Abstract

Polymer nanocomposites exhibit unique physical properties inaccessible from their individual constituents, which are tunable through the type of the polymer matrix, the type and size of the incorporated nanoparticles, and the doping level, and therefore, can be utilized in a wide range of potential applications. Here, we report the fabrication of pure Polyvinyl chloride (PVC) and PVC-based nanocomposites containing different loadings of pure and Cr-doped ZnO nanoparticles, using solvent casting method. Scanning electron microscopy images of the obtained nanocomposite films confirmed the successful incorporation of nanoparticles within the PVC matrix, with higher dispersion quality for the Cr-doped ZnO samples. The prepared nanocomposite samples were found to possess higher thermo-mechanical stability, compared to pure PVC, resulting from the strong interaction between the nanoparticles and polymeric chains, as inferred from their thermogravimetric and dynamic mechanical analysis (TGA and DMA) profiles. Specifically, the temperatures corresponding to the onset and 50% weight loss as well as the glass transition temperature are increased by ~ 88, ~ 34, and ~ 16 °C, respectively, after loading selected amounts of the nanoparticles. In addition to the thermo-mechanical stability, the nanocomposites revealed potentially relevant dielectric response, where the dielectric permittivity exhibits remarkable enhancement, by 400%, compared to pristine PVC. The optical transmission of the PVC is strongly suppressed over the entire visible spectral regime, upon loading the nanoparticles, and its optical band gap (~ 4.1 eV) is red shifted toward the value of pristine ZnO nanoparticles (~ 3.3 eV), while the distinct Cr3+ and Cr6+ optical transitions are preserved for the nanocomposites. The obtained thermo-mechanical stability, required for working devices, together with the here reported improvements in the dielectric response for the nanocomposite samples may alter the typical applications of PVC polymers from being insulating materials to be utilized in energy storage and capacitors manufacture, while the preserved optical properties of the incorporated nanoparticles render these nanocomposites suitable candidates for optoelectronic devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nanoparticles have attracted much attention because of their potential applications in many fields including optics, electronics, magnetism, ceramics, and catalysis [1,2,3,4,5,6,7,8,9,10,11,12,13]. For instance, they can be used as efficient and stable photocatalysts for wastewater treatment [14,15,16], as active materials to enhance the efficiency of solar cells [17, 18]. The nanomaterials can be widely classified as metals [1,2,3,4,5,6], non-metal ceramics [7,8,9], or semiconductors [10,11,12,13,14,15,16,17,18,19,20,21]. Semiconductor nanoparticles, in particular, have gained more attention over the past few years because of their novel and tunable optical and electrical properties originating from quantum confinement [12]. For example, the optical band gap can be finely tuned over the entire visible [22,23,24] and infrared spectral regimes [25,26,27] depending on the type and size of these nanoparticles. Among the most applicable semiconductors, it comes Zinc Oxide (ZnO) with its wide band gap (~ 3.3 eV), relatively large exciton binding energy (∼60 meV) [13, 14], high conductivity [20, 21], and its ability to host different transition metals (TMs) dopants [28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48]. Earlier literature showed that the doping process can potentially alter the electrical and optical properties of ZnO nanoparticles, thereby offering an interesting category of materials for wide range of applications such as photocatalysis [28,29,30], ultraviolet (UV) light emitters [31], piezoelectric devices [32, 33], ceramics [34], spintronics [35], solar cells [36] and optoelectronic devices [37]. Several TM dopants, such as Ag, Cr, Co, Ni, Fe, and Mn were utilized to modify the properties of ZnO nanoparticles [29, 30, 42]. Among these TM metals, Cr dopants showed improved optical and magnetic properties without noticeably affecting the crystal structure of the ZnO host over a wide range of dopant concentrations [46,47,48]. While relatively low Cr concentrations do not practically alter the optical band gap of pristine ZnO nanoparticles, distinct optical transition solely stemming from Cr3+ and Cr6+ oxidation states were identified near the ZnO absorption edge [48]. Their identification allowed us to precisely determinate the optical band gap and to claim an almost doping-independent optical band-gap behavior contrasting the largely underestimated band gap reported for Cr-doped semiconductors and glasses in earlier literature [48].

Despite the unique optical and electrical properties offered by pristine and doped semiconductor quantum dots, they are often synthesized in powder or colloidal forms, which are not readily suitable product for several applications. In order to maximize the benefits of the remarkable properties of these nanostructures, they can be incorporated within some applicable polymeric materials that are utilized in many engineering applications such as Polyvinyl alcohol (PVA), polyvinyl chloride (PVC), Polymethyl methacrylate (PMMA), Polyethylene (PE), polyimid (PI), Polyurethane (PU), etc. [43, 49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74], leading to nanocomposite materials class. At the one hand, the loading of nanoparticles into such polymeric fabrics drastically alters the properties of the polymers themselves and, on the other hand, the polymer passivates and protects the nanoparticles against external influences. Furthermore, superior properties resulting from incorporating these nanomaterials into polymers can emerge due to the strong interfacial interaction between the inserted nanoparticles and the polymeric chains, provided that a well-controlled synthetic routine is followed in the preparation of these nanocomposites [49,50,51,52,53,54,55,56,57,58,59]. For example, the enhancement in thermal and electrical conductivity as well as the magnetic and mechanical properties of polymer nanocomposites compared to their original unfilled polymer make them useful in different fields such as solar cells, electrical insulators, electromagnetic interference shielding, thermal management, sensors, flame retardancy, and biomedical applications [43, 61,62,63,64,65,66,67,68,69,70,71,72,73,74]. While several studies explored the effect of insertion of ZnO nanoparticles within PVC matrix and showed noticeable improvements in the structural, mechanical, electrical, and thermal properties of PVC [53,54,55,56,57], only few articles were devoted to studying the effect of “metal-doped” ZnO nanoparticles on engineering the properties of such polymers [58, 60]. Indeed, when TM-doped ZnO nanoparticles are incorporated in polymers, they also improve their mechanical, thermal, and optical properties due to their high interfacial interaction between the organic moieties and inorganic nanoparticles [58].

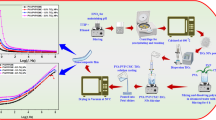

In this work, we provide the first utilization of PVC as a host polymer for our previously prepared pure and Cr-doped ZnO nanomaterials that were proven to exhibit good optical and physical properties [48]. The choice of PVC as a matrix in our novel nanocomposites is because it is one of the largest commercially used polymers, and it has wide range of applications such as microwave absorber, light emitting diode, antibacterial activity, solar cell, and gas sensors [58, 60]. Consequently, the obtained PVC nanocomposites with pure ZnO and Cr-doped nanoparticles could enhance the optical, electronic, mechanical, and structural properties compared to the pure PVC, thereby opening the door for numerous applications in coating, photocatalysis, energy storage, and optoelectronic applications [28,29,30,31,32,33,34,35,36,37]. The here explored nanocomposite samples were produced utilizing the solvent casting method. Several samples of PVC nanocomposites with different amounts of loaded pure and Cr-doped ZnO nanoparticles were prepared, and the obtained polymeric films were thoroughly characterized by different complementary techniques to explore the effect of the inserted nanostructures. We revealed that the incorporation of nanoparticles within PVC strongly enhances the thermo-mechanical stability and the dielectric response of the nanocomposites, while the optical properties of the ZnO and Cr-doped ZnO nanoparticles remain practically unaltered after loading.

2 Experimental section

The aim of this work is to investigate the effect of incorporating ZnO and Cr-doped ZnO nanoparticles on the thermal, electrical, mechanical, and optical properties of PVC. Therefore, following a good preparation method results in better judgment and improvement. Preparation of nanocomposites can be considered as an optimization process that aims to decide the suitable weight fraction of nanoparticles and other additives that exhibit maximum percentage enhancement in the considered properties. The preparation methods followed in this study were explained in details in this section, followed by describing the characterization techniques that are used in order to elucidate the structure of the prepared samples and to guarantee a good distribution of nanoparticles inside the chains of polymer matrix. Finally, the specifications of the experimental techniques which we utilized to investigate the physical properties of interest were given.

2.1 Materials

In this study, PVC nanocomposites containing different loadings and different types of ZnO nanoparticles were prepared using a pure PVC, and the pre-prepared and characterized Crx Zn(1−x) O], (where x = 0%, 1%, and 3%) nanoparticles [48]. The chemical reagents used for preparing ZnO-based nanoparticles, and their Cr-doped counterparts were as follows: Zinc acetate dehydrates with 98% purity, Chromium (III) chloride hexahydrate with 93% purity, and Sodium hydroxide with 93% purity purchased from LOBA Chemie. However, the reagents needed for preparing PVC nanocomposites samples were powdered PVC with > 99.5% purity and cyclohexanone with 99% purity, purchased from Sigma Aldrich and Merck, respectively.

2.2 Preparation of ZnO and Cr-doped ZnO nanoparticles

As reported in our previous work [48], Cr-doped ZnO, [Crx Zn(1−x) O] samples (x = 0 wt%, 1.0 wt%, and 3.0 wt%) were prepared by utilizing the conventional co-precipitation method in which a homogenous mixture of different amounts of CrCl3.6H2O and excess Zinc acetate was pipetted with NaOH solution, and its resulted solution was kept under continuous stirring for 3 h at room temperature (RT). Cr-doped ZnO precipitates were obtained, and they were filtered out, then washed thoroughly with ethanol and distilled water to eliminate any chemical residuals. The collected cleaned powders were eventually oven dried at 70 °C for 3–4 h, then they were softly annealed to 400 °C for 24 h to ensure good crystallinity of the formed nanoparticles. Another sample was prepared without adding CrCl3.6H2O to obtain pure ZnO nanoparticles. The crystalline structure and nanoparticle size of these samples were examined and reported elsewhere [48].

2.3 Preparation of Cr-doped ZnO/PVC nanocomposites

The approach presented in this study to prepare PVC nanocomposites with different types and different loadings of ZnO-based nanoparticles through solution casting method is the same approach presented elsewhere [66,67,68,69,70,71,72]. Three sets of PVC nanocomposites were prepared with three different concentrations of nanoparticles for each set: 1.0, 3.0, and 5.0 wt% of ZnO, 0.01 Cr-ZnO, and of 0.03 Cr-ZnO nanoparticles. The preparation method has been performed by suspending suitable amount of nano-powder in enough quantity of cyclohexanone using Elmasonic water bath sonicator at 30 °C for 10 min. This suspension was added into appropriate amount of PVC dissolved previously in cyclohexanone at 80 °C, and the mixture was mechanically stirred at the same temperature for 30 min. Then, the molten mixture was subjected to vigorous mixing using a suitable homogenizer. Hence, all of these sonication cycles used to guarantee an excellent dispersion of the nanoparticles within the polymer chains. The final mixture was then poured into an evaporating dish and kept at room temperature for 48 h for solvent evaporation. A neat PVC polymeric sample was also prepared by the same routine to be used as a reference. All polymeric samples were then annealed in an evacuated oven at 60 °C for 24 h, and all samples were kept under vacuum prior to characterization.

2.4 Characterization techniques

Investigation of all prepared samples by various techniques such as FT-IR, SEM, TGA, DMA, optical, and dielectric relaxation spectroscopy (DRS) were performed to elucidate their structures, and to guarantee a good dispersion of nanoparticles inside the chains of polymer matrix, or to explore the effect of incorporating ZnO or their Cr-doped nanoparticles on the thermal, dielectric, and mechanical properties of PVC. The pure PVC sample was also characterized by these selected techniques to be used as a reference upon determining the enhancement percentage in these measured properties. The obtained thermal, mechanical, electrical, and optical properties of pure PVC sample were in consistent with their previously reported equivalent values [53,54,55,56,57,58].

2.4.1 FT-IR spectroscopy

The structures of some selected polymeric samples were elucidated through recording their infrared spectra using a Thermo Scientific spectrometer with a wavenumber range of 400–4000 cm−1. The samples being examined using this technique were neat PVC and two different PVC nanocomposites with 1.0 wt% of ZnO and Cr-doped ZnO nanoparticles.

2.4.2 FE-SEM of micrographs

The phase morphology of nanocomposites particles in PVC matrix films was studied using scanning electron microscopy (SEM) in order to investigate the distribution of nanoparticles within the polymeric matrix which in turn affects their thermal, mechanical, and electrical properties. Four polymeric films with different loading of ZnO nanoparticles and their Cr-doped counterparts were tested by FE-SEM of type Quanta FEG-250 (FEI-Inc.) that operated at 10–30 kV, and with carbon fibers used to coat the fractured surfaces.

2.4.3 Thermogravimetric analysis (TGA)

The thermal stability of three different powdered nanoparticles, and seven different polymeric films with different types and loadings of nanoparticles was evaluated using TGA technique (SDT-Q600 TA instrument). In this test, the weight changes in well dried materials were monitored as a function of temperature under a controlled nitrogen atmosphere using an average of 10 mg samples analyzed in platinum pans over the temperature range of 25–1000 °C, and at a heating rate of 10 °C/min.

2.4.4 Dielectric properties for the polymeric films

For each prepared polymeric sample, the relative permittivity (εr) and the dissipation factor (tan δ) were estimated using Agilent E4980A precision LCR meter, and based on ASTMD-149-09 [75]. The tested sample resistance (Rp) and capacitance (Cp), in equivalent parallel model, were measured to calculate the values of εr and tan δ from the following equations [76].

where the dielectric constant and dielectric loss of the tested sample are ε′ and ε′′, respectively. The thickness of the tested sample is \(d\) and the electrode cross-sectional area of the test cell is\(A\). The permittivity of free space is εo = 8.85 × 10−12 F/m, and f is the frequency. The dielectric properties were measured along a frequency range between 20 Hz and 1.0 MHz, and the configuration of testing electrodes is described in [72]. The expression of relative permittivity, εr, of dielectric material refers directly to its ability to get polarized under the effect of applied electric field, while the dissipation factor of the dielectric material (tan δ) refers to the ratio between the dissipated energy and the stored energy inside it, whereas the angle δ represents the delaying between the change in the electric field and the change in the dielectric polarization.

2.4.5 Dynamic mechanical analysis (DMA)

In order to investigate the effect of ZnO nanoparticles and its Cr-doped ZnO counterparts on the mechanical behavior of PVC, as well as to obtain information about any possible phase transition that would be taken place in the resultant PVC networks, dynamic mechanical analysis of three polymeric samples was performed: pure PVC, PVC nanocomposites with 3.0 wt% ZnO, and 3.0 wt% 0.03Cr-doped ZnO nanoparticles. The measurements were performed using a Triton Technology instrument, TTDMA, and over a temperature range from − 50 to 100 °C, and with a heating rate of 5 °C/min. According to ASTM D-4065, rectangular samples (10 × 10.6 mm) were examined under nitrogen gas by tensile mode, and at a frequency of 1.0 Hz and with constant strain amplitude of 0.01 mm. The mechanical parameters: storage modulus E′, loss modulus E′′, and loss tangent (tan δ = E″/ Ε′) are evaluated as a function of temperature.

2.4.6 Optical properties for the polymeric films

Optical properties for pure PVC, and two nanocomposites with the same loading content (3.0 wt%) but different types of nanoparticles: ZnO and 0.03Cr-ZnO, were studied. The absorbance and transmittance spectra of these selected samples were recorded in the wavelength range 200–800 nm using JASCO V-650 spectrophotometer.

3 Results and discussion

3.1 FT-IR of polymeric films

It has been demonstrated that the FT-IR spectroscopy is an effective method for elucidating the structure of a material. Figure 1 shows the FT-IR spectra of three selected samples. These are neat PVC (black) and PVC nanocomposites loaded with 1.0 wt% of ZnO (blue) and 1.0 wt% 0.01Cr-doped ZnO nanoparticles (red). The samples display similar spectra consisting of several vibrational peaks indicated by the vertical dashed lines. The two absorption peaks at 2855 and 2920 cm−1 are assigned for the C–H stretching mode in CH and CH2 of PVC, while the two peaks observed at 1335and 1425 cm−1 correspond to the C–H aliphatic bending vibrations, although the peak at 1335 cm−1 as well as the peak at 1705 cm−1, observed well in nanocomposite samples, and this may be attributed to the bending O–H bond that is resulted from the complexation between PVC and the embedded nanoparticles [55]. The peak at 1000–1100 cm−1 corresponds to the C–C stretch bond of the PVC backbone chain, and the absorption peak at 1250 cm−1 is attributed to the bending bond of C–H near Cl. Finally, the absorption bands at 680 cm−1 is due to the C–Cl gauche bond which is overlapped with the Zn–O stretching band that should appear in the PVC nanocomposites samples containing ZnO or its Cr-doped counterpart [53,54,55,56,57, 77, 78].

3.2 Surface morphology of nanocomposites films (SEM)

While the FT-IR spectra just discussed revealed the characteristic structural groups of PVC, vibrational modes resulting from the loaded nanoparticles could not be unambiguously identified due to their overlap with PVC bands. In order to justify the successful incorporation of pure and Cr-doped ZnO nanoparticles and to fully examine their dispersion quality within the polymeric PVC chains, FE-SEM micrographs of cross-sectional fracture were taken for the PVC nanocomposite samples containing 1.0 wt% of ZnO and 0.01Cr-ZnO nanoparticles, and the data obtained are shown in Fig. 2. These SEM micrographs (a, b) together with the corresponding-colored quasi-3D plots (lower panels) confirmed the embedding of nanoparticles within the polymeric matrix which are better distributed in the case of Cr-doped ZnO nanoparticles (b) compared to pure ZnO nanoparticles (a) which appear as larger bright dots.

3.3 TGA of powdered nanoparticles and nanocomposites films

For most of practical applications and devices, the thermal stability is a fundamental prerequisite, which for polymeric materials can be largely enhanced upon the insertion of nanoparticles [77,78,79,80,81,82]. Therefore, this section explores the thermal response of our prepared samples, namely the pure and Cr-doped ZnO powder nanoparticles and the corresponding nanocomposites films. The measurement of the weight loss of samples upon heating using this technique was performed in inert atmosphere (under a flow of nitrogen gas) to avoid any oxidation could be taken place upon the thermal treatment of the tested samples which in turn affects their weight loss [83].

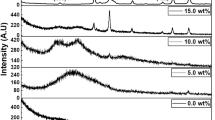

The thermal decomposition profiles of the powdered nanoparticles (ZnO, 0.01 Cr-doped ZnO, and 0.03Cr-doped ZnO) are shown in Fig. 3. The profiles exhibit a minimal weight loss in all samples (≤ 1.0%) up to 200 °C, which is attributed to the evaporation of adsorbed water molecules. This loss value is barely increased upon heating the sample up to 600 °C, due to the thermal decomposition of some residual organic species in the samples [77]. Compared to pristine ZnO nanoparticles, a significant weight loss, exceeding 3.0 wt% above 800 °C (see inset), is noticed for the Cr-doped ZnO samples, which could be attributed to the weakness of the chemical linkage between Cr ions and ZnO at such high temperatures. For the neat PVC and the nanocomposite samples containing different types and loadings of nanoparticles, shown in the same figure, the thermographs showed that the thermal decomposition behavior of all samples is similar, and it has taken place in three stages as reported for many PVC containing inorganic fillers [53,54,55,56,57,58]. The first stage identifies losses taking place at temperatures below 200 °C, which corresponds to the evaporation of either water molecules or volatile solvent in the samples. The other weight loss regime observed at 300–450 °C corresponds to the degradation of some organic moieties of the polymeric materials. The third loss in these polymeric samples shows up at temperatures beyond 450 °C, at which the nanocomposite samples lose most polymeric constituents, while the constituting nanomaterials remain without experiencing any practical heat effect at this temperature zone as they do in their pure profiles (inset of Fig. 3). The here reported enhancement of the thermal decomposition of the nanocomposite samples compared to pure PVC originates from the strong interaction between the polymeric chains and the nanomaterials that behave as cross-linkers joining the polymeric chains, especially, at the interface [77,78,79,80,81]. Furthermore, the thermal stability for the powdered Cr-doped ZnO nanoparticles recorded the highest thermal stability among all PVC nanocomposite samples, which reveals that these kinds of nanostructures are very utilizable in enhancing the thermal stability of polymeric materials. This behavior is consistent with literature regarding the dependence of the thermal properties of the polymer composites on the type, size, loading, distribution, and the interaction between the nanoparticles and the polymer chains [82].

To quantify the improvement of thermal stability, two characteristic parameters of the TGA curves are extracted, namely Tonset and T50%, which are the decomposition temperatures corresponding to 10% and 50% weight losses, respectively. The values of these two relevant parameters are listed in Table 1 for all investigated samples, and the extracted numbers suggest that both ZnO and Cr-ZnO nanostructures delay the thermal decomposition of PVC, as they link their chains in the same manner that the cross-linkers do [83,84,85]. Beyond T0.5%, the temperature at which 50 wt% loss occurs, degradation rapidly takes place [85]. One key aspect of the enhancement in thermal stability of any engineering materials is the shift of the thermal degradation onset temperature to the higher values compared to the pure host matrix, which in the present nanocomposite samples revealed an increase of ~ 40–50 °C upon inserting 1.0 wt% of ZnO (doped or undoped), and about 60–90 °C upon inserting 3.0 wt% of these nanoparticles. Such a substantial improvement is reported in several published articles, however, not often associated with enhancement in the mechanical performance as well. In this work, the improved thermal stability of the nanocomposite samples is accompanied with an increase in glass transition temperature (Tg) which reveals a strong interfacial interaction between the polymeric matrix and the nanoparticles as will be shown in Sect. 3.5 [79].

3.4 Dielectric properties of polymeric samples

The dielectric response of certain materials could be determined by studying the variation of the dielectric parameters (εr and tan δ) with frequency at fixed or different temperatures. Here, εr and tan δ are measured at room temperature for all prepared nanocomposite samples in the frequency range from 20 Hz to 1.0 MHz. The two parameters, also measured for the neat PVC sample under the same conditions, serve as a reference when monitoring the effect, the type and loading of nanomaterials have on the dielectric properties of PVC. Figure 4 shows the dependence of εr on the frequency for all investigated samples. It is clear that εr for all samples showed a common decreasing behavior with increasing the applied frequency, because dipoles in the polymeric chains have less ability for orientation along the direction of applied field [86,87,88,89,90,91]. In other words, upon the effect of an alternating electric field, a material with different dielectric permittivity, such as our polymeric nanocomposites based on undoped or Cr-doped ZnO nanoparticles, the charges in the form of dipoles or defects are distributed at the interface between the polymer and the nanoparticles, producing interfacial polarization along with the dipole polarization. The directions of both polarizations are constantly changing with changing the frequency of the electric field. Therefore, with increasing the speed of the alternating electric field (i.e., at high frequency), the polarization state takes a period of time to be followed up, and dielectric relaxation and energy loss will occur [91]. Such behavior is considered as the normal response of dielectric materials, and results from the reduction in the contribution of the orientation polarization by the increasing frequency [66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83, 92].

Dielectric permittivity of a material is a critical parameter that determines its ability to store electrical energy, low permittivity materials are used as electrical insulators and in high-speed integrated circuits, however, high-permittivity materials are used in transistors, capacitors, and/or supercapacitors [93]. These might be affected by the type and concentration of the loaded nanoparticles within the polymeric materials [94]. Herein, the variation of εr with both the type and concentration of pure and Cr-doped ZnO nanoparticles is shown in Fig. 4d, where εr clearly increases with the concentration of incorporated nanoparticle due to the surface charge polarization effect. This reveals that the nanostructures that act as impurities that capture the surface electrons at their interface with polymer, causing an increase in surface charge polarization [89]. The increasing in percentage in εr values for our PVC/ZnO nanocomposites compared to pure PVC, tabulated in Table 2, showed that εr is increased approximately by 400% for the sample containing 1.0 wt% ZnO nanoparticles. This strong enhancement of εr attenuates upon using other type or concentrations of the incorporated nanoparticles, since it was reduced to 300% and 200% for 1.0 wt% (0.03Cr-doped ZnO) and 3.0 wt% (0.01Cr-doped ZnO) nanoparticles, respectively. The here reported permittivity enhancement contrasts previous studies that revealed a decrease in εr upon filling PVC with less than 1.0 wt% ZnO nanoparticles, reflecting an enhancement in PVC electrical insulation due to the restriction of PVC chains [95]. However, the contradictory increase in permittivity reported in our systems at higher concentrations of incorporated nanoparticles should likely alter the typical applications of this polymer from being an insulating material to be used in energy storage and in capacitors manufacture. This conclusion is practically valid provided that the loss factors in these nanocomposites have very low values, which is the case here as will be noticed upon discussing the data of the dielectric loss factor, tan δ.

The reduction in permittivity enhancement in case of Cr-doped ZnO nanoparticles over that in case of undoped ZnO was explained in a reported study for ZnO nanoparticles doped with either Co [19] or Ni [96], and reduction in permittivity was attributed, for these two systems, to the strong interaction between localized electrons (d-type) of transition metals and delocalized electrons (s- or p-type band of Zn and O atoms, respectively) Such s, p-d exchange interaction was explained in basis of band gap changes which is in a direct correlation with the dielectric properties of a material.

The measured variations in loss factor (tan δ) with frequency at room temperature, displayed in Fig. 5, exhibit very small variation, especially at high frequency, among the entire investigated samples [Δ(tan δ)min] ~ 0.019]. This little increment in tan δ of PVC nanocomposites samples with ZnO nanoparticles and Cr-doped ZnO nanoparticles compared to the unfilled PVC could be attributed to the highest level of charge delocalization which causes an additional contribution to the dielectrics [87,88,89]. Moreover, our investigated samples did not display any relaxation in the higher frequency region, which occurs when the frequency of the applied AC field and the frequency of migrating the localized electric charge carriers are approximately equal. Furthermore, it is also noticeable for all samples that tan δ decreases with increasing the applied frequency because of the space charge polarization effect discussed above. The reported low values of the loss factor at high frequencies demonstrates the capability of our nanocomposite systems to be used in high frequency device applications [66,67,68,69,70,71,72].

3.5 Mechanical performance of some polymeric films

Dynamic Mechanical Analysis (DMA) is a technique often used to study the viscoelastic behavior of polymeric materials by applying a sinusoidal force (stress) to the examined sample and, from the measured resulting displacement (strain), the complex modulus (E*) can be determined based on the following equation [97]:

where E′ and E″ are the storage and loss moduli, respectively. The real part E′ is a measure of the energy stored elastically in a substance during deformation under the effect of an applied force, while the imaginary term E″ measures the energy dissipated as heat [95].

Figure 6 shows the dynamic storage modulus (E′) vs. temperature curves (solid lines) for selected samples: pure PVC, and two nanocomposites with the same loading content (3.0 wt%) but different types of nanoparticles; ZnO and 0.03Cr-ZnO. As seen in this figure, all samples exhibit the typical behavior of viscoelastic materials, i.e., glassy at low temperatures and rubbery at high temperatures, whereas E′ in the glassy region is nearly constant because the dynamics of the system are largely restricted to molecular vibrations and short-range rotational motions [95, 98]. However, going from the glassy region to the glass transition region (approximately around 50 °C), E′ drops due to the long-range molecular motion associated with the progressive material softening taking place in this region. For the selected investigated samples, the values of E′ for the nanocomposite containing 0.03Cr-doped ZnO nanoparticles are higher than those of the nanocomposite containing the same concentration of pristine ZnO or the pure PVC polymeric sample. This may be attributed to the increase in the restriction of the PVC chains by the action of the highly dispersed Cr-doped ZnO nanoparticles within the PVC chains (see SEM micrograph in Fig. 2b).

Figure 6 also shows the dependence of loss tangent (tan δ) on the temperature (dashed lines) for the same selected samples, where δ represents the phase lag of strain with respect to the stress, and it lies between 0o for a perfectly elastic material and 90o for a totally viscous one. Viscoelastic materials, such as our samples, exhibit behavior somewhere in between these two extremes (0o < δ < 90o) during the mechanical analysis [99]. This thermo-mechanical parameter, tan δ, is very important investigation for any applicable polymeric material since it helps to locate the glass transition temperature, Tg, of the examined material, and to identify any phase transition corresponding to other molecular motions [99]. As shown in Fig. 6, Tg is defined as the temperature corresponding to the highest values of tan δ, and this phase-dependence temperature is here found to be highly dependent on the type of nanostructure. For pure PVC, Tg takes a value of ~ 30 °C, and progressively shifts toward the higher temperature for the nanocomposites containing ZnO (Tg ~ 40 °C), and Cr-doped ZnO nanoparticles (Tg ~ 45 °C) [100]. This observation is in contrast to that reported by Duan et al. upon adding benzyl(4-fuorophenyl) phenyl phosphine oxide (BFPPO) to the epoxy resin causing a shift of Tg toward lower temperature, and this was attributed to the decrease in crosslinking density caused by the addition of BFPPO [101].

The shift of Tg toward higher temperature upon adding ZnO nanoparticles to PVC is in agreement with the thermal behavior observed in TGA thermographs, which confirmed that the PVC chains confinement are stronger for the sample containing 0.03Cr-doped ZnO nanoparticles compared to pure PVC or the nanocomposite sample of the same concentration of ZnO nanoparticles.

To conclude, the obtained DMA data showed better mechanical performance for the nanocomposite with Cr-doped ZnO nanoparticles, thereby assuring that incorporating this kind of nanostructures to our samples resulted in a good nanoparticles dispersion within the PVC matrix, which in turn led to a good interfacial adhesion between the polymer and the selected nanoparticles.

3.6 Optical properties of some polymeric samples

The incorporation of nanoparticles into transparent polymer matrices is expected to affect their optical response in various ways, despite the nanoparticle’s dimensions are typically much smaller than the light wavelength. The optical homogeneity and transparency of the nanocomposite demand high dispersion quality of the nanoparticles within the polymeric matrix and reduced aggregation that may causes light scattering phenomena [79].

Figure 7a presents the optical transmittance spectra for pristine PVC (black) and selected nanocomposite samples containing pure (blue) and Cr-doped (red) ZnO nanoparticles. The incorporation of nanoparticles clearly suppresses the transmittance at the entire visible wavelength compared to pure PVC. The optical transmission is further reduced for the Cr-doped ZnO nanocomposite in the wide wavelength range 400–700 nm, due to the optical transition from Cr3+ as indicated by the red arrow. For example, the optical transmission at 400 nm changes from ~ 68% for pure PVC to 18% and 3% for the pure and Cr-doped samples, respectively. In addition to this noticeable suppression of the transmitted light, onset of the transmission is red shifted for the nanocomposite samples reflecting a noticeable change in the optical band gap. The value of the band gap can be determined from the corresponding absorption spectra presented in Fig. 7b. The PVC absorption spectrum (black) is featureless and solely consists of a relatively broad absorption edge centered at ~ 300 nm, which corresponds to ~ 4.1 eV optical band-gap energy, consistent with the literature [56]. This absorption edge becomes sharper and noticeably shifts toward higher wavelengths for the nanocomposite samples, yielding optical band gap of 3.3 ± 0.1 eV, agreeing with the reported values for bulk and relatively large nanoparticles of ZnO [102]. The optical band gap determined in Fig. 7b is defined at the inflection point of the edge-like feature in the absorption spectra, as indicated by the vertical dashed arrows. An alternative and widely used method for the extraction of the band gap is the Tauc plot presented in Fig. 7c. By extrapolating the linear part of (αhν)2 vs. hν to zero (see dashed lines), the band gap is defined at the position indicated by the colored circles. The band-gap values obtained following this method agree with the previous estimation and assure the precise determination of the band-gap energy. The Cr-doped ZnO nanocomposite sample (red) additionally exhibits sharp and broad features at ~ 370 nm and ~ 600 nm (see inset in Fig. 7b), which can be assigned to optical transitions from Cr6+ and Cr3+, respectively [103]. It should be noted that the optical absorption spectra of the nanocomposites are practically identical to the corresponding spectra for the powdered ZnO and Cr-doped ZnO nanoparticles reported earlier [48], i.e., before incorporation in PVC, suggesting the utilization of PVC as a convenient host that conserves the optical properties of the incorporated nanoparticles.

Transmittance (a) and absorbance (b) spectra and the corresponding Tauc’s plots (c) of PVC and selected polymeric nanocomposites containing 3.0 wt% of ZnO and 0.03Cr-ZnO nanoparticles. The Cr3+ optical transition is indicated by the solid red arrow (see inset), and the band gaps are marked by the vertical dashed arrows in (b) and by colored circles in (c) (Color figure online)

4 Conclusion

Polymer nanocomposite samples consisting of PVC, as the host matrix, and different amounts of loaded ZnO and Cr-doped ZnO nanoparticles were prepared following the standard solvent casting method. The successful incorporation of nanoparticles within the polymer matrix was ensured from SEM images, and the dispersion quality was better for the Cr-doped ZnO nanocomposites. The thermal, mechanical, electrical, and optical properties of these nanocomposite were thoroughly explored and compared to pure PVC. The thermo-mechanical stability of the prepared nanocomposites noticeably exceeded the pristine PVC, where the combined TGA and MDA analysis revealed weight losses and glass transition temperatures shifted toward higher values than PVC. Importantly, the dielectric primitivity of the nanocomposites is strongly enhanced (by ~ 400%), a finding that may overturns the conventional applications of PVC polymers as insulating materials toward possible utilization in energy storage and capacitors manufactures. Additionally, the optical properties of the prepared nanocomposites were found to be solely determined by the incorporated nanoparticles, rendering these materials equally suitable for optoelectronic devices operating at tunable optical spectral regime, depending on the type, size, and doping level of the loaded quantum dots.

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

C.R. Rao, G.U. Kulkarni, P.J. Thomas, P.P. Edwards, Metal nanoparticles and their assemblies. Chem. Soc. Rev. 29(1), 27–35 (2000). https://doi.org/10.1039/A904518J

T. Song, F. Gao, S. Guo, Y. Zhang, S. Li, H. You, Y. Du, A review of the role and mechanism of surfactants in the morphology control of metal nanoparticles. Nanoscale 13(7), 3895–3910 (2021). https://doi.org/10.1039/D0NR07339C

Y. Cao, L. Xiao, M.L. Sushko, W. Wang, B. Schwenzer, J. Xiao, Z. Nie, L.V. Saraf, Z. Yang, J. Liu, Sodium ion insertion in hollow carbon nanowires for battery applications. Nano Lett. 7, 3783–3787 (2012). https://doi.org/10.1021/nl3016957

M.T. Siddiqui, S. Nizamuddin, H.A. Baloch, N.M. Mubarak, M. Al-Ali, S.A. Mazari, A.W. Bhutto, R. Abro, M. Srinivasan, G. Griffin, Fabrication of advance magnetic carbon nano-materials and their potential applications: a review. J. Environ. Chem. Eng. 7(1), 102812 (2019). https://doi.org/10.1016/j.jece.2018.102812

D. Pan, S. Wang, B. Zhao, M. Wu, H. Zhang, Y. Wang, Z. Jiao, Li storage properties of disordered graphene nanosheets. Chem. Mater 21(14), 3136–3142 (2009). https://doi.org/10.1021/cm900395k

N. Baig, I. Kammakakam, W. Falath, Nanomaterials: a review of synthesis methods, properties, recent progress, and challenges. Mater. Adv. 2(6), 1821–1871 (2021). https://doi.org/10.1039/D0MA00807A

Z. Chen, Z. Jiao, D. Pan, Z. Li, M. Wu, C.H. Shek, C.L. Wu, J.K. Lai, Recent advances in manganese oxide nanocrystals: fabrication, characterization, and microstructure. Chem. Rev. 112(7), 3833–3855 (2012). https://doi.org/10.1021/cr2004508

A. Chauhan, R. Verma, K.M. Batoo, S. Kumari, R. Kalia, R. Kumar, M. Hadi, E.H. Raslan, A. Imran, Structural and optical properties of copper oxide nanoparticles: a study of variation in structure and antibiotic activity. J. Mater. Res 36(7), ,1496-1509 (2021). https://doi.org/10.1557/s43578-021-00193-7

Y. He, A novel solid-stabilized emulsion approach to CuO nanostructured microspheres. Mater. Res. Bull. 42(1), 190–195 (2007). https://doi.org/10.1016/j.materresbull.2006.05.020

G.K. Dalapati, H. Sharma, A. Guchhait, N. Chakrabarty, P. Bamola, Q. Liu, G. Saianand, A.M. Sai Krishna, S. Mukhopadhyay, A. Dey, T.K. Wong, Tin oxide for optoelectronic, photovoltaic and energy storage devices: a review. J. Mater. Chem. A (2021). https://doi.org/10.1039/D1TA01291F

X. Li, Z. Lu, T. Wang, Self-assembly of semiconductor nanoparticles toward emergent behaviors on fluorescence. Nano Res. 14(5), 1233–1243 (2021). https://doi.org/10.1007/s12274-020-3140-y

A.D. Terna, E.E. Elemike, J.I. Mbonu, O.E. Osafile, R.O. Ezeani, The future of semiconductors nanoparticles: synthesis, properties and applications. Mater. Sci. Eng. B 272, 115363 (2021). https://doi.org/10.1016/j.mseb.2021.115363

Z.L. Pei, C. Sun, M.H. Tan, J.Q. Xiao, D.H. Guan, R.F. Huang, L.S. Wen, Optical and electrical properties of direct-current magnetron sputtered ZnO: Al films. J. Appl. Phys. 90(7), 3432–3436 (2001). https://doi.org/10.1063/1.1398070

E.Y. Shaba, J.O. Jacob, J.O. Tijani, M.A. Suleiman, A critical review of synthesis parameters affecting the properties of zinc oxide nanoparticle and its application in wastewater treatment. Appl. Wat Sci. 11(2), 1–41 (2021). https://doi.org/10.1007/s13201-021-01370-z

B. Jain, A. Hashmi, S. Sanwaria, A.K. Singh, M. Susan, A.B. Hasan, A. Singh, Zinc oxide nanoparticle incorporated on graphene oxide: an efficient and stable photocatalyst for water treatment through the Fenton process. Adv. Compos. Hybrid. Mater. 3(2), 231–242 (2020). https://doi.org/10.1007/s42114-020-00153-5

Z. Sun, Y. Zhang, S. Guo, J. Shi, C. Shi, K. Qu, H. Qi, Z. Huang, V. Murugadoss, M. Huang, Z. Guo, Confining FeNi nanoparticles in biomass-derived carbon for effectively photo-fenton catalytic reaction for polluted water treatment. Adv. Compos. Hybrid Mater. 5, 1566–1581 (2022). https://doi.org/10.1007/s42114-022-00477-4

N. Ibrayev, G. Omarova, E. Seliverstova, N. Nuraje, Plasmonic effect of Ag nanoparticles on polymethine dyes sensitized titanium dioxide. Eng. Sci. 14, 69–77 (2021). https://doi.org/10.30919/es8d1168

C. Qin, H. Gong, C. Sun, X. Wu, Optical properties of a core/shell/shell shape metal-insulator-metal composite nanoparticle for solar energy absorption. Eng. Sci. 17, 224–230 (2021). https://doi.org/10.30919/es8e509

C.K. Ghosh, K.K. Chattopadhyay, M.K. Mitra, Effect of Co doping on the static dielectric constant of ZnO nanoparticles. J. Appl. Phys 101(12), 124911–124920 (2007). https://doi.org/10.1063/1.2749481

Y. Xu, M. Goto, R. Kato, Y. Tanaka, Y. Kagawa, Thermal conductivity of ZnO thin film produced by reactive sputtering. J. Appl. Phys. 111(8), 084320 (2012). https://doi.org/10.1063/1.4706569

M. Maruthupandy, M. Anand, G. Maduraiveeran, S. Suresh, A.S. Beevi, R.J. Priya, Investigation on the electrical conductivity of ZnO nanoparticles-decorated bacterial nanowires. Adv. Nat. Sci.: Nanosci. Nanotecol 7(4), 045011 (2016). https://doi.org/10.1088/2043-6262/7/4/045011

M.B. Mohamed, D. Tonti, A. Al-Salman, A. Chemseddine, M. Chergu, Synthesis of high quality zinc blende CdSe nanocrystals. J. Phys. Chem. B 109(21), 10533 (2005). https://doi.org/10.1021/jp051123e

J.T. Siy, E.M. Brauser, M.H. Bartl, Low-temperature synthesis of CdSe nanocrystal quantum dots. Chem. Commun 47, 364 (2011). https://doi.org/10.1039/C0CC02304C

H. Zhao, F. Rosei, Colloidal quantum dots for solar technologies. Chem 3, 229 (2017). https://doi.org/10.1016/j.chempr.2017.07.007

M.A. Hines, G.D. Scholes, Colloidal PbS nanocrystals with size-tunable near‐infrared emission: observation of post‐synthesis self‐narrowing of the particle size distribution. Adv. Mater. 15(21), 1844 (2003). https://doi.org/10.1002/adma.200305395

I. Moreels, Y. Justo, B. De Geyter, K. Haustraete, J.C. Martins, Z. Hens, Size-tunable, bright, and stable PbS quantum dots: a surface chemistry study. ACS Nano 5(3), 2004 (2011). https://doi.org/10.1021/nn103050w

A.M. Smith, S. Nie, Bright and compact alloyed quantum dots with broadly tunable near-infrared absorption and fluorescence spectra through mercury cation exchange. J. Am. Chem. Soc. 133(1), 24 (2011). https://doi.org/10.1021/ja108482a

T.C. Bharat, S. Mondal, H.S. Gupta, P.K. Singh, A.K. Das, Synthesis of doped zinc oxide nanoparticles: a review. Mater. Today: Proc. 11, 767–775 (2019). https://doi.org/10.1016/j.matpr.2019.03.041

A.E. Ramírez, M. Montero-Muñoz, L.L. López, J.E. Ramos-Ibarra, J.A. Coaquira, B. Heinrichs, C.A. Páez, Significantly enhancement of sunlight photocatalytic performance of ZnO by doping with transition metal oxides. Sci. Rep. 11(1), 1–9 (2021). https://doi.org/10.1038/s41598-020-78568-9

M. Shkir, B. Palanivel, A. Khan, M. Kumar, J.H. Chang, A. Mani, S. AlFaify, Enhanced photocatalytic activities of facile auto-combustion synthesized ZnO nanoparticles for wastewater treatment: an impact of Ni doping. Chemosphere 291, 132687 (2022). https://doi.org/10.1016/j.chemosphere.2021.132687

V. Kumari, A. Mittal, J. Jindal, S. Yadav, N. Kumar, S-, N-and C-doped ZnO as semiconductor photocatalysts: a review. Front. Mater. Sci. 13(1), 1–22 (2019). https://doi.org/10.1007/s11706-019-0453-4

Y.T. Tsai, S.J. Chang, L.W. Ji, Y.J. Hsiao, I.T. Tang, H.Y. Lu, Y.L. Chu, High sensitivity of NO gas sensors based on novel Ag-doped ZnO nanoflowers enhanced with a UV light-emitting diode. ACS omega 3(10), 13798–13807 (2018)

Y.C. Yang, C. Song, X.H. Wang, F. Zeng, F. Pan, Giant piezoelectric d 33 coefficient in ferroelectric vanadium doped ZnO films. Appl. Phys. Lett. 92(1), 012907 (2008). https://doi.org/10.1021/acsomega.8b01882

Q. Sun, G. Li, T. Tian, Z. Man, L. Zheng, M. Barré, J. Dittmer, F. Goutenoire, A.H. Kassiba, Controllable microstructure tailoring for regulating conductivity in Al-doped ZnO ceramics. J. Eur. Ceram. Soc. 40(2), 349–354 (2020). https://doi.org/10.1016/j.jeurceramsoc.2019.10.011

K. Jeyasubramanian, R.V. William, P. Thiruramanathan, G.S. Hikku, M.V. Kumar, B. Ashima, P. Veluswamy, H. Ikeda, Dielectric and magnetic properties of nanoporous nickel doped zinc oxide for spintronic applications. J. Magn. Magn. Mater. 485, 27–35 (2019). https://doi.org/10.1016/j.jmmm.2019.04.032

B. Mehmood, M.I. Khan, M. Iqbal, A. Mahmood, W. Al-Masry, Structural and optical properties of Ti and Cu co‐doped ZnO thin films for photovoltaic applications of dye sensitized solar cells. Inter J. Energy Res. 45(2), 2445–2459 (2021). https://doi.org/10.1002/er.5939

I.L. Raj, S. Valanarasu, K. Hariprasad, J.S. Ponraj, N. Chidhambaram, V. Ganesh, H.E. Ali, Y. Khairy, Enhancement of optoelectronic parameters of Nd-doped ZnO nanowires for photodetector applications. Opt. Mater. 109, 110396 (2020). https://doi.org/10.1016/j.optmat.2020.110396

S.S. Wagh, C.V. Jagtap, Vs. Kadam, S.F. Shaikh, M. Ubaidullah, P. Bidhan, D.B. Salunkhe, R.S. Patil, Silver doped ZnO nanoparticles synthesized for photocatalysis application. ES Energy Environ 17, 94–105 (2022). https://doi.org/10.30919/esee8e720

B. Gab hale, H. Borate, A. Bhorde, P. Subhash, A. Punde, Y. Hase, S. Shah, A. Waghmare, B. Bade, M. Prasad, A. Rokade, Effect of boron doping on structural, optical, and electrical properties of hydrogenated nanocrystalline silicon thin films grown by Cat-CVD method. ES Mater. Manuf. (2022). https://doi.org/10.30919/esmm5f725

X. Wang, F. Qi, Z. Wang, Z. Zhang, Q. Li, J. Wu, G. Shi, Dependence of Al doping on the in-situ reactive preparation and mechanical properties of Ti3SiC2/Al2O3 composites. ES Mater. Manuf 15, 85–95 (2021). https://doi.org/10.30919/esmm5f467

J. Jiang, J. Xu, H. Walter, A. Kazi, D. Wang, G. Wangila, M. Mortazavi, C. Yan, Q. Jiang, The doping of alkali metal for halide perovskites. ES Mater. Manuf. 7, 25–33 (2020). https://doi.org/10.30919/esmm5f705

S. Gao, X. Zhao, Q. Fu, T. Zhang, J. Zhu, F. Hou, J. Ni, C. Zhu, T. Li, Y. Wang, V. Murugadoss, Highly transmitted silver nanowires-SWCNTs conductive flexible film by nested density structure and aluminum-doped zinc oxide capping layer for flexible amorphous silicon solar cells. J. Mater. Sci. Technol 126, 152–160 (2022). https://doi.org/10.1016/j.jmst.2022.03.012

Y. Wu, E. Chen, X. Weng, Z. He, G. Chang, X. Pan, J. Liu, K. Huang, K. Huang, M. Lei, Conductive polyvinyl Alcohol/Silver nanoparticles Hydrogel Sensor with large draw ratio, High Sensitivity and High Stability for Human Behavior Monitoring. Eng. Sci. 18, 113–120 (2022). https://doi.org/10.30919/es8d659

S.H. Khan, B. Pathak, M.H. Fulekar, A study on the influence of metal (Fe, Bi, and Ag) doping on structural, optical, and antimicrobial activity of ZnO nanostructures. Adv. Compos. Hybrid Mater. 3(4), 551–569 (2020). https://doi.org/10.1007/s42114-020-00174-0

M.V. Limaye, S.B. Singh, R. Das, P. Poddar, S.K. Kulkarni, Room temperature ferromagnetism in undoped and Fe doped ZnO nanorods: microwave-assisted synthesis. J. Solid State Chem. 184(2), 391–400 (2011). https://doi.org/10.1016/j.jssc.2010.11.008

K. Irshad, M.T. Khan, A. Murtaza, Synthesis and characterization of transition-metals-doped ZnO nanoparticles by sol-gel auto-combustion method. Phys. B: Condens. Matter 543, 1–6 (2018). https://doi.org/10.1016/j.physb.2018.05.006

B. Wang, J. Iqbal, X. Shan, G. Huang, H. Fu, R. Yu, D. Yu, Effects of Cr-doping on the photoluminescence and ferromagnetism at room temperature in ZnO nanomaterials prepared by soft chemistry route. Mater. Chem. Phys. 113(1), 103–106 (2009). https://doi.org/10.1016/j.matchemphys.2008.07.031

N.S. Anad, Z.M. El-Fattah, M. Attallah, H.M. Ahmed, M.M. El-Okr, H.H. El-Bahnasawy, Precise determination of optical band gap in Cr-doped semiconductor nanowires. Opt. Quantum Electron. 54(2), 1–4 (2022). https://doi.org/10.1007/s11082-021-03462-1

D. Ponnamma, J.J. Cabibihan, M. Rajan, S.S. Pethaiah, K. Deshmukh, J.P. Gogoi, S.K. Pasha, M.B. Ahamed, J. Krishnegowda, B.N. Chandrashekar, A.R. Polu, Synthesis, optimization and applications of ZnO/polymer nanocomposites. Mater. Sci. Eng. C 98, 1210–1240 (2019). https://doi.org/10.1016/j.msec.2019.01.081

Z. Wang, M.R. Bockstaller, K. Matyjaszewski, Synthesis and applications of ZnO/polymer nanohybrids. ACS Mater. Lett. 3(5), 599–621 (2021). https://doi.org/10.1021/acsmaterialslett.1c00145

N. Bouropoulos, G.C. Psarras, N. Moustakas, A. Chrissanthopoulos, S. Baskoutas, Optical and dielectric properties of ZnO-PVA nanocomposites. Phys. status solidi (a) 205(8), 2033–2037 (2008). https://doi.org/10.1002/pssa.200778863

P. Dhatarwal, R.J. Sengwa, Structural, dielectric dispersion and relaxation, and optical properties of multiphase semicrystalline PEO/PMMA/ZnO nanocomposites. Compos. Interfaces 28(8), 827–842 (2021). https://doi.org/10.1080/09276440.2020.1813474

M.S. Shakir, M.K. Khosa, K.M. Zia, M. Saeed, T.H. Bokhari, M.A. Zia, Investigation of thermal, antibacterial, antioxidant and antibiofilm properties of PVC/ABS/ZnO nanocomposites for biomedical applications. Korean J. Chem. Eng. 38(11), 2341–2346 (2021). https://doi.org/10.1007/s11814-021-0866-5

E.M. Sadek, N.A. Mansour, S.M. Ahmed, S.L. Abd-El-Messieh, D. El-Komy, Synthesis, characterization and applications of poly (vinyl chloride) nanocomposites loaded with metal oxide nanoparticles. Polym. Bull. 78(10), 5481–5502 (2021). https://doi.org/10.1007/s00289-020-03371-5

I.S. Elashmawi, N.A. Hakeem, L.K. Marei, F.F. Hanna, Structure and performance of ZnO/PVC nanocomposites. Phys. B: Condens. Matter 405(19), 4163–4169 (2010). https://doi.org/10.1016/j.physb.2010.07.006

A. Guedri, M. Zaabat, B. Boudine, A. Hafdallah, Synthesis, characterization, structural, and optical properties of polyvinyl chloride/zinc oxide nanocomposite films for photocatalysis application. J. Inorg. Organomet. Polym Mater. 30(12), 4884–4894 (2020). https://doi.org/10.1007/s10904-020-01604-8

A. Matei, I. Cernica, O. Cadar, C. Roman, V. Schiopu, Synthesis and characterization of ZnO–polymer nanocomposites. Int. J. Mater. Form. 1(1), 767–770 (2008). https://doi.org/10.1007/s12289-008-0288-5

W.E. Mahmoud, A.A. Al-Ghamdi, The influence of cd (ZnO) on the structure, optical and thermal stabilities of polyvinyl chloride nanocomposites. Polym. Compos. 32(7), 1143–1147 (2011). https://doi.org/10.1002/pc.21132

M.A. Malimabe, B.F. Dejene, H.C. Swart, S.V. Motloung, T.E. Motaung, L.F. Koao, Characterization of the incorporated ZnO doped and co-doped with Ce3+ and Eu3+ nanophosphor powders into PVC polymer matrix. J. Mol. Struct. 1202, 127339 (2020). https://doi.org/10.1016/j.molstruc.2019.127339

C. Jin, N. Hao, Z. Xu, I. Trase, Y. Nie, L. Dong, A. Closson, Z. Chen, J.X. Zhang, Flexible piezoelectric nanogenerators using metal-doped ZnO-PVDF films. Sens. Actuators A: Phys. 305, 111912 (2020). https://doi.org/10.1016/j.sna.2020.111912

J. Cai, V. Murugadoss, J. Jiang, X. Gao, Z. Lin, M. Huang, J. Guo, S.A. Alsareii, H. Algadi, M. Kathiresan, Waterborne polyurethane and its nanocomposites: a mini-review for anti-corrosion coating, flame retardancy, and biomedical applications. Adv. Compos. Hybrid. Mater. 5, 641–650 (2022). https://doi.org/10.1007/s42114-022-00473-8

D.E. Mansour, N.M. Abdel-Gawad, A.Z. El Dein, H.M. Ahmed, M.M. Darwish, M. Lehtonen, Recent advances in polymer nanocomposites based on polyethylene and polyvinylchloride for power cables. Materials 14(1), 66 (2020). https://doi.org/10.3390/ma14010066

Y. Li, M. Guo, Y. Li, Recent advances in plasticized PVC gels for soft actuators and devices: a review. J. Mater. Chem. C 7(42), 12991–13009 (2019). https://doi.org/10.1039/C9TC04366G

J. Chen, Y. Zhu, Z. Guo, A.G. Nasibulin, Recent progress on thermo-electrical properties of conductive polymer composites and their application in temperature sensors. Eng. Sci 12, 13–22 (2020). https://doi.org/10.30919/es8d1129

X. Chang, L. Chen, J. Chen, Y. Zhu, Z. Guo, Advances in transparent and stretchable strain sensors. Adv. Compos. Hybrid Mater. volume 4, 435–450 (2021). https://doi.org/10.1007/s42114-021-00292-3

M.M. Darwish, H.M. Ahmed, D.E. Mansour, thermo-mechanical properties of LDPE/SiO2 nanocomposites based on chemically functionalized SiO2 nanoparticles. In Proceedings of the IEEE International Symposium on Electrical Insulating Materials (ISEIM) 241–244 (2020)

N.M. Abdel-Gawad, A.Z. El Dein, D.E. Mansour, H.M. Ahmed, M.M. Darwish, M. Lehtonen, PVC nanocomposites for cable insulation with enhanced dielectric properties, partial discharge resistance and mechanical performance. High. Volt 5(4), 463–471 (2020). https://doi.org/10.1049/hve.2019.0116

N.M. Abdel-Gawad, E.Y. El-Kady, A.Z. El Dein, D.E. Mansour, H.M. Ahmed, M.M. Darwish, Dielectric Response of PVC and LDPE Nanocomposites Upon Functionalization of Their Containing Nanoparticles. Twentieth International Middle East Power Systems Conference (MEPCON) IEEE 1081–1086 (2018)

N.M. Abdel-Gawad, E.Y. El-Kady, A.Z. El Dein, D.E. Mansour, H.M. Ahmed, M.M. Darwish, M. Lehtonen, Multiple enhancement of PVC cable insulation using functionalized SiO2 nanoparticles based nanocomposites. Electr. Power Syst. Res. 163, 612–625 (2018). https://doi.org/10.1016/j.epsr.2017.11.011

N.M. Abdel-Gawad, E.Y. El-Kady, A.Z. El Dein, D.E. Mansour, H.M. Ahmed, M.M. Darwish, M. Lehtonen, Enhancement of dielectric and mechanical properties of polyvinyl chloride nanocomposites using functionalized TiO2 nanoparticles. IEEE Trans. Dielectr. Electr. Insul. 24(6), 3490–3499 (2017). https://doi.org/10.1109/TDEI.2017.006692

H.S. Karaman, H.M. Ahmed, M.M. Darwish, D.E. Mansour, The effect of graphene on the thermal and dielectric properties of epoxy resin. In: Proceedings of the IEEE International Symposium on Electrical Insulating Materials (ISEIM) 103–106 (2020)

N.M. Abdel-Gawad, E.Y. El-Kady, A.Z. El Dein, D.E. Mansour, H.M. Ahmed, M.M. Darwish, (2016) Effect of functionalized TiO2 nanoparticles on dielectric properties of PVC nanocomposites used in electrical insulating cables. 2016 Eighteenth International Middle East Power Systems Conference (MEPCON) IEEE 693–698

Y. Cao, M. Weng, M.H. Mahmoud, A.Y. Elnaggar, L. Zhang, I.H. AzabY. Chen, M. Huang, J. Huang, X. Sheng, Flame-retardant and leakage-proof phase change composites based on MXene/polyimide aerogels toward solar thermal energy harvesting. Adv. Compos. Hybrid. Mater. 5(2), 1253–1267 (2022). https://doi.org/10.1007/s42114-022-00504-4

X. Xu, F. Yao, O.A. Abu Ali, W. Xie, S.F. Mahmoud, P. Xie, S.M. El-Bahy, M. Huang, C. Liu, R. Fan, Z. Guo, A. Du, D. Estevez, F. Qin, H. Peng, D.P. Young, H. Gu, Adjustable core-sheath architecture of polyaniline-decorated hollow carbon nanofiber nanocomposites with negative permittivity for superb electromagnetic interference shielding. Adv. Compos. Hybrid. Mater. 18, 1–10 (2022). https://doi.org/10.1007/s42114-022-00538-8

ASTM D149–09, Standard test method for dielectric breakdown voltage and dielectric strength of solid electrical insulating materials at commercial power frequencies (University of Toronto, Toronto, 2013), pp.1–13

S. Havriliak, S. Negami, A complex plane analysis of α-dispersions in some polymer systems. J. Polym. Sci. C: Polym. Symposia 14(1), 99–117 (1966). https://doi.org/10.1002/polc.5070140111

A. Rajeh, H.M. Ragab, M.M. Abutalib, Co doped ZnO reinforced PEMA/PMMA composite: structural, thermal, dielectric and electrical properties for electrochemical applications. J. Mol. Struct. 1217, 128447 (2020). https://doi.org/10.1016/j.molstruc.2020.128447

A. Mostafaei, A. Zolriasatein, Synthesis and characterization of conducting polyaniline nanocomposites containing ZnO nanorods. Prog Nat. Sci.: Mater. Int 22(4), 273–280 (2012). https://doi.org/10.1016/j.pnsc.2012.07.002

J. Loste, J.M. Lopez-Cuesta, L. Billon, H. Garay, M. Save, Transparent polymer nanocomposites: an overview on their synthesis and advanced properties. Prog Polym. Sci. 89, 133–158 (2019). https://doi.org/10.1016/j.progpolymsci.2018.10.003

R.F. Bhajantri, V. Ravindrachary, A. Harisha, V. Crasta, S.P. Nayak, B. Poojary, Microstructural studies on BaCl2 doped poly (vinyl alcohol). Polymer 47(10), 3591–3598 (2006). https://doi.org/10.1016/j.polymer.2006.03.054

A.M. Abdelghany, A.H. Oraby, G.M. Asnag, Structural, thermal and electrical studies of polyethylene oxide/starch blend containing green synthesized gold nanoparticles. J. Mol. Struct. 1180, 15–25 (2019). https://doi.org/10.1016/j.molstruc.2018.11.095

J.K. Pandey, K.R. Reddy, A.P. Kumar, R.P. Singh, An overview on the degradability of polymer nanocomposites. Polym. Degrad. Stab. 88(2), 234–250 (2005). https://doi.org/10.1016/j.polymdegradstab.2004.09.013

D. Shao, D. Gao, Q. Wei, L. Tao, H. Zhu, M. Ge, Deposition of ZnO on polyacrylonitrile fiber by thermal solvent coating. Fibers Polym. 12(2), 214–219 (2011). https://doi.org/10.1007/s12221-011-0214-1

S.K. Nataraj, B.H. Kim, J.H. Yun, D.H. Lee, T.M. Aminabhavi, K.S. Yang, Electrospun nanocomposite fiber mats of zinc-oxide loaded polyacrylonitrile. Carbon Lett. 9(2), 108–114 (2008). https://doi.org/10.5714/CL.2008.9.2.108

T.W. Quadri, L.O. Olasunkanmi, O.E. Fayemi, M.M. Solomon, E.E. Ebenso, Zinc oxide nanocomposites of selected polymers: synthesis, characterization, and corrosion inhibition studies on mild steel in HCl solution. ACS Omega 2(11), 8421–8437 (2017). https://doi.org/10.1021/acsomega.7b01385

L. Zhu, Exploring strategies for high dielectric constant and low loss polymer dielectrics. J. Phys. Chem. Lett. 5(21), 3677–3687 (2014). https://doi.org/10.1021/jz501831q

J. Guo, Z. Chen, Z.M. El-Bahy, H. Liu, H.M. Abo-Dief, W. Abdul, K.M. Abualnaja, A.K. Alanazi, P. Zhang, M. Huang, G. Hu, J. Zhu, Tunable negative dielectric properties of magnetic CoFe2O4/graphite-polypyrrole metacomposites. Adv. Compos. Hybrid. Mater. 5, 899–906 (2022). https://doi.org/10.1007/s42114-022-00485-4

P. Wang, T. Song, H.M. A.Dief, J. Song, A.K. Alanazi, B. Fan, M. Huang, Z. Lin, A.A. Altalhi, S. Gao, L. Yang, J. Liu, S. Feng, T. Cao, Effect of carbon nanotubes on the interface evolution and dielectric properties of polylactic acid/ethylene-vinyl acetate copolymer nanocomposites. Adv. Compos. Hybrid. Mater. 5, 1100–1110 (2022). https://doi.org/10.1007/s42114-022-00489-0

N. Wu, B. Zhao, X. Chen, C. Hou, M. Huang, A. Alhadhrami, G.A.M. Mersal, M.M. Ibrahim, J. Tian, Dielectric properties and electromagnetic simulation of molybdenum disulfide and ferric oxide modified Ti3C2TX MXene hetero-structure for potential microwave absorption. Adv. Compos. Hybrid. Mater 5, 1548–1556 (2022). https://doi.org/10.1007/s42114-022-00490-782

D. Pan, G. Yang, H.M. Abo-Dief, J. Dong, F. Su, C. Liu, Y. Li, B.B. Xu, V. Murugadoss, N. Naik, S.M. El-Bahy, Z.M. El-Bahy, M. Huang, Z. Guo, Vertically aligned silicon carbide nanowires/boron nitride cellulose aerogel networks enhanced thermal conductivity and electromagnetic absorbing of epoxy composites. Nano-Micro Lett. 14, 118 (2022). https://doi.org/10.1007/s40820-022-00863-z

B. Dai, Y. Ma, F. Dong, J. Yu, M. Ma, H.K. Thabet, S.M. El-Bahy, M.M. Ibrahim, M. Huang, I. Seok, G. Roymahapatra, N. Naik, B.B. Xu, J. Ding, T. Li, Overview of MXene and conducting polymer matrix composites for electromagnetic wave absorption. Adv. Compos. Hybrid. Mater. 5, 704–754 (2022). https://doi.org/10.1007/s42114-022-00510-6

J. Lim, S.Y. Ryu, J. Kim, Y. Jun, A study of TiO2/carbon black composition as counter electrode materials for dye-sensitized solar cells. Nanoscale Res. Lett. 8(1), 1–5 (2013). https://doi.org/10.1186/1556-276X-8-227

W.R. Tinga, S.O. Nelson, Dielectric properties of materials for microwave processing-tabulated. J. Microw. Power 8(1), 23–65 (1973). https://doi.org/10.1080/00222739.1973.11689017

B. Sareni, L. Kr¨ahenb¨uhl, A. Beroual, C. Brosseau, Effective dielectric constant of random composite materials. J. Appl. Phys. 81(5), 2375–2383 (1997). https://doi.org/10.1063/1.364276

S.A. Mansour, R.A. Elsad, M.A. Izzularab, Dielectric properties enhancement of PVC nanodielectrics based on synthesized ZnO nanoparticles. J. Polym. Res. 23(5), 1–8 (2016). https://doi.org/10.1007/s10965-016-0978-5

C.K. Ghosh, S. Malkhandi, M.K. Mitra, K.K. Chattopadhyay, Effect of Ni doping on the dielectric constant of ZnO and its frequency dependent exchange interaction. J. Phys. D Appl. Phys. 41(24), 245113 (2008). https://doi.org/10.1088/0022-3727/41/24/245113

R.B. Bird, W.E. Stewart, E.N. Lightfoot, Transport phenomena (Wiley, New York, 1960)

L.H. Sperling, Introduction to physical polymer science, 4th edn. (Wiley, Hoboken, 2005)

M.A. Meyers, K.K. Chawla, Mechanical behavior of materials, 2nd edn. (Cambridge University Press, Cambridge, 2009)

A. Manzur, F. Hernández-Sánchez, Activation energy for the glass transition of a confined elastomer in HDPE/PP blends. J. Macromol. Sci. Part. B Phys. 45(1), 139–152 (2006). https://doi.org/10.1080/00222340500408143

H. Duan, C. Zhuang, F. Mei, C. Zeng, R.A. Pashameah, M. Huang, E. Alzahrani, J. Gao, Y. Han, Q. Yu, Z. Wang, Benzyl(4-fluorophenyl) phenylphosphine oxide-modified epoxy resin with improved flame retardancy and dielectric properties. Adv. Compos. Hybrid. Mater. 5, 776–787 (2022). https://doi.org/10.1007/s42114-022-00491-6

C. Jagadish, S.J. Pearton, Zinc oxide bulk, thin films and nanostructures: processing, properties, and applications, 1st edn. (Elsevier, Amsterdam, 2006)

M.A. Hassan, F. Ahmad, Z.M. Abd El-Fattah, Novel identification of ultraviolet/visible Cr6+/Cr3+ optical transitions in borate glasses. J. Alloys Compd. 750, 320–327 (2018). https://doi.org/10.1016/j.jallcom.2018.03.351

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design, and they all read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ahmed, H.M., Abd El-Fattah, Z.M., Anad, N.S. et al. Thermo-mechanical and opto-electrical study of Cr-doped-ZnO-based polyvinyl chloride nanocomposites. J Mater Sci: Mater Electron 34, 113 (2023). https://doi.org/10.1007/s10854-022-09412-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-022-09412-1