumarin introduced some steric impediments in particle formation.

The presence of a minor fraction of monofunctional coumarin moiety (HEOMC) during the synthesis of DHEOMC involved a reduction in achieved molecular weight in comparison to raw biobased polyurethane from end-capping effect of monohydroxyl specie in the chain extension. Nevertheless, the achieved performance of coumarin functionalized coating was improved. The presence of rigid DHEOMC coumarin structures involved a convincing improvement in scratch resistance, hardness (König) and tensile properties of the coatings when compared to biobased polyurethane synthesized with 1,3 propanediol as single chain extender. Besides, all this upgrading was achieved without hindering the film formation capability of the waterborne coating and the corresponding aesthetic response, which was evaluated by analyzing the surface morphology and the associated specular gloss.

The subsequent UV irradiation of the coumarin functionalized coating in the solid state led to a reversibly low crosslinking structure able to increase approximately three times the tensile strength of the biobased polyurethane without the photo-reactive moieties in its structure. Therefore, the reversible photo-crosslinking of coumarin could provide an attractive and effective tool to improve and modulate the performance of biobased waterborne polyurethane coatings. This work is particularly relevant in the coating sector for promoting the development of biobased systems as a real alternative to oil-based coatings.

Data Availability

The data that support the findings of this study are available from the corresponding author, L.G, upon reasonable request.

References

Engels, HW, et al. “Polyurethanes: Versatile Materials and Sustainable Problem Solvers for Today’s Challenges.” Angew. Chem. Int. Ed., 52 (36) 9422–9441. https://doi.org/10.1002/anie.201302766 (2013)

Jung, DH, Kim, EY, Kang, YS, Kim, BK, “High Solid and High Performance UV Cured Waterborne Polyurethanes.” Colloids Surfaces A Physicochem. Eng. Asp., 370 (1–3) 58–63. https://doi.org/10.1016/j.colsurfa.2010.08.046 (2010)

Yu, F, Xu, X, Lin, N, Liu, XY, “Structural Engineering of Waterborne Polyurethane for High Performance Waterproof Coatings.” RSC Adv., 5 (89) 72544–72552. https://doi.org/10.1039/c5ra12480h (2015)

Santamaria-Echart, A, Fernandes, I, Barreiro, F, Corcuera, MA, Eceiza, A, “Advances in Waterborne Polyurethane and Polyurethane-urea Dispersions and Their Eco-Friendly Derivatives: A Review.” Polymers (Basel), 13 (3) 1–32. https://doi.org/10.3390/polym13030409 (2021)

Poussard, L, Lazko, J, Mariage, J, Raquez, JM, Dubois, P, “Biobased Waterborne Polyurethanes for Coating Applications: How Fully Biobased Polyols May Improve the Coating Properties.” Prog. Org. Coat., 97 175–183. https://doi.org/10.1016/j.porgcoat.2016.04.003 (2016)

Zhang, C, Madbouly, SA, Kessler, MR, “Biobased Polyurethanes Prepared from Different Vegetable Oils.” ACS Appl. Mater. Interfaces, 7 (2) 1226–1233. https://doi.org/10.1021/am5071333 (2015)

Gurunathan, T, Arukula, R, “High Performance Polyurethane Dispersion Synthesized from Plant Oil Renewable Resources: A Challenge in the Green Materials.” Polym. Degrad. Stab., 150 (2017) 122–132. https://doi.org/10.1016/j.polymdegradstab.2018.02.014 (2018)

Zhang, Y, et al. “Waterborne Polyurethanes from Castor Oil-based Polyols for Next Generation of Environmentally-Friendly Hair-Styling Agents.” Prog. Org. Coat., 142 105588. https://doi.org/10.1016/j.porgcoat.2020.105588 (2020)

Bao, LH, Lan, YJ, Zhang, SF, “Synthesis and Properties of Waterborne Polyurethane Dispersions with Ions in the Soft Segments.” J. Polym. Res., 13 (6) 507–514. https://doi.org/10.1007/s10965-006-9073-7 (2006)

Athawale, VD, Nimbalkar, RV, “Polyurethane Dispersions Based on Sardine Fish Oil, Soybean Oil, and Their Interesterification Products.” J. Dispers. Sci. Technol., 32 (7) 1014–1022. https://doi.org/10.1080/01932691.2010.497459 (2011)

Saalah, S, et al. “Waterborne Polyurethane Dispersions Synthesized from Jatropha Oil.” Ind. Crops Prod., 64 194–200. https://doi.org/10.1016/j.indcrop.2014.10.046 (2015)

Gaddam, SK, Palanisamy, A, “Effect of Counterion on the Properties of Anionic Waterborne Polyurethane Dispersions Developed from Cottonseed Oil Based Polyol.” J. Polym. Res., 25 186. https://doi.org/10.1007/s10965-018-1580-9 (2018)

Liang, H, et al. “Tailoring the Performance of Vegetable Oil-Based Waterborne Polyurethanes Through Incorporation of Rigid Cyclic Rings into Soft Polymer Networks.” ACS Sustain. Chem. Eng., 8 (2) 914–925. https://doi.org/10.1021/acssuschemeng.9b05477 (2020)

Cuevas, JM, Seoane-Rivero, R, Navarro, R, Marcos-Fernández, Á, “Coumarins into Polyurethanes for Smart and Functional Materials.” Polymers (Basel), 12 (3) 630. https://doi.org/10.3390/polym12030630 (2020)

Cazin, I, Rossegger, E, Guedes de la Cruz, G, Griesser, T, Schlögl, S, “Recent Advances in Functional Polymers Containing Coumarin Chromophores.” Polymers (Basel), 13 (1) 1–51. https://doi.org/10.3390/polym13010056 (2021)

Ling, J, Rong, MZ, Zhang, MQ, “Photo-Stimulated Self-healing Polyurethane Containing Dihydroxyl Coumarin Derivatives.” Polymer (Guildf), 53 (13) 2691–2698. https://doi.org/10.1016/j.polymer.2012.04.016 (2012)

Aguirresarobe, RH, Martin, L, Aramburu, N, Irusta, L, Fernandez-Berridi, MJ, “Coumarin Based Light Responsive Healable Waterborne Polyurethanes.” Prog. Org. Coat., 99 314–321. https://doi.org/10.1016/j.porgcoat.2016.06.011 (2016)

Seoane Rivero, R, Bilbao Solaguren, P, Gondra Zubieta, K, Gonzalez-Jimenez, A, Valentin, JL, Marcos-Fernandez, A, “Synthesis and Characterization of a Photo-Crosslinkable Polyurethane Based on a Coumarin-Containing Polycaprolactone Diol.” Eur. Polym. J., 76 245–255. https://doi.org/10.1016/j.eurpolymj.2016.01.047 (2016)

Seoane Rivero, R, Navarro, R, Bilbao Solaguren, P, Gondra Zubieta, K, Cuevas, JM, Marcos-Fernández, A, “Synthesis and Characterization of Photo-Crosslinkable Linear Segmented Polyurethanes Based on Coumarin.” Eur. Polym. J., 92 263–274. https://doi.org/10.1016/j.eurpolymj.2017.05.016 (2017)

Seoane Rivero, R, Bilbao Solaguren, P, Gondra Zubieta, K, Peponi, L, Marcos-Fernández, A, “Synthesis, Kinetics of Photo-dimerization/Photo-cleavage and Physical Properties of Coumarin-Containing Branched Polyurethanes Based on Polycaprolactones.” Express Polym. Lett., 10 (2) 84–95. https://doi.org/10.3144/expresspolymlett.2016.10 (2016)

Yim, SH, Huh, J, Ahn, CH, Park, TG, “Development of a Novel Synthetic Method for Aliphatic Ester Dendrimers.” Macromolecules, 40 (2) 205–210. https://doi.org/10.1021/ma061859p (2007)

Malkoch, M, Malmström, E, Hult, A, “Rapid and Efficient Synthesis of Aliphatic Ester Dendrons and Dendrimers.” Macromolecules, 35 (22) 8307–8314. https://doi.org/10.1021/ma0205360 (2002)

Germán, L, Cuevas, JM, Cobos, R, Pérez-Alvarez, L, Vilas-Vilela, JL, “Green Alternative Cosolvents to N-Methyl-2-Pyrrolidone in Water Polyurethane Dispersions.” RSC Adv., 11 (31) 19070–19075. https://doi.org/10.1039/d1ra03157k (2021)

Ling, J, Rong, MZ, Zhang, MQ, “Coumarin Imparts Repeated Photochemical Remendability to Polyurethane.” J. Mater. Chem., 21 (45) 18373–18380. https://doi.org/10.1039/c1jm13467a (2011)

Fu, Q, Cheng, L, Zhang, Y, Shi, W, “Preparation and Reversible Photo-Crosslinking/Photo-Cleavage Behavior of 4-Methylcoumarin Functionalized Hyperbranched Polyester.” Polymer (Guildf), 49 (23) 4981–4988. https://doi.org/10.1016/j.polymer.2008.09.017 (2008)

Puyadena, M, et al. “Polyurethane/acrylic Hybrid Dispersions Containing Phosphorus Reactive Flame Retardants as Transparent Coatings for Wood.” Prog. Org. Coat., 170 107005. https://doi.org/10.1016/j.porgcoat.2022.107005 (2022)

Seoane-Rivero, R, et al. “Structural Characterization of Mono and Dihydroxylated Umbelliferone Derivatives.” Molecules, 25 (15) 1–20. https://doi.org/10.3390/molecules25153497 (2020)

Wen, J, Sun, Z, Xiang, J, Fan, H, Chen, Y, Yan, J, “Preparation and Characteristics of Waterborne Polyurethane with Various Lengths of Fluorinated Side Chains.” Appl. Surf. Sci., 494 (July) 610–618. https://doi.org/10.1016/j.apsusc.2019.07.170 (2019)

Aguirresarobe, RH, Irusta, L, Fernández-Berridi, MJ, “UV-light Responsive Waterborne Polyurethane Based on Coumarin: Synthesis and Kinetics of Reversible Chain Extension.” J. Polym. Res., 21 505. https://doi.org/10.1007/s10965-014-0505-5 (2014)

Lowry, GV, et al. “Guidance to Improve the Scientific Value of Zeta-potential Measurements in nanoEHS.” Environ. Sci. Nano, 3 (5) 953–965. https://doi.org/10.1039/c6en00136j (2016)

Tennebroek, R, et al. “Water-based Polyurethane Dispersions.” Polym. Int., 68 (5) 832–842. https://doi.org/10.1002/pi.5627 (2019)

Jaudouin, O, Robin, JJ, Lopez-Cuesta, JM, Perrin, D, Imbert, C, “Ionomer-Based Polyurethanes: A Comparative Study of Properties and Applications.” Polym. Int., 61 (4) 495–510. https://doi.org/10.1002/pi.4156 (2012)

Navarro, R, Seoane-Rivero, R, Cuevas, JM, Marcos-Fernandez, Á, “A Novel Strategy to Polyurethanes with Improved Mechanical Properties by Photoactivation of Amidocoumarin Moieties.” RSC Adv., 10 (50) 29935–29944. https://doi.org/10.1039/d0ra06372j (2020)

Yang, Z, Cui, X, “Effect of Chain Extenders with Different Functionalities on the Properties of Single-Component Waterborne Polyurethane Ink Binders.” RSC Adv., 12 (26) 16696–16705. https://doi.org/10.1039/d2ra02707k (2022)

Son, TW, Won, D, “Thermal and Phase Behavior of Polyurethane Based on Chain Extender, 2,2-Bis-[4-(2-hydroxyethoxy)phenyl]propane.” Polym. J., 31 (7) 563–568. https://doi.org/10.1295/polymj.31.563 (1999)

Asensio, M, Costa, V, Nohales, A, Bianchi, O, Gómez, CM, “Tunable Structure and Properties of Segmented Thermoplastic Polyurethanes as a Function of Flexible Segment.” Polymers (Basel), 11 (12) 1910. https://doi.org/10.3390/polym11121910 (2019)

Ling, J, Rong, MZ, Zhang, MQ, “Effect of Molecular Weight of PEG Soft Segments on Photo-stimulated Self-healing Performance of Coumarin Functionalized Polyurethanes.” Chin. J. Polym. Sci., 32 (10) 1286–1297. https://doi.org/10.1007/s10118-014-1522-x (2014)

Yong, Q, Liao, B, Huang, J, Guo, Y, Liang, C, Pang, H, “Preparation and Characterization of a Novel Low Gloss Waterborne Polyurethane Resin.” Surf. Coat. Technol., 341 (2017) 78–85. https://doi.org/10.1016/j.surfcoat.2018.01.012 (2018)

Acknowledgments

This work was financially supported by the biobased Industries Undertaking (JU) under the European Union’s Horizon 2020 research and innovation programme under USABLE PACKGING project grant agreement No 836884. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Bio Based Industries Consortium. The authors also gratefully acknowledge the financial support from the Basque Government (ELKARTEK programme, Research Project KK-2022/00109 – FRONTIERS 2022).

Author information

Authors and Affiliations

Contributions

LG contributed to conceptualization, methodology, writing—original draft, project administration; JMC contributed to methodology, investigation writing—original draft funding acquisition; RS contributed to methodology, investigation, validation, writing—original draft; RN contributed to validation and writing—original draft; AM-F contributed to writing—review and editing, supervision; and JL V-V writing—review and editing and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship and/or publication of this communication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Germán-Ayuso, L., Cuevas, J.M., Seoane-Rivero, R. et al. Improving the performance of biobased polyurethane dispersion by the incorporation of photo-crosslinkable coumarin. J Coat Technol Res 20, 1677–1690 (2023). https://doi.org/10.1007/s11998-023-00772-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-023-00772-9