Abstract

Background

Reliably measuring sharp details in displacement and strain maps returned by full-field measurement techniques remains an open question in the photomechanics community.

Objective

The primary objective of this study is to improve and fine-tune a deconvolution algorithm in order to limit the blur that obscures the details in displacement and strain maps.

Methods

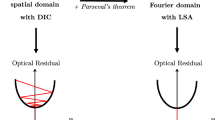

Checkerboard patterns are used and processed with a spectral method, namely the Localized Spectrum Analysis (LSA), and the raw maps returned by this technique are deconvolved. The influence of various settings on the quality of the results is studied by using synthetic images deformed through a well-vetted reference displacement field.

Results

It is shown that linking the size of the analysis window used in LSA on the one hand, and the size of the second derivative kernel employed in the deconvolution algorithm on the other hand, ensures the convergence of the deconvolution algorithm in all cases. This was not the case with the initial version. The ratio between these sizes, which optimizes the metrological performance of LSA followed by deconvolution, is identified. The influence of the sampling density of the checkerboard pattern in the images is also examined. The efficiency of the deconvolution algorithm employed with optimized settings is illustrated with strain maps obtained on two specimens, one in shape memory alloy, and the other in wood.

Conclusions

It is shown in this study that deconvolution with optimized settings is an effective tool to enhance small and sharp details in strain maps obtained with LSA.

Similar content being viewed by others

Data Availability

Data will be provided on demand.

References

Fayad SS, Seidl DT, Reu PL (2020) Spatial DIC errors due to pattern-induced bias and grey level discretization. Exp Mech 60(2):249–263

Bomarito GF, Hochhaltera JD, Rugglesb TJ, Cannon AH (2017) Increasing accuracy and precision of digital image correlation through pattern optimization. Opt Lasers Eng 91(April):73–85

Shi Y, Blaysat B, Chanal H, Grédiac M (2023) Introducing virtual DIC to remove interpolation bias and process optimal patterns. Exp Mech 63(4):637–653

Grédiac M, Blaysat B, Sur F (2017) A critical comparison of some metrological parameters characterizing local digital image correlation and grid method. Exp Mech 57(6):871–903

Grédiac M, Blaysat B, Sur F (2020) On the optimal pattern for displacement field measurement: random speckle and DIC, or checkerboard and LSA? Exp Mech 60(4):509–534

Grédiac M, Sur F, Blaysat B (2020) Comparing several spectral methods used to extract displacement and strain fields from checkerboard images. Opt Lasers Eng 127:105984

Schreier HW, Sutton MA (2002) Systematic errors in digital image correlation due to undermatched subset shape functions. Exp Mech 42(3):303–310

Schreier H, Orteu JJ, Sutton MA (2009) Image correlation for shape, motion and deformation measurements: basic concepts, theory and applications. Springer. ISBN-978-0-387-78746-6

Sur F, Grédiac M (2014) Towards deconvolution to enhance the grid method for in-plane strain measurement. Inverse Problems and Imaging 8(1):259–291

Grédiac M, Sur F, Badulescu C, Mathias J-D (2013) Using deconvolution to improve the metrological performance of the grid method. Opt Lasers Eng 51(6):716–734

Grédiac M, Blaysat B, Sur F (2019) Extracting displacement and strain fields from checkerboard images with the localized spectrum analysis. Exp Mech 59(2):207–218

Sur F, Blaysat B, Grédiac M (2018) Rendering deformed speckle images with a Boolean model. Journal of Mathematical Imaging and Vision 60(5):634–650

Grédiac M, Sur F, Blaysat B (2016) The grid method for in-plane displacement and strain measurement: a review and analysis. Strain 52(3):205–243

Khamsi MA, Kirk WA (2001) An introduction to metric spaces and fixed point theory. Wiley. ISBN-9780471418252

Sur F, Grédiac M (2016) Influence of the analysis window on the metrological performance of the grid method. Journal of Mathematical Imaging and Vision 56(3):472–498

Grafarend EW (2006) Linear and nonlinear models: fixed effects, random effects, and mixed models. Walter de Gruyter. ISBN-13:978-3-11-016216-5

Sur F, Blaysat B, Grédiac M (2016) Determining displacement and strain maps immune from aliasing effect with the grid method. Opt Lasers Eng 86:317–328

Foi A, Trimeche M, Katkovnik V, Egiazarian K (2008) Practical Poissonian-Gaussian noise modeling and fitting for single-image raw-data. IEEE Trans Image Process 17(10):1737–1754

Reu PL, Blaysat B, Andó E, Bhattacharya K, Couture C, Couty V, Deb D, Fayad SS, Iadicola MA, Jaminion S, Klein M, Landauer AK, Lava P, Liu M, Luan LK, Olufsen SN, Réthoré J, Roubin E, Seidl DT, Siebert T, Stamati O, Toussaint E, Turner D, Vemulapati CSR, Weikert T, Witz JF, Witzel O, Yang J (2022) DIC challenge 2.0: developing images and guidelines for evaluating accuracy and resolution of 2D analyses. Exp Mech 62(1):639–654

Blaysat B, Neggers J, Grédiac M, Sur F (2020) Towards criteria characterizing the metrological performance of full-field measurement techniques. Application to the comparison between local and global versions of DIC. Exp Mech 60(3):393–407

Chen B, Coppieters S (2023) Meshfree digital image correlation using element free Galerkin method: theory, algorithm and validation. Exp Mech 63(3):517–528

Wang Y, Zhao J (2023) DIC-Net: Upgrade the performance of traditional DIC with Hermite dataset and convolution neural network. Opt Lasers Eng 160:107278

Grédiac M, Blaysat B, Sur F (2019) A robust-to-noise deconvolution algorithm to enhance displacement and strain maps obtained with local DIC and LSA. Exp Mech 59(2):219–243

Qin S, Grédiac M, Blaysat B, Ma S, Sur F (2021) Influence of the sampling density on the noise level in displacement and strain maps obtained by processing periodic patterns. Measurement 173:108570

Reu P (2014) All about speckles: Aliasing. Exp Tech 38(5):1–3

Avril S, Vautrin A, Surrel Y (2004) Grid method: Application to the characterization of cracks. Exp Mech 44(1):37–43

Piro JL, Grédiac M (2004) Producing and transferring low-spatial-frequency grids for measuring displacement fields with moiré and grid methods. Exp Tech 28(4):23–26

Moulart R, Rotinat R, Pierron F, Lerondel G (2007) On the realization of microscopic grids for local strain measurement by direct interferometric photolithography. Opt Lasers Eng 45(12):1131–1147

Moulart R, Pierron F, Hallett SR, Wisnom MR (2011) Full-field strain measurement and identification of composites moduli at high strain rate with the virtual fields method. Exp Mech 51(4):509–536

Mathieu F, Hild F, Roux S (2012) Identification of a crack propagation law by digital image correlation. Int J Fatigue 36(1):146–154

Charbal A, Dufour J-E, Guery A, Hild F, Roux S, Vincent L, Poncelet M (2016) Integrated digital image correlation considering gray level and blur variations: Application to distortion measurements of IR camera. Opt Lasers Eng 78:75–85

Jailin T, Tardif N, Chaudet P, Desquines J, Coret M, Baietto M-C, Georgenthum V (2022) Measuring both thermal and kinematic full-fields using a single CMOS camera during high temperature tests. Opt Lasers Eng 158:107107

Keys R (1981) Cubic convolution interpolation for digital image processing. IEEE Trans Acoust Speech Signal Process 29(6):1153–1160

International Digital Image Correlation Society, Jones EMC, Iadicola MA (Eds) (2018) A good practices guide for Digital Image Correlation. https://doi.org/10.32720/idics/gpg.ed1. Online

Mathieu F, Leclerc H, Hild F, Roux S (2015) Estimation of elastoplastic parameters via weighted FEMU and integrated-DIC. Exp Mech 55:105–119

Delpueyo D, Jury A, Balandraud X, Grédiac M (2021) Applying full-field measurement techniques for the thermomechanical characterization of SMAs: a review and classification. Shape Memory and Superelasticity 7:462–490

Louche H, Schlosser P, Favier D, Orgéas L (2012) Heat source processing for localized deformation with non-constant thermal conductivity. Application to superelastic tensile tests of NiTi shape memory alloys. Exp Mech 52(9):1313–1328

Reedlunn B, Churchill CB, Nelson EE, Shaw JA, Daly SH (2014) Tension, compression, and bending of superelastic shape memory alloy tubes. J Mech Phys Solids 63:506–537

Xiao Y, Zeng P, Lei L, Du H (2015) Local mechanical response of superelastic niti shape-memory alloy under uniaxial loading. Shape Memory and Superelasticity 1(4):468–478

Su TH, Lu NH, Chen CH, Chen CS (2021) On the decrease in transformation stress in a bicrystal Cu-Al-Mn shape-memory alloy during cyclic compressive deformation. Materials 14(16)

Bauer A, Vollmer M, Niendorf T (2021) Effect of crystallographic orientation and grain boundaries on martensitic transformation and superelastic response of oligocrystalline Fe-Mn-Al-Ni shape memory alloys. Shape Memory and Superelasticity 7(3):373–382

Bouyra Q, Blaysat B, Chanal H, Grédiac M (2022) Using laser marking to engrave optimal patterns for in-plane displacement and strain measurement. Strain 58(2):12404

Oscarsson J, Olsson A, Enquist B (2012) Strain fields around knots in Norway spruce specimens exposed to tensile forces. Wood Sci Technol 46(4):593–610

van Blokland J, Olsson A, Oscarsson J, Daniel G, Adamopoulos S (2020) Crack formation, strain distribution and fracture surfaces around knots in thermally modified timber loaded in static bending. Wood Sci Technol 54(4):1001–1028

Chun-Wei C, Far-Ching L (2021) Strain concentration effects of wood knots under longitudinal tension obtained through digital image correlation. Biosys Eng 212:290–301

Grédiac M, Sur F (2014) Effect of sensor noise on the resolution and spatial resolution of the displacement and strain maps obtained with the grid method. Strain 50(1):1–27

Chrysochoos A, Surrel Y (2012) Chapter 1. Basics of metrology and introduction to techniques. In: Grédiac M, Hild F (eds.) Full-field Measurements and Identification in Solid Mechanics, pp. 1–29. Wiley

Wittevrongel L, Lava P, Lomov SV, Debruyne D (2015) A self adaptive global digital image correlation algorithm. Exp Mech 55(2):361–378

Acknowledgements

The authors acknowledge support from the ANR Grant ANR-18-CE08-0028-01. This work was also sponsored by the French government research program “Investissements d’Avenir” through the IDEX-ISITE initiative 16-IDEX-0001 (CAP 20-25), and from the AURA regional council. M. Grédiac & B. Blaysat are members of SEM.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Metrological Parameters

Appendix: Metrological Parameters

The metrological performance of the full-field measurement techniques discussed in this paper are estimated with four parameters, namely the measurement resolution \(\sigma _u\), the matching bias, the spatial resolution and the metrological efficiency indicator. These quantities are defined as follows:

-

The displacement resolution \(\sigma _u\) quantifies the random noise level which affects these maps. It is mainly caused by sensor noise propagation. According to [47], \(\sigma _u\) is equal to the standard deviation of the noise in the displacement maps.

-

The systematic error (or bias) reflects that the amplitude of small details is generally lower than the real one. This change in amplitude is expressed as a percentage \(\lambda\) of the amplitude of a sine wave characterized by a given period \(p_{wave}\). Thus, considering the reference displacement field of amplitude 0.5 [px] defined in 'Synthetic Displacement Field', and denoting by “\(\text {ampl}\)" the amplitude of the sine wave returned by the measuring system for a certain period \(p_{wave}\), we have:

$$\begin{aligned} \lambda = \dfrac{\text {ampl}-0.5}{0.5}\times 100~[\%{]} \end{aligned}$$(23)It is worth noting that contrary to the maps returned by DIC or by LSA for which \(\lambda\) is negative since we have a loss of amplitude, deconvolution may return an amplitude of the signal greater than the reference one, \(\lambda\) becoming positive in this case.

-

The spatial resolution reflects the ability of the technique to distinguish close features in a displacement/strain map. According to [48], it is defined as the period of the sine wave for which the value of \(\lambda\) equal to a threshold value arbitrarily fixed to -10 %, as in previous studies dealing with the metrological performance of full-field measurement techniques [4, 5, 19, 20]. The inverse of this period is referred to as the cutoff frequency. It is denoted by \(f_{c(\lambda )}\). Changing the threshold value \(\lambda\) also changes the value of this frequency.

-

These three quantities are not independent but linked. They depend in particular on some settings made arbitrarily by the user, the main one being the size over which calculations are performed around a given pixel to obtain a measurement at this pixel. With the present approach, this is the size of the analysis window used in LSA. With a Gaussian analysis window, this size is governed by the standard deviation \(\ell _{\textsf{LSA}}\). A quantity independent of this size has been introduced in [4] to overcome this shortcoming, namely the Metrological Efficiency Indicator denoted by MEI. It is merely defined as the product between the spatial resolution and the displacement resolution. The advantage of using the MEI is that it is independent of \(\ell _{\textsf{LSA}}\) before deconvolution, as discussed in [4]. The MEI is, therefore, a parameter that is intrinsic to the technique and thus enables a fair comparison between different techniques [4, 5], or between different versions of the same techniques like DIC [19, 20]. An issue addressed in this study is to know if MEI is still independent of \(\ell _{\textsf{LSA}}\) after deconvolution, and to what extent the sampling density \(\rho\) influences this quantity. These questions are addressed in 'Seeking the Optimal Ratio' and 'Influence of the Sampling Density', respectively.

Note that, in this paper, \(f_{c(\lambda )}\) and MEI are normalized with respect to the sampling density of the periodic pattern denoted by \(\rho\), see 'Influencing Parameters'. The corresponding normalized quantities are denoted by \(\widetilde{f}_{c(\lambda )} = f_{c(\lambda )} \times \rho\) and \(\widetilde{\text {MEI}} = \frac{\text {MEI}}{\rho }\), respectively.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Grédiac, M., Balandraud, X., Blaysat, B. et al. Fine-Tuning a Deconvolution Algorithm to Restore Displacement and Strain Maps Obtained with LSA. Exp Mech 63, 1509–1537 (2023). https://doi.org/10.1007/s11340-023-00997-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-00997-0