Abstract

The Joint Research Centre, in cooperation with the Commissariat à l’Energie Atomique et aux Energies Alternatives, produced a novel 243Am spike reference material for mass spectrometry. Americium solution with an isotopic composition of 88% 243Am and 12% 241Am was used as the source for the preparation of the spike material. The certified value of 5.696 (11) nmol g−1 for the amount content of 243Am and 0.136138 (54) for the n(241Am)/n(243Am) amount ratio were assigned. The assigned values from mass spectrometry were confirmed by alpha-particle spectrometry, alpha-particle counting at a defined solid angle, and high-resolution gamma-ray spectrometry. Furthermore, an external validation of the certified values was obtained from the results of an interlaboratory comparison exercise, using this americium reference solution as the test sample.

Similar content being viewed by others

Introduction

Americium (Am) is a non-naturally occurring element, produced by neutron capture in nuclear reactions. Among various Am radioactive isotopes, 241Am and 243Am are the two important isotopes with half-lives of 432.6 (1.2) [1] and 7345 (28) years (k = 2) [2]. 241Am and other isotopes of Am are usually determined by alpha-particle and gamma-ray spectrometry [3, 4]. However, mass-spectrometric techniques have become increasingly important in nuclear safeguards and nuclear security, particularly when Am measurement results with lower uncertainty are needed. To achieve this, suitable certified reference materials (CRMs) are indispensable for calibration of mass spectrometers, validation of methods and in quality control.

Until today, no Am reference materials for mass spectrometry certified for the isotopic composition or amount content have been available on the market. Ideally, spike CRMs are produced gravimetrically from well-characterised high-purity metals and compounds such as purified oxides. Unlike for uranium and plutonium, americium base materials are scarce or difficult to obtain. Consequently, this has resulted in rare application of mass-spectrometric techniques for determination of Am. The need for an isotopic Am CRM has been expressed by the International Atomic Energy Agency (IAEA) and at the 2016 Nuclear Security Summit [5, 6]. Such material can be applied in nuclear forensics to determine accurately the model age of plutonium (Pu) materials, i.e. the time elapsed since its last chemical purification, via 241Am/241Pu chronometry [7,8,9,10,11], in radiation waste management for characterisation of irradiated nuclear fuel/waste for long-term disposal at geological repositories [12], and in nuclear decay data application for the determination of nuclear half-lives.

To fill this gap, the Joint Research Centre of the European Commission (EC-JRC) in Geel and the Commissariat à l’Energie Atomique et aux Energies Alternatives in Marcoule jointly produced and certified an 243Am spike reference material. The Am starting material, enriched in 243Am (88%), was provided by the Atalante Analysis Laboratory (CEA/L2AT, Marcoule). The isotopic composition of the Am source is different from that found in the fuel cycle or in purification processes, making it suitable as the source for this spike material and for the quantification of Am by mass spectrometry. Nearly 600 units of this reference material were produced, with a mass fraction of Am of about 1.5 µg g−1 solution. The CEA and the JRC-Geel each received half of the total units produced. The material was certified for the Am content by isotope dilution mass spectrometry (IDMS), using an 241Am spike produced in-house from 241Pu material, and for the isotope amount ratios (e.g. isotopic abundance) by thermal ionisation mass spectrometry (TIMS). The preparation and certification of this material were done in compliance with ISO 17034 and the ISO Guide 35 [13, 14]. Radiometric techniques were used as independent confirmation measurements. In parallel to the certification process and prior to release of the material’s certificate, an interlaboratory comparison (ILC) was organised by the CEA’s Commission d’ETAblissement des Méthodes d’Analyse (CETAMA) using this reference material as the test sample [15].

In this paper, the preparation and the characterisation of this 243Am spike CRM (IRMM–0243/STAM) will be presented. All uncertainty values in this paper are expanded uncertainties with a coverage factor k = 2. They are given in parentheses.

Methodology

The solution was characterised for the amount content of Am (e.g. 243Am, 241Am and total Am) using isotope dilution mass spectrometry (IDMS) as a primary method of measurement [16, 17]. In IDMS, the amount of an element (or isotope) in the sample is determined on the basis of additions of known amounts of the same element (called a spike) whose isotopic composition differs from that of the unknown sample. By measuring the change in isotopic composition of the blend (sample-spike mixture) by isotope mass spectrometry, the unknown amount of the element (or isotope) can be derived.

In absence of a suitable, well-characterised 241Am spike, an alternative approach had to be chosen. The 241Am spike was produced from highly enriched 241Pu (99.3%) base material available at JRC-Geel. Two strategies for the characterisation of the 241Am in-house spike were considered. The first strategy is based on separating the ingrown 241Am from the 241Pu material since its last purification and, subsequently, characterising the 241Am amount content and the isotopic composition by means of mass spectrometry or radiometric techniques. This strategy, however, would require an 243Am spike, which was not available at JRC-Geel. On the other hand, the characterisation by alpha- or gamma spectrometry would result in higher uncertainty. The second strategy relies on the complete removal of the 241Am in the 241Pu material and setting the “clock” to zero (time zero). The amount of produced 241Am by beta decay of 241Pu (half-life 14.325 (24) years, k = 2 [18]) can be calculated at a given time using the appropriate Bateman equation [10]. The concentration of 241Pu in the purified solution is determined by reverse IDMS using a certified plutonium spike CRM. This approach had previously been tested in a feasibility study [19]. For that study, a less enriched 241Pu material (about 70%) originating from Oak Ridge National Laboratory was used for IDMS measurements of a similar 243Am working reference material and was successfully applied in age determination of Pu NBL SRM 147 material. The lessons learned from the feasibility study were further developed and optimised for this certification project.

The n(241Am)/n(243Am) and n(242mAm)/n(243Am) amount ratios were measured by TIMS. Alpha-particle spectrometry, alpha-particle counting at a defined solid angle (DSA), and high-resolution gamma-ray spectrometry were applied as independent confirmation measurement techniques. Furthermore, the reference values obtained through the certification process were verified externally against the results of an interlaboratory comparison (ILC) organised by CEA/CETAMA, using this reference material as the test sample. The steps in the preparation and certification of the americium reference material are shown in Fig. 1.

Material production

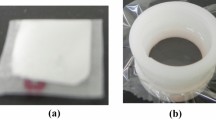

Four milligrams of the Am starting material consisting of approximately 88% 243Am, 12% 241Am and 0.01% 242mAm were purified by extraction chromatography to remove the major elemental impurities and subsequently diluted with about 2400 mL 1 M nitric acid solution to obtain an Am mass fraction of 1.5 µg g−1 solution. The solution was dispensed into pre-cleaned glass ampoules with screw-caps. In total 587 units of this reference material were prepared, each unit containing approximately 5 µg of Am in 3.5 mL nitric acid solution. Impurity analyses were carried out on the purified Am starting solution by inductively coupled plasma atomic emission spectroscopy (ICP-AES), as well as on the final product by inductively coupled plasma quadrupole mass spectrometry (ICP-QMS). All labware (flask, dispenser and ampoules) were cleaned prior to use with ultra-pure Milli Q water (resistivity 18.2 MΩ cm at 25 °C) and 10% (m/m) nitric acid solution for 24 h and dried in an oven at 60 °C [20].

Material characterisation

241Am/241Pu in-house spike

About 2 milligrams of 241Pu material were dissolved in nitric acid and purified by anion exchange separation (Biorad AG 1-X4 resin, 100–200 mesh) [21] to remove the daughter decay products. The purification procedure was performed three times in order to remove all the decay products that had been growing in since the production of this material in 1991. The final purification was carried out on June 10, 2014 at 15:10 CET (Central European Time) and marked the start of the 241Am in-growth (time zero). An aliquot of the purified 241Pu solution was measured by high-resolution gamma-ray spectrometry to verify the completeness of the purification; the atom ratio 241Am/241Pu was found to be less than 5.6 (6) × 10−5 at time zero.

The purified 241Pu material was diluted with 100 mL 1 M nitric acid solution and characterised for the amount content of 241Pu and for isotopic composition. The weight of the flask containing the 241Pu solution was monitored to correct for any evaporation loss.

Spiking

Spiking, chemical purifications, and subsequent measurements were carried out about one and a half year after the purification of the 241Pu material (June 10, 2014). During this period a sufficient amount of 241Am had been produced (about 5.67 nmol g−1 at t = 18 months, see also Fig. 3) for spiking. Eighteen units in total were selected (stratified random) from the whole batch and from each unit an aliquot of about 2.5 g was mixed with an aliquot of about 1.0 g of the 241Pu/241Am spike solution (blend) for the determination of the amount content of 243Am by IDMS. In addition an aliquot of about 0.7 g was taken from each ampoule for the determination of the n(241Am)/n(243Am) and n(242mAm)/n(243Am) isotope ratios by TIMS. Spiking was done by metrological weighing using the substitution method [22]. The chemical separation and isotope ratio measurements were carried on sets of two units over a period of 7 months (January to July 2016). This approach was used in order to have different amounts of ingrown 241Am for spiking and to assess the stability of the Am solution during the certification campaign.

Americium purification

Prior to the isotope ratio measurements, two purification steps were carried out to remove the 241Pu from the in-grown 241Am in the blends by means of UTEVA-spec [23] and DGA extraction resins [24] (both of Triskem International, Bruz, France). The time of the Am elution (i.e. separation of Am from Pu) from the first UTEVA-spec column was carefully recorded in order to calculate the ingrowth time Δt(241Am), i.e. the time elapsed since time zero. The DGA purification step was applied to remove the organic and other impurities that would interfere in the isotopic measurements. The purification steps of Am prior to isotopic measurement are shown in Fig. 2.

Isotope ratio measurements

Isotope ratio measurements were carried out using the total evaporation method on a multi-collector Triton Thermal Ionisation Mass Spectrometer (Thermo Fisher Scientific, Bremen, Germany), in a similar manner as routinely performed for uranium (U) and plutonium (Pu) samples of similar size. In the total evaporation method, the evaporation filament is heated up to maintain a steady intensity and measured until the whole sample is consumed. In this way, the fractionation effects in the ion source are minimized [25,26,27,28,29]. A mass fractionation correction by measuring an americium isotopic standard was not possible due to unavailability of such material. It can be assumed that Am behaves similar to U and Pu during the total evaporation measurements (similar first ionisation potentials) [30]. Therefore, Pu isotopic standards were measured to check the performance of the mass spectrometer. Degassed zone refined rhenium filaments (Thermo Fisher Scientific, Bremen, Germany) were used as ionization and evaporation filaments (double filament configuration). About 20 ng of Am in the form of nitrate solution were deposited on an evaporation filament, dried down and mounted on a sample turret. All ion currents were measured simultaneously on Faraday cups.

Confirmation measurements

High-resolution alpha-particle spectrometry [31,32,33] was used to determine the activity ratio A(243Am)/A(241Am) of the Am reference solution. The alpha source was prepared by electrodeposition on a polished stainless steel disk with an active diameter of 18.6 mm and measured using a passivated ion-implanted planar silicon detector (PIPS®, 150 mm2 active area, Mirion Technologies (MGPI) SA, France). The total Am activity per unit mass was determined by means of alpha-particle counting at a defined solid angle (DSA) [31, 34]. Gravimetrically quantified drops of Am solution were deposited on 34 mm glass plates and covered with 20 µg cm−2 VYNS foils (polyvinylchloride-polyvinylacetate copolymer) to prevent material loss.

Two independent gamma-ray measurement campaigns were carried out, one in the underground laboratory ‘HADES’ [35] and one above ground in the radionuclide metrology laboratory at the JRC-Geel. Point-like sources were prepared gravimetrically by drop deposition on laminated plastic foils supported by a stainless steel annulus of 34 mm outer diameter. They were measured above ground using two coaxial high purity germanium (HPGe) gamma-ray spectrometers, one of 35% and the other of 90% relative efficiency [Mirion Technologies (MGPI) SA, France]. One gamma source was selected for ultra-low-level gamma-ray spectrometry (ULGS) measurements in the ‘HADES’ laboratory using a HPGe detector of type Broad Energy Germanium Detector (BEGe) with a relative efficiency of 20% (Canberra, USA). The activities of 241Am and 243Am were calculated based on the main gamma-ray peaks of the nuclides, i.e. at 59.54 keV energy for 241Am and at 74.66 keV for 243Am [36, 37].

Results and discussion

241Am/241Pu in-house spike

The results of the characterisation measurements of the 241Pu solution after purification are summarised in Table 1.

The values for the isotope ratios were found to be in agreement with the values from the measurement certificate of the 241Pu material of 1991. The 241Pu content (i.e. mass fraction, amount content) was determined as the mean of the 10 blends measured by IDMS using 242Pu spike CRM (IRMM-049d). Each blend was measured in replicates on the Triton TIMS using the total evaporation method. The correction for mass fractionation effects was based on the measurement of the IRMM-290b/A3 Pu isotopic standard.

The ingrown amount of the 241Am (c241Am) was determined using the equation (Eq. 1):

where c o241Pu is the amount content [mol g−1] of 241Pu in the purified spike solution at time zero (June 10, 2014), Δt [a] is the ingrowth time of 241Am (time elapsed since time zero), λ241Pu and λ241Am are the decay constants [a−1] for 241Pu and 241Am, respectively, and c o241Am is the initial amount content [mol g−1] of 241Am in the purified spike solution. The half-lives and associated uncertainties used for the calculation of the respective decay constants were 14.325 (24) years for 241Pu and 432.6 (1.2) years for 241Am [1, 18].

To determine any 241Am impurity left in the 241Pu solution after purification, the 241Am ingrowth in the 241Pu solution was followed by high-resolution gamma-ray spectrometry over a longer period. This indicated a separation time of June 10, 2014 17:18 CET (uncertainty range from 10:10 to 23:55). This agrees very well with the actual separation time of June 10, 2014, 15:10 CET. Based on these measurements, the initial amount of 241Am in the purified 241Pu solution was considered to be negligible and therefore c o241Am ≈ 0.

The ingrowth of 241Am in the 241Pu solution after the purification is shown as a mass fraction in Fig. 3.

Impurities in the final reference material

The impurities measured in the reference material solution by ICP-QMS using a Perkin Elmer Elan instrument were potassium (Na), lead (Pb), uranium (238U) and zinc (Zn) with mass fractions of 5.3 (2.7) µg g−1, 0.96 (53) µg g−1, 1.62 (81) µg g−1 and 1.48 (75) µg g−1, respectively.

Furthermore, 242Cm and 243+244Cm radioisotopes were measured by alpha spectrometry with activity of 59 (6) Bq g−1 and 12 (1) Bq g−1, respectively. The contribution of 242Cm isobaric impurity (5 × 10−7 µg g−1) to the fraction of 242mAm in the reference material was about 0.2%. It was included in the uncertainty budget of the n(242mAm)/n(243Am) ratio.

Assigned values and uncertainty estimation

The amount content of 243Am in the reference material was determined as the mean of sixteen results obtained by IDMS on the selected units. Two units (unit no. 240 and 437) were excluded from the evaluation due to very low signal intensities during the isotope measurement.

The n(241Am)/n(243Am) and n(242mAm)/n(243Am) ratios were measured on a Triton TIMS using the total evaporation method. The results for the amount content of 243Am and the n(241Am)/n(243Am) ratio are shown in Figs. 4 and 5, respectively. The amount contents of the 241Am, the total Am and the corresponding mass fractions were derived from the 243Am amount content, the n(241Am)/n(243Am) amount ratio, and the respective atomic masses [38]. Measurement uncertainties were evaluated according to the Guide to the Expression of Uncertainty in Measurement (GUM) [39] using the GUM Workbench© software [40].

A mass fractionation correction using measurements of a CRM on the same magazine as the sample is recommended following ASTM C1672-17, but not mandatory [28]. This correction was not possible to perform for the Am measurements for this project, since there was no suitable Am isotopic standard available. Due to similarities in the chemical behaviour and similar ionization energies, it can be assumed that Am behaves similar to U or Pu during the total evaporation measurement and that the bias statements for U and Pu can equally be applied for americium. For the n(241Am)/n(243Am) ratio the uncertainty component was calculated as 0.033% (k = 2, for ratios spanning 2 mass units) and for the n(242mAm)/n(243Am) ratio to 0.017% (k = 2, for ratios spanning 1 mass unit). These two uncertainty components were included in the combined uncertainty for isotope measurements. In addition, an uncertainty of 0.020% (k = 2, for ratios spanning 2 mass units) derived from isotope measurements of the U and Pu quality control (QC) samples was added as a conservative contribution to the uncertainty budget for Am. In the case of n(242mAm)/n(243Am) amount ratio, an additional source of uncertainty (0.2% rel.) was added to account for the 242Cm impurity in the IRMM-0243 material. Relative contributions of various uncertainty components for the amount content of 243Am and the n(241Am)/n(243Am) ratio are shown in Figs. 6 and 7, respectively.

The relative expanded uncertainty (coverage factor k = 2) for the 243Am amount content from the assessment was 0.19%. The dominant source of uncertainty comes from the uncertainty of the half-life of 241Pu (rel. contribution of 73.5%) followed by the concentration of the 241Pu spike solution (rel. contribution of 12.3%). Other uncertainty components come from the 241Am ingrowth time, the between-unit variability (homogeneity assessment) and isotope ratio measurements.

The uncertainty of the n(241Am)/n(243Am) ratio consists of the repeatability of the isotope measurements and uncertainty components from the potential bias during the isotope ratio measurement and the QC measurements.

The assigned values and the results from the confirmation measurements (i.e. alpha and gamma spectrometry) and the results from the ILC contributing to the certification of STAM/IRMM-0243 are summarised in Table 2. An agreement was achieved within measurement uncertainties for all the measurands in Table 2 [39, 41]. In particular, good agreement was obtained for the results from alpha spectrometry and the reported results (as weighted mean) in the ILC. The compatibility between the assigned reference values and the ILC was quantified by the normalised deviation (En score) according to ISO 13528 [42]. The normalised deviations for the amounts of 243Am and 241Am and the n(241Am)/n(243Am) ratio, − 0.3, 0.1 and 0.8, respectively, were all less than 2 [15]. Therefore, the values were adopted as the certified values for IRMM–0243/STAM.

In the case of the n(242mAm)/n(243Am) ratio, a value of 0.0001506 (15) was measured by TIMS. This value was higher than the value obtained by the ILC, 0.0001367 (9). Additional measurements showed several hundreds of counts at masses 238, 239 and 242, which may explain this observation. These interferences came from the reagents, resins or other impurities that were not removed by chemical purification prior to the measurement. The n(242mAm)/n(243Am) ratio could not be corrected quantitatively for this effect and, therefore only an indicative value based on the ILC results has been assigned for this ratio.

Conclusions

A novel 243Am spike reference material IRMM-0243 (called STAM at CEA/CETAMA) was prepared and certified for the amount content of 243Am and the n(241Am)/n(243Am) isotope amount ratio by IDMS and TIMS and successfully confirmed by independent radioactivity measurements. Indicative values for the n(242mAm)/n(243Am) isotope amount ratio and its uncertainty were derived from the ILC organised by CEA/CETAMA. The material is supplied in a glass ampoule with a screw-cap containing about 3.5 mL of dilute nitric acid solution with an Am mass fraction of 1.5716 (30) µg g−1. This concentration is suitable for various mass spectrometry measurements using, e.g., TIMS, ICP-MS [43].

References

DDEP (2004–2020) DDEP Monographie BIPM-5—Table of Radionuclides http://www.lnhb.fr/nuclear-data/nuclear-data-table/ Accessed 4 Aug 2020

Marouli M, Pommé S, Jobbagy V, Stroh H, Van Ammel R, Fankhauser A, Jakopic R, Richter S, Aregbe Y, Crozet M, Maillard C, Rivier C, Roudil D (2020) Absolute and relative measurement of the 243Am half-life. J Radioanal Nucl Chem. https://doi.org/10.1007/S10967-020-07450-9

Vajda N, Kim CK (2010) Determination of 241Am isotope: a review of analytical methodology. J Radioanal Nucl Chem 284:341–366

Agarwal SK (2018) A review on the mass spectrometric studies of americium: present and future perspectives. Mass Spectrom Rev 37:43–56

Balsley SD (2014) Report of the 2014 technical meeting on nuclear reference materials for destructive analysis in the nuclear fuel cycle. IAEA SAL, 2–4 September, Vienna

The Nuclear Security Summit 2016. http://www.nss2016.org/

Wallenius M, Peerani P, Koch L (2000) Origin determination of plutonium material in nuclear forensics. J Radioanal Nucl Chem 246:317–321

Nygren U, Rameback H, Nilsson C (2007) Age determination of plutonium using inductively coupled plasma mass spectrometry. J Radioanal Nucl Chem 272:345–510

Wallenius M, Mayer K (2000) Age determination of plutonium material in nuclear forensics by thermal ionisation mass spectrometry. Fresenius J Anal Chem 366:234–238

Keegan RP, Gehrke RJ (2003) A method to determine the time since last purification of weapons grade plutonium. Appl Radiat Isot 59:137–143

Byerly BL, Stanley F, Spencer K, Colletti L, Garduno K, Kuhn K, Lujan E, Martinez A, Portfield D, Rim J, Schappert M, Thomas M, Townsend L, Xu N, Tandon L (2016) Forensic investigation of plutonium metal: a case study of CRM 126. J Radioanal Nucl Chem 310:623–632

Chartier F, Aubert M, Pilier M (1999) Determination of Am and Cm in spent nuclear fuels by isotope dilution inductively coupled plasma mass spectrometry and isotope dilution thermal ionization mass spectrometry after separation by high-performance liquid chromatography. Fresenius J Anal Chem 364:320–327

ISO 17034:2016 (2016) General requirements for the competence of reference material producers. International Organisation for Standardisation, Geneva

ISO Guide 35 (2017) Reference materials—general and statistical principles for certification. International Organization for Standardization, Geneva

Crozet M, Roudil D, Maillard C, Rivier C, Jakopic R, Fankhauser A, Aregbe Y, Richter S (2019) Contribution of an interlaboratory comparison to the certification of the STAM/IRMM-0243 243Am reference material. J Radioanal Nucl Chem 319:717–725

Vogl J, Pritzkow W (2010) Isotope dilution mass spectrometry—a primary method of measurement and its role for RM certification. J Metrol Soc India 25:135–164

Milton MJ, Quinn TJ (2001) Primary methods for the measurement of amount of substance. Metrologia 38:289–296

Wellum R, Verbruggen A, Kessel R (2009) A new evaluation of the half-life of 241Pu. J Anal At Spectrom 24:801–807

Sturm M (2017) Reference materials for age dating in nuclear forensics. Ph.D. dissertation, University of Natural Resources and Life Sciences (BOKU), Vienna

Jakopič R, Fanhauser A, Aregbe Y, Crozet M, Maillard C, Richter S, Rivier C, Roudil D, Altzitzoglou T, Pommé S, Marouli M, Tzika F (2017) Preparation and certification of 243Am spike reference material: IRMM-0243, certification report EUR 28748 EN

Jakopič R, Verbruggen A, Eykens R, Kehoe F, Kuhn H, Kushigeta J, Jacobsson U, Bauwens J, Richter S, Wellum R, Aregbe Y (2010) An inter-calibration campaign using various selected Pu spike isotopic reference materials. J Radioanal Nucl Chem 286:449–454

OIML R111-1 (2004) Weights of classes E1, E2, F1, F2, M1, M1-2, M2, M2-3 and M3, Part 1: Metrological and technical requirements. International Organisation of Legal Metrology, Paris

Morgenstern A, Apostolidis C, Carlos-Marquez R, Mayer K, Molinet R (2002) Single-column extraction chromatographic separation of U, Pu, Np and Am. Radiochim Acta 90:81–85

Kazi ZH, Cornett JR, Zhao X, Kieser L (2014) Americium and plutonium separation by extraction chromatography for determination by accelerator mass spectrometry. Anal Chim Acta 829:75–80

Callis EL, Abernathey RM (1991) High precision isotopic analysis of uranium and plutonium by total sample volatilization and signal integration. Int J Mass Spectrom Ion Process 103:322–327

Bürger S, Balsley SD, Baumann SD, Boulyga SF, Cunningham JA, Kappel S, Kopft A, Poths J (2012) Uranium and plutonium analysis of nuclear material samples by multi-collector thermal ionisation mass spectrometry: quality control, measurement uncertainty, and metrological traceability. Int J Mass Spectrom 311:40–50

Boulyga S, Konnegger-Kappel S, Richter S, Sangley L (2015) Mass spectrometry analysis for nuclear safeguards. J Anal At Spectrom 30:1469–1489

C1672-17 Standard Test Method for Determination of Uranium or Plutonium Isotopic Composition or Concentration by the Total Evaporation Method Using a Thermal Ionization Mass Spectrometer, ASTM International

Quemet A, Ruas A, Dalier V, Rivier C (2018) Americium isotope analysis by thermal ionisation mass spectrometry using the total evaporation method. Int J Mass Spectrom 431:8–14

Lide DR (1992) Ionization potentials of atoms and atomic ions. In: Handb. Chem Phys 10–211

Pommé S, Sibbens G (2008) Alpha-particle counting and Spectrometry in a primary Standardisation laboratory. Acta Chim Slov 52:111–119

Pommé S, Marroyo BC (2015) Improved peak shape fitting in alpha spectra. Appl Radiat Isotopes 96:148–153

Pommé S (2015) Typical uncertainties in alpha-particle spectrometry. Metrologia 52:S146–S155

Pommé S (2015) The uncertainty of counting at a defined solid angle. Metrologia 52:S73–S85

Hult M, Preusse W, Gasparro J, Kohler M (2006) Underground gamma-ray Spectrometry. Acta Chim Slov 53:1–7

Hult M (2007) Low-level gamma-ray spectrometry using Ge-detectors. Metrologia 44/4, S87-S94, Erratum at Metrologia 44/5, 425

Kawrakow I, Rogers DWO (2003) PIRS-701: the EGSnrc code system: Monte Carlo simulation of Electron and Photon Transport: Ionizing Radiation Standards. NRC, Otawa, Ontario

Wang M, Audi G, Wapstra AH, Kondev FG, MacCormick M, Xu X, Pfeiffer B (2012) The AME2012 atomic mass evaluation (II). Tables Gr Ref Chin Phys C 36:1603–2014

ISO, IEC 98–3 (2016) Guide to the expression of uncertainty in Measurement (GUM 1995). International Organisation for Standardisation, Geneva

MetroData GmbH, GUM Workbench Version 2.4: Software Package for the Evaluation of Uncertainty. http://www.metrodata.de

Pommé S, Keightley J (2015) Determination of a reference value and its uncertainty through a power-moderated mean. Metrologia 52:S200–S212

ISO13528 (2015) Statistical methods for use in proficiency testing by interlaboratory comparison. International Organisation for Standardisation, Geneva

Acknowledgements

The authors would like to thank Carmel Hennessy, Frances Kehoe and Saskia Werelds from the JRC-Geel for support in the preparation of the reference material and Monika Sturm from the IAEA Safeguards Analytical Service for support in separation chemistry, Am mass spectrometry, and sharing her experience about the use of a 241Pu/241Am spike from the feasibility study. The authors would also like to thank the Laboratory for target preparation at JRC-Geel for providing the 241Pu source material and Roger Wellum for the review of this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jakopič, R., Fankhauser, A., Aregbe, Y. et al. 243Am certified reference material for mass spectrometry. J Radioanal Nucl Chem 327, 495–504 (2021). https://doi.org/10.1007/s10967-020-07521-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-020-07521-x