Abstract

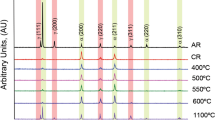

The hot deformation behavior of 2101 grade lean duplex stainless steel (DSS, containing ~5 wt pct Mn, ~0.2 wt pct N, and ~1.4 wt pct Ni) and associated microstructural changes within δ-ferrite and austenite (γ) phases were investigated by hot-compression testing in a GLEEBLE 3500 simulator over a range of deformation temperatures, T def [1073 K to 1373 K (800 °C to 1100 °C)], and applied strains, ε (0.25 to 0.80), at a constant true strain rate of 1/s. The microstructural softening inside γ was dictated by discontinuous dynamic recrystallization (DDRX) at a higher T def [1273 K to 1373 K (1000 °C to 1100 °C)], while the same was dictated by continuous dynamic recrystallization (CDRX) at a lower T def (1173 K (900 °C)]. Dynamic recovery (DRV) and CDRX dominated the softening inside δ-ferrite at T def ≥ 1173 K (900 °C). The dynamic recrystallization (DRX) inside δ and γ could not take place upon deformation at 1073 K (800 °C). The average flow stress level increased 2 to 3 times as the T def dropped from 1273 to 1173 K (1000 °C to 900 °C) and finally to 1073 K (800 °C). The average microhardness values taken from δ-ferrite and γ regions of the deformed samples showed a different trend. At T def of 1373 K (1100 °C), microhardness decreased with the increase in strain, while at T def of 1173 K (900 °C), microhardness increased with the increase in strain. The microstructural changes and hardness variation within individual phases of hot-deformed samples are explained in view of the chemical composition of the steel and deformation parameters (T def and ε).

Similar content being viewed by others

Notes

GLEEBLE is a trademark of Dynamic Systems Inc., New York, NY.

Zeiss is a trademark of Carl Zeiss microscopy GmbH, Germany.

MTex is a free matlab toolbox for analyzing and modeling crystallographic texture available on http://mtex-toolbox.github.io/.

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

WALTER UHL is a trademark of technische mikroskopie GMbH & CO. KG, Germany.

Abbreviations

- CDRX:

-

Continuous dynamic recrystallization

- DDRX:

-

Discontinuous dynamic recrystallization

- DRV:

-

Dynamic recovery

- DRX:

-

Dynamic recrystallization

- DSS:

-

Duplex stainless steel

- EBSD:

-

Electron backscatter diffraction

- HAB:

-

High-angle boundary

- IPF:

-

Inverse pole figure

- LAB:

-

Low-angle boundary

- LAM:

-

Local average misorientation

- ODF:

-

Orientation distribution function

- T def :

-

Deformation temperature

- ε :

-

Applied strain

- \( \dot{\varepsilon } \) :

-

Strain rate

- γ:

-

Austenite

- δ:

-

Delta-ferrite

References

Y.L. Fang, Z.Y. Liu, and G.D. Wang: J. Iron Steel Res. Int., 2011, vol. 18, pp. 58–62.

Y. Han, D. Zou, Z. Chen, G. Fan, and W. Zhang: Mater. Charact, 2011, vol. 62, pp. 198–203.

E. Evangelista, H.J. McQueen, M. Niewczas, and M. Cabibbo: Can. Metall. Q., 2004, vol. 43, pp. 339–54.

G.W. Fan, J. Liu, P.D. Han, and G.J. Qiao: Mater. Sci. Eng. A, 2009, vol. 515, pp. 108–12.

H. Farnoush, A. Momeni, K. Dehgani, J. AghaZadeh Mohandesi, and H. Keshmiri: Mater. Des., 2010, vol. 31, pp. 220–26.

A. Dehghan-Manshadi, M.R. Barnett, and P.D. Hodgson: Mater. Sci. Technol., 2007, vol. 23, pp. 1478–84.

A.M.J. Junior, G.S. Reis, and O. Balancin: Mater. Sci. Eng. A, 2011, vol. 528, pp. 1259–64.

S. Primig, K.S. Ragger, and B. Buchmeyr: Mater. Sci. Forum, 2014, vols. 783–86, pp. 973–79.

R.Z. Wang and T.C. Lei: Scripta Metall. Mater., 1994, vol. 31, pp. 1193–96.

C. Herrera, D. Ponge, and D. Raabe: Steel Res. Int., 2008, vol. 79, pp. 482–88.

C. Herrera, D. Ponge, and D. Raabe: Acta Mater., 2011, vol. 51, pp. 4653–64.

A. Iza-Mendia, A. Pin-Ol-Juez, J.J. Urcola, and I. Gutie´rrez: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2975–86.

O. Balancin, W.A.M. Hoffmann, and J.J. Jonas: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1353–64.

A. Momeni and K. Dehghani: Mater. Sci. Eng. A, 2011, vol. 528, pp. 1448–54.

A. Momeni, K. Dehghani, and X.X. Zhang: J. Mater. Sci., 2012, vol. 47, pp. 2966–74.

P. Cizek, B.P. Wyne, and W.M. Rainforth: J. Microsc., 2006, vol. 222, pp. 85–96.

P. Cizek and B.P. Wyne: Mater. Sci. Eng. A, 1997, vol. 230, pp. 88–94.

Y.L. Fang, Z.Y. Liu, W. Xue, H.M. Song, and L.Z. Jiang: Iron Steel Inst. Jpn. Int., 2010, vol. 50, pp. 286–93.

Y. Liu, H. Yan, X. Wang, and M. Yan: Mater. Sci. Eng. A, 2013, vol. 575, pp. 41–47.

D.N. Zou, K. Wu, Y. Han, W. Zhang, B. Cheng, and G.J. Qiao: Mater. Design, 2013, vol. 51, pp. 975–82.

S. Patra, A. Ghosh, V. Kumar, D. Chakrabarti, and L.K. Singhal: Mater. Sci. Eng. A, 2016, vol. 660, pp. 61–70.

A. Ghosh, S. Patra, A. Chatterjee, and D. Chakrabarti: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 2755–72.

J.J. Jonas, X. Quelennec, L. Jiang, and E. Martin: Acta Mater., 2009, vol. 57, pp. 2748–56.

L. Duprez, B.C. De Cooman, and N. Akdut: Metall. Mater. Trans. A, 2002, vol. 34A, pp. 1931–38.

S. Kim and Y.C. Yoo: Met. Mater. Int., 2002, vol. 8, pp. 7–13.

S. Gourdet and F. Montheillet: Acta Mater., 2003, vol. 51, pp. 2685–99.

C. Herrera, D. Ponge, and D. Raabe: Proc. 3rd Int. Conf. on Thermo-Mechanical Processing of Steels, Padna, Italy, Sept. 10–12, 2008, http://edoc.mpg.de/377522.

N. Tsuji, K. Tsuzaki, and T. Maki: ISIJ Int., 1993, vol. 33, pp. 783–92.

N. Tsuji, K. Tsuzaki, and T. Maki: ISIJ Int., 1994, vol. 34, pp. 1008–17.

A. Paggi, G. Angella, and R. Donnini: Mater. Charact., 2015, vol. 107, pp. 174–81.

R.K. Ray and J.J. Jonas: Int. Mater. Rev., 1990, vol. 35, pp. 1–36.

R.W. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials, Wiley, New York, NY, 1995.

G.E. Dieter: Mechanical Metallurgy, McGraw-Hill, London, 1988.

Acknowledgments

The authors acknowledge the experimental support received from Jindal Stainless Limited, the Indian Institute of Technology Kharagpur, and the Steel Authority of India. They also sincerely appreciate the financial support of the Department of Science and Technology, New Delhi, and the SGDRI Grant received from SRIC, IIT Kharagpur.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 31, 2016.

Rights and permissions

About this article

Cite this article

Patra, S., Ghosh, A., Singhal, L.K. et al. Hot Deformation Behavior of As-Cast 2101 Grade Lean Duplex Stainless Steel and the Associated Changes in Microstructure and Crystallographic Texture. Metall Mater Trans A 48, 294–313 (2017). https://doi.org/10.1007/s11661-016-3759-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3759-1