Abstract

We present an objective, singularity-free, path independent, numerically robust and efficient geometrically non-linear Reissner-Mindlin shell finite element formulation. The formulation is especially suitable for higher order ansatz spaces. The formulation utilizes geometric finite elements presented by Sander [74] and Grohs [34] for the interpolation on non-linear manifolds. The proposed method is objective and free from artificial singularities and spurious path dependence. Due to the fact that the director field lives on the unit sphere, a special linearization procedure is required to obtain the stiffness matrix. Here, we use the simple constructions of Absil et al. [2, 3], which yields an easy way to obtain the correct tangent operator of the potential energy. Additionally, we compare three different interpolation schemes for the shell director that can be found in the literature, where one of them is applied for the first time for the Reissner-Mindlin shell model. Furthermore, we compare the exponential map to the radial return normalization as procedure to update the nodal directors and conclude the superiority of the latter, in terms of fewer load steps. We also investigate the construction of a consistent tangent base update scheme. Path independence, efficiency and objectivity of the formulation are verified via a set of numerical examples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

This work presents a geometrically exact Reissner-Mindlin shell formulation with consistent interpolation of the director field. It is singularity free, path independent and objective as well as numerically efficient and robust. The origins of geometrically non-linear shell formulations can be traced back to [24]. For a historical review of non-linear shell theory in general we refer to [80] or [94] and for the historical context of Reissner’s developments we refer to [64]. A concise summary of geometrically exact shell formulation using stress resultants we refer to [101].

Classical shell theories can be grouped into Kirchhoff–Love and Reissner–Mindlin type models. The former rely on a kinematic description that is based on the midsurface position only, whereas the latter incorporate independent rotations of the director field, thus taking into account transverse shear deformation. Here, the director field is usually associated with the material fibers in normal direction in the undeformed configuration.

The treatment of this non-linear director field is discussed with respect to two major aspects in this paper: first, correct linearization of potential energy and second, feasible interpolation of the director in order to meet the requirements of being singularity-free, path independent and objective. Special attention is devoted to interpolation schemes with higher continuity, for instance using non-uniform rational B-splines (NURBS) as ansatz functions.

Such an inextensional single director shell model leads to a finite element formulation with five degrees of freedom per node. Three of them are the midsurface positions and the remaining two are increments associated with rotational change of the director, e.g., incremental rotations or director increments. Historically, these non-standard degrees of freedom gave rise to several uncertainties concerning a correct or optimal finite element formulation with respect to accuracy and efficiency. Mainly, two questions are crucial:

-

Which is the correct linearization process required to develop a well-defined and consistent iterative solution scheme?

-

Which interpolation scheme yields accurate results and does not violate fundamental properties, such as objectivity?

2 Historical Remarks

Correct linearization to obtain the stiffness matrix and, in particular, symmetry of the stiffness matrix are often discussed issues. In [82], Simo derived a tangent operator in the context of beams that may be unsymmetric away from equilibrium for a potential taking values from \({\mathcal {S}}{\mathcal {O}}(3)\). This is a result of using the second variation as a tool to construct the tangent operator.

Later, Simo [83] concluded that the Hessian (more precisely, the Riemannian Hessian) can be obtained by symmetrizing the unsymmetric second variation. We stress that this procedure is only useful for manifolds that can be classified as compact Lie Groups, which does not apply for the two-dimensional unit sphere. A short note on the history of unsymmetric tangent operators can be found in ([66], Ch. 1.7). Some of the questions concerning linearization were discussed in [53]. There, the authors concluded that a tangent operator can be unsymmetric, if it is constructed from the second variation. But they also pointed out that this construction does not lead to a well-defined operator.Footnote 1 The authors concluded that, therefore, the Hessian is the correct quantity to use as tangent operator since it is a well-defined tensorial quantity. For this Hessian, several works concluded that it needs to be symmetric for a torsion-free connectionFootnote 2, [2, 53, 56, 67, 70, 83, 91].

Furthermore, symmetry of the Riemannian Hessian does also hold during iteration. Nevertheless, symmetry of the tangent operator is still controversially discussed, see e.g. [92]. Therefore, to avoid uncertainties, we present the variation and linearization in detail and try to avoid vagueness. The resulting process of variation and linearization strongly depends on the results from [2]. We also refer to [20] for the interested reader. Using these results, the problem of optimization on non-linear manifolds can be solved elegantly using only Euclidean quantities and projection onto the manifold to simplify the construction of the gradient and the Hessian.

Historically, director rotations in Reissner-Mindlin type shell formulations were first formulated in terms of angle pairs that live in linear spaces in \({\mathbb {R}}^2\). This linearity naturally leads to a symmetric stiffness matrix. The shortcomings of this description is that it contains singularities, which may lead to convergence problems and limit the magnitude of the rotation, see e.g. [18, 23, 45, 63]. It is worth noting that the hairy ball theorem, see ([21], Sect. 2), excludes a singularity-free parametrization over a single domain in \(\mathbb {R}^2\) of the unit sphere \({{\mathcal {S}}}^2\). Therefore, the singularity requires a switch of parametrization in its vicinity. Additionally, these formulations require an involved evaluation of trigonometric functions for the residual and the stiffness matrix, see [63]. A similar history can be observed for Kirchhoff-Love rods, starting from [5], where Euler angles are used to rotate the cross section frame. Earlier, [7] proposed to include the Taylor expansion of the rotations only up to the quadratic term, which leads to a formulation allowing moderate rotations but non-objective results. An alternative solution of the problem is to avoid parametrization of the unit sphere in the first place.

To overcome the singularities of a parametrization, direct interpolation of the director was used in [43]. Here, the update of the nodal directors was done in terms of director increments that are expressed in the midsurface tangent vectors. This formulation leads to an objective and path independent approach. This approach and some of the aforementioned interpolation approaches are compared in [49]. An alternative approach was proposed by Simo and co-workers for Timoshenko beams [82] and for Reissner-Mindlin shells [84]. There, the authors exploited the manifold structure of \({{\mathcal {S}}}{{\mathcal {O}}}(3)\) and \({{\mathcal {S}}}^2\). The Riemannian manifold \({{\mathcal {S}}}{{\mathcal {O}}}(3)\) is the compact three-dimensional Lie Group called special orthogonal group and the Riemannian manifold \({{\mathcal {S}}}^2\) is the two dimensional unit sphere. These can be defined as \({{\mathcal {S}}}{{\mathcal {O}}}(3) = \{ {\textbf {X}}\in {{\,\textrm{Mat}\,}}_3(\mathbb {R})~|~ {\textbf {X}}^T {\textbf {X}}= {\textbf {I}}~\wedge ~ \det {\textbf {X}}=1 \}\) and \({{\mathcal {S}}}^2 = \{ {{\textbf {x}}}\in {{\,\textrm{Vec}\,}}_3(\mathbb {R})~|~ {{\textbf {x}}}^T {{\textbf {x}}}= 1 \}\). Additionally, \({{\,\textrm{Mat}\,}}_n(\mathbb {R})\) and \({{\,\textrm{Vec}\,}}_n(\mathbb {R})\) define all \(n \times n\) matrices and all n-sized vectors, respectively. The interest in \({{\mathcal {S}}}^2\) stems from the fact that the kinematic description of the Reissner-Mindlin model does not contain a stretch of transverse fibers (thickness change in direction of the director).Footnote 3 The approach from Simo and co-workers for the numerical treatment of the Reissner-Mindlin shell model leads to a singularity free formulation in terms of rotational parameters.

Nevertheless, this formulation is path dependent and non-objective due to the interpolation of rotation increments. Moreover, keeping track of fields of history variables at every quadrature point is necessary. [26] pointed out these shortcomings and presented a cure for the case of a non-linear Timoshenko beam formulation. In this formulation, the nodal quantities living in \({{\mathcal {S}}}{{\mathcal {O}}}(3)\) are interpolated, in contrast to the erroneous interpolation of quantities in the tangent space \(T{{\mathcal {S}}}{{\mathcal {O}}}(3)\). This approach yields an objective and path independent formulation. The proposed formula is well-known in computer graphics and is called SLERP (Spherical Linear intERPolation), see [70]. In ([26], Ch. 5b), this concept is extended to higher order polynomials, but it is still restricted to one-dimensional spaces. Therefore, it is only useful for beams. For a summary of different interpolation schemes for beams and their drawbacks we refer to [68].

For the two-dimensional representation in the context of shells, generalization of SLERP does not lead to a satisfying concept. For example, the formulation proposed in [6] generalizes SLERP and leads to an objective and path independent approach but it suffers from a spurious dependency of the computational results on node numbering, see ([6], Eq. 40). Furthermore, since the nodal director components are arguments inside trigonometric functions, evaluation and linearization are expensive. Additionally, the trigonometric function \(\arccos (x)\) (and its derivatives) exhibit poor numerical behavior near \(x=1\). As a result, a perturbation has to be applied for the special case of plane reference states and in general it is not possible for the nodal directors to be parallel.

Recently proposed isogeometric formulations limit the transverse shear to be geometrically linear, thus circumventing the treatment of large rotations [61, 16], where the latter approach inherits this property directly from the formulation of [14, 15]. In [61, 51] the ansatz space needs to be \(C^1\)-continuous between elements due to the presence of second derivatives in the weak form. This necessity is inherited from the Kirchhoff-Love model, as the shear deformation is hierarchically added to the Kirchhoff-Love formulation. Within patches, this continuity constraint can be trivially fulfilled using splines as shape functions. However, \(C^1\)-continuous patch coupling, as in [47], requires special attention and may compromise the elegance of the approach. Nevertheless, the formulations [61] and [51] are path independent and objective.

An isogeometric approach that includes the director rotation in a non-linear fashion has been proposed by [29]. It is based on the non-linear formulation of [86] and thus suffers from similar shortcomings, such as path dependence and non-objectivity inherited from the history fields at every integration point, see ([29], Table A.2.).

Finally, the formulation of [78] has to be mentioned, which inherits objectivity and path independence from the continuous model at the cost of solving a small non-linear minimization problem at every integration point to obtain the interpolated value. This formulation is constructed for Cosserat shell models with drilling rotations, which necessitates interpolation in \({{\mathcal {S}}}{{\mathcal {O}}}(3)\). The resulting finite elements are called geodesic finite elements.

Table 1 summarizes various shell formulations and their properties concerning objectivity, path independence, history variables and singularities.

In view of the aim to construct a formulation that enjoys all desired properties, the following can be concluded: Due to the difficulties arising from an interpolation of incremental rotations (non-objective, path dependent) and the interpolation of angles (singularities), interpolating the director field appears to be the most attractive option. An important issue in this context is the constraint that the director needs to have unit length, which is not naturally satisfied by standard interpolations. In the following we discuss three different approaches to interpolate the director field.

Nodal Finite Elements (NFE)

If the directors have unit length at the nodes only, as it is done in [15, 16, 43, 63], the constraint is violated in the domain. We will refer to this approach by the name Nodal Finite Elements.

In the following, we discuss two recent approaches to satisfy the unit length condition also in the domain. They are deduced from general constructions found in mathematical literature.

Geodesic Finite Elements (GFE)

The first approach is based on the works of Sander [73, 75] and Grohs [34] to generalize the concept of interpolation from vector spaces to manifolds. If such an interpolation is used, the resulting finite elements are called geodesic finite elements (GFE). These finite elements automatically inherit objectivity and path independence of the continuous formulation. This is due to the fact that the interpolation scheme is constructed from a weighted (geodesic) distance measure on the corresponding manifold. Since distances are invariant to rotations by definition, objectivity follows directly. Furthermore, due to the intrinsic nature, the interpolation always stays on the manifold and therefore this approach preserves unit length of the director in the domain. The major drawback is the implicit definition of the interpolation, which involves a non-linear minimization problemFootnote 4 at each integration point. This interpolation scheme is applied on the Reissner-Mindlin shell for the first time in this work.

Projection-Based Finite Elements (PBFE)

The second approach is projection-based interpolation, based on the works of Sprecher [90] and subsequent papers, e.g. Grohs et al. [36], which present a framework for finite elements that interpolate on manifolds by a closest point projection from an embedding space onto the manifold. The finite elements are constructed as in the nodal approach and then projected onto the corresponding manifold.

Luckily, the closest point projection of a vector in \(\mathbb {R}^3\) onto \({{\mathcal {S}}}^2\) has a closed form, namely the trivial normalization of the vector. This interpolation of projecting the vector back onto \({{\mathcal {S}}}^2\) was also used in [85], but only for the reference director field. A more involved version of this approach can be found in [30]. We refer to the resulting finite elements by the name Projection-Based Finite Elements (PBFE) in this paper.

Projection-based finite elements can be regarded as a special case of geodesic finite elements, where the distance measure for the interpolation is the one of the embedding space. For example, for the interpolation on \({{\mathcal {S}}}^2\) the distance measure is the Euclidean distance from \(\mathbb {R}^3\). Due to the construction of the interpolation as a distance measure, objectivity and path independence are inherited from geodesic finite elements.

Additionally, geodesic finite elements and projection-based finite elements are summarized as the group of geometric finite elements. Both interpolations (geodesic and projection-based) yield a path independent and objective discrete problem. The corresponding proofs can be found in ([36], Ch. 1.3) and ([74], Ch. 2.4, Lemma 2.5–2.6).

3 Scope of this Work

We use the projection-based finite element concept and the linearization results from [2, 3] to construct a sound shell formulation. The underlying shell theory is identical to the one put forward by Simo and Fox [84]. In summary, the presented shell finite element formulation enjoys the following desirable features:

-

It inherits the objectivity of the continuous model.

-

The magnitude of total rotations is not limited.

-

The unit length constraint of the interpolated director is satisfied in the domain.

-

As no history fields at the integration points are introduced, interpolation of the director is path independent.

-

The formulation goes without trigonometric functions. This simplifies linearization and results in a compact and fast implementation.

-

No singularities occur, as parametrization of the unit sphere is avoided.

-

The stiffness matrix is symmetric without neglecting any terms and without applying symmetrization procedures.

-

The resulting element vectors and matrices are invariant to node numbering.

Any of the above features can be found in shell formulations in the literature. However, to the authors’ best knowledge, there is no shell finite element formulation that enjoys all of them.

Beyond presentation of a novel shell finite element formulation, the following aspects are covered in the paper:

-

It is shown that the unit length of the director in the domain is crucial for using higher order interpolation schemes to circumvent a degeneration of the convergence order.

-

We show the superiority of the radial return normalization (projection-based retraction) for the nodal director instead of using the exponential map.

-

The non-linear space \({{\mathcal {S}}}^2\), in which the director is defined, needs special attention. Therefore, the consistent linearization process is presented in detail. A symmetric tangent operator is consistently derived rather than symmetrizing an initially unsymmetric result.

-

We show that the consistent linearization process yields an additional contribution to the stiffness matrix and provide a physical interpretation of this term.

-

We compare three update schemes for the nodal director tangent base, where two can be found in the literature and one is newly introduced.

-

We show the advantageous features of projection-based finite elements for the Reissner-Mindlin model.

The paper is organized as follows: In Sect. 4 we present the Reissner-Mindlin shell model up to the total potential energy in the total Lagrangian setting. After this, we deduce the construction of the correct gradient (residual, internal forces) and the correct Hessian (stiffness matrix) for an arbitrary energy living on \(M=\mathbb {R}^3 \times {{\mathcal {S}}}^2\) in Sect. 5. We apply these results onto the Reissner-Mindlin shell problem where only the Euclidean partial derivatives, i.e., the variation and linearization are needed to construct the correct Riemannian gradient and Riemannian Hessian following the results from [2, 3]. We obtain these Euclidean quantities in Sect. 5.3.

After the introduction of the correct operators, we establish our consistent interpolation in Sect. 6. In particular, we use projection-based finite elements (PBFE) for our shell discretization living in the space \(M=\mathbb {R}^3 \times {{\mathcal {S}}}^2\). Here, the midsurface displacement lives in \(\mathbb {R}^3\) and the unit director lives on \({{\mathcal {S}}}^2\). With this at hand, we explore several numerical examples to compare the presented approach with geodesic finite elements and nodal finite elements and conclude the superior behavior of the projection-based finite elements, especially in the context of higher order ansatz functions. This is done in Sect. 10. Furthermore, we investigate in our numerical examples the usage of the mixed interpolation point (MIP) technique to improve the convergence behavior, as introduced in [52]. Additionally, we compare the geometric meaning of the three interpolations (NFE, PBFE, GFE) in 10.2.

The notation used in the present work is a mixture of the one used in the classical papers of Simo and co-workers and the one of [36] and [2, 74]. Moreover, some quantities are newly introduced, see Table 2.

4 Non-linear Shell Theory Including Transverse Shear Deformation

4.1 Geometry and Kinematics

First, we define the geometric description of a shell structure as

Therefore, \({{\mathcal {M}}}\) represents the set of functions mapping from \({\varOmega }\) onto \(M = \mathbb {R}^3 \times {{\mathcal {S}}}^2\). The set \({\varOmega }\subset \mathbb {R}^2\) is the two-dimensional parameter space with the points

where \({\tilde{\textbf {{\textbf {E}}}}}_{{\alpha }}\) denote Cartesian base vectors. Furthermore, we introduce the map \({\varvec{\varphi }}: {\varOmega }\rightarrow \mathbb {R}^3\), defining the position vector of the midsurface of the shell, and the so-called director \({{\textbf {t}}}: {\varOmega }\rightarrow {{\mathcal {S}}}^2\), a field of unit vectors which are initially normal to the midsurface. The independent representation of \({\varvec{\varphi }}\) and \({{\textbf {t}}}\) allows the kinematic description of transverse shear deformation and thus realizes a Reissner-Mindlin type model. Using these quantities we can define the stress-free shell body as reference configuration

here \(h^-\) and \(h^+\) denote top and bottom surface coordinates of the shell and \(h=(h^+-h^-)\) is the shell thickness. Similarly, a configuration at time t is given by

For the total Lagrangian setting the kinematics are summarized in Fig. 1. With this, the reference and current position of a point of the shell body are given as

where we introduced the maps \(\hat{\varvec{{\Phi }}}: {{\mathcal {A}}}\rightarrow {{\mathcal {B}}}_t\) and \(\hat{\varvec{{\Phi }}}_0: {{\mathcal {A}}}\rightarrow {{\mathcal {B}}}_0\). \({{\mathcal {A}}}={\varOmega }\times [h^-,h^+]\) represents the three-dimensional parameter space, which can be also seen in Fig. 1. The deformation is then defined as a mapping \(\chi _t: {{\mathcal {B}}}_0 \rightarrow {{\mathcal {B}}}_t\) with

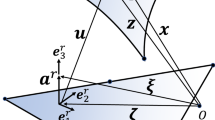

Kinematics and mappings of the Reissner-Mindlin shell model. We denote \({{\mathcal {B}}}_0 \) and \( {{\mathcal {B}}}_t \) as the Lagrangian and Eulerian manifold. \({{\mathcal {B}}}^C \) denotes the corresponding midsurfaces. Furthermore, we denote the two-dimensional and three-dimensional parameter space by \({\varOmega }, {{\mathcal {A}}}\). Here, \(\hat{\varvec{{\Phi }}},\hat{\varvec{{\Phi }}}_0 \) and \({\varvec{\chi }}\) denote the non-linear point maps between the spaces. The standard Cartesian bases associated with \({{\mathcal {B}}}_0,{{\mathcal {B}}}_t \) and \({\varOmega }\) are \(\{{\textbf {E}}_i \}_{i=1,3}, \{{\textbf {e}}_i \}_{i=1,3} \) and \(\{{\tilde{\textbf {{\textbf {E}}}}}_i \}_{i=1,3}\) respectively. \(\{{\textbf {A}}_1,{\textbf {A}}_2,{{\textbf {t}}}_0 \}\) and \(\{{\textbf {a}}_1,{\textbf {a}}_2,{{\textbf {t}}}\}\) are curvilinear co-variant bases at \({\textbf {X}}\) and \({{\textbf {x}}}\), similar to the definitions from [55]

For the base vectors \({{\textbf {g}}}_i \) and \({\textbf {G}}_i \) of both configurations it follows from Eq. (4.5)

where the base vectors of the reference and current midsurfaces \({\textbf {a}}_{\alpha }={\varvec{\varphi }}_{,{\alpha }}\) and \({\textbf {A}}_{\alpha }={\varvec{\varphi }}_{0,{\alpha }}\) are introduced. These relations are summarized in Fig. 1.

In view of the later introduction of the so-called effective stress resultants in Eq. (4.13), we define kinematic tensors based on the reference midsurface basis \( \{{\textbf {A}}_{\alpha },{{\textbf {t}}}_0\} \). The tensor of effective strains

is composed of the components of the Green-Lagrange strain tensor,

referring to the midsurface metric \({\textbf {A}}^i \otimes {\textbf {A}}^j \). Here, the usual Reissner-Mindlin kinematic assumptions \({{\textbf {t}}}_{,{\alpha }}\cdot {{\textbf {t}}}=0 \) and \({{\textbf {t}}}\cdot {{\textbf {t}}}={{\textbf {t}}}_0\cdot {{\textbf {t}}}_0 = 1 \) apply. The quadratic part \(\rho _{{\alpha }{\beta }}\) of \(E_{{\alpha }{\beta }}\) in \(\xi ^3\) is usually neglected. For the implications of this, see ([22], Chapter 9.1.3, Equation 9.34) or ([22], Chapter 3.7, Annahme A4). The effective membrane strain \({\varvec{\varepsilon }}\), curvature \({\varvec{\kappa }}\) and transverse shear strain \({\varvec{\gamma }}\)Footnote 5, implied by Eq. (4.9), read

4.2 Continuous Potential Energy of the Reissner-Mindlin Model

In the case of the Reissner-Mindlin shell model, the total potential energy functional depends on the function of the midsurface position \({\varvec{\varphi }}\in {{\mathcal {X}}}(\mathbb {R}^3)\) and the function of the director field \({{\textbf {t}}}\in {{\mathcal {X}}}({{\mathcal {S}}}^2)\), as in Eq. (4.5). Therefore, the functional \( {{\hat{{\varPi }}}}\) takes values from the non-linear manifold \({{\mathcal {M}}}\), which results in some non-trivial considerations concerning mainly the interpolation and linearization of these values. The total potential energy \({{\hat{{\varPi }}}}: {{\mathcal {M}}}\rightarrow \mathbb {R}\) reads

where \({{\mathcal {B}}}_0^C\) denotes the shell midsurface and \({{\mathcal {B}}}_0\) is the three-dimensional shell body. Here, \(\hat{\varvec{{\Phi }}} \in {{\mathcal {M}}}={{\mathcal {X}}}(M)\) is an element of the continuous configuration space. Furthermore, \({\bar{\psi }}\) denotes a generic strain energy volume density functional and \({{\hat{\psi }}}\) denotes a generic strain energy midsurface density functional.

We introduce the constitutive relations from the pre-integrated potential \({{\hat{\psi }}}\) resulting from a standard Coleman-Noll procedure as

The corresponding tensor quantities

are called second Piola Kirchhoff effective symmetric stress resultants. They do not represent the physical membrane forces, moments and shear forces, but they are energetically conjugate to the the effective strains defined in Eq. (4.10). For an explanation why the energy can be written in terms of the effective symmetric stress resultants, see [84, 19]. In Appendix 1, we show how to obtain the physical Cauchy stress resultants from these quantities. Again, since this energy expression contains values from \(\hat{\varvec{{\Phi }}}\in {{\mathcal {M}}}\), i.e. from \({{\mathcal {S}}}^2\), we have to take special care of its variation and linearization, which is carried out in Chapter 5. Before this, we make consideration about non-linear infinite-dimensional function spaces.

4.3 Dealing with Non-linear Infinite-Dimensional Function Spaces

Variation and linearization of a functional depending on quantities living in continuous vector spaces is a well understood topic in the context of solving PDEs in such spaces. In the case of quantities living in non-linear spaces, the situation becomes more difficult. For instance, in the continuous (infinite-dimensional) case, the important Sobolev space \(W^{1,2}({\varOmega },M)\) does not always possess the structure of a Banach manifold ([35], Ch. 3.2). Linearization and smoothness in these spaces is non-trivial, because the geometric structure can be unknown.

In Fig. 2, this situation corresponds to going down from the continuous potential \({{{\hat{{\varPi }}}}} \) on the left to the continuous weak form \({{{\hat{G}}}}\). The continuous weak form also needs to be linearized and therefore a connection on \({{\mathcal {M}}}\) has to be introduced to arrive at the linearized continuous weak form. This may or may not result in a consistent formulation if one moves from there to the right by discretization.

In order to manage this delicate situation, we restart from the continuous potential at the top left corner of Fig. 2. From there move to the discrete potential by direct discretization, following the red dash-dotted path to the right. Subsequently, there are several paths to develop an iterative solution scheme for a functional potential. Nevertheless, we introduce the Sobolev spaces where the continuous quantities live in. We first introduce the corresponding spaces as \( W^{k,p}({\varOmega },\mathbb {R}^3) \times W^{l,q}({\varOmega },{{\mathcal {S}}}^2) = {\mathbb {W}}_{k,p}^{l,q}({\varOmega },\mathbb {R}^3 \times {{\mathcal {S}}}^2)\) where \({\varvec{\varphi }}\in W^{k,p}({\varOmega },\mathbb {R}^3) \) and \({{\textbf {t}}}\in W^{l,q}({\varOmega },{{\mathcal {S}}}^2) \).

Numerical evidence suggests that only weak first order derivatives \((k=l=1)\) are needed, but we are not aware of any proofs. Lacking a more rigorous choice, we use the space \({\mathbb {W}}_{k,p}^{l,q}({\varOmega },\mathbb {R}^3 \times {{\mathcal {S}}}^2)={\mathbb {W}}_{k,p}^{l,q}({\varOmega },M)\) with \(M= \mathbb {R}^3 \times {{\mathcal {S}}}^2\) as surrogate. For more details we refer to [59]. Our model coincides with the one in Ch. 7.6. Moreover, Corollary 8.1 of [59] states that for a pure bending case at least one minimizer exists for \({\varvec{\varphi }}\in H^2({\varOmega },\mathbb {R}^3) = W^{2,2}({\varOmega },\mathbb {R}^3)\) and \({{\textbf {t}}}\in H^1({\varOmega },{{\mathcal {S}}}^2) = W^{1,2}({\varOmega },{{\mathcal {S}}}^2)\). Unfortunately, this is not useful for our case, since the minimizer corresponds to a deformation of Kirchhoff-Love type. For a theoretical treatment of these discrete and continuous non-linear function spaces of Sect. 4.3, we refer to [35, 40, 41, 42].

5 Discretization, Variation and Linearization

5.1 Dealing with Non-linear Discrete Configuration Spaces

We start in the top left corner of Fig. 2 at the continuous problem represented by the potential \({{\hat{\varPi }}}(\hat{\varvec{{\Phi }}}) \). Next, we discretize the continuous quantities in the potential to end up with the discrete finite element functions in the space \(V_h^{M}({\varOmega }) \subset {\mathbb {W}}_{k,p}^{l,q}({\varOmega },M)\). At this point we can formulate the first-order optimality condition in terms of the discrete test function space \( T_{\varvec{{\Phi }}^{\textrm {h}}}V_{\textrm {h}}^M({\varOmega }) \) by moving down from the discrete potential to the discrete weak form.

Alternatively, and more easily, we may first move to the algebraic settingFootnote 6 with the following procedure: We extract the nodal quantities from the finite element functions via the operator \({{\mathcal {E}}}\) and end up in the algebraic space \(M^n\), where n denotes the number of nodes. Here, the nodal evaluation operator \({{\mathcal {E}}}\) is defined as in [77] after Theorem 2.3. In the next step (now in the top right corner), using the construction of Absil et al. [3], the discrete variation and linearization can be obtained purely in the Euclidean embedding space and a projection afterwards. In this space, we can simply use partial derivatives instead of covariant derivatives. Moreover, we can treat the cumbersome Riemannian linearization (from weak form and discrete weak form, respectively, downwards via covariant derivatives) as a problem in Euclidean space. Thus, we can simply use the Gâteaux derivative in the Euclidean continuous vector space, which is easy to compute. The result is projected onto the tangent space of the manifold to obtain the correct Riemannian gradient and Riemannian Hessian, respectively, the residual and stiffness matrix of the Reissner-Mindlin formulation. With these algebraic quantities at hand, we can solve the non-linear minimization problem iteratively, ending up at the bottom right of Fig. 2.

The derivations sketched above, are described in more detail in the following, starting in Sect. 5.2 with the generic construction of the algebraic Riemannian gradient and Riemannian Hessian and eventually arriving at the element vectors and matrices in Sect. 7. Sect. 8 introduces the so-called retractions, defined in [2], which project nodal updates from the corresponding tangent space back onto the manifold. They are needed to generalize the standard addition to incrementally update the nodal displacements.

5.2 Computing the Gradient and the Hessian for the Algebraic Setting

5.2.1 The Intrinsic Approach

This section explains why the intrinsic algebraic linearization is cumbersome and why we use the extrinsic constructions of [2, 3], see Sects. 5.2.2 and 5.2.3. Starting point is the algebraic minimization problem of the functional \({\varPi }\)

which corresponds to the top right corner of Fig. 2. In the following we assume a Newton-Raphson-type solution process. For such an approach we need a residual quantity that typically arises from a weak form due to some virtual work principle, or, as in this case, simply as derivatives of \({\varPi }\). Furthermore, the Newton method requires the linearization of the residual at a specific point, which yields the Hessian operator. For the intrinsic approach we have to introduce a parametrization of the space M. For the midsurface vector space \(\mathbb {R}^3 \) this parametrization and the derivatives can be trivially constructed. Therefore, we focus on a single director \({{\textbf {t}}}\) living in \({{\mathcal {S}}}^2\). To point out the crucial aspects, we switch to index notation \({{\textbf {t}}}= t^{i} {\textbf {e}}_i\), where \({\textbf {e}}_i\) is the i-th Euclidean unit vector of \(\mathbb {R}^3 \) and \(i\in \{1,2, 3 \}\). A feasible parametrization of \({{\textbf {t}}}({\varvec{\alpha }})\in {{\mathcal {S}}}^2 \) is

Similar to [63] with \({\alpha }_1 \in [0, 2\pi [\) and \({\alpha }_2 \in [0, \pi ]\). The two-dimensional parameter space \(\mathbb {R}^2\) is then parametrized as \({\varvec{\alpha }}= {\alpha }^{\beta }{\hat{{\textbf {{\textbf {e}}}}}}_{\beta }\) where \({\hat{{\textbf {{\textbf {e}}}}}}_{\beta }\) is the \({\beta }\)-th Euclidean unit vector of \(\mathbb {R}^2\) with \({\beta }\in \{1,2\} \). Therefore, for the director the minimization reads

with the chain rule the first derivative of the potential \( {\varPi }({{\textbf {t}}}({\varvec{\alpha }}))\) is obtained as

where \(\frac{{\partial }t^i}{{\partial }{\alpha }^{\beta }} \) can be identified as the components of the two base vectors \({{\textbf {g}}}_{\beta }({\varvec{\alpha }})\) of the tangent space at \({{\textbf {t}}}\), such that

Due to the inevitable singularity in the parametrization Eq. (5.2) according to the hairy ball theorem, \({{\textbf {g}}}_{\beta }({\varvec{\alpha }})\) are doomed to vanish at some point \({\varvec{\alpha }}\), which leads to divergence of the solution procedure.

The second derivatives are straightforwardly obtained as

which can be recast to

The Christoffel symbol \(\varGamma _{{\beta }{\gamma }}^{\kappa }\) is defined as \(\frac{{\partial }^2{{\textbf {t}}}}{{\partial }{\alpha }^{\beta }{\alpha }^{\gamma }}=\frac{{\partial }{{\textbf {g}}}_{\beta }}{{\partial }{\alpha }^{\gamma }} = \varGamma _{{\beta }{\gamma }}^{\kappa }{{\textbf {g}}}_{\kappa }\). To find the stationary point \({\varvec{\alpha }}^*\), for which \({{\,\textrm{grad}\,}}{\varPi }({{\textbf {t}}}({\varvec{\alpha }})) =0\), a Newton-Raphson scheme can be used, where the first order Taylor expansion of the weak form is set to zero,

Eq. (5.8) is then solved for \(\Updelta {\varvec{\alpha }}_K \) and with this the configuration is simply updated as

To summarize, we repeat the singularities of the gradient and Hessian in Eqs. (5.5) and (5.7). Furthermore, the resulting quantities tend to be expensive to evaluate, due to the involved dependence on trigonometric functions inherited from the parametrization of Eq. (5.2). Both drawbacks can be circumvented using the extrinsic approach from [2, 3], which we will use and discuss in the following. As historical note, we mention [60, 65], who use a similar concept, which was also exploited by [6] to obtain the derivatives of their formulation. In contrast to the forecasted advantages, we point out that the trivial update formula of Eq. (5.9) will become more involved in the extrinsic approach and this will lead to the so-called retractions, described in Sect. 8. Furthermore, we mention that \({{\textbf {g}}}_{\alpha }\) is similar to the later introduced 3\(\times \)2 matrix \(\varvec{{\Lambda }}\).

5.2.2 The Extrinsic Approach: Projection of the Euclidean Gradient

The construction of the gradient and Hessian from [2] can only be applied in an algebraic setting. Therefore, we start from the discretized functional \({\varPi }^h: V_h^{{{\mathcal {M}}}}({\varOmega }) \rightarrow \mathbb {R}\). With the operator \({{\mathcal {E}}}: V_{\textrm {h}}^{{{\mathcal {M}}}} \rightarrow M^n\) it can be cast into a discrete function \({\varPi }: M^n \rightarrow \mathbb {R}\), which depends on n nodal values of the manifold M. The relation of \(V_{\textrm {h}}^{{{\mathcal {M}}}}\) and \(M^n\) for non-linear manifolds is more delicate than the case where \({{\mathcal {M}}}\) is a vector space. Especially the inverse \({{\mathcal {E}}}^{-1}\) is not unique in every case, as stated in ([74], Theorem 3.2). However this non-uniqueness is not an issue for Reissner-Mindlin energies, since the director does not vary by \(180^{\circ }\) from node to node. Nevertheless, with this at hand, we move in Fig. 2 from the top left to the top right corner. In the following we first describe the projection of gradients and Hessians.

We first introduce the standard concept of projecting a gradient, defined in an embedding space, onto a submanifold in such a way that it yields the correct gradient on the submanifold. This idea goes back at least to Rosen [71, 72]. The later projection of the Hessian has not such a long tradition, at least the authors could not find anything older than [65]. Here, M can be an arbitrary manifold and is not restricted to \({\mathbb {R}}^{3}\times {{{\mathcal {S}}}}^{2}\).

Any (co-)vector of a Euclidean embedding space can be decomposed into a tangential part and a normal part of a Riemannian submanifold \(M \subset {\mathbb {R}}^n\), see Fig. 3 and ([2], Chapter 3.6.1). For an arbitrary vector \({\varvec{\eta }}\in T_{{\textbf {x}}}\mathbb {R}^n\cong \mathbb {R}^n\) with its leg at \({{\textbf {x}}}\in \mathbb {R}^n\) this can be written as

here \(P_{{\textbf {x}}}\) denotes the projection onto \(T_{{\textbf {x}}}M\) and \(P_{{\textbf {x}}}^\perp \) is the projection onto \({(T_{{\textbf {x}}}M)}^\perp \).

We consider a function \({\bar{{\varPi }}}: \mathbb {R}^n \rightarrow \mathbb {R}\) defined on \(\mathbb {R}^n\) and a function \({\varPi }: M \rightarrow \mathbb {R}\), which is the same as \({\bar{{\varPi }}}\) with the restriction to take only values from M. The gradient of \({\varPi }\), which is a co-tangent vector, can then be expressed as the gradient of \({\bar{{\varPi }}}\), projected onto the submanifold M,

see also Fig. 3.

5.2.3 The Extrinsic Approach: Construction of the Riemannian Hessian

From the aforementioned projection to construct the Riemannian gradient, we can derive a similar reasoning to obtain the Riemannian Hessian. For two vectors \({\varvec{\eta }},{\varvec{\xi }}\in T_{{\textbf {x}}}M\) we get

here we made use of the relation \(\nabla _{\varvec{\eta }}=P_{{\textbf {x}}}{\textrm {D}}_{\varvec{\eta }}\), which stems from ([2], Ch. 5.3.3, Eq. 5.15). Additionally, \(\nabla _{\varvec{\eta }}\) denotes the covariant derivative, whereas \({\textrm {D}}_\eta \) describes a standard Euclidean directional derivative. Since \(P_{{\textbf {x}}}\) is a projection matrix, we additionally have the idempotency property \(P_{{\textbf {x}}}P_{{\textbf {x}}}=P_{{\textbf {x}}}\).

Thus, the Riemannian Hessian can be expressed by using four quantities, namely (i) the projection \(P_{{\textbf {x}}}\) from the embedding space onto the tangent space of the submanifold, (ii) the directional derivative of \(P_{{\textbf {x}}}\) in \(({\textrm {D}}_{\varvec{\eta }}P_{{\textbf {x}}})\), (iii) the gradient \({{\,\textrm{grad}\,}}{\bar{{\varPi }}}\) and (iv) the Hessian \({{\,\textrm{Hess}\,}}{\bar{{\varPi }}}\) of the Euclidean extension of the functional. This construction is obtained from [3]. With this we can calculate the Riemannian Hessian without any Christoffel symbols and using an extrinsic view without any singularities, since no parametrization, such as angles, are introduced.

In particular, for the case of the unit sphere \({{\textbf {x}}}\in {{\mathcal {S}}}^n\) the projection is

where \({\textbf {I}}\) is the identity matrix. For the partial derivative \({\textrm {D}}_{\varvec{\eta }}P_{{\textbf {x}}}\) we obtain

With this result we compute the product \(P_{{\textbf {x}}}({\textrm {D}}_{\varvec{\eta }}P_{{\textbf {x}}}) \) in Eq. (5.12) as follows

where the identities \({\varvec{\eta }}=P_{{\textbf {x}}}{\varvec{\eta }}\) and \(P_{{\textbf {x}}}{{\textbf {x}}}= {\varvec{0}}\) of the projection have been exploited. Naturally, we have for \(M={{\mathcal {S}}}^2\)

By comparing coefficients, we obtain

as Riemannian Hessian. Using \({\varvec{\eta }}=P_{{\textbf {x}}}{\varvec{\eta }}\), we can rewrite Eq. (5.16) in the form

which underlines the symmetry of the Riemannian Hessian.

5.2.4 Gradient and Hessian Final Form

We go back to the algebraic Reissner-Mindlin potential \({\varPi }(\varvec{{\Phi }})\), which takes values from \(M^n = (\mathbb {R}^3 \times {{\mathcal {S}}}^2)^n\). The aim is to move from the top right corner to the bottom right corner in Fig. 2. We restrict the subsequent derivations to the contributions of two nodes I and J, which can then be assembled to the full gradient and Hessian. Furthermore, if we use uppercase letters as indices no sum convention is applied. We express this explicitly by using the usual notation \(\sum _{I=1}^N\). First, the results from Eqs. (5.17) and (5.18) can be generalized for the midsurface \({\varvec{\varphi }}_I\). The tangent space of \(\mathbb {R}^3\) can be identified with itself \(T_{\varvec{\varphi }}\mathbb {R}^3\cong \mathbb {R}^3\) and we have as projection the identity \(P_{{\varvec{\varphi }}_I}={\textbf {I}}\). With this result at hand we find the projector \(P_{\varvec{{\Phi }}_I}: \mathbb {R}^6 \rightarrow T_{\varvec{{\Phi }}_I} M=T_{{\varvec{\varphi }}_I}\mathbb {R}^3 \times T_{{{\textbf {t}}}_I}{{\mathcal {S}}}^2 \cong \mathbb {R}^3 \times T_{{{\textbf {t}}}_I}{{\mathcal {S}}}^2 \) as

We can now fully define the contribution of node I to the Riemannian gradient \({{\,\textrm{grad}\,}}_I {\varPi }(\varvec{{\Phi }})\), similar to Eq. (5.11), as

To obtain the Hessian we need to specify the quantity \(P_{\varvec{{\Phi }}_I} ({\textrm {D}}_{\Updelta \varvec{{\Phi }}_I} P_{\varvec{{\Phi }}_J} ) \) as

where \(\delta _{IJ}\) is the Kronecker delta, taking care of the fact that \({\textrm {D}}_{\Updelta \varvec{{\Phi }}_I} P_{\varvec{{\Phi }}_J} ={\varvec{0}}\) for \(I\ne J\).

Using the results from Sect. 5.2.3, the contribution of nodes I and J to the Hessian reads

With the definitions from Eqs. (5.19) and (5.21) this can be expanded to

The Hessian inherits the dimensions \(6\times 6\) from the embedding space \(M_{{\textrm {E}}}=\mathbb {R}^3 \times \mathbb {R}^3\). With reference to the five-dimensional configuration space \(M=\mathbb {R}^3 \times {{\mathcal {S}}}^2\), however, it has to be reduced to \(5\times 5\). Moreover, the six-dimensional Hessian has a non-trivial kernel, since \(P_{{{\textbf {t}}}_I}\) projects a normal at \({{\textbf {t}}}_I\) onto the zero vector, \(P_{{{\textbf {t}}}_I} {{\textbf {t}}}_I={\varvec{0}}\). In particular, we have for a vector \({{\textbf {q}}}_I={[0\; 0\; 0\; {\alpha }{{\textbf {t}}}_I^T]}^T, {\alpha }\in \mathbb {R}\) as result

Therefore, Hessian-vector products are only non-zero in the tangent space of \(T_{{{\textbf {t}}}_I} {{\mathcal {S}}}^2\). Using this information, we apply a base change of the Hessian to get a final stiffness matrix with dimensions \(5 \times 5\), see ([78], Eq. 23) or similarly [84].

At this point, we postulate a generic tangent space of the director \({{\textbf {t}}}_I\) which we introduce as

see Fig. 4. Several options to explicitly obtain this nodal tangent space are presented in Section C.3. A generalization of this tangent space base that includes the midsurface can be written as

since the tangent space of \(\mathbb {R}^3\) is \(\mathbb {R}^3\) itself.

In Appendix 3, we present three different tangent base update schemes. The first two are based on parallel transport of the tangent base vectors from the old state to the new one. We will call these IncPT for incremental parallel transport and IncVT for incremental vector transport, see Algs. 4 and 3. The first one (IncPT) is similar to the approaches by, e.g. [29, 86]. The second one (IncVT) is newly introduced in this work. Both methods differ only slightly, but IncVT is computationally faster since it avoids evaulation of trigonometric functions and uses less multiplications. The third one is based on stereographic projection (SP), see Algo. 5. This tangent base construction is proposed in ([74], Eq. 31) for the general unit sphere \({{\mathcal {S}}}^{n-1} \).

In contrast to the first two schemes the stereographic projection does not need information of the old state. Instead the only information needed is the current nodal director to construct the new basis.

Since, by definition, the columns of \(\varvec{{\Lambda }}_I\) are elements of \(T_{{{\textbf {t}}}_I}{{\mathcal {S}}}^2\), we have \(P_{{{\textbf {t}}}_I} \varvec{{\Lambda }}_I=\varvec{{\Lambda }}_I\). Moreover, we always assume \({{\textbf {t}}}^{\alpha }_I\) to be unit vectors and \({{\textbf {t}}}_I^1 \cdot {{\textbf {t}}}_I^2 =0\). This yields \(\varvec{{\Lambda }}_I^T \varvec{{\Lambda }}_I= {\textbf {I}}_{2\times 2}\), which simplifies the formulation. Therefore, by rewriting Eq. (5.23), we can finally define the Riemannian stiffness matrix

With this tangent space representation we can also rewrite the three-dimensional director update \(\Updelta {{\textbf {t}}}_I \in T_{{{\textbf {t}}}_I}{{\mathcal {S}}}^2 \) as

with two degrees of freedom \(T_I^{\alpha }\) for the director update in the tangent plane \(T_{{{\textbf {t}}}_I}{{\mathcal {S}}}^2\). This construction is identical to the notation used by Simo et al. [86]. Additionally, since \({\textbf {K}}^{JI}_{5\times 5}\) is expressed in the tangent space of the nodal director, we also need to express the residual in the base given by Eq. (5.25). The corresponding version of Eq. (5.20) reads

At this point, we want to discuss why it is problematic to directly insert this base \(\varvec{{\Lambda }}_I\) into the energy like \({\varPi }({{\textbf {t}}}_I+ \varvec{{\Lambda }}_I {\textbf {T}}_I)\) and differentiate everything to obtain a formulation with five degrees of freedom. For the geometrically linear case this is a valid procedure, since the tangent space does not change during deformation. For the geometrically non-linear case this does not hold, since \(\varvec{{\Lambda }}_I\) is a function of \({{\textbf {t}}}_I\), which, in turn, changes during deformation. This results in a complicated linearization procedure (e.g. linearizing Algorithm 5). Furthermore, this ends up in the situation where the derivatives are not continuous, since the parametrization of the tangent space, due to the hairy ball theorem, contains singularities. The linearization of an incremental approach, see Algorithms 4 and 3 in the appendix, is complicated and not well-defined, because of the non-additive relation between the degrees of freedom and the tangent space of the director.

Finally, we have expressions for the Riemannian gradient and Riemannian Hessian that can be purely constructed from the Euclidean gradient and the Euclidean Hessian of the function \({\bar{{\varPi }}}\). With these, we can trivially compute by standard Euclidean partial derivatives the missing quantities and finally truly move down in Fig. 2 from the top right to the bottom right. Here, we apply the iterative Riemannian Newton-Raphson scheme to solve our non-linear optimization problem \(\min {\varPi }(\varvec{{\Phi }})\) or finding the root of the residual \({\textbf {R}}\). The resulting iterative scheme is summarized in Algo. 1, which differs from ([2], Alg. 5) by using the tangent space representation, similar to [78, 86].

5.3 Euclidean Variation and Linearization of the Continuous Reissner-Mindlin Energy

The last missing ingredient are the partial derivatives of the algebraic potential energy, see Eqs. (5.26) and (5.28). These can be simply obtained using e.g. automatic differentiation. Nevertheless, we choose another route in the following. Due to the fact that all quantities live in the six-dimensional Euclidean embedding space \(M_{\textrm {E}}=\mathbb {R}^3 \times \mathbb {R}^3\), the usual rules apply. We can therefore take a step back and derive everything in the continuous space \({\mathbb {W}}_{k,p}^{l,q}({\varOmega },M_E)\). Here, the stiffness matrix and the residual Eqs. (5.26) and (5.28) can be computed by using standard Gâteaux directional derivatives. Using this approach we obtain a template for the differential operators, the residual and the stiffness matrix. This template is independent of a particular interpolation scheme. Accordingly, in subsequent derivations we can start from the continuous Euclidean setting in the space \({\mathbb {W}}_{k,p}^{l,q}({\varOmega },M_E)\), which contains \(\hat{\bar{\varvec{{\Phi }}}}\). We start by applying the axiom of minimum of potential energy in this setting and obtain the first variation of \(\hat{{\bar{{\varPi }}}}(\hat{\bar{\varvec{{\Phi }}}})\) as

In the notation used for the energy \(\hat{{\bar{{\varPi }}}}(\hat{\bar{\varvec{{\Phi }}}})\), the hat indicates a continuous quantity and the bar denotes a function which lives in the embedding space. For simplicity and better readability, however, we refrain from introducing expressions like \(\hat{{\bar{{\textbf {a}}}}}_i\) for the base vectors and just stick to \({\textbf {a}}_i\). Instead, we restrict this notation to the total potential energy \(\hat{{\bar{{\varPi }}}}\), its density \(\hat{{\bar{\psi }}}\), the weak form \(\hat{{{\bar{G}}}}\) and the state variables \(\hat{\bar{\varvec{{\Phi }}}}\). The variation \(\updelta \hat{\bar{\varvec{{\Phi }}}}\) lives in \({\mathbb {W}}_{k,p}^{l,q}({\varOmega },\hat{\bar{\varvec{{\Phi }}}}^{-1}TM_{\textrm {E}})\), but we can identify this space with \({{\mathcal {M}}}_{\textrm {E}}={{\mathcal {X}}}(\mathbb {R}^6)\), since \(TM_{\textrm {E}}\) is a linear space. This simplifies the space in which the variation takes place to \({\mathbb {W}}_{k,p}^{l,q}({\varOmega },M_{\textrm {E}})\).

From Eq. (5.29) we can directly introduce the variations of the kinematic quantities.

5.3.1 Variations of Kinematic Quantities

The variation of the kinematics, Eq. (4.10), reads

These quantities can be rearranged according to Voigt notation, since the effective stress resultants are symmetric.

Introducing the quantities

the continuous strain-displacement differential operator of the Euclidean problem is obtained as

where the first superscript denotes the corresponding strain: “m” for membrane, “b” for bending and “s” for shear. The second superscript denotes the variables for which the variation takes place: “m” for midsurface displacement and “d” for the director. The vector of strain variations is thus \(\updelta {\textbf {E}}_{\textrm {V}}= {{\mathcal {B}}}\updelta \hat{\bar{\varvec{{\Phi }}}}\). In line with this notation, we introduce the following notation for the effective stress resultants

We can now write the Euclidean weak form by inserting \({{\mathcal {B}}}\) and \({\tilde{\textbf {{\textbf {S}}}}} \) into Eq. (5.29) as

or, in a more compact notation,

5.3.2 Linearization of the Continuous Euclidean Weak Form

Linearization of a weak form living in a vector space is a standard exercise in finite element analysis. With the Gâteaux derivative we obtain the following expression for the Euclidean linearization of the weak form

The two individual contributions resulting from application of the product rule of differentiation represent the classical separation of the tangent stiffness into a geometric and a material part. In the following derivations we take care of these contributions separately.

5.3.3 Material Part

The material part can be straightforwardly computed as

The material tangent moduli can be written in a local Cartesian coordinate system as

5.3.4 Geometric Part

By computing the Gâteaux derivative, the geometric part is obtained as

which, in turn, can be rewritten as

to implicitly define \({{\textbf {k}}}^{\textrm {g}}\). Furthermore, we used the definitions

We finally obtain

We stress that discretizing this quantity would yield the Euclidean algebraic stiffness matrix of an extensible director formulation living in \(\mathbb {R}^3\). This would result in a 6-parameter formulation but without any stiffness associated with the thickness stretch, due to the missing corresponding strain in Eq. (4.9). The reduction to a 5-parameter model is done as follows: We discretize Eqs. (5.45) and (5.38) and extract the Euclidean algebraic Hessian and the Euclidean algebraic residual from Eqs. (5.45) and (5.38). These are plugged into Eqs. (5.26) and (5.28) to obtain the Riemannian algebraic stiffness matrix and Riemannian algebraic residual.

So far, these derivations are general and no specific director interpolation was introduced. Therefore, we next specify interpolations of the director.

6 Director Interpolation

6.1 Motivation

We want to establish a Euclidean algebraic version of the internal forces of Eq. (5.38) and the tangent stiffness of Eq. (5.45). For this we first need to establish a consistent interpolation of the inextensible director. Consistency of the interpolation means satisfaction of the following properties. These are objectivity, path independence, invariance to node numbering, no singularities and unit length in the domain. At the end of this chapter we arrive at the algebraic element vectors and matrices in Sect. 7, which can be implemented directly. Furthermore, we show a possible C++-implementation of these quantities in Appendix 7. But before we derive the algebraic element vectors and matrices, we discuss properties of interpolation schemes for the director field found in literature.

6.2 Classical Interpolation Schemes

In the literature there are innumerable ways of interpolating the director in the non-linear Reissner-Mindlin model. Each of them have their unique advantages and drawbacks. In order to clarify some underlying issues and their origins, we take a small detour. It is tempting to simply define an angle pair \({\alpha },\beta \) to obtain a parametrization of quantities living on the unit sphere. Inevitably, this comes along with singularities according to the “hairy ball theorem”, see [37, 57, 62, 63, 97]. It is apparently straightforward to identify these angles as degrees of freedom and to apply standard interpolation such that \({\alpha }=\sum _{I=1}^n N^I {\alpha }_I,{\beta }=\sum _{I=1}^n N^I {\beta }_I\), see ([97], Eq. 54) and ([37], Eq 5.1). The director can then be constructed as \({{\textbf {t}}}={\textbf {R}}({\alpha },{\beta }){{\textbf {t}}}_0\). Unfortunately, using an additive update, such that \({\alpha }_I^{k+1}= {\alpha }_I^k + \Updelta \alpha _I\), leads to a non-objective formulation, since rigid body rotations do not cancel in the strain measures. Similar drawbacks can be found in [38, 79], where an incremental rotation vector \(\Updelta {\varvec{\theta }}\) is interpolated. The incremental quantities live in a linear space, where standard interpolation schemes apply. Because this contradicts the intrinsically non-linear nature of the problem, this construction leads to a non-objective formulation. This is also due to the results of [26].

The problem can be avoided by constructing nodal directors as \({{\textbf {t}}}_I={\textbf {R}}_I{{\textbf {t}}}_0^I\), and directly interpolating them, \({{\textbf {t}}}=\sum _{I=1}^n N^I {\textbf {R}}_I{{\textbf {t}}}_0 \), instead of the (rotational) degrees of freedom. The rotation matrix \({\textbf {R}}\) is updated multiplicatively as \({\textbf {R}}_I^{k+1} = \Updelta {\textbf {R}}(\Updelta {\alpha }_I,\Updelta {\beta }_I){\textbf {R}}_I^{k}\). This formulation uses incremental degrees of freedom \(\Updelta {\alpha }_I,\Updelta {\beta }_I\), see [30]. The relation between the director at the interpolation point and the nodal degrees of freedom is then

Equation (6.1) illustrates the complicated dependency of the interpolation scheme on the degrees of freedom.

The formulation is objective and the singularity that comes along with the parametrization of the unit sphere is practically irrelevant, since the iterative changes of the angles \(\Updelta {\alpha }_I,\Updelta {\beta }_I\) are typically small.

However, the procedure leads to a non-compact formulation and involves numerically expensive evaluations of trigonometric functions. Moreover, the interpolation does not conserve the director length. For low order finite elements and fine meshes this is not a big issue, but for higher order elements, which are typically larger, the effect is not only stronger but it results in a degeneration of the convergence order. This dramatic consequence, which is barely mentioned in the literature, is studied in detail in Sect. 10.2. The director \({{\textbf {t}}}\) can be normalized to remove this problem. However, as a consequence the expressions get even more involved. As an alternative to preserve the director length within the domain, several formulations introduce the director \({{\textbf {t}}}_{GP}\) as a history field at each Gauss point, see [17, 29, 86]. In these formulations, only the increment \(\Updelta {{\textbf {t}}}\) is interpolated from the nodes \(\Updelta {{\textbf {t}}}_{GP} =\sum _{I=1}^n N^I(\xi ^1,\xi ^2) \Updelta {{\textbf {t}}}_I\). This is then used to update the directors at each Gauss point as follows

or

where \(\Updelta {\varvec{\theta }}_I = \Updelta {{\textbf {t}}}_I \times {{\textbf {t}}}_I\) and \({\textbf {e}}_3={[0,0,1]}^T\). The resulting scheme is non-objective and path dependent in nature, which was also proven by [26]. Additionally, the interpolated increment \(\Updelta {{\textbf {t}}}_{GP}\) is not automatically in the tangent space of \({{\textbf {t}}}_{GP}\), which can also lead to undesired consequences. The drawbacks of some of these formulations are also discussed in [73].

The entire procedure seems to be error prone in terms of singularities, non-objectivity and path dependence. Moreover, the evaluation and linearization can be expensive due the involved interpolation schemes.

An apparently attractive option to circumvent these drawbacks is to avoid parametrization of the unit sphere and the introduction of rotation matrices in the first place. This can be trivially done, if relations of submanifolds and their embedding are exploited, as proposed in [2] on an abstract level, not related to finite elements. It is shown in the following, how this can be applied to the Reissner-Mindlin model.

6.3 Interpolation, Variation and Linearization of the Midsurface Position Field

At first, we present the quantities of the midsurface interpolation. These can be trivially obtained by the standard interpolation procedure

here \(N^I(\xi ^1,\xi ^2)= N^I\) is the basis function of node I. Obviously, here the linearization of the variation \(\Updelta \updelta {\varvec{\varphi }}^{\textrm {h}}\) of the field \({\varvec{\varphi }}^{\textrm {h}}\) vanishes, since the variation does not depend on the nodal values \({\varvec{\varphi }}_I\). This is different for the director field \({{\textbf {t}}}\), which will be treated next.

6.4 Interpolation, Variation and Linearization of the Director Field

In contrast to interpolation of the midsurface position, for the director field we use a non-linear interpolation scheme to ensure unit length. Here, we apply the projection-based approach used in [36, 90]. A similar approach can also be identified in a somewhat involved format in [30].

First, we construct the reference nodal directors \({{\textbf {t}}}_{0,I}\) according to the algorithm proposed in [28]. The reference director field and its spatial derivatives read

The algorithm in [28] returns the nodal reference directors \({{\textbf {t}}}_{0,I}\) in such a way that the interpolated directors of Eq. (6.5) at the integrations points are as normal as possible to the reference midsurface. Furthermore, the unit length constraint is also only fulfilled approximately. In general, however, the interpolated reference directors at each integration point are neither unit vectors nor are they normal to the midsurface. Still, in this algorithm the error is minimized in a least square sense. To cure at least the non-unit length of the interpolated reference director, we normalize it and obtain for the reference director field and its spatial derivatives

where the derivative of the closest point projection w.r.t. to its argument reads

Thus, the only remaining potential error for the reference interpolation of the director is its angle deviation from the surface normal. Note that the nodal directors do in general not have unit length, this is only true for the interpolated director. The treatment of this effect in the nodal update algorithm can be seen in Algo. 2.

Second, we introduce the projection-based interpolation for the current director field as

In the following, for a more compact notation we omit the superscript \({\textrm {h}}\), denoting discretized quantities. Moreover, the following operators are introduced:

With these operators the variation and linearization of the director quantities can be derived as

and the linearization of the variation reads

The partial derivatives of the projector onto the unit sphere \(\varvec{{{\mathcal {P}}}}\) are summarized in Appendix 4. Furthermore, the first derivative \(\varvec{{{\mathcal {P}}}}'\) does not coincide with the nodal projection \(P_{{{\textbf {t}}}_I}\) and only the numerator is a projection matrix, since \({(\varvec{{{\mathcal {P}}}}')}^n= \frac{1}{||{{\textbf {w}}}||^n}\varvec{{{\mathcal {P}}}}'\) instead of \({(\varvec{{{\mathcal {P}}}}')}^n= \varvec{{{\mathcal {P}}}}'\). Additionally, the quantities of Eq. (6.11) always occur in a scalar product with \({\textbf {a}}_{\alpha }\). They can be rewritten as

7 Element Vectors and Matrices

In the following, we present the quantities required to obtain the algebraic optimization problem. First, we present the Euclidean quantities and afterwards we apply the base change using \(\varvec{{\Lambda }}_{\varvec{{\Phi }}_I}\) and the projections to obtain the Riemannian quantities.

7.1 Internal Forces and Material Part of the Stiffness Matrix

Using the aforementioned definitions for the interpolation, the Euclidean algebraic strain-displacement operator — resulting from the continuous one from Eq. (5.35) — for a generic node I can be given as

With this and the fundamental lemma of variational calculus we can derive the Euclidean algebraic internal forces as

and the material part of the Euclidean stiffness matrix as

7.2 Geometric Part of the Stiffness Matrix

With the linearization of the variation of the strains and the definitions in Eq. (5.44) we obtain the following discrete quantities.

7.2.1 Contribution from Membrane Strains

For the membrane strains we have

using the abbreviation

The membrane contribution to the geometric stiffness matrix is thus

7.2.2 Contribution from Curvature

For the linearization of the variation of the curvature we get

Using the short cuts

the bending contribution to the geometric stiffness matrix reads

7.2.3 Contribution from Transverse Shear

Similarly, we obtain for transverse shear

This can be rearranged using the following short cuts

The corresponding contribution to the geometric stiffness matrix is

Finally, the Euclidean geometric stiffness contribution for a pair of nodes I and J is

This results in the total Euclidean algebraic stiffness matrix

as needed for the left part in Eq. (5.26). The last missing part for the stiffness matrix is the product in the last part in Eq. (5.26), i.e. \({{\textbf {t}}}_J^T \frac{{\partial }{\bar{{\varPi }}}}{{\partial }{{\textbf {t}}}_J}\).

Introducing the external potential \({\varPi }^{\text {ext}}\), as defined in Appendix 6, and inserting Eq. (7.2) the Euclidean residual \({\textbf {R}}_I^\text {euk}\) is obtained as

From the results of Appendix 6 we know that the external moment load vector lies in the tangent space of \({{\textbf {t}}}_J\) (for conservative loading) and this results in

since \({{\textbf {t}}}_J^T{\textbf {F}}_\text {ext}^{{{\textbf {t}}}_J}=0\). The stiffness matrix thus further simplifies, because it is now independent of the external loads.

If we introduce the following tangent base matrix, which consists of the tangent base of \(\mathbb {R}^3\), which is the identity, and the tangent base of \({{\mathcal {S}}}^2\) at node I, which is \(\varvec{{\Lambda }}_I\), we have

Recalling Eq. (5.26) and plugging in Eqs. (7.3), (7.13) and (7.15) to (7.17) we can derive the reduced Riemannian stiffness matrix

With the reduced discrete Riemannian strain-displacement operator of node I

we obtain the stiffness matrix

The part \({{\textbf {t}}}_J^T {\textbf {F}}_{\text {int}}^{\text {euk},{{\textbf {t}}}_J} {\textbf {I}}_{2\times 2} \delta _{IJ}\) is missing in similar formulations in the literature, with the exception of [86], where it can be found as last part in Eq. (B.5) and in Chapter C.2.4 (v) Geometric-diagonal. Furthermore, we stress that this contribution does not vanish at equilibrium, since only the tangential part of the residual vanishes at equilibrium. Therefore, an eigenvalue analysis to study stability problems does not yield the correct results, if this quantity is neglected. Additionally, it also does not vanish with mesh refinement. We study the influence of this quantity on the number of iterations in Sect. 10.

This additional quantity can be represented more explicitly by expanding the involved products as

with

The interested reader is refered to Appendix 8 for a geometric and physical interpretation of \({\textbf {K}}^{{\textrm {g}}2,\text {riem}}\).

Furthermore, with Eqs. (7.17) and (7.15) the final Riemannian gradient or residual in the tangent space representation reads

where \(\varvec{{\Lambda }}_{\varvec{{\Phi }}_J}^T P_{\varvec{{\Phi }}_J}=\varvec{{\Lambda }}_{\varvec{{\Phi }}_J}^T\) has been used.

Now, with Eqs. (7.23) and (7.20) we have all ingredients to apply Algo. 1, except the definition of retractions.

8 Retractions

Incremental solution procedures of non-linear problems require the update of the unknown variables. In displacement based methods in mechanics, these variables are the positions of the nodes, which are updated by the displacement increments. This is trivially accomplished by addition of the variables

Since all occurring variables live in \(\mathbb {R}^n\), this addition is well-defined.

In the following, the generic variable \({{\textbf {x}}}\) denotes an arbitrary quantity living in the manifold M. In our specific application, ths quantity is the director \( {{\textbf {t}}}\). In the general case of M being a non-linear manifold, the update of these variables is non-trivial, since the variable \({{\textbf {x}}}\) lives in the manifold M, but the update \(\Updelta {{\textbf {x}}}\) lives in the tangent space \(T_{{\textbf {x}}}M\) at \({{\textbf {x}}}\).

Therefore, a naive addition \({{\textbf {x}}}+\Updelta {{\textbf {x}}}\) results in a quantity which is not an element of M anymore. Hence, we need a retraction, which is an operator \(R_{{\textbf {x}}}(\Updelta {{\textbf {x}}}): T_{{\textbf {x}}}M \rightarrow M\), that maps the tangent vector \(\Updelta {{\textbf {x}}}\) back onto the manifold. This is illustrated in Figs. 5 and 6, for the general case and the case of the unit sphere, respectively.

The most prominent example of such an operator is the Riemannian exponential map, which maps the tangent vectors on locally uniquely defined geodesic curves \({\varvec{\gamma }}\) of the manifold. Since in most cases the computation of the exponential map is expensive or even not possible in closed form, an alternative attenuated concept of retractions can be defined, see ([2], Chapter 4.1) or more recently [1]. Additionally, this notion of retractions goes back to [4]. Luckily, for the unit sphere a closed form of the exponential map is available. For a shell formulation with an inextensible director in the nona-linear manifold \({{\mathcal {S}}}^2\) we end up with two different feasible possible retractions. The first retraction is the exponential map \(R_{{\textbf {x}}}^{em}\) of the unit sphere, which projects the quantity from the tangent space onto a geodesic curve. It can be written as

The second possible retraction, namely the projection-based retraction \(R_{{\textbf {x}}}^{pb}\), see [2] or [90], is defined as closest point projection onto the manifold, that is

The projection-based retraction and the Riemannian exponential map coincide up to second order in a Taylor expansion. As shown in ([2], Chapter 4, p. 76) or ([90], Chapter 1.5.1), the Taylor expansions read

Consequently, for small increments \(||\Updelta {{\textbf {x}}}||\) both retractions (or update schemes) yield similar updated quantities. Nevertheless, in the neighborhood of the solution even a first order retraction will still lead to quadratic convergence of 1. For a proof we refer to ([20], Theorem 6.5). The projection-based retraction was also used in [43] and was named radial return normalization in [18]. In Sect. 10.2.2 we will show the superiority of this procedure. In order to avoid confusion with the projection-based interpolation of the director, we use the term radial return normalization in the following, in spite of the fact that projection-based retration appears to be the denomination mostly used today, especially in the mathematical literature [90]. This renaming does only make sense for the case of the unit sphere, since for other manifolds the projection-based retraction is of course not a radial return.

9 Improving the Convergence Properties

We additionally use the mixed interpolation point (MIP) technique from [52] to further improve the convergence of the equilibrium iteration. This technique can be traced back to [48] and [49], where it is recommended to use for the first few iterations the stresses of the last converged step to compute the geometric stiffness matrix. In the MIP method at every integration point a Hellinger-Reissner functional is introduced, with the stresses at the integration points as free variables. These are eliminated via static condensation at integration point level. The corresponding stress values are only used for computation of the geometric stiffness matrices \({\textbf {K}}^{{\textrm {g}},\text {riem}}\) and in \({\textbf {K}}^{{\textrm {g}}2,\text {riem}}\) as

but the stresses for the internal forces are computed in the usual way as

where \({\textbf {E}}^V={[{\varvec{\varepsilon }}^V~{\varvec{\kappa }}^V~{\varvec{\gamma }}^V]}^T\). The subscript k denotes values from the previous iteration. For linear material laws the procedure to obtain the alternatives stresses for the geometric stiffness can also be interpreted as a linearized Taylor expansion from the previous iteration to the current one. This reads

Thus, the current stresses for the geometric tangent are extrapolated from the stresses and the strain-displacement operator of the previous step. This leads to significantly fewer iterations and allows much larger load steps. The corresponding improvements are numerically studied in Sect. 10.

For the converged state, where \(\Updelta \varvec{{\Phi }}={\varvec{0}}\), the stresses from the purely displacement based formulation are recovered and therefore at equilibrium the stiffness matrix corresponds to the one obtained with a primal formulation in terms of displacements. Therefore, the MIP technique does not pollute the final result, but it only influences convergence behavior. The reason for this can be found in [52]. The benefit of this method can be interpreted as a circumvention of an iteration locking phenomenon due to the highly different membrane and bending stiffnesses, which can be cured using the MIP technique.

10 Numerical Examples and Discussion

10.1 Overview

In the following we want to emphasize various properties of the presented formulation using numerical examples. Completely geometrically non-linear kinematic equations are used in all simulations. First, we compare the chosen projection-based director interpolation (PBFE) to the nodal (NFE) and geodesic (GFE) approach in Sect. 10.2. Furthermore, we study the influence of the MIP scheme as mentioned in Sect. 9 on the number of iterations required for convergence. The influences of the chosen tangent base update scheme and nodal director update scheme are also shown. After this, we study the problem of a doubly curved shell subject to a deformation and a subsequent rigid body rotation to show the objectivity and path independence of the formulation. We also investigate the consequences of neglecting the additional contribution \({\textbf {K}}^{{\textrm {g}}2,\text {riem}}_{5n \times 5n}\), equation ((7.21)), to the geometric stiffness matrix. We proceed with the study of a path following example with branch switching of an L-shaped shell. Finally, a simulation of wrinkling patterns and qualitative comparison to an experimental result demonstrates the applicability of the shell element formulation to more complex problems.

For all simulations, Non-Uniform Rational B-Spline (NURBS) are used as ansatz and test spaces, as proposed in [44]. We denote these spaces in the following as e.g. “P2C1” denoting quadratic NURBS with \(C^1\)-continuity between elements. The cases of P1C0 and P2C0 reproduces the standard Q1 and Q2 finite elements, respectively. Unless stated otherwise, we use the radial return normalization as nodal director update and the incremental vector transport (IncVT) as tangent base update as shown in Algo. 4. As default we use the projection-based finite elements (PBFE). Within the incremental-iterative solution procedure, load control with equidistant load increments is used. Additionally, we use a St.-Venant-Kirchhoff material law. In local Cartesian coordinates, the corresponding material tangent reads

with

where the vanishing normal stress condition is already enforced. Here, E is Young’s modulus, \(\nu \) Poisson’s ratio and h the shell thickness. A shear correction factor is not applied. No specific measures are taken to avoid membrane locking and transverse shear locking in this context. The focus is on the aforementioned aspects of consistency, efficiency, objectivity and path-independence.

Furthermore, to use a Cartesian material law we construct a Cartesian reference frame \(\theta ^i{\tilde{\textbf {{\textbf {A}}}}}_i\) from \(\xi ^i{\textbf {A}}_i\) identical to ([29], Eq. 9–13). The only change is the definition of the shape function derivatives \(N_{,{\alpha }}=\frac{{\partial }N}{{\partial }\xi ^{\alpha }}\), which are now carried out as \(N_{,{\alpha }}=\frac{{\partial }N}{{\partial }\theta ^{\alpha }}\) which is done by constructing the Jacobian \(\frac{{\partial }\xi ^{\alpha }}{{\partial }\theta ^{\beta }}\) between both coordinate frames. Explicitly, this yields \(N_{,{\alpha }}=\frac{{\partial }N}{{\partial }\theta ^{\alpha }}= \frac{{\partial }N}{{\partial }\xi ^{\alpha }}\frac{{\partial }\xi ^{\alpha }}{{\partial }\theta ^{\beta }}\). This is only done once before the start of the simulation and the derivative values are stored at the integration points. Additionally, this simplifies the strain measures due to \({\tilde{\textbf {{\textbf {A}}}}}_{\alpha }\cdot {\tilde{\textbf {{\textbf {A}}}}}_{\beta }={\delta }_{{\alpha }{\beta }} \).

10.2 Comparison of Nodal, Projection-Based and Geodesic Interpolation

10.2.1 Theoretical Comparison

In this section, we discuss the difference of three director interpolation schemes, which are all path independent and objective. In the projection-based approach (PBFE) from Eq. (6.8) the interpolation is

The first alternative is the nodal approach (NFE), in which the director is interpolated without normalization

This scheme corresponds to the interpolation approaches used in [15, 16, 43, 63, 87], where the inextensibility condition is only fulfilled at the nodes. The aforementioned schemes from literature differ by the definition of the degrees of freedom and the stiffness matrix. Therefore, it may not be possible to directly compare the NFE approach described herein to the mentioned references. The NFE residual and stiffness matrix can be constructed from the PBFE approach by skipping normalization of the director and by replacing \(\varvec{{{\mathcal {P}}}}'={\textbf {I}}, \varvec{{{\mathcal {Q}}}}_{{\alpha }}=\varvec{{{\mathcal {X}}}}_{{\alpha }{\beta }}=\varvec{{{\mathcal {S}}}}_{{\alpha }}={\varvec{0}}\) in all quantities. Compared to PBFE this results in a simpler formulation.

The third alternative are the geodesic finite elements (GFE), which use the interpolation scheme

taken from ([74], Eq. 29). Solving of the local minimization problem Eq. (10.5) at each integration point is documented in Appendix 5.