Abstract

The effect of hot deformation parameters on the flow behavior of newly developed 18Cr–12Ni–4Si has been studied. Hot compression tests were carried out in temperatures 1173–1473 K with varying strain rates from 0.01 to 10 s−1. The flow curves exhibited strain-hardening, strain-softening, and steady-state characteristics at different thermomechanical processing conditions. Constitutive modeling of the flow behavior has been carried out using a hyperbolic sinusoidal Arrhenius equation-based kinetic model to correlate the changes in the flow stress with temperature and strain rate. Due to low values of strain rate sensitivity, the proposed constitutive equation was less accurate at the lowest temperature and highest strain rate conditions. The dynamic materials model approach was adopted to identify the stable hot workability regimes using the processing maps. The regimes for optimum hot workability were found at 1222–1473 K/0.01–0.04 s−1; 1173–1473 K/0.04–0.36 s−1; and 1383–1473 K/3.89–10 s−1. Subsequently, the microstructural characterization using EBSD confirmed the occurrence of dynamic recrystallization (DRX) and was found to be the dominant recrystallization mechanism. The microstructures were segmented using the grain orientation spread analysis to distinguish between the deformed grains and the recrystallized grains. Avrami equation for DRX has been utilized for elucidating the DRX kinetics and prediction of recrystallized grains volume fraction at different strain rates and temperatures. The percentage of recrystallized grains that was obtained experimentally was in good agreement with the predicted results. It was discovered that, at a given strain, the recrystallization kinetics accelerates with the increasing temperature, while the reverse trend was observed with increasing strain rate.

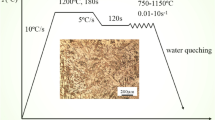

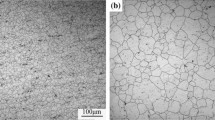

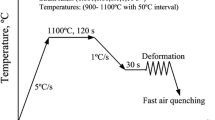

Graphical abstract

Similar content being viewed by others

References

Far SVS, Ketabchi M, Nourani MR (2010) Hot deformation characteristics of 34CrMo4 steel. J Iron Steel Res Int 17:65–69. https://doi.org/10.1016/S1006-706X(10)60199-9

Pu E, Zheng W, Xiang J, Song Z, Li J (2014) Hot deformation characteristic and processing map of superaustenitic stainless steel S32654. Mater Sci Eng A 598:174–182. https://doi.org/10.1016/j.msea.2014.01.027

Guo EY, Singh SS, Xie HX, Williams JJ, Jing T, Chawla N (2014) Microstructure-based modeling of deformation in steels based on constitutive relationships from micropillar compression. J Iron Steel Res Int 85:946–953. https://doi.org/10.1002/srin.201300217

Setia P, Venkateswaran T, Tharian KT, Jain J, Singh SS, Shekhar S (2022) Influence of Si content on the microstructure and mechanical properties of silicon stainless steel. Mater Sci Eng A 829:142141. https://doi.org/10.1016/j.msea.2021.142141

Prasad Y, Seshacharyulu T (1998) Modelling of hot deformation for microstructural control Inter. Mater Rev 43:243–258. https://doi.org/10.1179/imr.1998.43.6.243

Prasad Y, Rao K, Sasidhar S (2015) Hot working guide: a compendium of processing maps. ASM International, Almere

Ziegler H (1963) Some extremum principles in irreversible thermodynamics, with application to continuum mechanics. Prog Sol Mech 4:93–193

Narayana Murty S, Nageswara Rao B, Kashyap B (2000) Instability criteria for hot deformation of materials inter. Mater Rev 45:15–26. https://doi.org/10.1179/095066000771048782

Gegel HL (1987) Computer simulation in material science. Metals Park, OH, ASM, pp 291–344

Mishra MK, Balasundar I, Rao AG, Kashyap BP, Prabhu N (2017) On the high temperature deformation behaviour of 2507 super duplex stainless steel. J Mater Eng Perf 26:802–812. https://doi.org/10.1007/s11665-017-2508-y

Zou DN, Wu K, Han Y, Zhang W, Cheng B, Qiao GJ (2013) Deformation characteristic and prediction of flow stress for as-cast 21Cr economical duplex stainless steel under hot compression. Mater Des 51:975–982. https://doi.org/10.1016/j.matdes.2013.04.065

Sellars C, Tegart WM (1972) Hot workability, international metallurgical reviews 17:1–24. https://doi.org/10.1179/imtlr.1972.17.1.1

Deschamps A, Brechet Y (1998) Influence of quench and heating rates on the ageing response of an Al–Zn–Mg–Zr alloy. Mater Sci Eng A 251:200–207. https://doi.org/10.1016/S0921-5093(98)00615-7

Pan Q, Li B, Wang Y, Zhang Y, Yin Z (2013) Characterization of hot deformation behavior of Ni-base superalloy Rene’41 using processing map. Mater Sci Eng A 585:371–378. https://doi.org/10.1016/j.msea.2013.07.066

Momeni A, Dehghani K (2011) Hot working behavior of 2205 austenite–ferrite duplex stainless steel characterized by constitutive equations and processing maps. Mater Sci Eng A 528:1448–1454. https://doi.org/10.1016/j.msea.2010.11.020

Cizek P (2016) The microstructure evolution and softening processes during high-temperature deformation of a 21Cr–10Ni–3Mo duplex stainless steel. Acta Mater 106:129–143. https://doi.org/10.1016/j.actamat.2016.01.012

Venugopal S, Mannan S, Prasad Y (1992) Optimization of hot workability in stainless steel type AISI304L using processing map. Metall Trans A 23:3093–3103. https://doi.org/10.1007/BF02646128

Venugopal S, Mannan S, Prasad Y (1995) Optimization of cold and warm workability in stainless steel type AISI 316L using instability maps. J Nucl Mater 227:1–10. https://doi.org/10.1016/0022-3115(95)00154-9

Zhu YY, Ning LK, Xin TZ et al (2021) Hot deformation behavior and microstructure evolution of an Fe–30Cr–2Mo ultra-pure super ferritic stainless steel. J Iron Steel Res Int. https://doi.org/10.1007/s42243-021-00584-4

Huang K, Loge R (2016) A review of dynamic recrystallization phenomena in metallic materials. Mater Des 111:548–574. https://doi.org/10.1016/j.matdes.2016.09.012

Sakai T, Belyakov A, Kaibyshev R, Miura H, Jonas JJ (2014) Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci 60:130–207. https://doi.org/10.1016/j.pmatsci.2013.09.002

Castan C, Montheillet F, Perlade A (2013) Dynamic recrystallization mechanisms of an Fe–8% Al low density steel under hot rolling conditions. Scr Mater 68:360–364. https://doi.org/10.1016/j.scriptamat.2012.07.037

Haghdadi N, Cizek P, Beladi H, Hodgson P (2017) A novel high-strain-rate ferrite dynamic softening mechanism facilitated by the interphase in the austenite/ferrite microstructure. Acta Mater 126:44–57. https://doi.org/10.1016/j.actamat.2016.12.045

Yanushkevich Z, Belyakov A, Kaibyshev R (2015) Microstructural evolution of a 304-type austenitic stainless steel during rolling at temperatures of 773–1273 K. Acta Mater 82:244–254. https://doi.org/10.1016/j.actamat.2014.09.023

Pierce DT, Jimenez JA, Bentley J, Raabe D, Wittig JE (2015) The influence of stacking fault energy on the microstructural and strain-hardening evolution of Fe–Mn–Al–Si steels during tensile deformation. Acta Mater 100:178–190. https://doi.org/10.1016/j.actamat.2015.08.030

Mozumder YH, Babu KA, Saha R, Sarma VS, Mandal S (2020) Dynamic microstructural evolution and recrystallization mechanism during hot deformation of intermetallic-hardened duplex lightweight steel. Mater Sci Eng A. https://doi.org/10.1016/j.msea.2020.139613

Luton M, Sellars C (1969) Dynamic recrystallization in nickel and nickel-iron alloys during high temperature deformation. Acta Metall 17:1033–1043

Sakai T, Jonas JJ (1984) Overview no 35 dynamic recrystallization: mechanical and microstructural considerations. Acta Metall 32:189–209. https://doi.org/10.1016/0001-6160(84)90049-X

Ryan N, McQueen H (1990) Dynamic softening mechanisms in 304 austenitic stainless steel. Can Metall Q 29:147–162. https://doi.org/10.1179/cmq.1990.29.2.147

Poliak EI, Jonas JJ (1996) A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Mater 44:127–136. https://doi.org/10.1016/1359-6454(95)00146-7

Poliak E, Jonas JJ (2003) Initiation of dynamic recrystallization in constant strain rate hot deformation. ISIJ Int 43:684–691. https://doi.org/10.2355/isijinternational.43.684

Setia P, Vishwanath K, Mondal K, Venkateswaran T, Singh SS, Shekhar S (2022) Cushioning effect of austenite in silicon stainless steels (SiSS) leading to improved wear resistance. Tribo Int. https://doi.org/10.1016/j.triboint.2022.107678

Setia P, Anand A, Venkateswaran T et al (2020) Effect of heat treatment on the microstructure evolution and sensitization behavior of high-silicon stainless steel. J Mater Eng Perf 29:6014–6024. https://doi.org/10.1007/s11665-020-05060-w

Alvarez Armas I, Degallaix-Moreuil S (2013) Duplex stainless steels. Wiley, New Jersey

Nioi M, Pinna C, Celotto S et al (2019) Finite element modelling of surface defect evolution during hot rolling of Silicon steel. J Mater Process Technol 268:181–191. https://doi.org/10.1016/j.jmatprotec.2019.01.014

Sharma NK, Shekhar S (2021) New perspectives on twinning events during strain-induced grain boundary migration (SIBM) in iteratively processed 316L stainless steel. J Mater Sci 56:792–814. https://doi.org/10.1007/s10853-020-05240-y

Dieter GE, Kuhn HA, Semiatin SL (2003) Handbook of workability and process design. ASM International, Almere

Zener C, Hollomon JH (1944) Effect of strain rate upon plastic flow of steel. J Appl Phys 15:22–32. https://doi.org/10.1063/1.1707363

Rao K, Prasad Y, Hawbolt EB (1996) Hot deformation studies on a low-carbon steel: part 1-flow curves and the constitutive relationship. J Mater Process Technol 56:897–907. https://doi.org/10.1016/0924-0136(95)01902-2

Momeni A (2016) The physical interpretation of the activation energy for hot deformation of Ni and Ni–30Cu alloys. J Mater Res 31:1077–1084. https://doi.org/10.1557/jmr.2016.81

Guo B, Ji H, Liu X et al (2012) Research on flow stress during hot deformation process and processing map for 316LN austenitic stainless steel. J Mater Eng Perf 21:1455–1461. https://doi.org/10.1007/s11665-011-0031-0

Farnoush H, Momeni A, Dehghani K, Mohandesi JA, Keshmiri H (2010) Hot deformation characteristics of 2205 duplex stainless steel based on the behavior of constituent phases. Mater Des 31:220–226. https://doi.org/10.1016/j.matdes.2009.06.028

Kumar S, Karmakar A, Nath SK (2020) Comparative assessment on the hot deformation behaviour of 9Cr–1Mo steel with 1Cr–1Mo Steel. Met Mater Int 27:3875–3890. https://doi.org/10.1007/s12540-020-00826-2

Zhang B (2014) Calculation of self-diffusion coefficients in iron. AIP Adv 4:017128. https://doi.org/10.1063/1.4863462

Vasilyev A, Sokolov S, Kolbasnikov N, Sokolov D (2011) Effect of alloying on the self-diffusion activation energy in γ-iron. Phys Solid State 53:2194–2200. https://doi.org/10.1134/S1063783411110308

Imbert C, McQueen H (2001) Dynamic recrystallization of A2 and M2 tool steels. Mater Sci Eng A 313:104–116. https://doi.org/10.1016/S0921-5093(01)00974-1

Haghdadi N, Martin D, Hodgson P (2016) Physically-based constitutive modelling of hot deformation behavior in a LDX 2101 duplex stainless steel. Mater Des 106:420–427. https://doi.org/10.1016/j.matdes.2016.05.118

Chaudhuri A, Sarkar A, Suwas S (2018) Investigation of stress-strain response, microstructure and texture of hot deformed pure molybdenum Inter. J Refrac Met Hard Mater 73:168–182. https://doi.org/10.1016/j.ijrmhm.2018.02.011

Wang X, Liu Z, Luo H (2017) Hot deformation characterization of ultrahigh strength stainless steel through processing maps generated using different instability criteria. Mater Charact 131:480–491. https://doi.org/10.1016/j.matchar.2017.07.041

Han Y, Qiao G, Sun Y, Zou D (2012) Modeling the constitutive relationship of Cr20Ni25Mo4Cu superaustenitic stainless steel during elevated temperature. Mater Sci Eng A 539:61–67. https://doi.org/10.1016/j.msea.2012.01.036

Zhang S, Wang J, Huang L et al (2021) Correction of flow stress data due to non-homogeneous deformation and thermal conditions during hot compression testing of a polycrystalline nickel-base superalloy. J Mater Sci 56:7727–7739. https://doi.org/10.1007/s10853-020-05714-z

Kingklang S, Uthaisangsuk V (2016) Investigation of hot deformation behavior of duplex stainless steel grade 2507. Metall Mater Trans A 48:95–108. https://doi.org/10.1007/s11661-016-3829-4

Gegel HL, Malas J, Doraivelu S, Shende V (1987) Metals handbook, vol 14. ASM Metals Park, Ohio, p 417

Jain R, Jain A, Rahul MR et al (2020) Development of ultrahigh strength novel Co–Cr–Fe–Ni–Zr quasi-peritectic high entropy alloy by an integrated approach using experiment and simulation. Materialia. https://doi.org/10.1016/j.mtla.2020.100896

Venugopal S, Mannan S, Prasad Y (1993) Processing map for hot working of stainless steel type AISI 316L. Mater Sci Tech 9:899–906. https://doi.org/10.1179/mst.1993.9.10.899

Bembalge O, Panigrahi S (2021) Hot deformation behavior and processing map development of cryorolled AA6063 alloy under compression and tension. Int J Mech Sci 191:106100. https://doi.org/10.1016/j.ijmecsci.2020.106100

Min W, Baosheng L, Shoulu Z et al (2019) Hot deformation behavior and softening mechanism of As-cast S32750 super duplex stainless steel at low and high strain rates. J Mater Eng Perf 29:727–738. https://doi.org/10.1007/s11665-020-04571-w

Patra S, Ghosh A, Singhal LK et al (2017) Hot deformation behavior of As-cast 2101 grade lean duplex stainless steel and the associated changes in microstructure and crystallographic texture. Metall Mater Trans A 48:294–313. https://doi.org/10.1007/s11661-016-3759-1

Laughlin DE, Hono K (2014) Physical metallurgy. Elsevier, Amsterdam

Rout M, Ranjan R, Pal SK, Singh SB (2018) EBSD study of microstructure evolution during axisymmetric hot compression of 304LN stainless steel. Mater Sci Eng A 711:378–388. https://doi.org/10.1016/j.msea.2017.11.059

Beck PA, Sperry PR (1950) Strain induced grain boundary migration in high purity aluminum. J Appl Phys 21:150–152. https://doi.org/10.1063/1.1699614

Wang X, Brünger E, Gottstein G (2002) The role of twinning during dynamic recrystallization in alloy 800H. Scr Mater 46:875–880. https://doi.org/10.1016/S1359-6462(02)00072-6

Eghbali B (2010) Effect of strain rate on the microstructural development through continuous dynamic recrystallization in a microalloyed steel. Mater Sci Eng A 527:3402–3406. https://doi.org/10.1016/j.msea.2010.01.077

Stewart GR, Jonas JJ, Montheillet F (2004) Kinetics and critical conditions for the initiation of dynamic recrystallization in 304 stainless steel. ISIJ Int 44:1581–1589. https://doi.org/10.2355/isijinternational.44.1581

Zhang C, Zhang L, Shen W, Liu C, Xia Y, Li R (2016) Study on constitutive modeling and processing maps for hot deformation of medium carbon Cr–Ni–Mo alloyed steel. Mater Des 90:804–814. https://doi.org/10.1016/j.matdes.2015.11.036

Jonas JJ, Quelennec X, Jiang L, Martin É (2009) The Avrami kinetics of dynamic recrystallization. Acta Mater 57:2748–2756. https://doi.org/10.1016/j.actamat.2009.02.033

Lelito J (2020) Crystallization kinetics analysis of the amorphouse Mg72Zn24Ca4 alloy at the isothermal annealing temperature of 507 K. Materials 13:2815. https://doi.org/10.3390/ma13122815

Momeni A, Arabi H, Rezaei A, Badri H, Abbasi S (2011) Hot deformation behavior of austenite in HSLA-100 microalloyed steel. Mater Sci Eng A 528:2158–2163. https://doi.org/10.1016/j.msea.2010.11.062

Acknowledgements

This research work was supported by Vikram Sarabhai Space Centre (VSSC)–Indian Space Research Organization (ISRO), India (Grant Number STC/MET/2017193). The authors also acknowledge the Advanced Centre of Materials Science (ACMS) at the Indian Institute of Technology Kanpur, India, for supporting this research work. P.S would like to thank Dr. Sumanta Samal, Mr. Ashok Kumar at IIT Indore and Mr. Pankaj Rawat at IIT Roorkee, India, for their valuable guidance. S.M would like to acknowledge R&D, Tata Steel for performing thermomechanical processing using Gleeble.

Author information

Authors and Affiliations

Contributions

PS helped in conceptualization, methodology, investigation, data curation, visualization, formal analysis, and writing—original draft. SM investigated during the hot compression tests. SSS and SS contributed to supervision and writing—review and editing. TV helped in funding acquisition, realization of material and review.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest and have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Code availability

Not applicable.

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

Ethical approval

Not applicable.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Setia, P., Mukherjee, S., Singh, S.S. et al. Deformation characteristics and microstructure evolution during hot deformation of 18Cr–12Ni–4Si stainless steel. J Mater Sci 58, 4987–5009 (2023). https://doi.org/10.1007/s10853-023-08308-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08308-7