Abstract

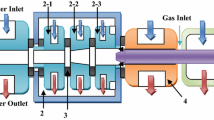

In this paper, a new multiple plasma jet tangentially mixed reactor (MPJ-TMR) is proposed. The impact of varying tangent circle diameters on the mixing process is investigated through CFD simulation. The MPJ-TMR has been preliminarily applied to high-conductive carbon black (HCCB) preparation. The results show that the MPJ-TMR with a tangent circle diameter dc/din = 0 is directed to form the "counter-flow recirculation zone", which impedes mixing between plasma jets and cold fluids. For the MPJ-TMR with a tangent circle diameter dc/din > 0, the intensity of the "counter-flow recirculation zone" weakens and disappears as the tangent circle diameter increases. The eccentric impact flow drives the fluid to spiral around the central axis. So that a spiral vortex structure is formed to enhance the mixing. Among them, the MPJ-TMR with a tangent circle diameter dc/din = 0.5 exhibits the best mixing efficiency due to its highest local circumferential velocity and axial vortex flux, resulting in good entrainment between plasma jets and cold fluids. Therefore, the MPJ-TMR with a tangent circle diameter dc/din = 0.5 is applied to prepare carbon black. The resulting products show a rich branched chain structure with over 90% of the primary particle size distributed within the range of 10–20 nm. The physicochemical indices DBP Absorption, IAN and resistivity of HCCB are very close to that of acetylene carbon black. The reactor demonstrates excellent product uniformity.

Similar content being viewed by others

Availability of Data and Materials

The datasets used or analysed during the current study are available from the corresponding author on reasonable request.

References

Bond RL, Galbraith IF, Ladner WR et al (1963) Production of acetylene from coal, using a plasma jet. Nature 200(4913):1313–1314

Nicholson R, Littlewood K (1972) Plasma pyrolysis of coal. Nature 236(5347):397–400

Mather PJ, Thomas KM (1997) Carbon black/high density polyethylene conducting composite materials: Part I Structural modification of a carbon black by gasification in carbon dioxide and the effect on the electrical and mechanical properties of the composite. J Mater Sci 32(2):401–407

Chen B, Gu Z (2015) Microstructure and application performance of conductive carbon black. High Power Laser Part Beams 27(8):289–294 (in Chinese)

Sircar AK, Lamond TG (1978) Effect of carbon black particle size distribution on electrical conductivity. Rubber Chem Technol 51(1):126–132

Deng Y (2001) Application of conductive carbon black in plastics. China Plastics 04:9–11 (in Chinese)

Fulcheri L, Probst N, Flamant G et al (2002) Plasma processing: a step towards the production of new grades of carbon black. Carbon 40(2):169–176

Jordan EH, Jiang C, Gell M (2015) The solution precursor plasma spray (SPPS) process: a review with energy considerations. J Therm Spray Technol 24(7):1153–1165

Vilotijević M, Marković P, Zec S et al (2011) Hydroxyapatite coatings prepared by a high power laminar plasma jet. J Mater Process Technol 211(6):996–1004

Zhukov MF, Smolyakov VY, Uryukov BA (1973) Electric arc gas heaters (plasmatrons). Publ Nauka, Moscow

Guo Z, Zhao W (2009) Arcs and thermal plasmas. Beijing: Science Press 2009 (in Chinese)

Xia W, Li L, Zhao Y et al (2006) Dynamics of large-scale magnetically rotating arc plasmas. Appl Phys Lett 88(21):211501

Li LC, Xia WD, Zhou HL et al (2008) Experimental observation and numerical analysis of arc plasmas diffused by magnetism. Eur Phys J D 47(1):75–81

Li LC, Chen Q, Zhou HL et al (2008) Images of a large-scale magnetically rotating arc. IEEE Trans Plasma Sci 36(4):1080–1081

Gannon RE, Krukonis VJ, Schoenberg T (1970) Conversion of coal to acetylene in arc-heated hydrogen. Ind Eng Chem Prod Res Dev 9(3):343–347

ZhZh Z, Engelsht VS (1983)Two-jet plasma torch

Donskoi AV, Dresvin SV, El-Mikati K (1974) Proceedings of 6th all-rus. Conference on low-temperature plasma generators

Donskoi AV, Klubnikin VS (1979) Electric plasma processes and equipment in engineering. Mashinostroenie, Leningrad

Wang C, Cui H, Zhang Z et al (2017) Production of long, laminar plasma jets at atmospheric pressure with multiple cathodes. Contrib Plasma Phys 57(2):58–66

Thermal plasma torches: design, characteristics, application. Cambridge Int Science Publishing, 2007

Pfender E (1999) Thermal plasma technology: Where do we stand and where are we going? Plasma Chem Plasma Process 19(1):1–31

Chen J, Cheng Y (2009) Process development and reactor analysis of coal pyrolysis to acetylene in hydrogen plasma reactor. J Chem Eng Jpn 42(Supplement): s103–s110

Schein J, Zierhut J, Dzulko M et al (2007) Improved plasma spray torch stability through multi-electrode design. Contrib Plasma Phys 47(7):498–504

Zhukov MF (2016) Arc Plasma Torch. Beijing Science Press. (in Chinese)

Fang Q, Huang L, Yao B et al (2006) Simulation of co-combustion of blended coal in a four-corner tangentially fired boiler using double-mixed fraction/mixture fraction PDF method. Power Eng 02:185–190 (in Chinese)

Du B (2005) Research on large-scale magnetic rotating arc plasma generators. University of Science and Technology of China. (in Chinese)

Launder BE, Spalding DB (1972) Lectures in mathematical model of turbulence

Shih TH et al (1995) A new κ-ε Eddy viscosity model for high reynolds number turbulent flows. Comput Fluids 24(3):227–238

Murphy AB (1995) Transport coefficients of air, argon-air, nitrogen-air, and oxygen-air plasmas. Plasma Chem Plasma Process 15(2):279–307

Wang K (2010) Numerical simulation study on the enhanced mixing process in microchannel flows. Zhejiang University. (in Chinese)

Fulcheri L et al (2002) Plasma processing: a step towards the production of new grades of carbon black. Carbon 40(2):169–176

Fabry F, Flamant G, Fulcheri L (2001) Carbon black processing by thermal plasma. Analysis of the particle formation mechanism. Chem Eng Sci 56(6):2123–2132

Fincke JR et al (2002) Plasma pyrolysis of methane to hydrogen and carbon black. Ind Eng Chem Res 41(6):1425–1435

Fulcheri L et al (2023) An energy-efficient plasma methane pyrolysis process for high yields of carbon black and hydrogen. Int J Hydrog Energy 48(8):2920–2928

Smagorinsky J (1963) General circulation experiments with the primitive equations. Mon Weather Rev 91:99–164

Hunt JC, Wray AA, Moin P (1988) Eddies, streams, and convergence zones in turbulent flows. In: Proceedings of the 1988 summer program studying turbulence using numerical simulation databases

Weidong X, Quan C, Minghou L, Zhongen F, Min Y (2010) A non-transfer arc plasma torch anode and plasma torch. China Patent: CN101699928A (in chinese)

Acknowledgements

This work is supported by National Natural Science Foundation of China (NO. 120350015) and Youth Fund of the National Natural Science Foundation of China (NO. 12105282).

Funding

Youth Fund of the National Natural Science Foundation of China (NO. 12105282).

Author information

Authors and Affiliations

Contributions

SW: Conceptualization, Methodology, Software, Investigation, Formal analysis, Writing—original draft, Writing—review &editing. XC: Conceptualization, Funding acquisition, Resources, Supervision, Writing—review & editing. WX: Resources, Supervision, Data curation, Project administration. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

I declare that the authors have no competing interests as defined by Springer, or other interests that might be perceived to influence the results and/ or discussion reported in this paper.

Ethical Approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, X., Wang, S. & Xia, W. A Novel Multiple Plasma Jet Tangentially Mixed Reactor: Design and Carbon Black Production. Plasma Chem Plasma Process 44, 721–738 (2024). https://doi.org/10.1007/s11090-024-10446-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-024-10446-y