Abstract

Background

Damage index parameters that have been formulated to identify damage localization in plastically deformed materials typically require all six stress or strain components. Recently, simulations through Crystal Plasticity Finite Element Method (CPFEM) have been widely used to extract damage initiation parameters. However, these models are rarely verified due to the challenges in measuring the out of plane deformation/strains experimentally.

Objective

A damage index combining the effective plastic strain and surface roughness change is investigated for identifying damage accumulation sites in a tensile sample.

Method

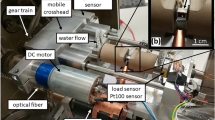

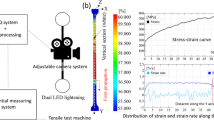

A point-wise Digital Image Correlation (DIC) technique is developed to measure large deformations from surface topography images, based on which the effective plastic strains and the surface roughness changes are determined at different load levels. A simple technique that creates random, micro size reflective speckles for sub-grain strain calculation is demonstrated.

Results

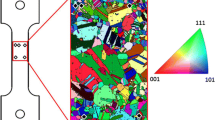

Damage accumulation sites detected by the effective strain, surface roughness change, and the combined damage index are assessed in terms of damage localization and localization consistency. The combined damage index identified the localized damage accumulation sites consistently after the yielding load. In contrast, the effective strain damage index showed a low degree of localization and consistency while the surface roughness damage index detected only half of the damage accumulation sites identified by the combined damage index. The detected damage accumulation sites were found to be associated with grain orientations that favor “sunken” out-of-plane deformations and large misorientations among neighboring grains.

Conclusions

Considering both effective plastic strain and out of plane surface deformation, the combined damage index provides an enhanced damage localization and localization consistency.

Similar content being viewed by others

Data Availability

Data will be provided upon request.

References

Xue L (2007) Damage accumulation and fracture initiation in uncracked ductile solids subject to triaxial loading. Int J Solids Struct 44:5163–5181. https://doi.org/10.1016/j.ijsolstr.2006.12.026

Ewing JA, Humfrey JC VI (1903) The fracture of metals under repeated alternations of stress. Philosophical Transactions of the Royal Society of London. Series A, Containing Papers of a Mathematical or Physical Character 200(321-330):241–250

Forsyth PJE (1953) Exudation of Material from Slip Bands at the Surface of Fatigued Crystals of an Aluminium-Copper Alloy. Nature 171:172–173. https://doi.org/10.1038/171172a0

Kuhlmann-Wilsdorf D, Laird C (1980) Dislocation behavior in fatigue V: Breakdown of loop patches and formation of persistent slip bands and of dislocation cells. Mater Sci Eng 46:209–219. https://doi.org/10.1016/0025-5416(80)90176-7

Kuhlmann-Wilsdorf D (1989) Theory of plastic deformation: - properties of low energy dislocation structures. Mater Sci Eng A 113:1–41. https://doi.org/10.1016/0921-5093(89)90290-6

Neumann P (1987) Dislocation dynamics in fatigue. Phys Scr 1987:537–543. https://doi.org/10.1088/0031-8949/1987/T19B/035

Sangid MD (2013) The physics of fatigue crack initiation. Int J Fatigue 57:58–72. https://doi.org/10.1016/j.ijfatigue.2012.10.009

Mughrabi H (2009) Cyclic slip irreversibilities and the evolution of fatigue damage. Metall Mater Trans B Process Metall Mater Process Sci 40:431–453. https://doi.org/10.1007/s11663-009-9240-4

Benjamin Britton T, Wilkinson AJ (2012) Stress fields and geometrically necessary dislocation density distributions near the head of a blocked slip band. Acta Mater 60:5773–5782. https://doi.org/10.1016/j.actamat.2012.07.004

Bao-Tong MA, Laird C (1989) Overview of fatigue behavior in copper single crystals—I. Surface morphology and stage I crack initiation sites for tests at constant strain amplitude. Acta Metall 37:325–336

Sadananda* K, Glinka G (2005) Dislocation processes that affect kinetics of fatigue crack growth. Philos Mag 85:189 203

Bao-Tong M, Laird C (1989) Overview of fatigue behavior in copper single crystals—V. Short crack growth behavior and a new approach to summing cumulative damage and predicting fatigue life under variable amplitudes. Acta Metall 37:369–379

Bao-Tong M, Laird C (1989) Overview of fatigue behavior in copper single crystals—II. Population, size distribution and growth kinetics of Stage I cracks for tests at constant strain amplitude. Acta Metall 37:337–348

Essmann U, Mughrabi H (1979) Annihilation of dislocations during tensile and cyclic deformation and limits of dislocation densities. Philos Mag A 40:731–756

Differt K, Esmann U, Mughrabi H (1986) A model of extrusions and intrusions in fatigued metals II. Surface roughening by random irreversible slip. Philos Mag A 54:237–258

Essmann U, Gösele U, Mughrabi H (1981) A model of extrusions and intrusions in fatigued metals I. Point-defect production and the growth of extrusions. Philos Mag A 44:405–426

Owolabi GM, Whitworth HA (2014) Modeling and simulation of microstructurally small crack formation and growth in notched nickel-base superalloy component. J Mater Sci Technol 30:203–212. https://doi.org/10.1016/j.jmst.2013.09.011

Shenoy M, Zhang J, McDowell DL (2007) Estimating fatigue sensitivity to polycrystalline Ni-base superalloy microstructures using a computational approach. Fatigue Fract Eng Mater Struct 30:889–904. https://doi.org/10.1111/j.1460-2695.2007.01159.x

Castelluccio GM, McDowell DL (2015) Microstructure-sensitive small fatigue crack growth assessment: Effect of strain ratio, multiaxial strain state, and geometric discontinuities. Int J Fatigue 82:521–529. https://doi.org/10.1016/j.ijfatigue.2015.09.007

Przybyla C, Prasannavenkatesan R, Salajegheh N, McDowell DL (2010) Microstructure-sensitive modeling of high cycle fatigue. Int J Fatigue 32:512–525. https://doi.org/10.1016/j.ijfatigue.2009.03.021

Prithivirajan V, Sangid MD (2020) Examining metrics for fatigue life predictions of additively manufactured IN718 via crystal plasticity modeling including the role of simulation volume and microstructural constraints. Mater Sci Eng A 783:139312. https://doi.org/10.1016/j.msea.2020.139312

Musinski WD, McDowell DL (2016) Simulating the effect of grain boundaries on microstructurally small fatigue crack growth from a focused ion beam notch through a three-dimensional array of grains. Acta Mater 112:20–39. https://doi.org/10.1016/j.actamat.2016.04.006

Proudhon H, Li J, Ludwig W et al (2017) Simulation of Short Fatigue Crack Propagation in a 3D Experimental Microstructure. Adv Eng Mater 19. https://doi.org/10.1002/adem.201600721

Manonukul A, Dunne FPE (2004) High- and low-cycle fatigue crack initiation using polycrystal plasticity. Proc R Soc A Math Phys Eng Sci 460:1881–1903. https://doi.org/10.1098/rspa.2003.1258

Wan VVC, Maclachlan DW, Dunne FPE (2014) A stored energy criterion for fatigue crack nucleation in polycrystals. Int J Fatigue 68:90–102. https://doi.org/10.1016/j.ijfatigue.2014.06.001

Zhang J, Johnston J, Chattopadhyay A (2014) Physics-based multiscale damage criterion for fatigue crack prediction in aluminium alloy. Fatigue Fract Eng Mater Struct 37:119–131. https://doi.org/10.1111/ffe.12090

Bandyopadhyay R, Prithivirajan V, Peralta AD, Sangid MD (2020) Microstructure-sensitive critical plastic strain energy density criterion for fatigue life prediction across various loading regimes. Proc R Soc A Math Phys Eng Sci 476. https://doi.org/10.1098/rspa.2019.0766

Hochhalter JD, Littlewood DJ, Christ RJ, et al (2010) A geometric approach to modeling microstructurally small fatigue crack formation: II. Physically based modeling of microstructure-dependent slip localization and actuation of the crack nucleation mechanism in AA 7075-T651. Model Simul Mater Sci Eng 18. https://doi.org/10.1088/0965-0393/18/4/045004

Korsunsky AM, Dini D, Dunne FPE, Walsh MJ (2007) Comparative assessment of dissipated energy and other fatigue criteria. Int J Fatigue 29:1990–1995. https://doi.org/10.1016/j.ijfatigue.2007.01.007

Sangid MD, Maier HJ, Sehitoglu H (2011) A physically based fatigue model for prediction of crack initiation from persistent slip bands in polycrystals. Acta Mater 59:328–341. https://doi.org/10.1016/j.actamat.2010.09.036

Man J, Obrtlík K, Polák J (2009) Extrusions and intrusions in fatigued metals. Part 1. State of the art and history. Philos Mag 89:1295–1336. https://doi.org/10.1080/14786430902917616

Kastner J, Harrer B, Degischer HP (2011) High resolution cone beam X-ray computed tomography of 3D-microstructures of cast Al-alloys. Mater Charact 62:99–107. https://doi.org/10.1016/j.matchar.2010.11.004

Salvo L, Suéry M, Marmottant A et al (2010) 3D imaging in material science: Application of X-ray tomography. Comptes Rendus Phys 11:641–649. https://doi.org/10.1016/j.crhy.2010.12.003

Babout L, Maire E, Fougères R (2004) Damage initiation in model metallic materials: X-ray tomography and modelling. Acta Mater 52:2475–2487. https://doi.org/10.1016/j.actamat.2004.02.001

Sedigh Rahimabadi P, Khodaei M, Koswattage KR (2020) Review on applications of synchrotron-based X-ray techniques in materials characterization. X-Ray Spectrom 49:348–373. https://doi.org/10.1002/xrs.3141

Lienert U, Li SF, Hefferan CM et al (2011) High-energy diffraction microscopy at the advanced photon source. Jom 63:70–77. https://doi.org/10.1007/s11837-011-0116-0

Poulsen HF, Nielsen SF, Lauridsen EM et al (2001) Three-dimensional maps of grain boundaries and the stress state of individual grains in polycrystals and powders. J Appl Crystallogr 34:751–756

Carroll JD, Abuzaid W, Lambros J, Sehitoglu H (2013) High resolution digital image correlation measurements of strain accumulation in fatigue crack growth. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2012.06.010

Abuzaid W, Sehitoglu H, Lambros J (2013) Plastic strain localization and fatigue micro-crack formation in Hastelloy X. Mater Sci Eng A 561:507–519. https://doi.org/10.1016/j.msea.2012.10.072

Carroll J, Abuzaid W, Lambros J, Sehitoglu H (2010) An experimental methodology to relate local strain to microstructural texture. Rev Sci Instrum 81. https://doi.org/10.1063/1.3474902

Mello AW, Nicolas A, Lebensohn RA, Sangid MD (2016) Effect of microstructure on strain localization in a 7050 aluminum alloy: Comparison of experiments and modeling for various textures. Mater Sci Eng A 661:187–197. https://doi.org/10.1016/j.msea.2016.03.012

Zhao Z, Ramesh M, Raabe D et al (2008) Investigation of three-dimensional aspects of grain-scale plastic surface deformation of an aluminum oligocrystal. Int J Plast. https://doi.org/10.1016/j.ijplas.2008.01.002

Sachtleber M, Zhao Z, Raabe D (2002) Experimental investigation of plastic grain interaction. Mater Sci Eng A. https://doi.org/10.1016/S0921-5093(01)01974-8

Raabe D, Sachtleber M, Zhao Z et al (2001) Micromechanical and macromechanical effects in grain scale polycrystal plasticity experimentation and simulation. Acta Mater. https://doi.org/10.1016/S1359-6454(01)00242-7

Efstathiou C, Sehitoglu H, Lambros J (2010) Multiscale strain measurements of plastically deforming polycrystalline titanium: Role of deformation heterogeneities. Int J Plast. https://doi.org/10.1016/j.ijplas.2009.04.006

Wang Z, Guo W, Li L et al (2011) Optical virtual imaging at 50 nm lateral resolution with a white-light nanoscope. Nat Commun. https://doi.org/10.1038/ncomms1211

Stinville JC, Lenthe WC, Miao J, Pollock TM (2016) A combined grain scale elastic-plastic criterion for identification of fatigue crack initiation sites in a twin containing polycrystalline nickel-base superalloy. Acta Mater 103:461–473. https://doi.org/10.1016/j.actamat.2015.09.050

Stinville JC, Lenthe WC, Echlin MP et al (2017) Microstructural statistics for fatigue crack initiation in polycrystalline nickel-base superalloys. Int J Fract. https://doi.org/10.1007/s10704-017-0241-z

Zhang Z, Lunt D, Abdolvand H et al (2018) Quantitative investigation of micro slip and localization in polycrystalline materials under uniaxial tension. Int J Plast 108:88–106. https://doi.org/10.1016/j.ijplas.2018.04.014

Di Gioacchino F, Quinta da Fonseca J (2013) Plastic Strain Mapping with Sub-micron Resolution Using Digital Image Correlation. Exp Mech. https://doi.org/10.1007/s11340-012-9685-2

Jiang J, Zhang T, Dunne FPE, Ben Britton T (2016) Deformation compatibility in a single crystalline Ni superalloy. Proc R Soc A Math Phys Eng Sci. https://doi.org/10.1098/rspa.2015.0690

Tschopp MA, Bartha BB, Porter WJ et al (2009) Microstructure-Dependent local strain behavior in polycrystals through In-Situ scanning electron microscope tensile experiments. Metall Mater Trans A Phys Metall Mater Sci. https://doi.org/10.1007/s11661-009-9938-6

Clair A, Foucault M, Calonne O et al (2011) Strain mapping near a triple junction in strained Ni-based alloy using EBSD and biaxial nanogauges. Acta Mater. https://doi.org/10.1016/j.actamat.2011.01.051

Jin H, Lu WY, Korellis J (2008) Micro-scale deformation measurement using the digital image correlation technique and scanning electron microscope imaging. J Strain Anal Eng Des. https://doi.org/10.1243/03093247JSA412

Nemcko MJ, Qiao H, Wu P, Wilkinson DS (2016) Effects of void fraction on void growth and linkage in commercially pure magnesium. Acta Mater. https://doi.org/10.1016/j.actamat.2016.04.008

Kahn-Jetter ZL, Chu TC (1990) Three-dimensional displacement measurements using digital image correlation and photogrammic analysis. Exp Mech. https://doi.org/10.1007/BF02322695

Bhavikatti S, Bhat M, Murthy C (2011) Fatigue Crack Growth Monitoring in Ti-6Al-4V Alloy using Acoustic Emission Technique and Digital Image Correlation. J Non-Destructive Eval 9

Lu YW, Lupton C, Zhu ML, Tong J (2015) In Situ Experimental Study of Near-Tip Strain Evolution of Fatigue Cracks. Exp Mech. https://doi.org/10.1007/s11340-015-0014-4

Winiarski B, Schajer GS, Withers PJ (2012) Surface Decoration for Improving the Accuracy of Displacement Measurements by Digital Image Correlation in SEM. Exp Mech. https://doi.org/10.1007/s11340-011-9568-y

Scrivens WA, Luo Y, Sutton MA et al (2007) Development of patterns for digital image correlation measurements at reduced length scales. Exp Mech. https://doi.org/10.1007/s11340-006-5869-y

Kammers AD, Daly S (2013) Self-Assembled Nanoparticle Surface Patterning for Improved Digital Image Correlation in a Scanning Electron Microscope. Exp Mech. https://doi.org/10.1007/s11340-013-9734-5

Walley JL, Wheeler R, Uchic MD, Mills MJ (2012) In-Situ Mechanical Testing for Characterizing Strain Localization During Deformation at Elevated Temperatures. Exp Mech. https://doi.org/10.1007/s11340-011-9499-7

Schreier H, Orteu J-J, Sutton MA (2009) Image correlation for shape, motion and deformation measurements: Basic concepts, theory and applications. Springer

Lava P, Cooreman S, Coppieters S et al (2009) Assessment of measuring errors in DIC using deformation fields generated by plastic FEA. Opt Lasers Eng 47:747–753. https://doi.org/10.1016/j.optlaseng.2009.03.007

Lava P, Cooreman S, Debruyne D (2010) Study of systematic errors in strain fields obtained via DIC using heterogeneous deformation generated by plastic FEA. Opt Lasers Eng 48:457–468. https://doi.org/10.1016/j.optlaseng.2009.08.013

Pan B (2011) Recent Progress in Digital Image Correlation. Exp Mech 51:1223–1235. https://doi.org/10.1007/s11340-010-9418-3

Risbet M, Feaugas X, Guillemer-Neel C, Clavel M (2003) Use of atomic force microscopy to quantify slip irreversibility in a nickel-base superalloy. Scr Mater 49:533–538. https://doi.org/10.1016/S1359-6462(03)00357-9

Ho HS, Risbet M, Feaugas X (2015) On the unified view of the contribution of plastic strain to cyclic crack initiation: Impact of the progressive transformation of shear bands to persistent slip bands. Acta Mater 85:155–167. https://doi.org/10.1016/j.actamat.2014.11.020

Cretegny L, Saxena A (2001) AFM characterization of the evolution of surface deformation during fatigue in polycrystalline copper. Acta Mater 49:3755–3765. https://doi.org/10.1016/S1359-6454(01)00271-3

Vladimirov AP, Kamantsev IS, Veselova VE et al (2016) Use of dynamic speckle interferometry for contactless diagnostics of fatigue crack initiation and determining its growth rate. Tech Phys 61:563–568. https://doi.org/10.1134/S106378421604023X

Haghshenas A, Khonsari MM (2018) Damage accumulation and crack initiation detection based on the evolution of surface roughness parameters. Int J Fatigue 107:130–144. https://doi.org/10.1016/j.ijfatigue.2017.10.009

Jha DK, Singh DS, Gupta S, Ray A (2012) Fractal analysis of crack initiation in polycrystalline alloys using surface interferometry. Epl 98. https://doi.org/10.1209/0295-5075/98/44006

Stoudt MR, Levine LE, Creuziger A, Hubbard JB (2011) The fundamental relationships between grain orientation, deformation-induced surface roughness and strain localization in an aluminum alloy. Mater Sci Eng A 530:107–116. https://doi.org/10.1016/j.msea.2011.09.050

Fathi Sola J, Kelton R, Meletis EI, Huang H (2019) A surface roughness based damage index for predicting future propagation path of microstructure-sensitive crack in pure nickel. Int J Fatigue 122:164–172. https://doi.org/10.1016/j.ijfatigue.2019.01.012

Fathi Sola J, Kelton R, Meletis EI, Huang H (2019) Predicting crack initiation site in polycrystalline nickel through surface topography changes. Int J Fatigue 124:70–81. https://doi.org/10.1016/j.ijfatigue.2019.02.027

James, D, Dally, and Riley William F (2005) Experimental Stress Analysis. College House Enterprises

Carter JLW, Uchic MD, Mills MJ (2015) Impact of Speckle Pattern Parameters on DIC Strain Resolution Calculated from In-situ SEM Experiments. In: Conference Proceedings of the Society for Experimental Mechanics Series

Reis M, Diebels S, Jung A (2019) Noise reduction for DIC measurements. Pamm 19:4–5. https://doi.org/10.1002/pamm.201900077

Carroll JD, Abuzaid WZ, Lambros J, Sehitoglu H (2013) On the interactions between strain accumulation, microstructure, and fatigue crack behavior. Int J Fract 180:223–241. https://doi.org/10.1007/s10704-013-9813-8

Abuzaid W, Oral A, Sehitoglu H et al (2013) Fatigue crack initiation in Hastelloy X - The role of boundaries. Fatigue Fract Eng Mater Struct 36:809–826. https://doi.org/10.1111/ffe.12048

Balusu K, Kelton R, Meletis EI, Huang H (2019) Investigating the relationship between grain orientation and surface height changes in nickel polycrystals under tensile plastic deformation. Mech Mater 134:165–175. https://doi.org/10.1016/j.mechmat.2019.04.011

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflicts of Interest

The authors declare that there is no potential conflicts of interest regarding the materials presented in this research and all the authors consent to the content of the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Valiollahi, A., Sola, J.F. & Huang, H. Combining Effective Plastic Strain and Surface Roughness Change for Identifying Damage Accumulation Sites in a Tensile Sample. Exp Mech 63, 759–772 (2023). https://doi.org/10.1007/s11340-023-00947-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-00947-w