Abstract

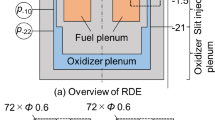

Thermal barrier coatings for gas turbine engines are mainly produced by electron beam physical vapor deposition or atmospheric plasma spray depending on the thermomechanical loading of engine components. This study deals with the numerical design of a two-step thermal plasma-aided physical vapor deposition process capable of efficiently evaporating the coating material processed in the plasma jet and of producing a strain-tolerant coating microstructure from vapor phase condensation. The system involved a high-pressure chamber and a low-pressure chamber connected by an expansion nozzle. The objective was to achieve the highest deposition efficiency for a given plasma specific enthalpy. The numerical simulations based on computational fluid dynamics and direct simulation Monte Carlo models projected the effect of the process geometry and operating conditions on the gas flow fields, powder vaporization efficiency and nucleation/growth phenomena in the gas phase. For a targeted powder feed rate, they allowed to determine the length of the high-pressure chamber, the diameter of the expansion nozzle and other dimensions of the deposition system. The expansion nozzle that linked the two chambers was the crucial component of the process, and the predictions made it possible to select the geometry and process operating parameters that avoided its clogging and/or melting.

Similar content being viewed by others

References

M.F. Smith, A.C. Hall, J.D. Fleetwood, and P. Meyer, Very Low Pressure Plasma Spray—A Review of an Emerging Technology in the Thermal Spray Community, Coatings, 2011, 1(2), p 117-132

E. Muehlberger, Method of forming uniform thin coatings on large substrates, US, US5853815A, 1998

G. Mauer, A. Hospach, and R. Vaßen, Process Development and Coating Characteristics of Plasma Spray-PVD, Surf. Coat. Technol., 2013, 220, p 219-224

K. von Niessen, M. Gindrat, and A. Refke, Vapor Phase Deposition Using Plasma Spray-PVDTM, J. Therm. Spray Technol., 2009, 19(1–2), p 502-509

K. von Niessen and M. Gindrat, Plasma Spray-PVD: A New Thermal Spray Process to Deposit Out of the Vapor Phase, J. Therm. Spray Technol., 2011, 20(4), p 736-743

B.J. Harder, D. Zhu, M.P. Schmitt, and D.E. Wolfe, Microstructural Effects and Properties of Non-line-of-Sight Coating Processing via Plasma Spray-Physical Vapor Deposition, J. Therm. Spray Technol., 2017, 26(6), p 1052-1061

E. Bakan and R. Vaßen, Ceramic Top Coats of Plasma-Sprayed Thermal Barrier Coatings: Materials, Processes, and Properties, J. Therm. Spray Technol., 2017, 26(6), p 992-1010

A. Anwaar, L. Wei, Q. Guo, B. Zhang, and H. Guo, Novel Prospects for Plasma Spray-Physical Vapor Deposition of Columnar Thermal Barrier Coatings, J. Therm. Spray. Technol., 2017, 26(8), p 1810-1822

W. He, G. Mauer, M. Gindrat, R. Wäger, and R. Vaßen, Investigations on the Nature of Ceramic Deposits in Plasma Spray-Physical Vapor Deposition, J. Therm. Spray Technol., 2016, 26(1–2), p 83-92

G. Mauer, Plasma Characteristics and Plasma-Feedstock Interaction Under PS-PVD Process Conditions, Plasma Chem. Plasma Process., 2014, 34(5), p 1171-1186

Q.-Y. Chen, X.-Z. Peng, G.-J. Yang, C.-X. Li, and C.-J. Li, Characterization of Plasma Jet in Plasma Spray-Physical Vapor Deposition of YSZ Using a < 80 kW Shrouded Torch Based on Optical Emission Spectroscopy, J. Therm. Spray. Technol., 2015, 24(6), p 1038-1045

V.A. Nemchinsky and M. Shigeta, Simple Equations to Describe Aerosol Growth, Modell. Simul. Mater. Sci. Eng., 2012, 20(4), p 045017

M.A. Gallis, J.R. Torczynski, S.J. Plimpton, D.J. Rader, and T. Koehle, Direct Simulation Monte Carlo: The Quest for Speed, Proceedings of the 29th Rarefied Gas Dynamics (RGD) Symposium, J. Fan, Ed., July 13–18, 2014 (Xi’an, China), AIP Publishing, 2014, p 27-36

SPARTA Direct Simulation Monte Carlo Simulator, https://sparta.sandia.gov. Accessed 7 Jul 2018

P.C. Huang, J. Hebeylein, and E. Pfender, A two-fluid model of turbulence for a thermal plasma jet, Plasma Chem. Plasma Process., 1995, 15(1), p 25-46

K. Bobzin, M. Öte, M. A. Knoch, I. Alkhasli, U. Reisgen, O. Mokrov, and O. Lisnyi, Simulation of the Particle Melting Degree in Air Plasma Spraying, J. Phys.: Conf. Ser., 2017, 825, p 012002

M. De Sousa, “Contribution to solar-grade oxidized silicon waste purification using a thermal plasma based process,” Ph.D. Thesis, Université de Limoges, 2014 (in French)

B. Vautherin, M.-P. Planche, R. Bolot, A. Quet, L. Bianchi, and G. Montavon, Vapors and Droplets Mixture Deposition od Metallic Coatings by Very Low Pressure Plasma Spraying, J. Therm. Spray Technol., 2014, 23(4), p 596-608

B. Jodoin, M. Gindrat, J.-L. Dorier, C. Hollenstein, M. Loch, and G. Barbezat, Modelling and Diagnostics of a Supersonic DC Plasma Jet Expanding at Low Pressure, International Thermal Spray Conference, E. Lugscheider and C.C. Berndt, Ed., March 4-6, 2002 (Essen, Germany), DVS Deutscher Verband für Schweißen, 2002, p 716–720

M.-J. Liu, K.-J. Zhang, Q. Zhang, M. Zhang, G.-J. Yang, C.-X. Li, and C.-J. Li, Thermodynamic conditions for cluster formation in supersaturated boundary layer during plasma spray-physical vapor deposition, Appl. Surf. Sci., 2019, 441, p 950-959

S. Chapman, T.G. Cowling, and D. Burnett, The Mathematical Theory of Non-uniform Gases: An Account of the Kinetic Theory of Viscosity, Thermal Conduction and Diffusion in Gases, Cambridge University Press, 1990

K. Sinha, K. Mahesh, and G.V. Candler, Modeling shock unsteadiness in shock/turbulence interaction, Phys. Fluids, 2003, 15(8), p 2290-2297

S.E. Selezneva, M.I. Boulos, M.C.M. van de Sanden, R. Engeln, and D.C. Schram, Stationary supersonic plasma expansion: continuum fluid mechanics versus direct simulation Monte Carlo method, J. Phys. D: Appl. Phys., 2002, 35(12), p 1362-1372

T.M. Rodgers, H. Zhao, and H.N.G. Wadley, Vapor deposition on doublet airfoil substrates: Coating thickness control, J. Vac. Sci. Technol., A, 2015, 33(6), p 061509

D. Ivchenko, T. Zhang, G. Mariaux, A. Vardelle, S. Goutier, and T.E. Itina, On the Validity of Continuum Computational Fluid Dynamics Approach Under Very Low-Pressure Plasma Spray Conditions, J. Therm. Spray Technol., 2017, 27(1–2), p 3-13

D. Ivchenko, “Modeling and design of a physical vapor deposition process assisted by thermal plasma (PS-PVD),” Ph.D. Thesis, Université de Limoges, 2018

P. André, M. Abbaoui, A. Augeard, P. Desprez, and T. Singo, Study of Condensed Phases, of Vaporization Temperatures of Aluminum Oxide and Aluminum, of Sublimation Temperature of Aluminum Nitride and Composition in an Air Aluminum Plasma, Plasma Chem. Plasma Process., 2016, 36(4), p 1161-1175

G. Mauer, D. Ivchenko, G. Mariaux, A. Vardelle, S. Goutier, T. Itina, C. Zhao, and R. Vassen, “Plasma spraying at very low pressure (VLPPS): Model development and experimental validation beyond continuum conditions,” presented at the 15th International High-Tech Plasma Processes Conference (HTPP15), Toulouse, 2018

G. Mariaux, E. Legros, and A. Vardelle, Modeling of coating formation and heat flux to substrate by particles and plasma jet in plasma spraying, Thermal Spray 2003: Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Ed., May 5-8, 2003 (Orlando, FL), ASM International, 2003, p 895–904

P.L. Fauchais, J.V.R. Heberlein, and M.I. Boulos, Thermal Spray Fundamentals, Springer, US, 2014

P. Fuzet, “Etude expérimentale de l’ablation de matériaux thermo-ablatifs sous impacts d’alumine liquide, modélisation et développement d’un moyen d’essai,” Ph.D. Thesis, Université de Limoges, 2014 (in French)

X. Chen and E. Pfender, Effect of the Knudsen number on heat transfer to a particle immersed into a thermal plasma, Plasma Chem. Plasma Process., 1983, 3(1), p 97-113

X. Chen and E. Pfender, Behavior of small particles in a thermal plasma flow, Plasma Chem. Plasma Process., 1983, 3(3), p 351-366

S.L. Girshick and C.-P. Chiu, Kinetic nucleation theory: A new expression for the rate of homogeneous nucleation from an ideal supersaturated vapor, J. Chem. Phys., 1990, 93(2), p 1273-1277

G. Mauer and R. Vaßen, Conditions for nucleation and growth in the substrate boundary layer at plasma spray-physical vapor deposition (PS-PVD), Surf. Coat. Technol., 2018, 371, p 417-427

G.V. Samsonov and G.V. Samsonov, The Oxide Handbook, Springer, US, 1973

A. Stoklosa, Molar Volume, Ionic Radii in Stoichiometric and Nonstoichiometric Metal Oxides, Stoichiometry and Materials Science - When Numbers Matter, A. Innocenti, Ed., IntechOpen Ltd., 2012, p 219–244

M. Rösner-Kuhn, W.H. Hofmeister, G. Kuppermann, R.J. Bayuzick, and M.G. Frohberg, Investigations of the influence of oxygen on the surface tension of zirconium by the oscillating drop technique, Surf. Sci., 1999, 443(3), p 159-164

S.K. Friedlander, Smoke, Dust, and Haze: Fundamentals of Aerosol Dynamics, 2nd ed., Oxford University Press, 2000

J. Welty, C.E. Wicks, G.L. Rorrer, and R.E. Wilson, Fundamentals of Momentum, Heat and Mass Transfer, 5th ed., Wiley, 2007

R.L. Williamson, J.R. Fincke, and C.H. Chang, A Computational Examination of the Sources of Statistical Variance in Particle Parameters During Thermal Plasma Spraying, Plasma Chem. Plasma Process., 2000, 20(3), p 299-324

G. Mauer, A. Hospach, N. Zotov, and R. Vaßen, Process Conditions and Microstructures of Ceramic Coatings by Gas Phase Deposition Based on Plasma Spraying, J. Therm. Spray Technol., 2012, 22(2-3), p 83-89

Acknowledgments

The authors would like to thank the Région Limousin (later merged into the Région Nouvelle-Aquitaine) for providing financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited paper selected from presentations at the 2019 International Thermal Spray Conference, held on May 26–29, 2019, in Yokohama, Japan, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Ivchenko, D., Mariaux, G., Vardelle, A. et al. Feasibility Study of an Adaptive-Pressure Plasma Coating Process—Part 1: Model Description. J Therm Spray Tech 29, 25–37 (2020). https://doi.org/10.1007/s11666-019-00948-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00948-z