Abstract

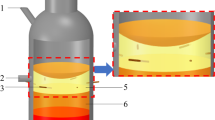

In bath smelting, the study of gas–liquid interaction and the local bubble characteristics is very important. Physical simulation is used to study the effect of the nozzle diameter, the number of lances, total gas flow rate, and the position of the measurement on the local bubble characteristics and gas–liquid interaction in the side-blown vortex smelting reduction reactor. The results show that as the total gas flow rate increases, the gas distribution range will expand, the location of the maximum gas holdup will be away from the lances. As the nozzle diameter decreases, the location of the maximum gas holdup will be away from the lances. When 6 lances are used, a bubble band with uniform bubble velocity distribution is generated in the jet control area. When using 3 lances, the uniformity of the bubble velocity distribution is worse than that when 6 lances are used, but the bubble velocity will be larger. As the total gas flow rate increases, the mean specific interfacial area in the reactor increases. When the total gas flow rate is high, using 3 lances will produce more interfacial area than using 6 lances. The empirical correlation of the local specific interfacial area is obtained.

Similar content being viewed by others

Abbreviations

- a i :

-

Local specific interfacial area (mm−1)

- a i, mean :

-

Mean specific interfacial area (mm−1)

- C :

-

Constant in the transformation from CLD to BSD

- Ca :

-

Interfacial tension number

- D :

-

Vessel diameter (m)

- d b :

-

Bubble diameter (mm)

- d n :

-

Nozzle diameter (mm)

- dt :

-

Bubble lag time (s)

- d 32 :

-

Bubbles Sauter mean diameter (mm)

- \(\overline{{d_{32} }}\) :

-

Sauter mean diameter obtained by taking the bubbles measured at all measuring points as samples (mm)

- Eo :

-

Eötvös number

- Fr’ :

-

Modified Froude number

- g :

-

Acceleration of gravity (m s−2)

- H :

-

Vessel height (m)

- H L :

-

Lance installation height (m)

- H l :

-

Liquid depth (m)

- I :

-

Number of bubbles counted during the sampling time

- J :

-

Number of the bubble groups

- K :

-

Number of measuring points

- l :

-

Distance between the two tips of the probe (mm)

- Mo :

-

Morton number

- n :

-

Number of lances

- P b(r b), P b(d b):

-

Bubble size distribution

- P c(y c):

-

Bubble chord length distribution

- \(\widetilde{P}_{{{\text{b, }}j}} \left( {r_{{\text{b}}} } \right)\) :

-

Correction term in the transformation from CLD to BSD

- \(P_{{\text{c}}}^{^{\prime}} \left( {y_{{\text{c}}} } \right)\) :

-

Derivative of Pc(yc)

- Q :

-

Total volume flow rate of gas (Nm3 h−1)

- R :

-

Vessel radius (m)

- Re :

-

Reynolds number

- r :

-

Distance between the measuring point and reactor center (m)

- r b :

-

Bubble radius (mm)

- S L :

-

Lance submersion depth (m)

- t :

-

Sampling time (s)

- Δt :

-

Bubble duration time (s)

- u b :

-

Local bubble mean velocity, (m s−1)

- u b, i :

-

Velocity of a single bubble (m s−1)

- u g :

-

Apparent velocity of the gas at the nozzle outlet (m s−1)

- V a, V b :

-

Level voltage (V)

- y c :

-

Bubble chord length (mm)

- \(\overline{{y_{{\text{c}}} }}\) :

-

Bubble mean chord length (mm)

- \(\overline{{y_{{{\text{c, }}j}} }}\), A j , w j :

-

Fitting parameters for Gaussian function

- z :

-

Measuring plane (m)

- α :

-

Tangential angles of lance (deg)

- β :

-

Vertical angles of lance (deg)

- γ j :

-

Area share of each Gaussian fit function in the original CLD function after dividing into J groups.

- ε g :

-

Local gas holdup

- \(\overline{{\varepsilon_{{\text{g}}} }}\) :

-

Mean gas holdup of all measuring points

- θ :

-

The angle between the measuring point and the Lance installation position (deg)

- λ :

-

Bubble shape factor

- μ :

-

Dynamic viscosity (Pa s)

- μ g :

-

Gas viscosity (Pa s)

- μ l :

-

Liquid viscosity (Pa s)

- ρ :

-

Density (kg m−3)

- ρ g :

-

Gas density (kg m−3)

- ρ l :

-

Liquid density (kg m−3)

- σ :

-

Surface tension (N m−1)

- a:

-

Tip of the probe

- b:

-

Tip of the probe; bubble

- c:

-

Chord

- g:

-

Gas

- i:

-

Interface

- i :

-

The ith bubble

- j :

-

The jth bubble groups

- k :

-

The kth measuring points

- L:

-

Lance

- l:

-

Liquid

- mean:

-

Mean

- n:

-

Nozzle

References

E.K. Ramasetti, V.V. Visuri, P. Sulasalmi, R. Mattila, and T. Fabritius: Steel Res. Int., 2018, vol. 90(2), p. 1800365.

K. Chattopadhyay, M. Isac, and R.I.L. Guthrie: Ironmak. Steelmak., 2010, vol. 37(8), pp. 554–61.

J.M. Zhou, Q. Gao, L. Liu, F.K. Liu, and H.J. Yan: International Conference on Chemical, Material and Metallurgical Engineering, 2011, pp. 365–70.

L.J. Yao, R. Zhu, K. Dong, G.S. Wei, F. Zhao, and Y.X. Tang: Ironmak. Steelmak., 2021, vol. 48(2), pp. 180–90.

K. Krishnapisharody and G.A. Irons: Metall. Mater. Trans. B., 2013, vol. 44B(6), pp. 1486–98.

N. Lundkvist, P.Y. Ni, M. Iguchi, A. Tilliander, and P.G. Jönsson: Steel Res. Int., 2018, vol. 89(6), p. 1700536.

L.L. Cao, Y.N. Wang, Q. Liu, L.F. Sun, S.S. Liao, W.D. Guo, K.S. Ren, B. Blanpain, and M.X. Guo: 9th International Symposium on High-Temperature Metallurgical Processing, 2018, pp. 353–64.

X. Zhao, H.L. Zhao, L.F. Zhang, and L.Q. Yang: Int. J. Miner. Metall. Mater., 2018, vol. 25(1), pp. 37–44.

J.Y. Xie, B. Wang, and J.Y. Zhang: J. Iron Steel Res. Int., 2020, vol. 27(9), pp. 1018–34.

G. Akdogan and R.H. Eric: Metall. Mater. Trans. B., 1999, vol. 30B(2), pp. 231–39.

A.H. Castillejos and J.K. Brimacombe: Metall. Mater. Trans. B., 1987, vol. 18B(4), pp. 649–58.

A.H. Castillejos and J.K. Brimacombe: Metall. Mater. Trans. B., 1987, vol. 18B(4), pp. 659–71.

H.K. Park and J.K. Yoon: Metall. Mater. Trans. B., 1990, vol. 21B(4), pp. 665–75.

J.B. Xiao, H.J. Yan, L. Liu, F. Möller, Z.W. Hu, and S. Unger: Metall. Mater. Trans. B., 2019, vol. 50B(6), pp. 3002–11.

J.B. Xiao, H.J. Yan, M. Schubert, L. Liu, A. Döß, E. Schleicher, and U. Hampel: Metall. Mater. Trans. B., 2021, vol. 52B(6), pp. 4002–11.

M. Bjurström, A. Tilliander, M. Iguchi, and P. Jönsson: ISIJ Int., 2006, vol. 46(4), pp. 523–29.

P. Ternstedt, P.Y. Ni, N. Lundkvist, A. Tilliander, and P.G. Jönsson: Ironmak. Steelmak., 2018, vol. 45(10), pp. 944–50.

J.P.T. Kapusta: JOM., 2017, vol. 69(6), pp. 970–79.

H.L. Zhao, J.Q. Wang, F.Q. Liu, and H.Y. Sohn: Metall. Mater. Trans. B., 2021, vol. 52(1), pp. 440–50.

X.L. Li, Y. Liu, D.X. Wang, and T.A. Zhang: Metals., 2020, vol. 10(11), p. 1520.

M. Akashi, O. Keplinger, N. Shevchenko, S. Anders, M.A. Reuter, and S. Eckert: Metall. Mater. Trans. B., 2020, vol. 51B(1), pp. 124–39.

M. Salcudean, K.Y.M. Lai, and R.I.L. Guthrie: Can. J. Chem. Eng., 1985, vol. 63(1), pp. 51–61.

M.P. Schwarz and W.J. Turner: Appl. Math. Model., 1988, vol. 12(3), pp. 273–79.

D. Mazumdar and R.I.L. Guthrie: ISIJ Int., 1994, vol. 34(5), pp. 384–92.

M.P. Schwarz: Appl. Math. Model., 1996, vol. 20(1), pp. 41–51.

Q. Cao and L. Nastac: Metall. Mater. Trans. B., 2018, vol. 49B(3), pp. 1388–1404.

J.H. Wei, Y. He, and G.M. Shi: Steel Res. Int., 2011, vol. 82(6), pp. 693–702.

D.K. Chibwe, G. Akdogan, G.A. Bezuidenhout, J.P.T. Kapusta, S. Bradshaw, and J.J. Eksteen: J. S. Afr. Inst. Min. Metall., 2015, vol. 115(5), pp. 349–54.

H.L. Zhao, X. Zhao, L.Z. Mu, L.F. Zhang, and L.Q. Yang: Int. J. Miner. Metall. Mater., 2019, vol. 26(9), pp. 1092–1104.

Y.T. Liu, T.Z. Yang, Z. Chen, Z.Y. Zhu, L. Zhang, and Q. Huang: Trans. Nonferrous Met. Soc. China., 2020, vol. 30(1), pp. 249–58.

K.F. Feng, J.Y. Zhang, B. Wang, J. Xu, J.Y. Xie, W.L. Cheng, D.Y. Yin, and S.B. Zheng: 5th International Symposium on High-Temperature Metallurgical Processing, 2014, pp. 451-57.

D. Obiso, S. Kriebitzsch, M. Reuter, and B. Meyer: Metall. Mater. Trans. B., 2019, vol. 50B(5), pp. 2403–20.

D. Obiso, M. Reuter, and A. Richter: Metall. Mater. Trans. B., 2021, vol. 52B(5), pp. 3064–77.

H.L. Zhao, Y.D. Xiao, F.Q. Liu, and H.Y. Sohn: Metall. Mater. Trans. B., 2021, vol. 52B(6), pp. 3767–76.

S. Zhu, Q.Y. Zhao, Y. Liu, M.Z. Zheng, X.L. Li, and T.A. Zhang: Metall. Mater. Trans. B., 2021, vol. 52B(6), pp. 4082–95.

Y.M. Zhao, X. Peng, Y.F. Wang, Z.Y. Wei, G.S. Yu, and F.C. Wang: Ind. Eng. Chem. Res., 2020, vol. 59(8), pp. 3560–74.

X.P. Guan and N. Yang: Chem. Eng. Res. Des., 2017, vol. 127, pp. 103–12.

L.S. Zhai, P. Bian, Z.K. Gao, and N.D. Jin: Chem. Eng. Sci., 2016, vol. 144, pp. 346–63.

X. Peng, Y.F. Wang, Z.Y. Wei, and G.S. Yu: Chem. Eng. Res. Des., 2018, vol. 136, pp. 358–70.

X. Peng, Y.F. Wang, Z.Y. Wei, G.S. Yu, and F.C. Wang: Chem. Eng. Sci., 2018, vol. 190, pp. 126–39.

N.H. Hoang, D.J. Euh, B.J. Yun, and C.H. Song: Int. J. Multiph. Flow., 2015, vol. 71, pp. 23–31.

W.D. Liu, N.N. Clark, and A.I. Karamavruc: AICHE J., 1996, vol. 42(10), pp. 2713–20.

N.N. Clark and R. Turton: Int. J. Multiph. Flow., 1988, vol. 14(4), pp. 413–24.

W.D. Liu and N.N. Clark: Int. J. Multiph. Flow., 1995, vol. 21(6), pp. 1073–89.

G. Bozzano and M. Dente: Comput. Chem. Eng., 2000, vol. 8, pp. 649–54.

M. Rüdisüli, T.J. Schildhauer, S.M.A. Biollaz, and J.R. van Ommen: Int. J. Multiph. Flow., 2012, vol. 44, pp. 1–14.

E.O. Hoefele and J.K. Brimacombe: Metall. Mater. Trans. B., 1979, vol. 10B(4), pp. 631–48.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (U1702253 and 52174332).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, S., Zhao, Q., Liu, Y. et al. Local Bubble Characteristics in a Side-Blown Vortex Smelting Reduction Reactor. Metall Mater Trans B 53, 2303–2320 (2022). https://doi.org/10.1007/s11663-022-02530-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02530-5