Abstract

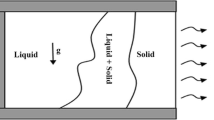

Channel segregation is one of the most common defects in solidifying steel, particularly in ultra-heavy advanced steel ingots, and it has a significant effect on the mechanical properties of the final products. However, the formation mechanism remains unclear. Here, based on numerical simulations and experimental characterization of 100-ton ultra-heavy 30Cr2Ni4MoV steel ingots used in nuclear power plants, it is strikingly found that channel segregations in the top riser and body are caused by two distinct mechanisms, natural convection and inclusion flotation, respectively. The flow instability and mush deformation in the riser originates from the complex geometry and heat transport. However, the onset of channel segregation in the ingot body stems from perturbation by inclusion flotation. Quantitatively, the initiation criterion of the modified Rayleigh number, including the inclusion effect and its critical value of 30, is proposed for the first time. In addition, it is proven that reducing the number of inclusions prevents channel segregation and improves the entire compositional homogeneity. This study highlights a novel idea by jointly controlling impurities and optimizing hot-top design to produce homogenized ultra-heavy steel ingots in key areas.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- C l,C s , C Mix :

-

Liquid, solid, and mixture concentrations (wt pct)

- H s,H L , H Mix :

-

Solid, liquid, and mixture enthalpies (J kg−1)

- ΔH :

-

Latent heat (J kg−1)

- C * :

-

Reference concentration (wt pct)

- T * :

-

Reference temperature (K)

- u p :

-

vp, Particle velocity components in x and y directions (m s−1)

- u, :

-

v, Liquid velocity components in x and y directions (m s−1)

- \(\overline{{u_{p} }}\), \(\overline{{v_{p} }}\) :

-

Average particle velocities in x and y directions (m s−1)

- f s,f l :

-

Fractions of solid and liquid

- \(\overrightarrow {U}\) :

-

Superficial velocity (m s−1)

- m :

-

Liquidus slope (K wt pct−1)

- λ :

-

Heat conductivity (W m−1 K−1)

- c p :

-

Specific heat (J kg−1 K−1)

- μ :

-

Liquid dynamic viscosity (pa s)

- \(\overrightarrow {g}\) :

-

Acceleration of gravity (m s−2)

- t :

-

Time (s)

- K :

-

Permeability coefficient (m2)

- Ra :

-

Rayleigh number

- T l,T m :

-

Liquidus of steel and melting point of solvent (K)

- d s :

-

Secondary dendritic arm spacing (μm)

- k :

-

Partition coefficient

- P :

-

Pressure (pa)

- β T :

-

Thermal expansion coefficient (K−1)

- β C :

-

Compositional expansion coefficient (wt pct−1)

- ρρ p :

-

Densities of steel and inclusion (kg m−3)

- R :

-

Solidification rate (m s−1)

- s, l, mix :

-

Solid phase, liquid phase, mixture

- p :

-

Inclusion particle

- i :

-

The ith

- j :

-

The jth

- s,l, pl :

-

Interaction between liquid and solid or inclusion

- T :

-

Temperature effect

- C :

-

Compositional effect

References

M.C. Flemings: J. Cryst. Growth, 2020, vol. 530, 125246.

M.C. Flemings: ISIJ Int., 2000, vol. 40, pp. 833–41.

C. Beckermann: Int. Mater. Rev., 2002, vol. 47, pp. 243–61.

G. Lesoult: Mater. Sci. Eng. A, 2005, vol. 413–414, pp. 19–29.

E.J. Pickering: ISIJ Int., 2013, vol. 53, pp. 935–49.

M.C. Schneider and C. Beckerman: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 2373–88.

M. Wu and A. Ludwig: Acta Mater., 2009, vol. 57, pp. 5621–31.

H. Combeau, M. Zaloznik, S. Hans, and P. Richy: Metall. Mater. Trans. B, 2009, vol. 40B, pp. 289–304.

J. Li, M. Wu, A. Ludwig, and A. Kharicha: Int. J. Heat Mass Transf., 2014, vol. 72, pp. 668–79.

C.Y. Wang and C. Beckerman: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2754–64.

S. Karagadde, L. Yuan, N. Shevchenko, S. Eckert, and P.D. Lee: Acta Mater., 2014, vol. 79, pp. 168–80.

L. Yuan and P.D. Lee: Acta Mater., 2012, vol. 60, pp. 4917–26.

G. Guillemot, C.-A. Gandin, and M. Bellet: J. Cryst. Growth, 2007, vol. 303, pp. 58–68.

J.P. Gu and C. Beckerman: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1357–66.

W.S. Li, H.F. Shen, X. Zhang, and B.C. Liu: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 464–71.

M. Wu and A. Ludwig: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1613–31.

W.T. Tu, H.F. Shen, and B.C. Liu: ISIJ Int., 2014, vol. 54, pp. 351–55.

D.Z. Li, X.Q. Chen, P.X. Fu, X.P. Ma, H.W. Liu, Y. Chen, Y.F. Cao, Y.K. Luan, and Y.Y. Li: Nat. Commun., 2014, vol. 5, p. 5572.

Y.F. Cao, Y. Chen, and D.Z. Li: Acta Mater., 2016, vol. 107, pp. 325–36.

E.J. Pickering, C. Chesman, S. Al-Bermani, M. Holland, P. Davies, and J. Talamantes-Silva: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1860–74.

E.J. Pickering and H.K.D.H. Bhadeshia: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 2983–97.

H.H. Ge, F.L. Ren, J. Li, Q.D. Hu, M.X. Xia, and J.G. Li: J. Mater. Process. Technol., 2018, vol. 252, pp. 362–36.

Z.Y. Chen, D. Senk, and F. Firsbach: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 2514–32.

Y.F. Cao, Y. Chen, D.Z. Li, H.W. Liu, and P.X. Fu: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 2927–39.

H. Shibata, D.R. Poirier, and T. Emi: ISIJ Int., 1998, vol. 38, pp. 339–47.

J. Miettinen, S. Louhenkilpi, H. Kytonen, and J. Laine: Math. Comput. Simul., 2010, vol. 80, pp. 1536–50.

ProCAST v14, ESI Group, Paris, France.

S.W. Qian, X.Q. Hu, Y.F. Cao, P.X. Fu, X.H. Kang, and D.Z. Li: Mater. Des., 2015, vol. 87, pp. 205–14.

J. Li, M. Wu, J. Hao, A. Kharicha, and A. Ludwig: Comput. Mater. Sci., 2012, vol. 55, pp. 419–29.

T. Sawada, K. Oikawa, and K. Anzai: Tetsu-to-Hagane, 2013, vol. 12, pp. 135–40.

P. Auburtin, T. Wang, S.L. Cockcroft, and A. Mitchell: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 801–11.

J.C. Ramirez and C. Beckermann: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1525–36.

J. Valdes, P. King, and X. Liu: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 2408–16.

M. Torabi Rad, P. Kotas, and C. Beckermann: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 4266–81.

E.J. Pickering, S.S. Al-Bermani, and J. Talamantes-Silva: Mater. Sci. Technol., 2015, vol. 31, pp. 1313–19.

Y.F. Cao, Y. Chen, P.X. Fu, H.W. Liu, and D.Z. Li: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 2260–73.

A.C. Wang, Y.Y. Li, C.G. Fan, K. Yang, D.F. Li, X. Zhao, and C.X. Shi: Scripta Metall. Mater., 1994, vol. 31, pp. 1695–1700.

S.N. Geng, P. Jiang, X.Y. Shao, G.Y. Mi, H. Wu, Y.W. Ai, C.M. Wang, C. Han, R. Chen, W. Liu, and Y.H. Zhang: Acta Mater., 2018, vol. 160, pp. 85–96.

J.F. Nie, K. Oh-ishi, X. Gao, and K. Hono: Acta Mater., 2008, vol. 56, pp. 6061–76.

H. Hayakawa, N. Fukada, T. Udagawa, M. Koizumi, H.G. Suzuki, and T. Fukuyama: ISIJ Int., 1991, vol. 31, pp. 775–84.

Acknowledgments

This work was supported by the National Natural Science Foundation (Grant No. 52031013), the National Key Research and Development Program (Grant No. 2018YFA0702900), and the Project to Strengthen Industrial Development at the Grass-roots Level (Grant No. TC190A4DA/35).

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cao, Y., Liu, H., Fu, P. et al. Distinct Mechanisms for Channel Segregation in Ultra-Heavy Advanced Steel Ingots via Numerical Simulation and Experimental Characterization. Metall Mater Trans B 54, 2771–2783 (2023). https://doi.org/10.1007/s11663-023-02873-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02873-7