Abstract

Aluminum engine blocks with ceramic-coated cylinder bores can effectively reduce the self-weight and largely improve the wear resistance. However, the presence of coatings to some extent also affects the heat transfer of internal combustion (IC) engine between the cylinder and the coolant due to their low thermal conductivities. In this paper, electrolytic jet plasma oxidation (EJPO) coatings were adopted to deposit on the engine cylinder bores. A three-dimensional transient finite element analysis (FEA) thermal model was developed to investigate the thermal behavior of EJPO-coated cylinders. It was found that both coating thickness and thermal conductivity could significantly influence the bore surface temperature and temperature fluctuation behaviors at the different crank angles. A possible selection of the parameter combination of coating thickness and thermal conductivity would provide a newly promising opportunity in the design of a high-quality coating for the cylinder bores to improve IC engine efficiency.

Similar content being viewed by others

Abbreviations

- b :

-

Cylinder wall thickness, m

- c :

-

Specific heat capacity, J/kg·K

- F :

-

Geometric view factor

- h :

-

Enthalpy, J = kg

- k :

-

Thermal conductivity, W/m•K

- l :

-

Length from BDC to the top surface of the piston, m

- .l 1 :

-

Length from BDC and the top ring, m

- l 2 :

-

Length from BDC and the second ring, m

- L :

-

Cylinder length, m

- \( {q}_{cond,c}^{\prime \prime } \) :

-

Heat flux in the tangential direction (adiabatic), W/m2

- \( {q}_{cond,h}^{\prime \prime } \) :

-

heat flux from cylinder head, W/m2

- \( {q}_{cond,r}^{\prime \prime } \) :

-

Heat flux from the top and second rings, W/m2

- \( {q}_{cond,s}^{\prime \prime } \) :

-

Heat flux to the engine chamber skirt, W/m2

- \( {q}_{conv, fc}^{\prime \prime } \) :

-

Forced convection heat flux from coolant, W/m2

- \( {q}_{conv, fg}^{\prime \prime } \) :

-

Forced convection heat flux from air-fuel combustion, W/m2

- \( {q}_{conv, fp}^{\prime \prime } \) :

-

Forced convection heat flux near the chamber skirt, W/m2

- \( {q}_{rad}^{\prime \prime } \) :

-

Radiation heat flux from combustion gases, W/m2

- R :

-

Cylinder bore radius, m S stroke length, m

- t :

-

Time, s

- T :

-

Temperature, K

- T in-cy :

-

Instantaneous in-cylinder air-fuel temperature, K

- T ini :

-

Engine block initial temperature, K

- T w,g :

-

Cylinder wall surface temperature on air-fuel side, K

- r, θ, z :

-

Cylindrical coordinates

- ρ :

-

Density, kg/m3

- σ:

-

Stefan-Boltzmann constant = 5.67 × 10−8 W/m2K4

- ε 1 :

-

Emissivity of combustion gases

- ε 2 :

-

Emissivity of cylinder bore surface

- BDC :

-

Bottom dead center

- CGI :

-

Compacted graphite iron

- EJPO :

-

Electrolytic jet plasma oxidation

- FEA :

-

Finite element analysis

- IC :

-

Internal combustion

- MMC :

-

Metal matrix composite

- MSC :

-

Middle stroke center

- PTWA :

-

Plasma transferred wire arc

- PVD :

-

Physical vapor deposition

- SiRPA :

-

Silica-reinforced porous anodized

- TDC :

-

Top dead center

References

Keith H (2002) Plasma sprayed bores for a greener future. Product Finishing (London) 55:19–20

Rauch J, Manzat A, Killinger A, Gadow R (2009) HVOF and HVSFS coatings for reduction of wear and friction in cylinder liners. Proc Int Thermal Spray Conf: 1100–1105

Candel A, Gadow R, Lopez D (2005) Ceramic and cermet coatings for cylinder liners in ultra-light weight engines. Ceram Eng Sci Proc 26:199–209

Buchmann M, Gadow R (2001) Ceramic coatings for cylinder liners in advanced combustion engines. Manufact Process Charact Ceram Eng Sci Proc 22:75–86

Dawson S (2011) Compacted graphite iron - A material solution for modern engine design, SAE Technical Papers, SAE 2011 World Congress and Exhibition

Verlag Moderne Industrie (2006) Aluminum Cylinder Blocks, KS-Aluminium-Technologie 75–58

Ceschini L, Lanzoni E, Martini C, Prandstraller D, Sambogna G (2008) Comparison of dry sliding friction and Wear of Ti6Al4V alloy treated by plasma electrolytic oxidation and PVD coating. Wear. 264:86–95

Datta A, Carpenter JD, Ott RD, Blau PJ (2002) Tribological characteristics of electrolytic coatings for aluminum engine cylinder lining applications. SAE Technical Papers, SAE 2002 World Congress

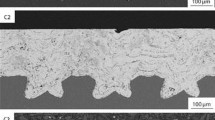

Su JF, Nie X, Hu H, Tjong J (2012) Friction and counterface wear influenced by surface profiles of plasma electrolytic oxidation coatings on an aluminum A356 alloy. J Vacuum Sci Technol A: Vacuum, Surf Films 30(n6):61402–1–61402–6140211

Mistry K, Priest M, Shrestha S (2010) The potential of plasma electrolytic oxidized eutectic Aluminium-silicon alloy as a Cylinder Wall surface for lightweight engine blocks. Proc Instit Mech Eng Part J: J Eng Tribol 224:221–229

Wang G, Nie X (2014) Effect of surface roughness and sliding velocity on tribological properties of an oxide-coated aluminum alloy. SAE Technical Papers. 1, SAE 2014 World Congress and Exhibition

X. Nie, A. Leyland, H.W. Song, A.L. Yerokhin, S.J. Dowey, A. Matthews (1999) Thickness effects on the mechanical properties of micro-arc discharge oxide coatings on aluminium alloys. Surf Coat Technol 116-119: 1055–1060

Shen X, Nie X, Hu H (2012) Numerical analysis of thermal distributions in aluminum engine cylinders influenced by alumina ceramic coatings. Num Heat Transf Part A: Applic 62(n6):463–478

Nie X, Meletis EI, Jiang JC, Leyland A, Yerokhin AL, Matthews A (2002) Abrasive Wear/corrosion properties and TEM analysis of Al2O3 coatings fabricated using plasma electrolysis. Surf Coat Technol 149:245–251

Zhang P, Nie X, Northwood DO (2009) Influence of coating thickness on the galvanic corrosion properties of mg oxide in an engine coolant. Surf Coat Technol 203:3271–3277

Yerokhin AL, Nie X, Leyland A, Matthews A (2000) Characterisation of oxide films produced by plasma electrolytic oxidation of a Ti-6Al-4V alloy. Surf Coat Technol 130:195–206

Yerokhin AL, Nie X, Leyland A, Matthews A, Dowey SJ (1999) Plasma electrolysis for surface engineering. Surf Coat Technol 122:73–93

Wu SC, Zhang HO, Tang Q, Chen L, Wang GL (2009) Meshless analysis of the substrate temperature in plasma spraying process. Int J Therm Sci 48:674–681

Shen X, Nie X, Hu H, Tjong J (2012) Effects of coating thickness on thermal conductivities of alumina coatings and alumina/aluminum hybrid materials prepared using plasma electrolytic oxidation. Surf Coat Technol 207:96–101

Karamangil MI, Kaynakli O, Surmen A (2006) Parametric investigation of cylinder and jacket side convective heat transfer coefficients of gasoline engines. Energy Convers Manag 47:800–816

Stone R (2012) Introduction to internal combustion engine, 4th edn. SAE International and Macmillan Press, USA

Bahadori A, Vuthaluru HB (2009) Predicting Emissivities of combustion gases. Chem Eng Prog 105:38–41

ANSYS Inc. ANSYS (finite element analysis package), Release 16.0

Kosaka H, Wakisaka Y, Nomura Y, Hotta Y et al (2013) Concept of “temperature swing heat insulation” in combustion chamber walls, and appropriate Thermo-physical properties for heat insulation coat. SAE Int J Engines 6(n1):142–149

Ferguson CR (2000) A.T. Kirkpatrick, Internal combustion engines: applied thermosciences. John Wiley & Sons, New York

Acknowledgements

The research was supported by a Collaborative Research Development Grant, Natural Sciences and Engineering Research Council of Canada.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shen, X., Nie, X. & Tjong, J. Effects of electrolytic jet plasma oxidation (EJPO) coatings on thermal behavior of engine cylinders. Heat Mass Transfer 55, 2503–2515 (2019). https://doi.org/10.1007/s00231-019-02600-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02600-6