Abstract

Plant-based proteins are increasingly being utilized as they are sustainable, economical, and can enhance the organoleptic properties of food products. This study investigated the effect of extraction and isolation techniques (alkaline extraction & isoelectric precipitation and salt extraction & micellization) on the functional properties ((solubility, water holding and oil absorption capacity (WHC/OAC), emulsifying activity and stability index (EAI/ESI), foaming capacity and stability (FC/FS), and gelation)) of Moringa oleifera protein isolates. The effect of ionic strength (0.2–1.0 M NaCl) and pH (2–10) on the functional properties were also investigated. Salt extraction & micellization produced an isolate with a high solubility at 0.8 M NaCl and pH 10 (98.1%, 91.8%), EAI at 0.6 M NaCl and pH 6 (56.2 m2/g, 77.0 m2/g), and ESI at 0.8 M NaCl and pH 4 (64.4 min, 243.5 min). Alkaline extraction & isoelectric precipitation resulted in an isolate with a high WHC at 0.6 M NaCl and pH 10 (5.8 g/g, 4.0 g/g), OAC (4.9 g/g), FC at 0.4 M NaCl and pH 2 (203.3%, 163.3%), and gelation at 0.2 M NaCl, 0.4 M NaCl, and pH 8 (20.0%). Both extraction methods can be applied in the valorization of M. oleifera seedcake. Micellized isolate could be used in food emulsions due to better emulsifying properties, while isoelectric isolate can be applied in meats and sauces, owing to better water holding and oil absorption capacity. M. oleifera protein isolates are promising plant-based proteins that can be used in food formulations or to replace animal-derived proteins in food.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Proteins, also known as polypeptides, comprise long chains of up to twenty different amino acids linked by peptide bonds. Proteins have unique sequences of amino acids with a number of different side chains that impart specificity and functionality. They are essential macromolecules in the human diet which play vital nutritional and functional roles in the human body. The need for more protein sources has intensified in the last two decades, as a result of the growing population, that is expected to increase to over 9 billion by the year 2050 (United Nations, 2019). In addition, demands for specifically plant-based proteins, have soared due to environmental factors such as increased greenhouse gas emissions, water and land use, and deforestation, along with the increasing number of consumers who have dietary, religious, or ethical concerns, associated with the consumption of animal-based proteins. A review on protein alternatives by Lee et al. (2023) revealed that meat consumption is also bound to increase in developing countries, this will subsequently put enormous pressure on the food production system to fulfil this demand. Therefore, the active research for new plant-based protein products is crucial.

Plant-based proteins have been prepared from cereals, grains, legumes, oilseeds, pulses, and more (Cai et al., 2013; Dong et al., 2023; Lee et al., 2023; Rawat & Saini, 2023; Rosas-Ulloa et al., 2023; Silventoinen et al., 2019; Singh & Sit, 2023; Sosa et al., 2020). Legumes, like chickpea, represent a major source of high-quality protein. Cereals are also nutritious and have been used extensively for industrial applications, while oilseeds are known to contain appreciable amounts of protein and beneficial phenolic compounds (Langyan et al., 2022). They can potentially be used in a variety of food products, as fortificants, functional ingredients/ food additives, and even animal feed. Plant-based proteins have gained popularity as they represent a “greener”, more sustainable, and economical source of protein, dietary fibre, fats, and vitamins, in comparison to animal proteins (Deng et al., 2019; Hadnađev et al., 2018; Viana et al., 2023). Increasing efforts are being made to develop new sources of plant-based proteins to replace animal proteins, at least partially, in food products that are traditionally based on the functionality of animal proteins.

The different functional properties of plant-based proteins are attributed to differences in amino acid profiles, conformation, hydrophobicity, etc., which are affected by extraction and isolation techniques. A study on the effect of preparation techniques on the functional properties of Bambara groundnut protein isolates revealed the micellization technique to result in production of isolates with higher solubility, foaming and emulsifying capacity and stability, oil and water absorption than isolates prepared by isoelectric precipitation (Adebowale et al., 2011). Likewise, Hu et al. (2017) reported the functionality of walnut proteins to be dependent on extraction conditions, where proteins obtained through enzyme-assisted reverse micelles had greater water holding and foaming capacities compared to isolates prepared by Aerosol-OT or also known as AOT reverse micelles ((micelles formed from water and sodium bis(2-ethylhexyl) sulfosuccinate)) and aqueous phase extraction. Processing conditions (pH, salt concentration/ ionic strength, and temperature), can induce protein denaturation, which influences the functional properties of a protein (Farooq & Boye, 2011; Singh & Sit, 2023). For instance, a thermally treated protein may have a lower solubility, due to increased exposure of hydrophobic side chains as a result of denaturation. Studies often evaluate functional properties of proteins, but no serious consideration is given to the various conditions of the environment, such as pH and ionic strength. This is crucial to understand the properties of the protein isolates, to predict the protein behaviour, to maximise protein functionality, in order to enhance their application in different food systems.

Fruit and vegetable seeds are often discarded as waste. The valorisation of this waste into plant-based protein could be a positive step towards the reduction of the environmental and economic burden of food waste. Alfalfa, bitter melon, hemp seeds, Manila tamarind, orange seeds, Persian lime, sesame meal, and sunnhemp, are some of the recent sources of plant-based proteins that have been isolated and researched, with promising results indicative of their potential use in food applications (Fathollahy et al., 2021; Hadidi et al., 2023; Hadnađev et al., 2018; Naik et al., 2022; Rawat & Saini, 2023; Rosas-Ulloa et al., 2023; Singh & Sit, 2023; Wan et al., 2023). In this context, Moringa oleifera seeds represent another source of plant-based proteins with potentially important functional properties that could enhance the structure, texture, and organoleptic properties of food products. Moringa oleifera protein isolates can be isolated from the by-product of Moringa oil production, the M. oleifera seed cake. According to Illingworth et al. (2022), M. oleifera protein isolates produced by different isolation techniques possess different physicochemical properties. Micellized isolates were reported to possess a higher surface hydrophobicity (So = 184) than isoelectric isolates, which indicates the potential of micellized isolates to have greater emulsifying properties (Dong et al., 2023; Illingworth et al., 2022; Rawat & Saini, 2023). A study on M. oleifera seed proteins, prepared by salt extraction and ammonium sulphate precipitation, reported the proteins to exhibit water-holding and oil- absorption capacity, emulsifying capacity and stability, foaming capacity and stability, and gelation properties (Du et al., 2022). Another study reported globulin fractions of M. oleifera seed proteins to possess better foaming and emulsifying properties than their albumin fractions (Aderinola et al., 2020). Although the study by Du et al. (2022) has demonstrated the functionality of M. oleifera seed proteins, the method involves additional steps for the removal of ammonium sulphate and may require further analysis to confirm its complete removal before use in food applications. In addition, the isolation of specific protein fractions, such as globulin and albumin, require a longer duration and additional purification steps to achieve the required degree of purity. Crude M. oleifera seed proteins, derived as the by-products of M. oleifera oil processing, are a potential protein source for food applications. The functional properties of crude M. oleifera seed proteins have yet to be reported. This study aims to investigate the effect of different preparation techniques on the functional properties of crude M. oleifera seed protein isolates, addressing current knowledge gaps.

The main objective of this study is to investigate the functionality of M. oleifera protein isolates as prepared by two techniques, micellization and isoelectric precipitation, which are common isolation techniques used to prepare protein isolates due to the simplicity of implementation and stability of the precipitated proteins (Lee, 2017; Rawat & Saini, 2023; Singh & Sit, 2023). The same functional properties are studied under the influence of varying pH and ionic strengths, in order to understand the behaviour of M. oleifera protein isolates under different food processing conditions. To the best of our knowledge, the influence of micellization and isoelectric precipitation on the functional properties of M. oleifera seed proteins have yet to be investigated. The effect of pH and ionic strength on the resultant protein isolates remains unclear. The findings of this study serve as a guide for the preparation of M. oleifera protein isolates in order to obtain the desired functional properties and is a reference for its potential applications in systems of various pH and ionic strengths.

Materials and Methods

Materials

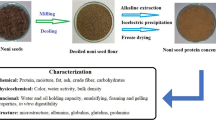

M. oleifera kernels were purchased from India. The kernels were dried in an oven (2.5 h, 40 °C) prior to being ground into flour. Oil was removed by defatting the flour three times with hexane (1:3 w/v, 6 h), followed by air-drying under a fume hood (24 h). The defatted flour was stored hermetically at room temperature (25 °C) until further use. All chemicals used in this study were of analytical grade. Commercial soy protein isolate (SPI) (Synerchem Sdn. Bhd., Malaysia) was used in some analyses as a control for comparison.

Preparation of Protein Isolates

Salt Extraction and Micellization

M. oleifera protein isolate was prepared according to Illingworth et al. (2022). Briefly, M. oleifera flour was extracted with 0.5 M NaCl at a 1:10 (w/v) ratio and stirred on a magnetic stir plate (550 rpm, 40 °C, 10 min). The protein extract was centrifuged (2000 × g, 10 min) and the supernatant collected was diluted with cold deionised water at a ratio of 1:10 (v/v). The suspension was left to stand (4 °C, 1 h). The protein precipitate was separated by centrifugation (2000 × g, 10 min) and washed two times with deionized water (pH 7). The protein isolate was stored in a − 80 °C freezer, followed by freeze-drying (− 105 °C, 24 h) (Labconco, USA). The freeze-dried sample was ground, packed, and labelled as Micellized Protein (MP). The sample was stored hermetically at 25 °C until further use. The protein content of MP was 93.86 g100g−1 as reported earlier (Illingworth et al., 2022).

Alkaline Extraction and Isoelectric Precipitation

M. oleifera protein isolate was prepared according to Illingworth et al. (2022). Briefly, defatted M. oleifera flour was mixed with deionized water at a 1:10 (w/v) ratio. The mixture was adjusted to pH 8.5 using 1.0 M NaOH and stirred on a magnetic stir plate (550 rpm, 40 °C, 10 min). The protein extract was centrifuged (2000 × g, 10 min) and the supernatant collected was adjusted to the isoelectric point (pH 2.5) using 1 M HCl. The proteins were precipitated for 1 h at 25 °C. The protein precipitate was separated by centrifugation (2000 × g, 10 min) and washed two times with deionized water (pH 7). The protein isolate was stored in a − 80 °C freezer, followed by freeze-drying (− 105 °C, 24 h) (Labconco, USA). The freeze-dried sample was ground, packed, and labelled as Isoelectric Protein (IP). The sample was stored hermetically at 25 °C until further use. The protein content of IP was 80.98 g100g−1 as reported earlier (Illingworth et al., 2022).

Functional Properties

The effect of pH and ionic strength on the functional properties was investigated by using 0.2, 0.4, 0.6, 0.8, and 1.0 M NaCl solutions, and the pH was adjusted to pH 2, 4, 6, 8, and 10 using 1.0 M NaOH and 1.0 M HCl.

Protein Solubility

Protein solubility was determined according to Pham et al. (2017) with slight modifications. A sample (MP and IP) (125 mg) was dispersed in distilled water. The solution was adjusted to the specified pH, made up to 25 mL, stirred (550 rpm, 25 °C, 30 min), and centrifuged (2000 × g, 15 min). The protein content in the supernatant was determined using the Kjeldahl method and protein solubility was calculated according to Eq. 1.

Water Holding Capacity (WHC)

WHC was determined according to the method described by Piornos et al. (2015). A sample (MP, IP, and SPI) (1 g) was added to 10 g distilled water in a pre-weighed centrifuge tube. The sample was vortexed (1600 rpm, 2 min) and left to stand (25 °C, 1 h), after that was centrifuged (5000 × g, 30 min) and the supernatant was removed. The weight of sample and centrifuge tube was measured. The WHC was calculated according to Eq. 2.

W2 was the weight of centrifuge tube, sample, and absorbed water (g); W1 was the weight of centrifuge tube and sample (g); W0 was the weight of sample (g).

Oil Absorption Capacity (OAC)

OAC was determined according to the method described by Piornos et al. (2015). A sample (MP, IP, and SPI) (1 g) was added to 10 g of commercial sunflower oil in a pre-weighed centrifuge tube. The suspension was vortexed (1600 rpm, 2 min) and left to stand (25 °C, 1 h). The suspension was centrifuged (5000 × g, 30 min) and the supernatant was removed. The weight of sample and centrifuge tube was measured. The OAC was calculated according to Eq. 3.

F2 was the weight of centrifuge tube, sample, and absorbed oil (g); F1 was the weight of centrifuge tube and sample (g); F0 was the weight of sample (g).

Emulsifying Activity Index (EAI) and Emulsion Stability Index (ESI)

EAI and ESI were determined according to Pearce and Kinsella (1978). A 2% (w/v) protein dispersion was firstly prepared. An aliquot (15 mL) was mixed with 5 mL of sunflower oil. The mixture was homogenized using a homogenizer (IKA T25 digital Ultra-Turrax, Germany) (10,000 rpm, 1 min). After homogenization, 50 μL of the emulsion was pipetted from the bottom of the container immediately and diluted with 5 mL of 0.1% sodium dodecyl sulphate (SDS) solution in order to determine the EAI. The absorbance was read at 500 nm using a spectrophotometer (Prim, Secomam, France), with 0.1% SDS as the blank. To determine the ESI, 50 μL of the emulsion was pipetted from the bottom of the container at 10 min after homogenization and measured as described. The EAI and ESI were calculated according to Eqs. 4 and 5, respectively.

A0 and A10 is the absorbance at 0 min and 10 min after the homogenization, respectively; T = 2.303; DF (dilution factor) = 100; C = concentration of sample (mg/mL); \(\varnothing\) = oil volumetric fraction (0.25); L = width of the optical path (0.01 m); 10,000 = conversion to units m2/g; t = 10 min.

Foam Capacity (FC) and Foam Stability (FS)

FC was measured according to the methods of Chew et al. (2003). A 2% (w/v) protein dispersion was prepared. The dispersion was transferred to a 50 mL graduated measuring cylinder and homogenized using a homogenizer (IKA T25 digital Ultra-Turrax, Germany) (10,000 rpm, 2 min). The volume of foam was measured immediately (to determine FC), and after 30 min (to determine FS). FC and FS were calculated according to Eqs. 6 and 7, respectively.

V1 was the foam volume before homogenization; V2 was the foam volume after homogenization; V3 was the foam volume after 30 min of the foam formation.

Least Gelation Concentration (LGC)

LGC was determined according to Coffmann and Garciaj (1977). Protein solutions of different concentrations were prepared (5 – 25%) in tubes and vortexed (5 min, 1600 rpm). The tubes were placed in a water bath (90 °C, 1 h) and then cooled under flowing water and stored (4 °C, 2 h). Semi-solid gels were defined as gels that moved gradually when the test tube was slanted or inverted (Figs. 5a and 6a); gels showed no movement, were stable but less cohesive like pastes (Fig. 6b); brittle gels showed no movement but crumbled with applied pressure (Fig. 5b); firm gels did not move or crumble but were not able to maintain its shape with applied pressure (Fig. 6c); very firm gels showed no movement, and were able to revert to its original shape when pressure was removed (Fig. 5c). The LGC was qualitatively determined as the lowest concentration at which the sample did not slip from the inverted tube.

Statistical Analysis

All analyses were done in triplicates. Data was statistically analyzed using analysis of variance (ANOVA). Tukey’s range test was used to compare means and significance was accepted at p ≤ 0.05.

Results and Discussion

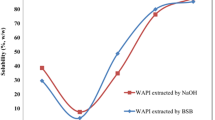

Protein Solubility

The solubility of MP significantly (p ≤ 0.05) increased beyond 0.2 M NaCl concentration, whereas the solubility of IP was unaffected by ionic strength (Fig. 1a). The trend exhibited by MP could be attributable to the salting-in effect of proteins, where electrostatic repulsion between protein molecules decreases, increasing solubility. Hu et al. (2017) credited the varying solubility of walnut protein isolates in salt solutions with different protein conformational characteristics, which are a consequence of the use of different extraction methods. This may explain the trends observed in this study, where ionic strength influenced the solubility of MP but had no effect on the solubility of IP (Fig. 1a). The protein solubility of MP and IP was observed to be pH dependent (Fig. 1b). The “U” shaped curve observed is typical for pH dependent protein solubility profiles and have also been reported for Hyacinth bean, orange seed, pine nut, quinoa, and walnut protein isolates (Cai et al., 2013; Elsohaimy et al., 2015; Hu et al., 2017; Mohan & Mellem, 2020; Rosas-Ulloa et al., 2023). The significant (p ≤ 0.05) decrease in solubility at pH around 4 was expected, as it represents the isoelectric region, where repulsive electrostatic forces between proteins decrease and protein–protein interactions increase, leading to precipitation.

The significantly (p ≤ 0.05) higher solubility of MP in comparison to IP, across all ionic strengths (0.2 M-1.0 M NaCl concentration) and pH (2–10), implies that micellization resulted in better solubility of M. oleifera proteins than isoelectric precipitation. These findings were in line with reports from Mohan and Mellem (2020) and Adebowale et al. (2011), who also found that micellized protein isolates from Bambara groundnut and Hyacinth bean possess better solubility than the isoelectric isolates. Pearce and Kinsella (1978) stated that poor solubilities are indicative of protein denaturation. Moreover, when pH of the medium reaches the isoelectric point of the proteins, this leads to an increase in hydrophobic interactions between protein molecules and the formation of insoluble aggregates with unsatisfactory solubility (Krause et al., 2002). Solubility is a crucial parameter for protein functional properties which is often correlated with emulsification, foaming, and gelation. The improvement of solubility of MP beyond 0.2 M NaCl concentration, and at pH values outside the isoelectric region (pH 4) for both MP and IP, may increase its potential food applications.

Water Holding Capacity (WHC)

WHC was highest at 0.2 M NaCl concentration for MP, 0.6 M NaCl concentration for IP, and 0.8 M and 1.0 M NaCl concentrations for SPI (Fig. 2a). The WHC of MP and IP decreased at 0.4 M and 0.8 M NaCl concentrations, respectively (Fig. 2a). This is due to the salting-in and salting-out properties of proteins. At lower ionic strengths, charged protein groups weakly bind to the hydrated sodium and chloride ions in solution, improving WHC. At higher ionic strengths, existing water favors the binding to the sodium and chloride ions, leading to decreased interactions between the ions and charged protein groups, resulting in protein dehydration and reduction in WHC. This may explain the trends in WHC observed for MP and IP (Fig. 2a). Similar trends were also observed for African locust bean and walnut proteins, where the maximum WHC was achieved at 0.2 M and 0.6 M NaCl concentrations, respectively, before a progressive decrease was noted as the ionic strength (NaCl concentration) increased (Hu et al., 2017; Lawal, 2004). SPI recorded a significantly (p ≤ 0.05) higher WHC than MP and IP, at 0.8 M and 1.0 M NaCl concentrations (Fig. 2a). This indicates that SPI possesses a greater ability to retain water at higher ionic strengths, compared to MP and IP.

Effect of ionic strength (a) and pH (b) on water holding capacity (WHC) of MP, IP, and SPI. Difference in lower case letters (a, b, c) indicate significant differences within sample at different ionic strengths/pH. Difference in upper case letters (A, B, C) indicate significant differences between samples

The WHC of MP and SPI significantly (p ≤ 0.05) improved beyond pH 2 and 4, respectively (Fig. 2b). This was expected as protein–protein interactions are the highest at the isoelectric region (pH 2–4), limiting their interaction with the water. Increased repulsive electrostatic forces at pHs away from the isoelectric region improved WHC. Notably, IP and SPI had significantly (p ≤ 0.05) higher WHC in comparison to MP (Fig. 2b). This could be attributable to the higher amounts of exposed amino acid residues present in IP and SPI, due to a higher degree of denaturation. The exposed amino acid residues are able to bind to more water molecules, resulting in a greater WHC. This supports earlier findings by Illingworth et al. (2022), who reported M. oleifera isolates prepared by isoelectric precipitation to possess a higher degree of denaturation, as revealed by its lower transition enthalpy. Likewise, Ma et al. (2011) reported heat denatured lentil, chickpea, and pea flours possess improved WHC due to amino acid residues that promoted fluid entrapment. Studies on protein isolates from Lupinus campestris, flaxseed, and hempseed also found isoelectric isolates to possess better WHC than micellized isolates (Hadnađev et al., 2018; Krause et al., 2002; Rodríguez-Ambriz et al., 2005). Hadnađev et al. (2018) reported the greater WHC values of isoelectric proteins to be due to their aggregated structure, where micro- and nano pores retain water through capillary mechanisms.

While MP possessed poorer WHC (maximum of 1.21 g/g at pH 10), IP had WHC values higher than protein isolates prepared from chickpea (1.34–1.47 g/g), hemp (0.80–1.59 g/g), and pea (1.91–2.37 g/g) (Hadnađev et al., 2018; Kaur & Singh, 2005; Stone et al., 2015). Proteins that possess good WHC can be added into products where high WHCs are desired such as creams, soups, and bakery products. This is due to their ability to retain water without dissolution, thus providing the required viscosity and thickening of a product (Rosas-Ulloa et al., 2023).

Oil Absorption Capacity (OAC)

The OAC of IP was significantly greater (p ≤ 0.05) than MP, while both IP and MP were significantly greater (p ≤ 0.05) than SPI (Table 1). A study on the OAC of pea protein isolates observed OAC to be affected by hydrophobicity, surface charge, and conformational characteristics, which were influenced by preparation techniques (Reinkensmeier et al., 2015). This is supported by Lin et al. (1974) and Wang et al. (2020), who stated that oil retention is result from the binding of the hydrocarbon chains of oil to the non-polar side chains of amino acids through hydrophobic, electrostatic, and hydrogen bonding. It could also be due to the higher proportion of hydrophobic amino acids in IP as previously reported by Illingworth et al. (2022). Similar inferences were made for Hyacinth bean, Manila tamarind, mung bean, and orange seed protein isolates (Brishti et al., 2017; Mohan & Mellem, 2020; Rosas-Ulloa et al., 2023; Singh & Sit, 2023). The OAC of IP and MP were considerably higher than OAC of protein isolates prepared from chickpea (1.05–1.24 g/g), pea (1.07- 1.27 g/g), and quinoa (1.88 g/g), but lower than reported for hempseed (12.54- 13.70 g/g) and avocado meal protein (5.53 g/g) (Elsohaimy et al., 2015; Kaur & Singh, 2005; Malomo et al., 2014; Stone et al., 2015; Wang et al., 2019). The good OAC values indicate that MP and IP could potentially be an ingredient in lipid-rich foods like meat and sauces, and to replace commercially used SPI.

Emulsifying Activity Index (EAI) and Emulsion Stability Index (ESI)

Maximum EAI was obtained at 0.6 M and 0.8 M NaCl concentrations for MP, 0.2 M NaCl concentration for IP, and 0.2 M, 0.6 M and 0.8 M NaCl concentrations for SPI (Fig. 3a). All isolates showed poor EAI at 1.0 M NaCl concentration (Fig. 3a). This is attributable to the salting-in and salting-out properties of proteins, where lower salt concentrations improved protein solubility (salting-in) and high salt concentrations led to the dehydration and poor solubility of proteins (salting-out), due to decreased interaction between the ions and charged protein groups, as similarly observed for WHC (Fig. 2a). Qi et al. (1997) stated that the emulsifying properties of proteins depend on protein solubility; so the more protein that is dissolved, the more protein will reach the oil–water interface to form cohesive films around oil droplets. This association was evident in this study, where MP possessed greater solubility than IP (Fig. 1a).

Effect of ionic strength on Emulsifying Activity Index (EAI) (a); effect of ionic strength on Emulsifying Stability Index (ESI) (b); effect of pH on EAI (c), and effect of pH on ESI (d) of MP, IP, and SPI. Difference in lower case letters (a, b, c) indicate significant differences within sample at different ionic strengths/pH. Difference in upper case letters (A, B, C) indicate significant differences between samples

Maximum ESI was recorded at 0.4 M NaCl concentration for IP and SPI, and 0.4 M and 0.8 M NaCl concentration for MP (Fig. 3b). Similar to the observations for EAI, all isolates showed poor ESI at 1.0 M NaCl concentration (Fig. 3b). Low electrostatic repulsion would have encouraged protein–protein interaction and aggregation, resulting in the destabilization of the emulsions as previously seen by Shao et al. (2017) in emulsions stabilized by Ulva fasciata polysaccharide. Aluko and Yada (1995) attributed the good ESI of cowpea protein isolates to the formation of charged layers around oil droplets that resulted in repulsion and formation of a hydrated layer around interfacial materials, which reduced interfacial tension and prevented coalescence. It is possible that a high surface charge of proteins, in 0.4 M and 0.8 M NaCl concentrations, prevented the aggregation of suspended oil droplets and stabilized the emulsions. Similar observations were made for African locust bean, Gingko biloba seed, pumpkin seed, and walnut proteins (Deng et al., 2011; Hu et al., 2017; Lawal, 2004; Pham et al., 2017).

Dependence of EAI on pH was expected (Fig. 3c), as it is well documented that emulsion capacities of proteins are dependent on the hydrophilic–lipophilic balance, which is influenced by pH (Ochoa-Rivas et al., 2017; Sathe et al., 1982). The EAI was lower at pH 2 to 4 for all isolates, with the exception of pH 6 for IP at which EAI was also recorded to be low (32 m2/g). This was expected as pH 2 to 4 is the isoelectric region where proteins take on a more stable conformation that is more resistant to unfolding, resulting in poor film forming abilities. Protein solubility is the lowest at the isoelectric region, affecting protein diffusion to the water and oil interface and preventing film formations, surrounding the suspended oil droplets in oil-in-water emulsions (Belitz et al., 2009). EAI was significantly (p ≤ 0.05) improved at pH values away from the isoelectric region. This could be due to increased exposure of hydrophobic surfaces or non-polar side chains, resulting from denaturation at extreme conditions, which would have promoted protein adsorption at the oil–water interface and the formation of films around oil droplets (Hu et al., 2017). These observations were in line with data reported by Fasuan et al. (2018); Hu et al. (2017); Lawal (2004); Pham et al. (2017); and Ragab et al. (2004) for African locust bean, cowpea proteins, pumpkin seeds, sesame seeds, and walnut proteins.

It is observed that ESI values were the highest at pH 4 for MP and SPI, and at pH 2 and pH 4 for IP (Fig. 3d). This indicates that the emulsions were more stable at acidic pHs than alkaline pHs. This was not in agreement with previous studies that reported ESI to increase with an increase in pH, due to increased protein solubility that enhanced the formation of interfacial films, as the isolates recorded low solubilities at around pH 4 (Fig. 1b). Sathe et al. (1982) reported that the differences observed in ESI is due to the hydrophilic–lipophilic balance of the proteins along the pH gradient. It is possible that acidic conditions (pH 4) resulted in a better hydrophilic–lipophilic balance of the proteins, hence the higher ESI that was observed. This observation is also akin to pea proteins that can stabilize emulsions at acidic environments (pH 3) (Sridharan et al., 2020). According to the authors, pea proteins possess the ability to irreversibly adsorb at the air–water interface and stabilize the oil droplets, in acidic environments, also known as a Pickering stabilization mechanism. This could explain the trends observed in our study, although more research is needed to confirm this. These findings demonstrate that MP and IP could potentially be used in the production of food emulsions with acidic pH, such as salad dressings.

It is noteworthy that MP showed significantly (p ≤ 0.05) better EAI values in comparison to SPI and IP at all ionic strengths and pH values studied. This can be associated with the better solubility (Fig. 1a, b) and higher protein concentration (93.86 g100g−1) of MP, comparative to IP. Elsohaimy et al. (2015) previously reported the EAI of quinoa protein isolates to increase (1.24–3.38 m2/g) with increasing protein concentrations (0.10–3.00%). In addition, the high surface hydrophobicity of micellized isolates, So = 184, as reported by Illingworth et al. (2022), could also be responsible for the high EAI values recorded. This implies that MP may have greater use in emulsification, in comparison to IP and SPI. Belitz et al. (2009) and Mishyna et al. (2019) stated that the protein concentration, protein solubility, amino acid composition, and surface hydrophobicity are the properties of proteins that influence emulsifying properties and stabilization of oil-in-water emulsions. This is also proven in the research of Rawat and Saini (2023), who reported that the emulsifying properties of sunnhemp protein isolate have increased, due to an increased surface hydrophobicity induced by ultrasound treatment. Previous studies, that examined the effect of extraction and isolation techniques on the emulsifying properties of protein isolates from Bambara groundnut, sweet and bitter lupin seeds, also found micellized isolates to possess better emulsifying properties in contrast to isoelectric isolates (Adebowale et al., 2011; El-Adawy et al., 2001). Proteins that possess good emulsifying properties could be used in the production of various food emulsions, such as ice cream, ground meats, and mayonnaise (Hernández Ramírez et al., 2023).

Foaming Capacity (FC) and Foam Stability (FS)

Maximum FC was achieved at 0.4 M NaCl concentration for IP, and 0.6 M NaCl concentration for MP and SPI (Fig. 4a). The highest FS was recorded at 0.2 M and 0.6 M NaCl concentrations for SPI, and 0.8 M NaCl concentration for MP and IP (Fig. 4b). All isolates recorded a reduction in FC and FS at 1.0 M NaCl concentration (Fig. 4a, b). These trends were similar to previous EAI measurements, where lower ionic strengths improved foaming properties, while higher ionic strengths (1.0 M NaCl concentration) had the inverse effect. Lower ionic strengths increased protein solubility, which aided in the formation of continuous, gas-impermeable films around air bubbles in a foam system (Yuliana et al., 2014). Higher ionic strengths (1.0 M NaCl concentration) limited protein solubility (as seen for MP in Fig. 1a), resulting in the destruction of protein films and promotion of aggregation and protein precipitation. Similar observations were made for African locust bean, Gingko biloba seed, and pumpkin seed proteins (Deng et al., 2011; Lawal, 2004; Pham et al., 2017).

Effect of ionic strength on Foaming Capacity (FC) (a); effect of ionic strength on Foam Stability (FS) (b); effect of pH on FC (c), and effect of pH on FS (d) of MP, IP, and SPI. Difference in letters (a, b, c) indicate significant differences within sample at different ionic strengths/pH. Difference in upper case letters (A, B, C) indicate significant differences between samples

FC and FS were observed to be pH dependent (Fig. 4c, d). Maximum FC values were measured at pH 2 for all isolates (Fig. 4c), while further increase in pH resulted in poorer foaming properties. FC was the lowest at pH 4 for all the isolates (Fig. 4c), and this can be associated to the low solubility of MP and IP at pH 4 (Fig. 1b). The low solubility led to the deceleration of protein molecules to the air–water interface during foaming. The slight improvement in FC beyond pH 4 may be attributable to increased protein flexibility and solubility due to the denaturation and unfolding of proteins at the air–water interface, which resulted in better air encapsulation and formation of air bubbles. These findings are in agreement with Deng et al. (2019); Fasuan et al. (2018); Hu et al. (2017); Lawal (2004); and Pham et al. (2017), who observed significant (p ≤ 0.05) improvements in FC away from isoelectric regions for African locust bean, Chinese quince seed, pumpkin seed, sesame seed, and walnut proteins. The high FC at low pH suggests that the foams formed are more stable at acidic pHs and these protein isolates could potentially be used in the production of carbonated beverages (soft drinks, beer, sparkling wine), where foam formation is desired.

Maximum FS were recorded between pH 2 to 4 for all the three isolates, showing good stability in the isoelectric region. Although these observations opposed findings by Hu et al. (2017) and Deng et al. (2019), they were in agreement with Pham et al. (2017) and Lawal (2004). The authors reported that FS is the highest at the isoelectric region due to the lack of repulsive interactions, allowing the improvement of film formation at the air–water interface. Belitz et al. (2009) stated that low net charges at the isoelectric region is essential in the improvement of FS. This is further confirmed by Wang et al. (2010), who claimed that a net neutral charge on protein molecules is critical in foam stabilization.

A study by Mohan and Mellem (2020) reported similarly to our observations, where isoelectric Hyacinth bean proteins possessed higher FC but lower FS in comparison to micellized protein isolates. Low FS values indicate weak interfacial films formed by the proteins. IP showed significantly (p ≤ 0.05) better FC in comparison to MP and SPI at all ionic strengths and pH values studied. Of the three isolates, it is evident that both IP and MP possessed greater foaming properties than SPI.

Least Gelation Concentration (LGC)

MP had a higher LGC of 25% at all conditions (except 1.0 M NaCl concentration and pH 2, where LGC was not achieved), in comparison to IP which recorded a LGC of 20% at all conditions (except 1.0 M NaCl concentration) (Tables 2 and 3). The physical appearance of the formed gels was also a major difference between the isolates (Figs. 5 and 6). The network formation of gels involves the participation of hydrogen bonding, hydrophobic, and electrostatic interactions; the contributions of these forces vary with protein type, protein concentration, heating, and environmental conditions (Damodaran & Parkin, 2017). This indicates that the extraction and isolation techniques influenced the gelation capacity of M. oleifera protein isolates through the manipulation of these various forces and interactions. According to Damodaran and Parkin (2017), proteins can either form coagulum (opaque) gels or translucent gels; however, proteins that contain high proportions of hydrophobic amino acids are known to form coagulum type gels. The observation of coagulum gels in this study supports the findings of Illingworth et al. (2022), who reported M. oleifera protein isolates to possess higher proportions of hydrophobic amino acids.

MP and IP showed similar gelling behaviour in response to ionic strength. For MP, very firm gels were obtained from 0.2 to 0.4 M NaCl (Fig. 5c), brittle gels were obtained from 0.6 to 0.8 M NaCl (Fig. 5b), and semi-solid (weak) gels were obtained at 1.0 M NaCl (Fig. 5a). Similarly, for IP, firm gels were obtained at 0.2 to 0.4 M NaCl (Fig. 6c), gels were obtained at 0.6 M NaCl (Fig. 6b), and semi-solid (weak) gels were obtained at 1.0 M NaCl (Fig. 6a). The mechanism of gelation is influenced by the balance between attractive hydrophobic interactions and electrostatic interactions, which controls the protein–protein and protein-solvent interactions in a gelling system (Damodaran & Parkin, 2017). This elucidates the effect of ionic strength on the gelation capacity, where at lower ionic strengths (0.2 to 0.4 M NaCl), protein-solvent interactions are slightly promoted, resulting in better gelation capacity, hence the gels are firmer. This was better emphasized in the lowest LGC recorded (10%) for MP at 0.2 M NaCl. In contrast, higher ionic strengths (0.6 M to 1.0 M NaCl) promote protein–protein interactions, causing the precipitation of the proteins, thus impairing gelling ability and producing the semi-solid (weak) gels. Similar trends were observed for African locust bean and pumpkin seed proteins when varying the ionic strength (Lawal, 2004; Pham et al., 2017).

Although differences in LGC were not observed when varying pH values, there were notable differences in the physical appearance of the gels formed. Interestingly, MP and IP both produced firm gels at pH 8 (Tables 2 and 3), while gels formed at other pH values were not as firm, except for MP at pH 2, where no gelling ability was recorded. It is possible that an appropriate balance between attractive hydrophobic interactions and electrostatic interactions was attained at pH 8, resulting in firm gels. Gels obtained at other pH values were less cohesive and more like pastes (Fig. 6b). Raikos et al. (2014) recorded similar observations for hemp flour. According to the authors, this is due to the phenomenon where dominant repulsive forces retard gelling abilities. MP and IP had comparable LGCs to hempseed protein isolate (22%) but were inferior to SPI (14%) and chickpea (10–14%) (Brishti et al., 2017; Kaur & Singh, 2005; Malomo et al., 2014). Gelation is often a desired property in food products such as pudding and meat products. The results of the study of LGC show that M. oleifera protein isolates possess gelling abilities, but if they are used in the composition of food products that require gelling, it is necessary to put them in a higher concentration (20 to 25% w/v).

Conclusion

Two extraction methods (alkaline extraction & isoelectric precipitation and salt extraction & micellization) can be applied in the valorization of M. oleifera seedcake, with each technique producing a protein isolate suited for different applications. The micellized isolate could be used in food emulsions due to a better EAI, while the isoelectric isolate can be applied in meats and sauces, owing to a better OAC, although further research into their application is necessary. It is concluded that the manipulation of pH and ionic strength can enhance the solubility of M. oleifera protein isolates. Improved solubility was noted in the micellized isolate beyond 0.2 M NaCl concentration, and in both isolates away from the isoelectric region (pH 2–4). This is important as the solubility of a protein ultimately determines its use. The functional properties, namely, WHC, OAC, EAI, ESI, FC, FS, and LGC, of M. oleifera protein isolates can be maximized and enhanced with the adjustment of pH and ionic strength. Overall, these findings reveal that the selection of an appropriate extraction method, pH, and ionic strength, can yield M. oleifera protein isolates with desirable functional properties that can be used in the formulation of a variety of food products (beverages, sauces, bakery products, etc.) or even as a possible replacement for animal derived proteins in conventional foods.

Data Availability

The data obtained for the publication of this article are available upon reasonable request to the corresponding author.

References

Adebowale, Y. A., Schwarzenbolz, U., & Henle, T. (2011). Protein Isolates from Bambara Groundnut (Voandzeia subterranean L.): Chemical Characterization and Functional Properties. International Journal of Food Properties, 14(4), 758–775. https://doi.org/10.1080/10942910903420743

Aderinola, T. A., Alashi, A. M., Nwachukwu, I. D., Fagbemi, T. N., Enujiugha, V. N., & Aluko, R. E. (2020). In Vitro Digestibility, Structural and Functional Properties of Moringa oleifera Seed Proteins. Food Hydrocolloids, 101, 105574. https://doi.org/10.1016/j.foodhyd.2019.105574

Aluko, R., & Yada, R. (1995). Structure-function relationships of cowpea (Vigna unguiculata) globulin isolate: influence of pH and NaCl on physicochemical and functional properties. Food Chemistry, 53(3), 259–265. https://doi.org/10.1016/0308-8146(95)93931-G

Belitz, H.-D., Grosch, W., & Schieberle, P. (2009). Food Chemistry (4th ed.). Springer.

Brishti, F. H., Zarei, M., Muhammad, S. K. S., Ismail-Fitry, M. R., Shukri, R., & Saari, N. (2017). Evaluation of the functional properties of mung bean protein isolate for development of textured vegetable protein. International Food Research Journal, 24(4), 1595–1605.

Cai, L., Xiao, L., Liu, C., & Ying, T. (2013). Functional properties and bioactivities of pine nut (Pinus gerardiana) protein isolates and its enzymatic hydrolysates. Food and Bioprocess Technology, 6(8), 2109–2117. https://doi.org/10.1007/s11947-012-0885-7

Chew, P. G., Casey, A. J., & Johnson, S. K. (2003). Protein quality and physico-functionality of australian sweet lupin (Lupinus angustifolius cv. Gungurru) protein concentrates prepared by isoelectric precipitation or ultrafiltration. Food Chemistry, 83(4), 575–583. https://doi.org/10.1016/S0308-8146(03)00156-0

Coffmann, C. W., & Garciaj, V. V. (1977). Functional properties and amino acid content of a protein isolate from mung bean flour. International Journal of Food Science & Technology, 12(5), 473–484. https://doi.org/10.1111/j.1365-2621.1977.tb00132.x

Damodaran, S., & Parkin, K. L. (2017). Fennema's Food Chemistry (5 ed.). CRC Press.

Deng, Q., Wang, L., Wei, F., Xie, B., Huang, F., Huang, W., Shi, J., Huang, Q., Tian, B., & Xue, S. (2011). Functional properties of protein isolates, globulin and albumin extracted from Ginkgo biloba Seeds. Food Chemistry, 124(4), 1458–1465. https://doi.org/10.1016/j.foodchem.2010.07.108

Deng, Y., Huang, L., Zhang, C., Xie, P., Cheng, J., Wang, X., & Li, S. (2019). Physicochemical and functional properties of chinese quince seed protein isolate. Food Chemistry, 283, 539–548. https://doi.org/10.1016/j.foodchem.2019.01.083

Dong, M., Sun, Y., Xiong, D., Song, Q., & jia, J., Liu, X., Sheng, L., & Duan, X. (2023). Comparison of the effects of pH-shifting, acetic acid modification, and TGase treatment on the physicochemical and functional properties of wheat gluten protein. Food and Bioprocess Technology. https://doi.org/10.1007/s11947-023-03130-0

Du, Q.-H., Wu, Y.-H., Xue, S., & Fu, Z. (2022). Extraction concentration of NaCl on structural, physicochemical and functional properties of Moringa oleifera seeds protein. Food Science & Technology, 155, 112988. https://doi.org/10.1016/j.lwt.2021.112988

El-Adawy, T., Rahma, E., El-Bedawey, A., & Gafar, A. (2001). Nutritional potential and functional properties of sweet and bitter lupin seed protein isolates. Food Chemistry, 74(4), 455–462. https://doi.org/10.1016/S0308-8146(01)00163-7

Elsohaimy, S. A., Refaay, T. M., & Zaytoun, M. A. M. (2015). Physicochemical and functional properties of quinoa protein isolate. Annals of Agricultural Science, 60(2), 297–305. https://doi.org/10.1016/j.aoas.2015.10.007

Farooq, Z., & Boye, J. I. (2011). Novel food and industrial applications of pulse flours and fractions. In Pulse Foods: Processing, Quality and Nutraceutical Applications (pp. 283–323).

Fasuan, T. O., Gbadamosi, S. O., & Omobuwajo, T. O. (2018). Characterization of protein isolate from Sesamum indicum seed: In vitro protein digestibility, amino acid profile, and some functional properties. Food Science & Nutrition, 6(6), 1715–1723. https://doi.org/10.1002/fsn3.743

Fathollahy, I., Farmani, J., Kasaai, M. R., & Hamishehkar, H. (2021). Characteristics and functional properties of persian lime (Citrus latifolia) seed protein isolate and enzymatic hydrolysates. LWT, 140, 110765. https://doi.org/10.1016/j.lwt.2020.110765

Hadidi, M., Palacios, J. C. O., McClements, D. J., Mahfouzi, M., & Moreno, A. (2023). Alfalfa as a sustainable source of plant-based food proteins. Trends in Food Science & Technology.

Hadnađev, M., Dapčević-Hadnađev, T., Lazaridou, A., Moschakis, T., Michaelidou, A. M., Popović, S., & Biliaderis, C. G. (2018). Hempseed meal protein isolates prepared by different isolation techniques. Part I. Physicochemical Properties. Food Hydrocolloids, 79, 526–533. https://doi.org/10.1016/j.foodhyd.2017.12.015

Hernández Ramírez, J. A., Ulloa, J. A., Ulloa Rangel, B. E., & Rosas Ulloa, P. (2023). Valorization of the Noni (Morinda citrifolia) Seeds as Source of a Protein Concentrate and Its Physicochemical, Functional, and Structural Characterization. Waste and Biomass Valorization. https://doi.org/10.1007/s12649-023-02270-w

Hu, H., Fan, T., Zhao, X., Zhang, X., Sun, Y., & Liu, H. (2017). Influence of pH and salt concentration on functional properties of walnut protein from different extraction methods. Journal of Food Science and Technology, 54(9), 2833–2841. https://doi.org/10.1007/s13197-017-2721-6

Illingworth, K. A., Lee, Y. Y., & Siow, L. F. (2022). The effect of isolation techniques on the physicochemical properties of Moringa oleifera protein isolates. Food Chemistry Advances, 1. https://doi.org/10.1016/j.focha.2022.100029

Kaur, M., & Singh, N. (2005). Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chemistry, 91(3), 403–411. https://doi.org/10.1016/j.foodchem.2004.06.015

Krause, J. P., Schultz, M., & Dudek, S. (2002). Effect of extraction conditions on composition, surface activity and rheological properties of protein isolates from flaxseed (Linum usitativissimum L). Journal of the Science of Food and Agriculture, 82(9), 970–976. https://doi.org/10.1002/jsfa.1140

Langyan, S., Yadava, P., Khan, F. N., Dar, Z. A., Singh, R., & Kumar, A. (2022). Sustaining protein nutrition through plant-based foods. Frontiers in Nutrition, 8. https://doi.org/10.3389/fnut.2021.772573

Lawal, O. S. (2004). Functionality of African locust bean (Parkia biglobossa) protein isolate: effects of pH, ionic strength and various protein concentrations. Food Chemistry, 86(3), 345–355. https://doi.org/10.1016/j.foodchem.2003.09.036

Lee, C. H. (2017). A simple outline of methods for protein isolation and purification. Endocrinology and Metabolism (seoul), 32(1), 18–22. https://doi.org/10.3803/EnM.2017.32.1.18

Lee, S. Y., Lee, D. Y., Jeong, J. W., Kim, J. H., Yun, S. H., Joo, S.-T., Choi, I., Choi, J. S., Kim, G.-D., & Hur, S. J. (2023). Studies on meat alternatives with a focus on structuring technologies. Food and Bioprocess Technology, 16(7), 1389–1412. https://doi.org/10.1007/s11947-022-02992-0

Lin, M.J.-Y., Humbert, E., & Sosulski, F. (1974). Certain functional properties of sunflower meal products. Journal of Food Science, 39(2), 368–370. https://doi.org/10.1111/j.1365-2621.1974.tb02896.x

Ma, Z., Boye, J. I., Simpson, B. K., Prasher, S. O., Monpetit, D., & Malcolmson, L. (2011). Thermal processing effects on the functional properties and microstructure of lentil, chickpea, and pea flours. Food Research International, 44(8), 2534–2544. https://doi.org/10.1016/j.foodres.2010.12.017

Malomo, S. A., He, R., & Aluko, R. E. (2014). Structural and functional properties of hemp seed protein products. Journal of Food Science, 79(8), C1512–C1521. https://doi.org/10.1111/1750-3841.12537

Mishyna, M., Martinez, J.-J.I., Chen, J., & Benjamin, O. (2019). Extraction, characterization and functional properties of soluble proteins from edible grasshopper (Schistocerca gregaria) and Honey Bee (Apis mellifera). Food Research International, 116, 697–706. https://doi.org/10.1016/j.foodres.2018.08.098

Mohan, N., & Mellem, J. J. (2020). Functional properties of the protein isolates of hyacinth bean [Lablab purpureus (L.) Sweet]: an effect of the used procedures. LWT, 129, 109572. https://doi.org/10.1016/j.lwt.2020.109572

Naik, M., Natarajan, V., Modupalli, N., Thangaraj, S., & Rawson, A. (2022). Pulsed ultrasound assisted extraction of protein from defatted bitter melon seeds (Momardica charantia L.) meal: kinetics and quality measurements. LWT, 155, 112997. https://doi.org/10.1016/j.lwt.2021.112997

Ochoa-Rivas, A., Nava-Valdez, Y., Serna-Saldívar, S. O., & Chuck-Hernández, C. (2017). Microwave and ultrasound to enhance protein extraction from peanut flour under alkaline conditions: effects in yield and functional properties of protein isolates. Food and Bioprocess Technology, 10(3), 543–555. https://doi.org/10.1007/s11947-016-1838-3

Pearce, K. N., & Kinsella, J. E. (1978). Emulsifying properties of proteins: evaluation of a turbidimetric technique. Journal of Agricultural and Food Chemistry, 26(3), 716–723. https://doi.org/10.1021/jf60217a041

Pham, T. T., Tran, T. T. T., Ton, N. M. N., & Le, V. V. M. (2017). Effects of pH and salt concentration on functional properties of pumpkin seed protein fractions. Journal of Food Processing and Preservation, 41(4), e13073. https://doi.org/10.1111/jfpp.13073

Piornos, J. A., Burgos-Díaz, C., Ogura, T., Morales, E., Rubilar, M., Maureira-Butler, I., & Salvo-Garrido, H. (2015, Oct). Functional and physicochemical properties of a protein isolate from AluProt-CGNA: A novel protein-rich lupin variety (Lupinus luteus). Food Research International, 76(Pt 3), 719–724. https://doi.org/10.1016/j.foodres.2015.07.013

Qi, M., Hettiarachchy, N., & Kalapathy, U. (1997). Solubility and emulsifying properties of soy protein isolates modified by pancreatin. Journal of Food Science, 62(6), 1110–1115. https://doi.org/10.1111/j.1365-2621.1997.tb12224.x

Ragab, D. M., Babiker, E. E., & Eltinay, A. H. (2004, 2004/02/01/). Fractionation, solubility and functional properties of cowpea (Vigna unguiculata) proteins as affected by pH and/or salt concentration. Food Chemistry, 84(2), 207–212. https://doi.org/10.1016/S0308-8146(03)00203-6

Raikos, V., Neacsu, M., Russell, W., & Duthie, G. (2014). Comparative study of the functional properties of lupin, green pea, fava bean, hemp, and buckwheat flours as affected by pH. Food Science & Nutrition, 2(6), 802–810. https://doi.org/10.1002/fsn3.143

Rawat, R., & Saini, C. S. (2023). High-Intensity Ultrasound (HIUS) treatment of sunnhemp protein isolate (Crotalaria juncea L.): Modification of functional, structural, and microstructural properties. Food and Bioprocess Technology, 16(7), 1464–1477. https://doi.org/10.1007/s11947-023-03011-6

Reinkensmeier, A., Bußler, S., Schlüter, O., Rohn, S., & Rawel, H. M. (2015). Characterization of individual proteins in pea protein isolates and air classified samples. Food Research International, 76, 160–167. https://doi.org/10.1016/j.foodres.2015.05.009

Rodríguez-Ambriz, S., Martínez-Ayala, A., Millán, F., & Dávila-Ortíz, G. (2005). Composition and functional properties of Lupinus campestris protein isolates. Plant Foods for Human Nutrition, 60(3), 99–107. https://doi.org/10.1007/s11130-005-6835-z

Rosas-Ulloa, P., Ulloa, J. A., Ulloa Rangel, B. E., & López Mártir, K. U. (2023). Protein isolate from orange (Citrus sinensis L.) seeds: Effect of high-intensity ultrasound on its physicochemical and functional properties. Food and Bioprocess Technology, 16(3), 589–602. https://doi.org/10.1007/s11947-022-02956-4

Sathe, S., Deshpande, S., & Salunkhe, D. (1982). Functional properties of lupin seed (Lupinus mutabilis) proteins and protein concentrates. Journal of Food Science, 47(2), 491–497. https://doi.org/10.1111/j.1365-2621.1982.tb10110.x

Shao, P., Ma, H., Zhu, J., & Qiu, Q. (2017). Impact of ionic strength on physicochemical stability of O/W emulsions stabilized by Ulva fasciata polysaccharide. Food Hydrocolloids, 69, 202–209. https://doi.org/10.1016/j.foodhyd.2017.01.039

Silventoinen, P., Rommi, K., Holopainen-Mantila, U., Poutanen, K., & Nordlund, E. (2019). Biochemical and techno-functional properties of protein- and fibre-rich hybrid ingredients produced by dry fractionation from rice bran. Food and Bioprocess Technology, 12(9), 1487–1499. https://doi.org/10.1007/s11947-019-02307-w

Singh, A., & Sit, N. (2023, 2023/05/13). Dual Modification of Manila Tamarind Protein Isolate by Ultrasonication and Autoclaving and Their Characterization. Food and Bioprocess Technology. https://doi.org/10.1007/s11947-023-03100-6

Sosa, E. F., Thompson, C., Chaves, M. G., Acevedo, B. A., & Avanza, M. V. (2020). Legume seeds treated by high hydrostatic pressure: Effect on functional properties of flours. Food and Bioprocess Technology, 13(2), 323–340. https://doi.org/10.1007/s11947-019-02386-9

Sridharan, S., Meinders, M. B. J., Bitter, J. H., & Nikiforidis, C. V. (2020). On the emulsifying properties of self-assembled pea protein particles. Langmuir, 36(41), 12221–12229. https://doi.org/10.1021/acs.langmuir.0c01955

Stone, A. K., Avarmenko, N. A., Warkentin, T. D., & Nickerson, M. T. (2015). Functional properties of protein isolates from different pea cultivars. Food Science and Biotechnology, 24(3), 827–833. https://doi.org/10.1007/s10068-015-0107-y

United Nations. (2019). World Population Prospects 2019: Highlights. Department of Economic and Social Affairs, Population Division.

Viana, A., Ethur, E. M., de Freitas, E. M., & Hoehne, L. (2023). Chicken Eggs Substitute Using Vegetable Origin − A Review. Food and Bioprocess Technology, 16(8), 1652–1667. https://doi.org/10.1007/s11947-023-02999-1

Wan, Y., Zhou, Q., Zhao, M., & Hou, T. (2023). Byproducts of Sesame Oil Extraction: Composition, Function, and Comprehensive Utilization. Foods, 12(12), 2383. https://doi.org/10.3390/foods12122383

Wang, C., Tian, Z., Chen, L., Temelli, F., Liu, H., & Wang, Y. (2010). Functionality of barley proteins extracted and fractionated by alkaline and alcohol methods. Cereal Chemistry, 87(6), 597–606. https://doi.org/10.1094/CCHEM-06-10-0097

Wang, J.-S., Wang, A.-B., Zang, X.-P., Tan, L., Xu, B.-Y., Chen, H.-H., Jin, Z.-Q., & Ma, W.-H. (2019). Physicochemical, functional and emulsion properties of edible protein from avocado (Persea americana Mill.) oil processing by-products. Food Chemistry, 288, 146–153. https://doi.org/10.1016/j.foodchem.2019.02.098

Wang, N., Maximiuk, L., Fenn, D., Nickerson, M. T., & Hou, A. (2020). Development of a method for determining oil absorption capacity in pulse flours and protein materials. Cereal Chemistry, 97(6), 1111–1117. https://doi.org/10.1002/cche.10339

Yuliana, M., Truong, C. T., Huynh, L. H., Ho, Q. P., & Ju, Y.-H. (2014). Isolation and characterization of protein isolated from defatted cashew nut shell: Influence of pH and NaCl on solubility and functional properties. LWT-Food Science and Technology, 55(2), 621–626. https://doi.org/10.1016/j.lwt.2013.10.022

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions This work was funded by the graduate research fund provided by Monash University Malaysia.

Author information

Authors and Affiliations

Contributions

Kirsty Anne Illingworth: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Visualization, Writing—Original Draft, Lee Yee Ying: Supervision, Writing—Review & Editing, Siow Lee Fong: Supervision, Writing—Review & Editing, Resources and Funding acquisition.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Illingworth, K.A., Lee, Y.Y. & Siow, L.F. Functional Properties of Moringa Oleifera Protein Isolates as Influenced by Different Isolation Techniques, pH, and Ionic Strength. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-023-03279-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-023-03279-8