Abstract

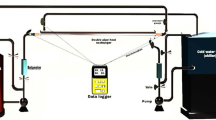

In this study, an electro-thermo-structural coupled numerical analysis is conducted to evaluate the thermal, electrical, and structural performances of a thermoelectric generator system. The hot heat exchangers with six different internal fin structures are compared in terms of temperature distribution, pressure drop, net power output, overall efficiency, and stress using the coupled numerical approach. Experiments are conducted on the heat exchanger with straight fins to validate the accuracy and reliability of the proposed coupled analysis. The hot gas outlet temperature, coolant outlet temperature, power output, and stress predicted using the coupled approach are validated within errors of 1.5, 6, 3, and 5.45%, respectively. Among the proposed heat exchanger designs, the heat exchanger with inclined fins and that with the combination of inclined and perpendicular fins exhibit higher net power outputs and overall efficiencies. The heat exchanger with the inclined fins and that with the combined fins exhibit overall efficiencies of 1.81 and 1.88% and net power outputs higher by 29 and 35%, respectively, than those of the heat exchanger with straight fins at the hot gas temperature of 600 °C. At the hot gas temperature 600 °C, the maximum stresses induced in the heat exchanger with the inclined fins and that with the combined fins are approximately 25.87 and 26.53 MPa, respectively, which are lower than the maximum allowable stress of 70 MPa.

Similar content being viewed by others

Abbreviations

- \(C_{\text{ph}}\) :

-

Specific heat (J kg−1 K−1) of hot gas

- \(D_{\text{H}}\) :

-

Hydraulic diameter (m)

- \(\vec{E}\) :

-

Electric field intensity (V m−1)

- \(\overline{E}\) :

-

Young’s modulus (GPa)

- \(H_{{{\text{a}},{\text{T}}}}\) :

-

Heat absorbed (W) by thermoelectric modules

- \(h\) :

-

Enthalpy (J)

- \(I\) :

-

Current (A)

- \(\vec{J}\) :

-

Electric current intensity (A m−2)

- \(k\) :

-

Thermal conductivity (W m−1 K−1)

- \(\dot{m}_{\text{h}}\) :

-

Mass flow rate (kg s−1) of hot gas

- \(P\) :

-

Static pressure (Pa)

- \(\Delta P\) :

-

Pressure drop (Pa)

- \(P_{\text{L}}\) :

-

Power loss (W) from system

- \(P_{\text{M}}\) :

-

Power output (W) from the thermoelectric modules

- \(P_{\text{N}}\) :

-

Net power output (W) from system

- \(P_{\text{T}}\) :

-

Total power output (W) from system

- \(p\) :

-

Peltier coefficient (V)

- \(Q_{\text{h}}\) :

-

Total heat transferred from the hot gas

- \(S_{\text{E}}\) :

-

Energy source

- \(S_{\text{M}}\) :

-

Momentum source

- \(T_{\text{c}}\) :

-

Cold side temperature of thermoelectric module (°C)

- \(T_{\text{h}}\) :

-

Hot side temperature of thermoelectric module (°C)

- \(T_{\text{hi}}\) :

-

Hot gas inlet temperature (°C)

- \(T_{\text{ho}}\) :

-

Hot gas outlet temperature (°C)

- \(U\) :

-

Average velocity (m s−1)

- \(V\) :

-

Voltage load (V)

- \(\dot{V}\) :

-

Volume flow rate (m3 s−1)

- \(V_{\text{opt}}\) :

-

Optimum voltage (V)

- \(\rho\) :

-

Density (kg m−3)

- \(\nabla\) :

-

Gradient operator

- \(\tau\) :

-

Stress tensor

- \(\mu\) :

-

Dynamic viscosity (Pa s)

- \(\sigma\) :

-

Electrical conductivity (Ω−1 m−1)

- \(\alpha\) :

-

Seebeck coefficient (V K−1)

- \(\nabla \emptyset\) :

-

Electric potential (J C−1)

- \(\overline{\sigma }\) :

-

Stress (Pa)

- \(\overline{\varepsilon }\) :

-

Strain

- \(v\) :

-

Poisson’s ratio

- \(\overline{\alpha }\) :

-

Coefficient of thermal expansion (°C−1)

- \(\eta\) :

-

Conversion efficiency (%) of thermoelectric modules

- \(\eta_{\text{o}}\) :

-

Overall efficiency (%) of whole thermoelectric generator system

References

Wang Y, Li S, Xie X, Deng Y, Liu X, Su C. Performance evaluation of an automotive thermoelectric generator with inserted fins or dimpled-surface hot heat exchanger. Appl Energy. 2018;218:391–401.

Huang DH, Tran TN, Yang B. Investigation on the reaction of iron powder mixture as a portable heat source for thermoelectric power generators. J Therm Anal Calorim. 2014;116(2):1047–53.

Romano MS, Gambhir S, Razal JM, Gestos A, Wallace GG, Chen J. Novel carbon materials for thermal energy harvesting. J Therm Anal Calorim. 2012;109(3):1229–35.

Pourkiaei SM, Ahmadi MH, Sadeghzadeh M, Moosavi S, Pourfayaz F, Chen L, Pour Yazdi MA, Kumar R. Thermoelectric cooler and thermoelectric generator devices: a review of present and potential applications, modeling and materials. Energy. 2019;45:50. https://doi.org/10.1016/j.energy.2019.07.179.

Zhang AB, Wang BL, Pang DD, Chen JB, Wang J, Du JK. Influence of leg geometry configuration and contact resistance on the performance of annular thermoelectric generators. Energy Convers Manag. 2018;166:337–42.

Weng CC, Huang MJ. A simulation study of automotive waste heat recovery using a thermoelectric power generator. Int J Therm Sci. 2013;71:302–9.

Massaguer A, Massaguer E, Comamala M, Pujol T, Montoro L, Cardenas MD, Carbonell D, Bueno AJ. Transient behavior under a normalized driving cycle of an automotive thermoelectric generator. Appl Energy. 2017;206:1282–96.

Nithyanandam K, Mahajan RL. Evaluation of metal foam based thermoelectric generators for automobile waste heat recovery. Int J Heat Mass Transf. 2018;122:877–83.

Liu X, Deng YD, Zhang K, Xu M, Xu Y, Su CQ. Experiments and simulations on heat exchangers in thermoelectric generator for automotive application. Appl Therm Eng. 2014;71(1):364–70.

Quan R, Liu G, Wang C, Zhou W, Huang L, Deng Y. Performance investigation of an exhaust thermoelectric generator for military SUV application. Coatings. 2018;8(1):45.

He W, Wang S, Yang Y. Optimal heat exchanger dimensional analysis under different automobile exhaust temperatures for thermoelectric generator system. Energy Procedia. 2016;104:366–71.

He W, Wang S, Yang Y. Peak power evaluation and optimal dimension design of exhaust heat exchanger for different gas parameters in automobile thermoelectric generator. Energy Convers Manag. 2017;151:661–9.

Luo D, Wang R, Yu W, Sun Z, Meng X. Modelling and simulation study of a converging thermoelectric generator for engine waste heat recovery. Appl Therm Eng. 2019;153:837–47.

Marvão A, Coelho PJ, Rodrigues HC. Optimization of a thermoelectric generator for heavy-duty vehicles. Energy Convers Manag. 2019;179:178–91.

Bai S, Lu H, Wu T, Yin X, Shi X, Chen L. Numerical and experimental analysis for exhaust heat exchangers in automobile thermoelectric generators. Case Stud Therm Eng. 2014;4:99–112.

Rana S, Date A, Iqbal A, Akbarzadeh A. Optimization model for power generation using thermoelectric generator. Energy Procedia. 2019;160:723–30.

Cao Q, Luan W, Wang T. Performance enhancement of heat pipes assisted thermoelectric generator for automobile exhaust heat recovery. Appl Therm Eng. 2018;130:1472–9.

Lu X, Yu X, Qu Z, Wang Q, Ma T. Experimental investigation on thermoelectric generator with non-uniform hot-side heat exchanger for waste heat recovery. Energy Convers Manag. 2017;150:403–14.

He W, Wang S. Performance comparison of different exhaust exchanger types considering peak net power and optimal dimension in a thermoelectric generator system. Adv Theory Simul. 2018;1(4):1800012.

Arasteh H, Mashayekhi R, Ghaneifar M, Toghraie D, Afrand M. Heat transfer enhancement in a counter-flow sinusoidal parallel-plate heat exchanger partially filled with porous media using metal foam in the channels’ divergent sections. J Therm Anal Calorim. 2019;131:1–17.

Cheng F, Hong Y, Zhong W, Zhu C. Performance prediction and test of a Bi2Te3-based thermoelectric module for waste heat recovery. J Therm Anal Calorim. 2014;118(3):1781–8.

Borcuch M, Musiał M, Gumuła S, Sztekler K, Wojciechowski K. Analysis of the fins geometry of a hot-side heat exchanger on the performance parameters of a thermoelectric generation system. Appl Therm Eng. 2017;127:1355–63.

Wang Y, Li S, Zhang Y, Yang X, Deng Y, Su C. The influence of inner topology of exhaust heat exchanger and thermoelectric module distribution on the performance of automotive thermoelectric generator. Energy Convers Manag. 2016;126:266–77.

Li W, Peng J, Xiao W, Wang H, Zeng J, Xie J, Huang Q, Mao K, Zhang L. The temperature distribution and electrical performance of fluid heat exchanger-based thermoelectric generator. Appl Therm Eng. 2017;118:742–7.

Wu Y, Ming T, Li X, Pan T, Peng K, Luo X. Numerical simulations on the temperature gradient and thermal stress of a thermoelectric power generator. Energy Convers Manag. 2014;88:915–27.

Al-Merbati AS, Yilbas BS, Sahin AZ. Thermodynamics and thermal stress analysis of thermoelectric power generator: influence of pin geometry on device performance. Appl Therm Eng. 2013;50(1):683–92.

Erturun U, Erermis K, Mossi K. Effect of various leg geometries on thermo-mechanical and power generation performance of thermoelectric devices. Appl Therm Eng. 2014;73(1):128–41.

Meng JH, Wang XD, Chen WH. Performance investigation and design optimization of a thermoelectric generator applied in automobile exhaust waste heat recovery. Energy Convers Manag. 2016;120:71–80.

Raj AK, Kunal G, Srinivas M, Jayaraj S. Performance analysis of a double-pass solar air heater system with asymmetric channel flow passages. J Therm Anal Calorim. 2019;136(1):21–38.

Kumar RA, Babu BG, Mohanraj M. Thermodynamic performance of forced convection solar air heaters using pin–fin absorber plate packed with latent heat storage materials. J Therm Anal Calorim. 2016;126(3):1657–78.

Park SH, Jin Y, Cha J, Hong K, Kim Y, Yoon H, Yoo C-Y, Chung I. High-power-density skutterudite-based thermoelectric modules with ultralow contact resistivity using Fe–Ni metallization layers. ACS Appl Energy Mater. 2018;1(4):1603–11.

Seo JH, Patil MS, Cho CP, Lee MY. Heat transfer characteristics of the integrated heating system for cabin and battery of an electric vehicle under cold weather conditions. Int J Heat Mass Transf. 2018;117:80–94.

Ma Q, Fang H, Zhang M. Theoretical analysis and design optimization of thermoelectric generator. Appl Therm Eng. 2017;127:758–64.

Lu C, Wang S, Chen C, Li Y. Effects of heat enhancement for exhaust heat exchanger on the performance of thermoelectric generator. Appl Therm Eng. 2015;89:270–9.

Menni Y, Azzi A, Chamkha A. Enhancement of convective heat transfer in smooth air channels with wall-mounted obstacles in the flow path. J Therm Anal Calorim. 2019;135(4):1951–76.

Adam AY, Oumer AN, Najafi G, Ishak M, Firdaus M, Aklilu TB. State of the art on flow and heat transfer performance of compact fin-and-tube heat exchangers. J Therm Anal Calorim. 2020;139(4):2739–68.

Ma T, Pandit J, Ekkad SV, Huxtable ST, Wang Q. Simulation of thermoelectric-hydraulic performance of a thermoelectric power generator with longitudinal vortex generators. Energy. 2015;84:695–703.

Ma T, Lu X, Pandit J, Ekkad SV, Huxtable ST, Deshpande S, Wang QW. Numerical study on thermoelectric–hydraulic performance of a thermoelectric power generator with a plate-fin heat exchanger with longitudinal vortex generators. Appl Energy. 2017;185:1343–54.

Jia X, Gao Y. Estimation of thermoelectric and mechanical performances of segmented thermoelectric generators under optimal operating conditions. Appl Therm Eng. 2014;73(1):335–42.

Acknowledgements

This work was conducted under the framework of Research and Development Program of the Korea Institute of Energy Research (KIER) (B9-2431).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Garud, K.S., Seo, JH., Patil, M.S. et al. Thermal–electrical–structural performances of hot heat exchanger with different internal fins of thermoelectric generator for low power generation application. J Therm Anal Calorim 143, 387–419 (2021). https://doi.org/10.1007/s10973-020-09553-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09553-7