Abstract

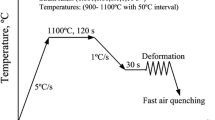

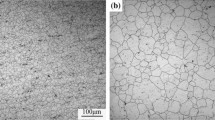

In this study, the hot deformation behavior of austenitic stainless steel was investigated using Gleeble-3500 thermomechanical simulator at deformation temperatures in the range of 900-1200 °C and strain rates in the range of 0.001-10 s−1. The effects of initial austenitic grain size and deformation conditions on hot deformation behavior of 316LN were analyzed through true stress-strain curves under different deformation conditions. Both the constitutive equation and processing map for 316LN were obtained. The results show that, with the increase of the deformation temperature and the decrease of the strain rate, the peak stress decreases, and the initial austenitic grain size has a little influence on the peak stress. The relative error between the peak stress values calculated using the constitutive equation and the values measured is less than 10%. Using the processing map, the best hot-working condition for 316LN in the range of experimental deformation parameters appears when T = 1200 °C and \(\dot{\upvarepsilon } = 0.001\,{\text{s}}^{-1}.\)

Similar content being viewed by others

References

J.A. DeAlmeida and R. Barbosa, Hot Deformation of Austenitic Stainless Steel Type 316 up to Strain Rates of 100 s−1, ISIJ Int., 2005, 45(2), p 296–298

M. Jafari and A. Najafizadeh, Correlation between Zener–Hollomon Parameter and Necklace DRX During Hot Deformation of 316 Stainless Steel, Mater. Sci. Eng. A, 2009, 501(1–2), p 16–25

N.D. Ryan and H.J. McQueen, Hot Strength and Microstructural Evolution of 316 Stainless Steel During Simulated Multistage Deformation by Torsion, J. Mater. Process. Technol., 1993, 36(2), p 103–123

S.-I. Kim, Y.S. Lee, and B.-L. Jang, Modeling of Recrystallization and Austenite Grain Size for AISI, 316 Stainless Steel and Its Application to Hot Bar Rolling, Mater. Sci. Eng. A, 2003, 357(1–2), p 235–239

H.J. McQueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A, 2002, 322(1–2), p 43–63

J.Y. Xiang, R.B. Song, and P.D. Ren, 316L 不锈钢动态再结晶行为 (Dynamic Recrystallization Behavior of 316L Stainless Steel), J. Univ. Sci. Technol. Beijing, 2009, 31(12), p 1555–1559 (in Chinese)

M.F. Abbod, C.M. Sellars, A. Tanaka, D.A. Linkens, and M. Mahouf, Effect of Changing Strain Rate on Flow Stress During Hot Deformation of Type 316L Stainless Steel, Mater. Sci. Eng. A, 2008, 491(1–2), p 290–296

G.Q. He, C.S. Chen, and Q. Gao, 316L, 316LN 奥氏体不锈钢的单轴低周疲劳特性及其微结构 (The Characteristic and Microstructure of Uniaxial Low Cycle Fatigue of 316L and 316LN Austenitic Stainless Steels), J. Southwest Jiaotong Univ., 1996, 31(3), p 283–287 (in Chinese)

Y.L. Xu, J.Q. Zhang, F.M. Zhu, and A. Gessi, 国产 316LN 不锈钢在动态Pb-Bi中的腐蚀 (The Corrosion of Domestic 316LN Stainless Steel in Dynamic Pb-Bi). Annual of China Atomic Energy Science Research Institute, 2008, p 10–12 (in Chinese)

N.S. Bharasi, K. Thyagarajan, H. Shaikh, A.K. Balamurugan, Santanu. Bera, S. Kalavathy, K. Gurumurthy, A.K. Tyagi, R.K. Dayal, K.K. Rajan, and H.S. Khatak, Effect of Flowing Sodium on Corrosion and Tensile Properties of AISI, Type 316LN Stainless Steel at 823 K, J. Nucl. Mater., 2008, 377(2), p 378–384

T.S. Byun, E.H. Lee, and J.D. Hunn, Plastic Deformation in 316LN Stainless Steel—Characterization of Deformation Microstructures, J. Nucl. Mater., 2003, 321(1), p 29–39

D.W. Kim, J.H. Chang, and W.S. Ryu, Evaluation of the Creep-Fatigue Damage Mechanism of Type 316L and Type 316N Stainless Steel, Int. J. Press. Vessel Pip., 2008, 85(6), p 378–384

J.P. Strizak, H. Tian, P.K. Liaw, and L.K. Mansur, Fatigue Properties of Type 316LN Stainless Steel in Air and Mercury, J. Nucl. Mater., 2005, 343(1–3), p 134–144

J. Ganesh Kumar, M. Chowdary, V. Ganesan, R.K. Paretkar, K. Bhanu Sankara Rao, and M.D. Mathew, High Temperature Design Curves for High Nitrogen Grades of 316LN Stainless Steel, Nucl. Eng. Des., 2010, 240(6), p 1363–1370

J.Q. Xiong, G. Xie, and G.B. Tang, Research on Dynamic Recrystallization of Austenite and Flow Stress during Hot Deformation Process of 304 Stainless Steel 304 不锈钢热变形过程奥氏体动态再结晶及流变应力研究, Yunnan Metall., 2008, 37(5), p 37–42 (in Chinese)

W. Bingxin, W. Jiafu, L. Xianghua, and W. Guodong, Dynamic Recrystallization and Grain Refinement in a New Mn-Cr Gear Steel. 新型 Mn-Cr 齿轮钢的动态再结晶及晶粒细化, J. Iron Steel Res., 2006, 18(5), p 38–41 (in Chinese)

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta Metall, 1966, 14(9), p 1136–1138

C. Zener and J.H. Hollomon, Effect of Strain-Rate Upon the Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–32

Y.Q. Bai, M.M. Chen, and H.Q. Chen, 316LN 热变形行为及动态再结晶晶粒的演变规律 (Hot Deformation and Dynamic Recrystallization Behaviors of 316LN), J. Taiyuan Univ. Sci. Technol., 2009, 30(5), p 424–427 (in Chinese)

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morqan, K.A. Lark, and D.R. Barker, Modeling of Dynamic Materials Behavior in Hot Deformation: Forging of Ti-6242, Metall. Mater. Trans. A, 1984, 15(10), p 1883–1892

Y.V.R.K. Prasad and S. Sasidharas, Hot Working Guide: A Compendium of Processing Map, 1st ed., Y.V.R.K. Prasad and S. Sasidharas, Ed., ASM International, Materials Park, OH, 1997, p 3–23

H.L. Gegel, J.C. Malas, and S.M. Doraivelu, Process Modelling of p/m Extrusion, Innovations in Materials Processing, G. Bruggeman and V. Weiss, Ed., Plenum Press, New York, 1985, p 137–140

Acknowledgments

The authors acknowledge China National Erzhong Group Co. for providing the experimental material and the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, B., Ji, H., Liu, X. et al. Research on Flow Stress During Hot Deformation Process and Processing Map for 316LN Austenitic Stainless Steel. J. of Materi Eng and Perform 21, 1455–1461 (2012). https://doi.org/10.1007/s11665-011-0031-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-0031-0