Abstract

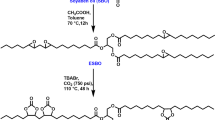

In the present study, TEIA bioresin was blended with the diglycidyl ether bisphenol A (DGEBA) epoxy resin in different ratios (i.e. 10, 20, 30, 40 mass%), cured with methylhexahydrophthalic anhydride curing agent in the presence of 2-methylimidazole catalyst. The optimized composition of DGEBA and TEIA bioresin blends system was employed as an adhesive strength. The adhesive strength of the TEIA-modified DGEBA epoxy resin blend system was increased from 4.14 to 6.31 MPa on an aluminium substrate compared to the DGEBA epoxy resin. The curing kinetics of non-isothermal, DGEBA epoxy resin and its bio-based blend systems were investigated employing differential scanning calorimetry. An increase in the peak temperature and reduction in a heat of curing as well as activation energy in DGEBA epoxy resin were observed with the addition of TEIA bioresin content. The activation energy (Ea) of the DGEBA resin and their bio-based blend system were obtained from Kissinger and Flynn–Wall–Ozawa methods.

Similar content being viewed by others

References

Kumar S, Samal SK, Mohanty S, Nayak SK. Epoxidized soybean oil-based epoxy blend cured with anhydride-based cross-linker: thermal and mechanical characterization. Ind Eng Chem Res. 2017;56:687–98.

Kumar S, Krishnan S, Samal SK, Mohanty S, Nayak SK. Itaconic acid used as a versatile building block for the synthesis of renewable resource based resins and polyesters for future prospective: a review. Polym Int. 2017;66:1349–63.

Qin J, Liu H, Zhang P, Wolcott M, Zhang J. Use of eugenol and rosin as feedstocks for biobased epoxy resins and study of curing and performance properties. Polym Int. 2004;63:760–5.

Wan J, Gan B, Li C, Molina-Aldareguia J, Kalali EN, Wang X, Wang DY. A sustainable, eugenol-derived epoxy resin with high biobased content, modulus, hardness and low flammability: synthesis, curing kinetics and structure–property relationship. Chem Eng J. 2016;284:1080–93.

Wan J, Zhao J, Gan B, Li C, Molina-Aldareguia J, Zhao Y, Wang DY. Ultrastiff biobased epoxy resin with high T g and low permittivity: from synthesis to Properties. ACS Sustain Chem Eng. 2016;4:2869–80.

Liu X, Zhang J. High-performance biobased epoxy derived from rosin. Polym Int. 2010;59:607–9.

Wang H, Liu B, Liu X, Zhang J, Xian M. Synthesis of biobased epoxy and curing agents using rosin and the study of cure reactions. Green Chem. 2008;10:1190–6.

Atta AM, Mansour R, Abdou MI, El-Sayed AM. Synthesis and characterization of tetra-functional epoxy resins from rosin. J Polym Res. 2005;12:127–38.

Jin FL, Park SJ. Thermomechanical behavior of epoxy resins modified with epoxidized vegetable oils. Polym Int. 2008;57:577–83.

Ratna D. Mechanical properties and morphology of epoxidized soyabean-oil-modified epoxy resin. Polym Int. 2001;50:179–84.

Sudha GS, Kalita H, Mohanty S, Nayak SK. Biobased epoxy blends from epoxidized castor oil: effect on mechanical, thermal, and morphological properties. Macromol Res. 2017;25:420–30.

Xia Y, Larock RC. Vegetable oil-based polymeric materials: synthesis, properties, and applications. Green Chem. 2010;12:1893–909.

Sahoo SK, Mohanty S, Nayak SK. Synthesis and characterization of bio-based epoxy blends from renewable resource based epoxidized soybean oil as reactive diluents. Chin J Polym Sci. 2015;33:137–52.

Lukaszczyk J, Janicki B, Kaczmarek M. Synthesis and properties of isosorbide based epoxy resin. Eur Polym J. 2011;47:1601–6.

Chrysanthos M, Galy J, Pascault JP. Preparation and properties of bio-based epoxy networks derived from isosorbide diglycidyl ether. Polymer. 2011;52:3611–20.

Hong J, Radojcic D, Ionescu M, Petrovic ZS, Eastwood E. Advanced materials from corn: isosorbide-based epoxy resins. Polym Chem. 2014;5:5360–8.

Kumar S, Samal SK, Mohanty S, Nayak SK. Recent development of bio-based epoxy resins: a review. Polym Plast Technol Eng. 2018;57:133–55.

Mohan P. A critical review: the modification, properties, and applications of epoxy resins. Polym Plast Technol Eng. 2013;52:107–25.

Chen Y, Xi Z, Zha L. Curing kinetics of bio-based epoxy resin based on epoxidized soybean oil and green curing agent. AIChE J. 2017;63:147–53.

Hwang SH, Jung JC. Curing kinetics and thermal properties of diglycidylether of bisphenol A with various diamines. J Appl Polym Sci. 2001;81:279–84.

Ampudia J, Larrauri E, Gil EM, Rodriguez M, Leon LM. Thermal scanning rheometric analysis of curing kinetic of an epoxy resin. I. An anhydride as curing agent. J Appl Polym Sci. 1999;71:1239–45.

Miyagawa H, Mohanty AK, Misra M, Drzal LT. Thermo-physical and impact properties of epoxy containing epoxidized linseed oil, 1. Macromol Mater Eng. 2004;289:629–35.

Miyagawa H, Mohanty AK, Misra M, Drzal LT. Thermo-physical and impact properties of epoxy containing epoxidized linseed oil, 2. Macromol Mater Eng. 2004;289:636–41.

Espinoza-Perez JD, Nerenz BA, Haagenson DM, Chen Z, Ulven CA, Wiesenborn DP. Comparison of curing agents for epoxidized vegetable oils applied to composites. Polym Compos. 2011;32:1806–16.

Altuna FI, Esposito LH, Ruseckaite RA, Stefani PM. Thermal and mechanical properties of anhydride-cured epoxy resins with different contents of biobased epoxidized soybean oil. J Appl Polym Sci. 2011;120:789–98.

Chen Y, Yang L, Wu J, Ma L, Finlow DE, Lin S, Song K. Thermal and mechanical properties of epoxy resin toughened with epoxidized soybean oil. J Therm Anal Calorim. 2013;113:939–45.

Boquillon N, Fringant C. Polymer networks derived from curing of epoxidised linseed oil: influence of different catalysts and anhydride hardeners. Polymer. 2000;41:8603–13.

Pin JM, Sbirrazzuoli N, Mija A. From epoxidized linseed oil to bioresin: an overall approach of epoxy/anhydride cross-linking. Chemsuschem. 2015;8:1232–43.

Supanchaiyamat N, Shuttleworth PS, Hunt AJ, Clark JH, Matharu AS. Thermosetting resin based on epoxidised linseed oil and bio-derived crosslinker. Green Chem. 2012;14:1759–65.

Patel SR, Patel RG. Effect of the anhydride structure on the curing kinetics and thermal stability of tetrafunctional epoxy resin. Thermochim Acta. 1992;202:97–104.

Vyazovkin S, Burnham AK, Criado JM, Perez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

He Z, Wang Y, Zhao T, Ye Z, Huang H. Ultrasonication-assisted rapid determination of epoxide values in polymer mixtures containing epoxy resin. Anal Methods. 2014;6:4257–61.

Kumar S, Samal SK, Mohanty S, Nayak SK. Synthesis and characterization of itaconic-based epoxy resins. Polym Adv Technol. 2018;29:160–70.

Kumar S, Samal SK, Mohanty S, Nayak SK. Study of curing kinetics of anhydride cured petroleum-based (DGEBA) epoxy resin and renewable resource based epoxidized soybean oil (ESO) systems catalyzed by 2-methylimidazole. Thermochim Acta. 2017;654:112–20.

Vyazovkin S, Sbirrazzuoli N. Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromol Rapid Comm. 2006;27:1515–32.

Natarajan M, Murugavel SC. Cure kinetics of bio-based epoxy resin developed from epoxidized cardanol–formaldehyde and diglycidyl ether of bisphenol–A networks. J Therm Anal Calorim. 2016;125:387–96.

Dobic SN, Filipovic JM, Tomic SL. Synthesis and characterization of poly (2-hydroxyethyl methacrylate/itaconic acid/poly (ethylene glycol) dimethacrylate) hydrogels. Chem Eng J. 2012;179:372–80.

Dai J, Ma S, Zhu L, Wang S, Yang L, Song Z, Zhu J. UV-thermal dual cured anti-bacterial thiol-ene networks with superior performance from renewable resources. Polymer. 2017;108:215–22.

Ma S, Liu X, Fan L, Jiang Y, Cao L, Tang Z, Zhu J. Synthesis and properties of a bio-based epoxy resin with high epoxy value and low viscosity. Chemsuschem. 2014;7:555–62.

Ma S, Liu X, Jiang Y, Tang Z, Zhang C, Zhu J. Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem. 2013;15:245–54.

Okamatsu T, Ochi M. Effect on the toughness and adhesion properties of epoxy resin modified with silyl-crosslinked urethane microsphere. Polymer. 2002;43:721–30.

Tao Q, Su L, Frost RL, He H, Theng BK. Effect of functionalized kaolinite on the curing kinetics of cycloaliphatic epoxy/anhydride system. Appl Clay Sci. 2014;95:317–22.

Zhang Y, Ferdosian F, Yuan Z, Xu CC. Sustainable glucose-based phenolic resin and its curing with a DGEBA epoxy resin. Taiwan Inst Chem Eng. 2017;71:381–7.

Ferdosian F, Zhang Y, Yuan Z, Anderson M, Xu CC. Curing kinetics and mechanical properties of bio-based epoxy composites comprising lignin-based epoxy resins. Eur Polym J. 2016;82:153–65.

El-Thaher N, Mekonnen T, Mussone P, Bressler D, Choi P. Nonisothermal DSC study of epoxy resins cured with hydrolyzed specified risk material. Ind Eng Chem Res. 2013;52:8189–99.

Huang K, Zhang P, Zhang J, Li S, Li M, Xia J, Zhou Y. Preparation of biobased epoxies using tung oil fatty acid-derived C21 diacid and C22 triacid and study of epoxy properties. Green Chem. 2013;15:2466–75.

Yang T, Zhang C, Zhang J, Cheng J. The influence of tertiary amine accelerators on the curing behaviors of epoxy/anhydride systems. Thermochim Acta. 2014;577:11–6.

Sbirrazzuoli N, Mititelu-Mija A, Vincent L, Alzina C. Isoconversional kinetic analysis of stoichiometric and off-stoichiometric epoxy-amine cures. Thermochim Acta. 2006;447:167–77.

Matejka L, Lovy J, Pokorny S, Bouchal K, Dusek K. Curing epoxy resins with anhydrides: model reactions and reaction mechanism. J Polym Sci. A. 1983;21:2873–85.

Leukel J, Burchard W, Kruger RP, Much H, Schulz G. Mechanism of the anionic copolymerization of anhydride-cured epoxies–analyzed by matrix-assisted laser desorption ionization time-of-flight mass spectrometry (MALDI-TOF-MS). Macromol Rapid Commun. 1996;17:359–66.

Ham YR, Kim SH, Shin YJ, Lee DH, Yang M, Min JH, Shin JS. A comparison of some imidazoles in the curing of epoxy resin. J Ind Eng Chem. 2010;16:556–9.

Tan SG, Ahmad Z, Chow WS. Relationships of cure kinetics and processing for epoxidized soybean oil bio-thermoset. Ind Crop Prod. 2013;43:378–85.

Tan SG, Chow WS. Thermal properties, curing characteristics and water absorption of soybean oil-based thermoset. eXPRESS Polym Lett. 2011;5:480–92.

Acknowledgements

The authors would you like to thank the Department of Chemical and Petrochemicals, Government of India, for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S., Samal, S.K., Mohanty, S. et al. Curing kinetics of bio-based epoxy resin-toughened DGEBA epoxy resin blend. J Therm Anal Calorim 137, 1567–1578 (2019). https://doi.org/10.1007/s10973-019-08080-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08080-4