Abstract

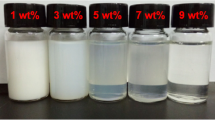

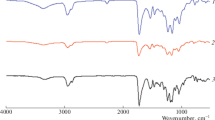

In order to increase the concentrations of bio-based alkyd polyols (or fatty acids) in self-crosslinking polyurethane dispersions, herein, a series of novel alkyd polyol-based autoxidizable waterborne polyurethane dispersions (AWPUDs) with different fatty acid contents, long storage stability, and low viscosity were successfully prepared by adding dimethylol propionic acid (DMPA) self-emulsifier in the late stage of their synthesis. They and their corresponding curing films were characterized by Fourier transform infrared spectroscopy (FTIR), particle size analysis, rheology measurement, storage stability evaluation, thermogravimetric analysis, dynamic thermomechanical analysis (DMA), etc. The results showed that the addition process of DMPA played a critical role for the excellent features of AWPUDs. Additionally, the crosslinking density, gel contents, and water contact angles of AWPUD films increased with the enlarged fatty acid contents, whereas their water uptake capability decreased. Moreover, a series of AWPUD coatings were prepared, and their properties like drying times, hardness development, pencil hardness, adhesion capability, impact resistance, flexibility, and water resistances were all effectively improved with the increased fatty acid contents, significantly superior to those of waterborne alkyd coatings and waterborne polyurethane coatings without fatty acids.

Similar content being viewed by others

References

Chardon, F, Denis, M, Negrell, C, Caillol, S, “Hybrid Alkyds, the Glowing Route to Reach Cutting-Edge Properties?” Prog. Org. Coat., 151 106025. https://doi.org/10.1016/j.porgcoat.2020.106025 (2021)

Yousefi, AA, Bigdeli, E, “Synthesis of Water-Based Alkyd Resins.” J. Color Sci. Tech., 1 (1) 25–40 (2007)

Huang, Q, Liu, C, Chen, S, Bai, G, An, Q, Cao, J, Zheng, S, Liang, Y, Xiang, B, “Effects of Formulation on Set-to-Touch Time of Waterborne Alkyd Resin by Uniform Design.” Prog. Org. Coat., 87 189–196. https://doi.org/10.1016/j.porgcoat.2015.06.001 (2015)

Jones, F, Nichols, M, Pappas, SP, Organic Coatings: Science and Technology, 4th ed. Wiley. https://doi.org/10.1002/9781119337201 (2017)

Dhoke, S, Sinha, TJM, Dutta, P, Khanna, A, “Formulation and Performance Study of Low Molecular Weight, Alkyd-Based Waterborne Anticorrosive Coating on Mild Steel.” Prog. Org. Coat., 62 (2) 183–192. https://doi.org/10.1016/j.porgcoat.2007.10.008 (2008)

Ifijen, IH, Maliki, M, Odiachi, IJ, Aghedo, ON, “Review on Solvents Based Alkyd Resins and Water Borne Alkyd Resins: Impacts of Modification on Their Coating Properties.” Chem. Africa, 5 (2) 211–225. https://doi.org/10.1007/s42250-022-00318-3 (2022)

Mańczyk, K, Szewczyk, P, “Highly Branched High Solids Alkyd Resins.” Prog. Org. Coat., 44 (2) 99–109. https://doi.org/10.1016/S0300-9440(01)00249-1 (2002)

Aigbodion, AI, Okieimen, FE, Obazee, EO, Bakare, IO, “Utilisation of Maleinized Rubber Seed Oil and Its Alkyd Resin as Binders in Water-Borne Coatings.” Prog. Org. Coat., 46 (1) 28–31. https://doi.org/10.1016/S0300-9440(02)00181-9 (2003)

Acar, I, Bal, A, Güçlü, G, “The Use of Intermediates Obtained from Aminoglycolysis of Waste Poly(ethylene Terephthalate) (PET) for the Synthesis of Water-Reducible Alkyd Resin.” Can. J. Chem., 91 (5) 357–363. https://doi.org/10.1139/cjc-2012-0370 (2013)

Bulak, E, Acar, I, “The Use of Aminolysis, Aminoglycolysis, and Simultaneous Aminolysis–Hydrolysis Products of Waste PET for Production of Paint Binder.” Polym. Eng. Sci., 54 (10) 2272–2281. https://doi.org/10.1002/pen.23773 (2014)

Güçlü, G, “Alkyd Resins Based on Waste PET for Water-Reducible Coating Applications.” Polym. Bull., 64 739–748. https://doi.org/10.1007/s00289-009-0166-4 (2010)

Kartaloğlu, N, Akçin, SE, Eren, M, Delibas, A, “Waterborne Hybrid (Alkyd/Styrene Acrylic) Emulsion Polymers and Exterior Paint Applications.” J. Coat. Technol. Res., https://doi.org/10.1007/s11998-023-00767-6 (2023)

Ouyang, S, Lin, Z, Cao, L, Ding, Y, Shen, L, “Preparation of Excellent-Water-Resistance Water-Borne Alkyd/Acrylic Hybrid Coatings with Varied Maleic Anhydride Content.” Prog. Org. Coat., 161 106537. https://doi.org/10.1016/j.porgcoat.2021.106537 (2021)

Zeng, Q, Xue, S, Li, J, Jiang, W, Ding, Y, Shen, L, “Preparation of Bio-Based Air-Drying Water-Borne Polyurea Coatings with Excellent Coating Properties and Anticorrosive Performance.” Prog. Org. Coat., 171 107040. https://doi.org/10.1016/j.porgcoat.2022.107040 (2022)

Athawale, V, Nimbalkar, R, “Emulsifyable Air Drying Urethane Alkyds.” Prog. Org. Coat., 67 (1) 66–71. https://doi.org/10.1016/j.porgcoat.2009.09.017 (2010)

Patil, D, Phalak, G, Mhashe, S, “Design and Synthesis of Bio-Based Epoxidized Alkyd Resin for Anti-corrosive Coating Application.” Iran. Polym. J., 27 (10) 709–719. https://doi.org/10.1007/s13726-018-0646-1 (2018)

Pellegrene, B, Soucek, MD, “Effect of Humidity on Curing of Alkoxysilane-Functionalized Alkyd Coatings.” J. Coat. Technol. Res., 18 (6) 1543–1555. https://doi.org/10.1007/s11998-021-00494-w (2021)

Kurt, İ, Acar, I, Güçlü, G, “Preparation and Characterization of Water Reducible Alkyd Resin/Colloidal Silica Nanocomposite Coatings.” Prog. Org. Coat., 77 (5) 949–956. https://doi.org/10.1016/j.porgcoat.2014.01.017 (2014)

Elfadel, RG, Refat, HM, Abdelwahab, H, Salem, SS, Awad, MA, Abdel Reheim, MAM, “Synthesis of Modified Poly(Ester-Amide) and Alkyd Resins Based on Phenolic and Schiff Base Compounds to Study Their Biological and Insecticide Activity for Surface Coating Applications.” Pigment Resin Technol. https://doi.org/10.1108/PRT-03-2023-0031 (2023)

Kivit, PJJ, Aramendia, E, Cabrera, AA, Ríos, LM, “Water-Based Coatings Based on Mixtures of Acrylic Dispersions and Alkyd Emulsions.” Macromol. Symp., 283–284 290–299. https://doi.org/10.1002/masy.200950933 (2009)

Yousefi, AA, Pishvaei, M, Yousefi, A, “Preparation of Water-Based Alkyd/Acrylic Hybrid Resins.” Prog. Color Color. Coat., 4 15–25 (2011)

Saravari, O, Phapant, P, Pimpan, V, “Synthesis of Water-Reducible Acrylic–Alkyd Resins Based on Modified Palm Oil.” J. Appl. Polym. Sci., 96 (4) 1170–1175. https://doi.org/10.1002/app.21009 (2005)

Akgün, N, Büyükyonga, ÖN, Acar, I, Güçlü, G, “Synthesis of Novel Acrylic Modified Water Reducible Alkyd Resin: Investigation of Acrylic Copolymer Ratio Effect on Film Properties and Thermal Behaviors.” Polym. Eng. Sci., 56 (8) 947–954. https://doi.org/10.1002/pen.24324 (2016)

Büyükyonga, ÖN, Akgün, N, Acar, I, Güçlü, G, “Synthesis of Four-Component Acrylic-Modified Water-Reducible Alkyd Resin: Investigation of Dilution Ratio Effect on Film Properties and Thermal Behaviors.” J. Coat. Technol. Res., 14 117–128. https://doi.org/10.1007/s11998-016-9835-z (2017)

Büyükyonga, ÖN, Akgün, N, Acar, I, Güçlü, G, “The Usage of Novel Acrylic-Modified Water-Reducible Alkyd Resin Obtained from Post-consumer PET Bottles in Water-Based Paint Formulation.” J. Mater. Cycles Waste Manag., 22 187–196. https://doi.org/10.1007/s10163-019-00929-y (2020)

Wicks, DA, Wicks, ZW, “Autoxidizable Urethane Resins.” Prog. Org. Coat., 54 (3) 141–149. https://doi.org/10.1016/j.porgcoat.2004.12.006 (2005)

Zafar, F, Ghosal, A, Sharmin, E, Chaturvedi, R, Nishat, N, “A Review on Cleaner Production of Polymeric and Nanocomposite Coatings Based on Waterborne Polyurethane Dispersions from Seed Oils.” Prog. Org. Coat., 131 259–275. https://doi.org/10.1016/j.porgcoat.2019.02.014 (2019)

Tennebroek, R, Casteren, I, Swaans, R, van der Slot, S, Stals, P, Tuijtelaars, B, Koning, C, “Wate-Based Polyurethane Dispersions.” Polym. Int., 68 (5) 832–842. https://doi.org/10.1002/pi.5627 (2018)

Mucci, VL, Hormaiztegui, MEV, Amalvy, JI, Aranguren, MI, “Formulation, Structure and Properties of Waterborne Polyurethane Coatings: A Brief Review.” J. Adhes. Sci. Technol. https://doi.org/10.1080/01694243.2023.2240587 (2023)

Deflorian, F, Fedel, M, DiGianni, A, Bongiovanni, R, Turri, S, “Corrosion Protection Properties of New UV Curable Waterborne Urethane Acrylic Coatings.” Corros. Eng. Sci. Technol., 43 (1) 81–86. https://doi.org/10.1179/174327808X286194 (2008)

Acar, I, Orbay, M, “Aminoglycolysis of Waste Poly(Ethylene Terephthalate) with Diethanolamine and Evaluation of the Products as Polyurethane Surface Coating Materials.” Polym. Eng. Sci., 51 (4) 746–754. https://doi.org/10.1002/pen.21885 (2011)

Çavuşoğlu, FC, Acar, I, “Synthesis of PET-Based Urethane-Modified Alkyd Resins from Depolymerization Intermediates of Post-consumer PET Bottles: Coating Properties and Thermal Behaviors.” J. Coat. Technol. Res., 20 (2) 741–761. https://doi.org/10.1007/s11998-022-00705-y (2023)

Villada, Y, Inciarte, H, Gomez, C, Cardona, S, Orozco, LM, Estenoz, D, Rios, L, “Alkyd-Urethane Resins Based on Castor Oil: Synthesis, Characterization and Coating Properties.” Prog. Org. Coat., 180 107556. https://doi.org/10.1016/j.porgcoat.2023.107556 (2023)

Gündüz, G, Idlibi, Y, Akovali, G, “Oil Modified and Waterborne Polyurethane Resin.” J. Coat. Technol. Res., 74 59–62. https://doi.org/10.1007/BF02697968 (2002)

Athawale, VD, Nimbalkar, RV, “Novel Urethane/Acrylic Hybrid Emulsions for VOC Compliant Coatings.” Pigment Resin Technol., 40 (3) 181–190. https://doi.org/10.1108/03699421111130450 (2011)

Eckhoff, PS, “Chemistry and Process for a Stain Resistant Aqueous House Paint Free of Heavy Metals.” U.S. Patent 3,919,145 (1975), https://www.freepatentsonline.com/3919145.html

Fong, JJ, “Waterborne Maleinized Polybutadiene Emulsion Coating Composition.” U.S Patent 5,552,228 (1996), https://www.freepatentsonline.com/5552228.html

Williams, RC, Rogemoser, DR, “Waterborne-Dispersible Urethane Polymers.” U.S. Patent 4,268,426 (1981), https://www.freepatentsonline.com/4268426.html

Treasurer, UY, “Water-Dispersible Poly(Urethane-Urea) Compositions.” U.S. Patent 5,504,145 (1996), https://www.freepatentsonline.com/5504145.html

Blum, H, Gertzmann, R, Irle, C, Guiteras, M, Garcia Martinez, JM, “Polyurethane-Modified Alkyd Resin Dispersions." U.S. Patent Application 20110236667, https://www.freepatentsonline.com/y2011/0236667.html

Patel, A, Patel, C, Patel, MG, Patel, M, Dighe, A, “Fatty Acid Modified Polyurethane Dispersion for Surface Coatings: Effect of Fatty Acid Content and Ionic Content.” Prog. Org. Coat., 67 (3) 255–263. https://doi.org/10.1016/j.porgcoat.2009.11.006 (2010)

Patel, AN, Patel, MM, “Influence of Compositional Variables on the Morphological and Dynamic Mechanical Behavior of Fatty Acid Based Self-crosslinking Poly(Urethane Urea) Anionomers.” Prog. Org. Coat., 74 (3) 443–452. https://doi.org/10.1016/j.porgcoat.2012.01.008 (2012)

Schlarb, B, Rau, MG, Haremza, S, “Hydroresin Dispersions: New Emulsifier Free Binders for Aqueous Coatings.” Prog. Org. Coat., 26 (2–4) 207–215. https://doi.org/10.1016/0300-9440(95)00579-X (1995)

Chaudhari, A, Kulkarni, R, Mahulikar, P, Sohn, D, Gite, V, “Development of PU Coatings from Neem Oil Based Alkyds Prepared by the Monoglyceride Route.” J. Am. Chem. Soc., 92 (5) 733–741. https://doi.org/10.1007/s11746-015-2642-3 (2015)

Saalah, S, Abdullah, LC, Aung, MM, Salleh, MZ, Biak, DRA, Basri, M, Jusoh, ER, Mamat, S, “Colloidal Stability and Rheology of Jatropha Oil-Based Waterborne Polyurethane (JPU) Dispersion.” Prog. Org. Coat., 125 348–357. https://doi.org/10.1016/j.porgcoat.2018.09.018 (2018)

Tielemans, M, Roose, P, Groote, PD, Vanovervelt, J-C, “Colloidal Stability of Surfactant-Free Radiation Curable Polyurethane Dispersions.” Prog. Org. Coat., 55 (2) 128–136. https://doi.org/10.1016/j.porgcoat.2005.08.010 (2006)

Duffy, J, “Controlling Suspension Rheology.” Chem. Eng., 122 (1) 34–39 (2015)

Pérez Das Dores, A, Llorente, O, Martin, L, González, A, Irusta, L, “Polydimethylsiloxane Containing Waterborne Hydrophobic Polyurethane Coatings with Good Adhesion to Metals: Synthesis and Characterization.” Prog. Org. Coat., 162 106564. https://doi.org/10.1016/j.porgcoat.2021.106564 (2022)

Chang, J, Wang, X, Shao, J, Li, X, “Synthesis and Characterization of Environmentally-Friendly Self-matting Waterborne Polyurethane Coatings.” Coatings, 10 (5) 494–506. https://doi.org/10.3390/coatings10050494 (2020)

Waldner, C, Hirn, U, “Modeling Liquid Penetration into Porous Materials Based on Substrate and Liquid Surface Energies.” J. Colloid Interface Sci., 640 445–455. https://doi.org/10.1016/j.jcis.2023.02.116 (2023)

Liu, Y, Meng, Z, Wang, Y, Li, P, Sun, Y, “Analysis and Modeling of Viscosity for Aqueous Polyurethane Dispersion as a Function of Shear Rate, Temperature, and Solid Content.” ACS Omega, 5 (40) 26237–26244. https://doi.org/10.1021/acsomega.0c03959 (2020)

Mooney, M, “The Viscosity of a Concentrated Suspension of Spherical Particles.” J. Colloid Sci., 6 (2) 162–170. https://doi.org/10.1016/0095-8522(51)90036-0 (1951)

Jones, DAR, Leary, B, Boger, D, “The Rheology of a Sterically Stabilized Suspension at High Concentration.” J. Colloid Interface Sci., 150 (1) 84–96. https://doi.org/10.1016/0021-9797(92)90270-V (1992)

Petrović, ZS, Guo, A, Javni, I, Cvetković, I, Hong, DP, “Polyurethane Networks from Polyols Obtained by Hydroformylation of Soybean Oil.” Polym. Int., 57 (2) 275–281. https://doi.org/10.1002/pi.2340 (2008)

Lu, Y, Larock, RC, “Soybean-Oil-Based Waterborne Polyurethane Dispersions: Effects of Polyol Functionality and Hard Segment Content on Properties.” Biomacromolecules, 9 (11) 3332–3340. https://doi.org/10.1021/bm801030g (2008)

Madbouly, SA, Xia, Y, Kessler, MR, “Sustainable Polyurethane-Lignin Aqueous Dispersions and Thin Films: Rheological Behavior and Thermomechanical Properties.” ACS Appl. Polym., 2 (11) 5198–5207. https://doi.org/10.1021/acsapm.0c00954 (2020)

Hill, LW, “Calculation of Crosslink Density in Short Chain Networks.” Prog. Org. Coat., 31 (3) 235–243. https://doi.org/10.1016/S0300-9440(97)00081-7 (1997)

Ourique, P, Krindges, I, Aguzzoli, C, Figueroa, C, Amalvy, J, Wanke, C, Bianchi, O, “Synthesis, Properties, and Applications of Hybrid Polyurethane–Urea Obtained from Air-Oxidized Soybean Oil.” Prog. Org. Coat., 108 15–24. https://doi.org/10.1016/j.porgcoat.2017.04.002 (2017)

Man, L, Feng, Y, Hu, Y, Yuan, T, Yang, Z, “A Renewable and Multifunctional Eco-Friendly Coating from Novel Tung Oil-Based Cationic Waterborne Polyurethane Dispersions.” J. Clean. Prod., 241 118341. https://doi.org/10.1016/j.jclepro.2019.118341 (2019)

Honzíček, J, “Curing of Air-Drying Paints: A Critical Review.” Ind. Eng. Chem. Res., 58 (28) 12485–12505. https://doi.org/10.1021/acs.iecr.9b02567 (2019)

Velayutham, TS, Abd, W, Ng, B, Gan, SN, “Effect of Oleic Acid Content and Chemical Crosslinking on the Properties of Palm Oil-Based Polyurethane Coatings.” J. Appl. Polym. Sci., 129 415–421. https://doi.org/10.1002/app.38768 (2013)

Kalita, DJ, Tarnavchyk, I, Selvakumar, S, Chisholm, BJ, Sibi, M, Webster, DC, “Poly (Vinyl Ethers) Based on the Biomass-Derived Compound, Eugenol, and their One-Component, Ambient-Cured Surface Coatings.” Prog. Org. Coat., 170 106996. https://doi.org/10.1016/j.porgcoat.2022.106996 (2022)

Streitberger, H, Goldschmidt, A, BASF Handbook Basics of Coating Technology, 3rd edn. Vincentz Network GmbH & Co. KG (2018)

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51963010) and the Research Fund of Jiangxi Provincial Department of Education (No. GJJ211126).

Author information

Authors and Affiliations

Contributions

YB Ding and L Shen supervised and designed this research. ZC Lin, QY Zeng and YC Zhang did the experiment. YB Ding and ZC Lin collected and analyzed the data. YB Ding, ZC Lin, and L Shen interpreted the results and wrote the manuscript. S Chen and QY Luo discussed and revised the manuscript. All authors declare that they have no competing financial interests and gave final approval for publication.

Corresponding authors

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lin, Z., Zeng, Q., Zhang, Y. et al. Preparation and coating properties of alkyd polyol-based autoxidizable waterborne polyurethane dispersions with high fatty acid content, long storage stability, and low viscosity. J Coat Technol Res (2024). https://doi.org/10.1007/s11998-024-00928-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11998-024-00928-1