Abstract

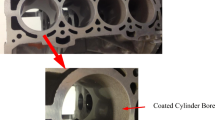

Internal rotating plasma spraying has been widely used in industrial applications to enhance performance properties and prolong the service life of internal components, such as gas turbines, engine blocks, and oil pipelines. As it is difficult to dissipate the excess heat in the limited and semi-enclosed space, the temperature characteristics of the internal parts have a significant influence on the spraying process. In this study, a three-dimensional (3D) numerical model was developed to describe the temperature evolution and distribution of a cylinder under different heating modes that considers one (plasma jet only) and two contributions (plasma jet and sprayed particles), respectively. Moreover, air and water cooling modes were also implemented to alleviate the heat accumulation of the cylinder. The results indicated that heat accumulation was mainly caused by plasma jets, whereas the sprayed drops contributed slightly. The temperature increased abruptly from initial 283 to 550 K after two back and forth movements within the cylinder without the application of coolants. However, the temperature could be controlled at 420 K under the condition of air cooling and at 390 K under the condition of water cooling. Using an infrared camera and temperature sensor, experiments were conducted to validate the numerical model corresponding to the working conditions implemented in the numerical simulation. A decrease in the porosity and increase in micro-hardness of the coating could be achieved under the cooling effect of water, rather than the compressed air. The percentage improvements in the porosity and micro-hardness of the coating were approximately 14.2 and 6.1%, respectively, by the application of water cooling.

Graphic Abstract

Similar content being viewed by others

Abbreviations

- \(\phi (r)\) :

-

Heat flux from plasma jets (W/m2)

- \(\psi (r)\) :

-

Heat flux from particles (W/m2)

- \(\phi_{0}\) :

-

Maximum heat flux of plasma jets (W/m2)

- \(\psi_{0}\) :

-

Maximum heat flux of particles (W/m2)

- \(R_{0}\) :

-

Maximum spread radius of plasma jets (m)

- \(r\) :

-

Distance from the axis of plasma jet (m)

- \(\sigma\) :

-

Gaussian dispersion radius (m)

- Fr:

-

Total flow rate of plasma gas (L/min)

- Ar:

-

Volume fraction of argon in the plasma gas

- d :

-

Spraying distance (m)

- p :

-

Electrical power (W)

- D :

-

Nozzle diameter (m)

- \(m_{s}\) :

-

Mass deposition rate of particles (kg/s)

- \(\delta\) :

-

Stefan–Boltzmann constant (J/m2 s K)

- \(h_{\text{rad}}\) :

-

Equivalent convection coefficient (W/m2K)

- C p :

-

Specific heat (J/kg K)

- L m :

-

Latent heat (J/kg)

- \(Q(r)\) :

-

Overall heat flux (W/m2)

- \(q_{\text{cov}}\) :

-

Convection heat flux (W/m2)

- \(q_{\text{rad}}\) :

-

Radiation heat flux (W/m2)

- \(q_{\text{cool}}\) :

-

Cooling heat flux (W/m2)

- \(h_{\text{cov}}\) :

-

Convection coefficient (W/m2K)

- \(\Delta h_{\text{mat}}\) :

-

Enthalpy change (J/kg)

- \(T\) :

-

Substrate temperature (K)

- \(T_{0}\) :

-

Ambient temperature (K)

- \(\varepsilon\) :

-

Emissivity coefficient

- \(\rho\) :

-

Substrate density (kg/m3)

- t :

-

Heating time (s)

- λ :

-

Conduction coefficient (W/m K)

- \(\Phi\) :

-

Inner heat source (W/m2)

References

A. Vardelle, C. Moreau, J. Akedo, H. Ashrafizadeh, C.C. Berndt, J.O. Berghaus, M. Boulos, J. Brogan, A.C. Bourtsalas, and A. Dolatabadi, The Thermal Spray Roadmap, J. Therm. Spray Technol., 2016, 25(2016), p 1376-1440

S. Uozato, K. Nakata, and M. Ushio, Evaluation of Ferrous Powder Thermal Spray Coatings on Diesel Engine Cylinder Bores, Surf. Coat. Technol., 2005, 200, p 2580-2586

D. Shifler and S. Choi, CMAS Effects on Ship Gas-Turbine Components/Materials, ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, American Society of Mechanical Engineers, 2018, pp. V001T025A003–V001T025A003

M. Priest and C.M. Taylor, Automobile Engine Tribology: Approaching the Surface, Wear, 2000, 241, p 193-203

R. Rajendran, Gas Turbine Coatings: An Overview, Eng. Fail. Anal., 2012, 26, p 355-369

Y. Zhang, S. Matthews, and M. Hyland, Role of Solidification in the Formation of Plasma Sprayed Nickel Splats Through Simulation and Experimental Observation, Int. J. Heat Mass Transf., 2017, 115, p 488-501

Z.Y. Piao, Z.Y. Zhou, J. Xu, and H.D. Wang, Use of X-ray Computed Tomography to Investigate Rolling Contact Cracks in Plasma Sprayed Fe–Cr–B–Si Coating, Tribol. Lett., 2019, 67, p 11

B. Selvan, K. Ramachandran, B.C. Pillai, and D. Subhakar, Modelling of the Plasma-Substrate Interaction and Prediction of Substrate Temperature During the Plasma Heating, The European Physical Journal D, 2011, 61, p 663-675

H.D. Wang, P.F. He, S.Y. Chen, G.Z. Ma, M. Liu, H.J. Wang, and B.S. Xu, Research and Prospect on Internal Thermal Spraying Techniques, China Surface Engineering, 2018, 31, p 14-38

K. Nagashio, K. Kodaira, K. Kuribayashi, and T. Motegi, Spreading and Solidification of a Highly Undercooled Y3Al5O12 Droplet Impinging on a Substrate, Int. J. Heat Mass Transf., 2008, 51, p 2455-2461

G. Barbezat, Advanced Thermal Spray Technology and Coating for Lightweight Engine Blocks for the Automotive Industry, Surf. Coat. Technol., 2005, 200, p 1990-1993

Z. Arabgol, H. Assadi, T. Schmidt, F. Gärtner, and T. Klassen, Analysis of Thermal History and Residual Stress in Cold-Sprayed Coatings, J. Therm. Spray Technol., 2013, 23, p 84-90

K.-P. Heinig, D.A. Stephenson, and T.G. Beyer, Thermal Response of Aluminum Engine Block During Thermal Spraying of Bores: Comparison of FEA and Thermocouple Results, SAE Int. J. Mater. Manuf., 2017, 10, p 360-365

M. Honner and J. Sroub, Modeling of Thermal Spraying Heat Transfer Processes by Exodus Stochastic Method, J. Therm. Spray Technol., 2009, 18, p 1014-1021

R. Bolot, S. Deng, Z. Cai, H. Liao, and G. Montavon, A Coupled Model Between Robot Trajectories and Thermal History of the Workpiece During Thermal Spray Operation, J. Therm. Spray Technol., 2013, 23, p 296-303

T. Zhang, Y. Bao, D.T. Gawne, and P. Mason, Effect of a Moving Flame on the Temperature of Polymer Coatings and Substrates, Prog. Org. Coat., 2011, 70, p 45-51

H. Xu, Y. Bao, and D.T. Gawne, Process Control for Thermal-Spray Deposition of Thermoset Coatings Using Computer Simulation, Prog. Org. Coat., 2016, 101, p 407-415

D. Yi and M. Zhang, Heat Flux Investigations During Flame Thermal Spray Process Using the Lumped Capacitance Method, Appl. Therm. Eng., 2017, 123, p 554-561

J. Liu, R. Bolot, and S. Costil, Residual Stresses and Final Deformation of an Alumina Coating: Modeling and Measurement, Surf. Coat. Technol., 2015, 268, p 241-246

T. Ba, C.W. Kang, and H.W. Ng, Numerical Study of the Plasma Flow Field and Particle in-flight Behavior with the Obstruction of a Curved Substrate, J. Therm. Spray Technol., 2009, 18, p 858-874

R. Bolot, J. Li, R. Bonnet, C. Mateus, and C. Coddet, Modeling of the Substrate Temperature Evolution During the APS Thermal Spray Process, Thermal Spray 2003: Advancing the Science & Applying the Technology, C. Moreau and B. Marple, Ed., ASM, Materials Park, OH, USA, 2003

R. Bolot, M. Imbert, and C. Coddet, On the Use of a low-Reynolds extEnsion to the Chen-Kim (k–ε) Model to Predict Thermal Exchanges in the Case of an Impinging Plasma Jet, Int. J. Heat Mass Transf., 2001, 44, p 1095-1106

J. Liu, Y. Wang, H. Li, S. Costil, and R. Bolot, Numerical and Experimental Analysis of Thermal and Mechanical Behavior of NiCrBSi Coatings During the Plasma Spray Process, J. Mater. Process. Technol., 2017, 249, p 471-478

Y. Chen, X. Liang, Y. Liu, J. Bai, and B. Xu, Finite Element Modeling of Coating Formation and Transient Heat Transfer in the Electric Arc Spray Process, Int. J. Heat Mass Transf., 2010, 53, p 2012-2021

Y. Song, Z. Lv, Y. Liu, X. Zhuan, and T. Wang, Effects of Coating Spray Speed and Convective Heat Transfer on Transient Thermal Stress in Thermal Barrier Coating System During the Cooling Process of Fabrication, Appl. Surf. Sci., 2015, 324, p 627-633

H. Zhang, W. Xia, G. Wang, Y. Yang, and Y. Zou, An Integrated Investigation Approach for Coating Temperature Measurement and Control During Plasma Spraying, J. Therm. Spray Technol., 2008, 17, p 263-274

H.J. Jiang and H.L. Dai, Analytical Solutions for Three-Dimensional Steady and Transient Heat Conduction Problems of a Double-Layer Plate with a Local Heat Source, Int. J. Heat Mass Transf., 2015, 89, p 652-666

D. Bäuerle, Laser Processing and Chemistry, Z. Phys. Chem., 1999, 208, p 291-292

M.G. Sobamowo, Free Convection Flow and Heat Transfer of Nanofluids of Different Shapes of Nano-Sized Particles Over a Vertical Plate at Low and High Prandtl Numbers, J. Appl. Comput. Mech., 2019, 5, p 13-39

J.M. Coulson, J.F. Richardson, J.R. Backhurst, and J.H. Harker, Fluid Flow, Heat Transfer and Mass Transfer, Butterworth-Heinemann, Oxford, 1990

S.Y. Chen, G.Z. Ma, H.D. Wang, P.F. He, and Z. Liu, Solidification Mechanism and Quantitative Characterization of Fe-Based Amorphous Splat Formed by Plasma Sprayed Droplets with Different In-Flight Status, J. Alloy. Compd., 2018, 768, p 789-799

G. Darut, H. Liao, C. Coddet, J.M. Bordes, and M. Diaby, Steel Coating Application for Engine Block Bores by Plasma Transferred Wire Arc Spraying Process, Surf. Coat. Technol., 2015, 268, p 115-122

L. Tang, J.J. Kang, P.F. He, S.Y. Ding, S.Y. Chen, M. Liu, Y.C. Xiong, G.Z. Ma, and H.D. Wang, Effects of Spraying Conditions on the Microstructure and Properties of NiCrBSi Coatings Prepared by Internal Rotating Plasma Spraying, Surf. Coat. Technol., 2019, 374, p 625-633

W. Qin, J. Li, Y. Liu, J. Kang, L. Zhu, D. Shu, P. Peng, D. She, D. Meng, and Y. Li, Effects of Grain Size on Tensile Property and Fracture Morphology of 316L Stainless Steel, Mater. Lett., 2019, 254, p 116-119

Acknowledgments

The authors are grateful to the priority support by National Natural Science Foundation of China (51675531, 51535011) and Beijing Natural Science Foundation (3172038), Pre-research Program in National 13th Five-Year Plan (41423060315) and Joint Fund of Ministry of Education for Pre-research of Equipment (6141A02033120).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ding, Sy., He, Pf., Ma, Gz. et al. Numerical Simulation and Experimental Study of Heat Accumulation in Cylinder Parts During Internal Rotating Plasma Spraying. J Therm Spray Tech 28, 1636–1650 (2019). https://doi.org/10.1007/s11666-019-00908-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00908-7