Abstract

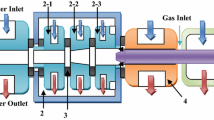

Plasma atomization (PA) is a highly recognized method for producing spherical powders for additive manufacturing and metal injection molding. It uses multiple converging plasma jets to simultaneously melt and atomize the metal wire to spherical powders. The quality of the atomized powders is highly dependent on the plasma torch for generating the plasma jet. Although the reverse-polarity plasma torch (RPT) has been commercially applied in the PA, its working characteristics relating to the high stability, high thermal efficiency, and supersonic plasma jet with high temperature desired in the PA are unclear. Therefore, experimental and numerical investigations of a self-manufactured RPT for PA were conducted to reveal its volt-ampere, thermal and jet characteristics. Results showed that the RPT works stably with the arc voltage fluctuation within 10 V ensuring the uniform quality of the produced powders. Besides, compared with the common argon plasma torch, the RPT works at high arc voltage and low arc current leading to less erosion of electrodes and purer powders. Furthermore, the thermal efficiency of the RPT and the mean enthalpy of its plasma jet is higher than 70% and 3 × 106 J/kg respectively, making it ideal for generation of the plasma jet with high energy density. Moreover, numerical results showed that the RPT with the De-Laval nozzle can generate supersonic plasma jet with temperature high enough for melting and atomizing most of materials. Finally, the PA experiment showed the effectiveness of the RPT for the production of high quality powders with smooth surfaces, high sphericity and small particle size.

Similar content being viewed by others

References

Alagheband A, Brown C (1998) Plasma Atomization goes commercial. Met Powder Rep 53(11):26–28. https://doi.org/10.1016/S0026-0657(99)80007-1

Baskoro AS, Supriadi S, Dharmanto (2019) Review on plasma atomizer technology for metal powder. MATEC Web Conf 269:05004

Sun P, Fang ZZ, Zhang Y, Xia Y (2017) Review of the methods for production of spherical Ti and Ti alloy powder. JOM 69(10):1853–1860. https://doi.org/10.1007/s11837-017-2513-5

Entezarian M, Allaire F, Tsantrizos P, Drew RAL (1996) Plasma atomization: A new process for the production of fine, spherical powders. JOM 48(6):53–55. https://doi.org/10.1007/BF03222969

Tsantrizos PG, Entezarian M (1998) Method of production of metal and ceramic powders by plasma atomization. US5707419A,

Frazier WE (2014) Metal additive manufacturing: a review. J Mater Eng Perform 23(6):1917–1928. https://doi.org/10.1007/s11665-014-0958-z

Hartwig T, Veltl G, Petzoldt F, Kunze H, Scholl R, Kieback B (1998) Powders for metal injection molding. J Eur Ceram Soc 18(9):1211–1216. https://doi.org/10.1016/S0955-2219(98)00044-2

Dodun O, Tsetkou A, Papapanos G, Vardavoulias M, Nagit G, Slatineanu L (2007) A THEORETICAL EQUATION FOR THE THERMAL BALANCE AT PLASMA ATOMIZING PROCESS. Non Conventional Technologies Review:23–28

Rao L, Rivard F, Carabin P (2013) Thermal Plasma Torches for Metallurgical Applications. 4th International Symposium on High‐Temperature Metallurgical Processing:57–65. doi: https://doi.org/10.1002/9781118663448.ch8

Camacho SL (1989) The reverse-polarity plasma torch. Paper presented at the ISPC-8, Tokyo,

Park S-C, Kim D-U, Kim M-H, Seo J-H, Yang OB (2013) Numerical analysis of a hollow electrode plasma torch with a reversed polarity discharge for radioactive waste treatment. J Korean Phys Soc 63(9):1746–1754. https://doi.org/10.3938/jkps.63.1746

Hur MIN, Cho H, Hong SH (1999) Numerical analysis and experiment on a plasma torch with hollow electrodes for hazardous waste treatment. Ann N Y Acad Sci 891(1):49–56. https://doi.org/10.1111/j.1749-6632.1999.tb08751.x

Brilhac JF, Pateyron B, Coudert JF, Fauchais P, Bouvier A (1995) Study of the dynamic and static behavior of de vortex plasma torches: Part II: well-tye cathode. Plasma Chem Plasma Process 15(2):257–277. https://doi.org/10.1007/BF01459699

Batomunkuev DY, Vashenko SP (2019) Electric arc plasmatorch of a two-chamber scheme with reverse polarity of electrodes connection. J Phys: Conf Ser 1393:012003. https://doi.org/10.1088/1742-6596/1393/1/012003

Yang I-M, Choi M-G, Nam J-S, Lee M-Y, Seo J-H (2019) Experimental and numerical analyses of a hollow electrode plasma torch with inter-electrodes and reversed polarity discharges. J Korean Phys Soc 74(5):465–472. https://doi.org/10.3938/jkps.74.465

Boulos MI, Fauchais PL, Pfender E (2016) The plasma state. In: Handbook of thermal plasmas, Springer International Publishing, Switzerland. https://doi.org/10.1007/978-3-319-12183-3_1-2

Kim KS, Hong SH, Lee K, Ju WT (2007) Continuous synthesis of nanostructured sheetlike carbons by thermal plasma decomposition of methane. IEEE Trans Plasma Sci 35(2):434–443. https://doi.org/10.1109/TPS.2007.892556

Mauer G, Vaßen R, Stöver D (2010) Plasma and particle temperature measurements in thermal spray: approaches and applications. J Therm Spray Technol 20:391–406. https://doi.org/10.1007/s11666-010-9603-z

Chazelas C, Trelles JP, Choquet I, Vardelle A (2017) Main issues for a fully predictive plasma spray torch model and numerical considerations. Plasma Chem Plasma Process 37(3):627–651. https://doi.org/10.1007/s11090-017-9808-8

Sun J, Sun S, Wang H, Niu C, Zhu T (2020) Comparative analysis of the arc characteristics inside the converging-diverging and cylindrical plasma torches. Plasma Sci Technol 22(3):034012. https://doi.org/10.1088/2058-6272/ab6635

He-Ping L, Xi C (2002) Three-dimensional modelling of the flow and heat transfer in a laminar non-transferred arc plasma torch. Chin Phys 11(1):44–49. https://doi.org/10.1088/1009-1963/11/1/310

Li H-P, Pfender E (2007) Three dimensional modeling of the plasma spray process. J Therm Spray Technol 16(2):245–260. https://doi.org/10.1007/s11666-007-9023-x

Sun J-H, Sun S-R, Zhang L-H, Wang H-X (2020) Two-temperature chemical non-equilibrium modeling of argon dc arc plasma torch. plasma Chem Plasma Process 40(6):1383–1400. https://doi.org/10.1007/s11090-020-10108-9

Launder BE, Spalding DB (1972) Lectures in mathematical models of turbulence. Academic, New York

Kim KS, Park JM, Choi S, Kim J, Hong SH (2008) Comparative study of two- and three-dimensional modeling on arc discharge phenomena inside a thermal plasma torch with hollow electrodes. Phys Plasmas 15(2):023501. https://doi.org/10.1063/1.2825670

Pierre F, Gonzalez J, Masquère M, Reichert F (2011) Magnetic field approaches in dc thermal plasma modelling. J Phys D Appl Phys 44:345202. https://doi.org/10.1088/0022-3727/44/34/345202

Liu S-H, Trelles JP, Murphy AB, Li L, Zhang S-L, Yang G-J, Li C-X, Li C-J (2019) Numerical simulation of the flow characteristics inside a novel plasma spray torch. J Phys D Appl Phys 52(33):335203. https://doi.org/10.1088/1361-6463/ab228b

Zhang X-n, Li H-P, Murphy A, Xia W-D (2013) A numerical model of non-equilibrium thermal plasmas. I Transport properties Physics of Plasmas. https://doi.org/10.1063/1.4794969

Li H-P, Zhang X-n, Xia W-D (2013) A numerical model of non-equilibrium thermal plasmas II governing equations. Phys Plasmas. https://doi.org/10.1063/1.4794970

Scott DA, Kovitya P, Haddad GN (1989) Temperatures in the plume of a dc plasma torch. J Appl Phys 66(11):5232–5239. https://doi.org/10.1063/1.343709

Osaki K, Fukumasa O, Kobayashi A (2000) High thermal efficiency-type laminar plasma jet generator for plasma processing. Vacuum 59(1):47–54. https://doi.org/10.1016/S0042-207X(00)00253-0

Pan W, Meng X, Wu C, Chen X (2006) Experimental study on the thermal argon plasma generation and jet length change characteristics at atmospheric pressure. Plasma Chem Plasma Process 26(4):335–345. https://doi.org/10.1007/s11090-006-9000-z

Pan W, Zhang W, Ma W, Wu C (2002) Characteristics of argon laminar dc plasma jet at atmospheric pressure. Plasma Chem Plasma Process 22:271–283. https://doi.org/10.1023/A:1014899510362

Pershin L, Mitrasinovic A, Mostaghimi J (2013) Treatment of refractory powders by a novel, high enthalpy dc plasma. J Phys D Appl Phys 46(22):224019. https://doi.org/10.1088/0022-3727/46/22/224019

Nogues E, Vardelle M, Fauchais P, Granger P (2008) Arc voltage fluctuations: comparison between two plasma torch types. Surf Coat Technol 202(18):4387–4393. https://doi.org/10.1016/j.surfcoat.2008.04.014

Zhao W, Cao F, Ning Z, Zhang G, Li Z, Sun J (2012) A computational fluid dynamics (CFD) investigation of the flow field and the primary atomization of the close coupled atomizer. Comput Chem Eng 40:58–66. https://doi.org/10.1016/j.compchemeng.2012.02.014

Zeoli N, Gu S (2006) Numerical modelling of droplet break-up for gas atomisation. Comput Mater Sci 38(2):282–292. https://doi.org/10.1016/j.commatsci.2006.02.012

Fritsching U (2004) Spray simulation modelling and numerical simulation of sprayingforming metals. Cambridge University Press. https://doi.org/10.1017/CBO9780511536649

Dawes J, Bowerman R, Trepleton R (2015) Introduction to the additive manufacturing powder metallurgy supply chain. Johnson Matthey Technology Review 59:243–256. https://doi.org/10.1595/205651315X688686

Kim Y, Kim E-P, Song Y-B, Lee SH, Kwon Y-S (2014) Microstructure and mechanical properties of hot isostatically pressed Ti–6Al–4V alloy. J Alloy Compd 603:207–212. https://doi.org/10.1016/j.jallcom.2014.03.022

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yin, Z., Yu, D., Zhang, Q. et al. Experimental and Numerical Analysis of a Reverse-polarity Plasma Torch for Plasma Atomization. Plasma Chem Plasma Process 41, 1471–1495 (2021). https://doi.org/10.1007/s11090-021-10181-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-021-10181-8