Abstract

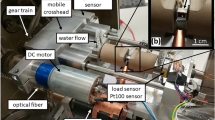

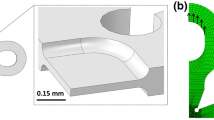

An experimental methodology has been developed to study materials deformed at high temperatures using high resolution ex situ digital image correlation (DIC). This study is an advancement of techniques that have used sub-grain level strain measurements and linked them to microstructural data obtained with electron back-scatter diffraction (EBSD). The approach utilized air blasting particles that were capable of remaining unchanged onto a sample surface and loading the sample at elevated temperatures in vacuum to prevent oxidation. Two tensile experiments were performed at temperatures of 700 and 800 °C on Haynes 230 (a nickel-based superalloy) using DIC at high magnifications in order to study the heterogeneous strain fields. Overlaying the strain fields and microstructure data, global trends and areas of high strain were studied. The strain evolution at these areas was compared to the mean strain accumulation. This study represents an advancement of the usefulness of high resolution DIC by expanding the loading conditions that can be studied and provided experimental results to prove the feasibility.

Similar content being viewed by others

References

Argon AS (2012) Strengthening mechanisms in crystal plasticity. Oxford University Press, Inc, New York

Wilkinson AJ, Meaden G, Dingley DJ (2006) High resolution mapping of strains and rotations using electron backscatter diffraction. Mater Sci Technol 22(11):1271

Wright SI, Nowell MM, Field DP (2011) A review of strain analysis using electron backscatter diffraction. Microsc Microanal 17(03):316–329. doi:10.1017/S1431927611000055

Soula A, Renollet Y, Boivin D, Pouchou JL, Locq D, Caron P, Bréchet Y (2009) Analysis of high-temperature creep deformation in a polycrystalline nickel-base superalloy. Mater Sci Eng A 510–511:301

Thibault K, Locq D, Caron P, Boivin D, Renollet Y, Bréchet Y (2013) Influence of microstructure on local intra- and intergranular deformations during creep of a nickel-based superalloy at 700 °C. Mater Sci Eng A 588:14

Badulescu C, Grediac M, Haddadi H, Mathias JD, Balandraud X, Tran HS (2011) Applying the grid method and infrared thermography to investigate plastic deformation in aluminium multicrystal. Mech Mater 43(1):36–53. doi:10.1016/j.mechmat.2010.11.001

Delaire F, Raphanel JL, Rey C (2000) Plastic heterogeneities of a copper multicrystal deformed in uniaxial tension: experimental study and finite element simulations. Acta Mater 48(5):1075–1087

Héripré E, Dexet M, Crépin J, Gélébart L, Roos A, Bornert M, Caldemaison D (2007) Coupling between experimental measurements and polycrystal finite element calculations for micromechanical study of metallic materials. Int J Plast 23(9):1512–1539

Rastogi P, Surrel Y (2000) Fringe Analysis. In: Photomechanics, vol 77. Topics in Applied Physics. Springer Berlin Heidelberg, pp 55–102

Sutton M, Orteu J-J, Schreier H (2009) Image Correlation for Shape Motion and Deformation Measurements: Basic Concepts, Theory and Applications. Spring Media,

Pataky GJ, Sehitoglu H, Maier HJ (2013) High temperature fatigue crack growth of Haynes 230. Mater Charact 75:69

Sangid MD, Pataky GJ, Sehitoglu H, Rateick RG, Niendorf T, Maier HJ (2011) Superior fatigue crack growth resistance, irreversibility, and fatigue crack growth microstructure relationship of nanocrystalline alloys. Acta Mater 59(19):7340

Lyons JS, Liu J, Sutton MA (1996) High-temperature deformation measurements using digital-image correlation. Exp Mech 36(1):64–70

Merzouki T, Collard C, Bourgeois N, Ben Zineb T, Meraghni F (2010) Coupling between measured kinematic fields and multicrystal SMA finite element calculations. Mech Mater 42(1):72–95

Zhao Z, Ramesh M, Raabe D, Cuitino AM, Radovitzky R (2008) Investigation of three-dimensional aspects of grain-scale plastic surface deformation of an aluminum oligocrystal. Int J Plast 24(12):2278

Sutton MA, Li N, Joy DC, Reynolds AP, Li X (2007) Scanning electron microscopy for quantitative small and large deformation measurements part I: SEM imaging at magnifications from 200 to 10,000. Exp Mech 47(6):775–787

Carroll J, Abuzaid W, Lambros J, Sehitoglu H (2010) An experimental methodology to relate local strain to microstructural texture. Rev Sci Instrum 81(8):083703. doi:10.1063/1.3474902

Jonnalagadda KN, Chasiotis I, Yagnamurthy S, Lambros J, Pulskamp J, Polcawich R, Dubey M (2010) Experimental investigation of strain rate dependence of nanocrystalline Pt films. Exp Mech 50(1):25–35

Pan B, Wu D, Wang Z, Y. X (2011) High-temperature digital image correlation method for full-field deformation measurement at 1200 °C. Meas Sci Technol. 22 (1). doi:10.1088/0957-0233/22/1/015701

Preibisch S, Saalfeld S, Tomancak P (2009) Globally optimal stitching of tiled 3D microscopic image acquisitions. Bioinformatics 25(11):1463–1465. doi:10.1093/bioinformatics/btp184

Abuzaid WZ, Sangid MD, Carroll JD, Sehitoglu H, Lambros J (2012) Slip transfer and plastic strain accumulation across grain boundaries in Hastelloy X. J Mech Phys Solids 60(6):1201–1220. doi:10.1016/j.jmps.2012.02.001

Carroll JD, Clark BG, Buchheit TE, Boyce BL, Weinberger CR (2013) An experimental statistical analysis of stress projection factors in BCC tantalum. Mater Sci Eng A 581:108

Swaminathan B, Lambros J, Sehitoglu H (2013) Digital image correlation study of mechanical response of nickel superalloy hastelloy X under thermal and mechanical cycling: uniaxial and biaxial stress states. J Strain Anal Eng Des. doi:10.1177/0309324713503959

Jiang L, Hu R, Kou H, Li J, Bai G, Fu H (2012) The effect of M23C6 carbides on the formation of grain boundary serrations in a wrought Ni-based superalloy. Mater Sci Eng A 536:37

Pataky GJ, Sehitoglu H, Maier HJ (2013) Creep deformation and mechanisms in Haynes 230 at 800 °C and 900 °C. J Nucl Mater 443(1–3):484

Acknowledgments

The research was supported by the US Department of Energy Nuclear Energy University Program (NEUP) under grant DOE-INL-00091210.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pataky, G.J., Sehitoglu, H. Experimental Methodology for Studying Strain Heterogeneity with Microstructural Data from High Temperature Deformation. Exp Mech 55, 53–63 (2015). https://doi.org/10.1007/s11340-014-9926-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-014-9926-7