Abstract

This review paper provides a recent overview of current international research that is being conducted into the functional properties of cellulose as a nanomaterial. A particular emphasis is placed on fundamental and applied research that is being undertaken to generate applications, which are now becoming a real prospect given the developments in the field over the last 20 years. A short introduction covers the context of the work, and definitions of the different forms of cellulose nanomaterials (CNMs) that are most widely studied. We also address the terminology used for CNMs, suggesting a standard way to classify these materials. The reviews are separated out into theme areas, namely healthcare, water purification, biocomposites, and energy. Each section contains a short review of the field within the theme and summarizes recent work being undertaken by the groups represented. Topics that are covered include cellulose nanocrystals for directed growth of tissues, bacterial cellulose in healthcare, nanocellulose for drug delivery, nanocellulose for water purification, nanocellulose for thermoplastic composites, nanocellulose for structurally colored materials, transparent wood biocomposites, supercapacitors and batteries.

Similar content being viewed by others

Introduction

The world is facing a very near and present crisis in terms of climate change and the threat to life. A dramatic reduction in global greenhouse gas emissions is needed, and in doing so fossil fuels require significant replacement. Linked to this is a decarbonization of our materials cycle. Our continued reliance on fossil fuels, and in particular oil, for the production of plastics is simply not sustainable. To this end we need to use sources of materials that are renewable, sustainable and have at least the potential to be placed into a closed-loop recycling system. These criteria are often used as a justification for the use of cellulose, which is derived from a renewable resource, i.e., plants, which in addition sequester carbon dioxide from the Earth’s atmosphere for its production and can be potentially returned to the Earth at end-of-life. Nevertheless, this perfect view of cellulose is not yet realized in practice, and we are somewhat far yet in reaching this goal.

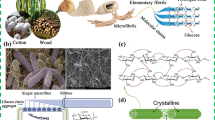

Cellulose is a carbohydrate polymeric material, containing carbon (C), hydrogen (H) and oxygen (O). It also belongs to a broader class of natural polymeric materials called polysaccharides, some of which have similar structures to cellulose, but also include other atomic groups like nitrogen (N) (e.g., chitin [1]). We would like to address early on a mistake in the previous review [2] where it stated that the repeat unit of cellulose is cellobiose. It is in fact glucose [3], and cellulose is rather unique among carbohydrates in that it can be both synthesized from, and hydrolyzed to, monosaccharides [4]. In synthesis, glucose monomers are polymerized into long chains, forming anhydroglucose units joined via β-1,4 glycosidic linkages, as shown in Fig. 1.

An established convention for the repeated structure of cellulose (left) showing the ‘Repeated unit’ of glucose (right), with the correct convention for β-1,4 glycosidic linkages and highlighting the non- and reducing ends of the chain. Image reproduced from [3]. Reproduced with permission from [3] (

The crystalline forms of cellulose are numerous. For the purposes of this article, the two sub-allomorphs of cellulose type I—cellulose Iα and Iβ [5]—are perhaps the most relevant in that they appear to different degrees in the various types of native cellulose from plants, some animals (tunicates), and bacterial forms. The crystal structures of these allomorphs have been determined with great accuracy, in particular their complex and extensive hydrogen bonding [6, 7]. The hydrogen bonding is often quoted as the reason for the high axial stiffness of cellulose, although this is perhaps sometimes overstated, and quite likely hydrophobic interactions between the planes of the pyranose rings play a role too, but most importantly limit solubility [8]. The recalcitrance of cellulose to common solvents has long been an issue for its processing, and it is perhaps for this reason, among many, that the material has been traditionally ‘structured’ by top-down processing, or bottom-up chemical modification or biosynthesis. Recent attempts to self-assemble cellulose-like polymers from enzymatically generated oligomers offer perhaps new ways of producing nanomaterials [9, 10], but these approaches are in their infancy, and not yet suitable for application.

The main forms of cellulose nanomaterials (CNMs) covered in this review are cellulose nanocrystals (CNCs), cellulose nanofibrils (CNFs) and bacterial cellulose (BC); we address the terminology used here in the "Cellulose nanomaterial terminology" section. CNCs are typically produced via the acid hydrolysis of plant-based and other forms of cellulose to produce rod-like particles (see Fig. 2a), although many other production routes are possible. The production and properties of CNCs have been previously reviewed, and readers are referred to that publication for more details [13]. CNFs are typically produced by the mechanical fibrillation of plant cellulose, either via processes such as homogenization, grinding, or excessive beating of pulp. This generates fibrillar materials (see Fig. 2b), and the reader is referred to a previous publication on this subject (where the material is termed ‘microfibrillated cellulose’) [14]. Finally, BC is typically produced by the gram-negative bacterium Glucanobacter xylinum and forms a reticulated network of fibrils, (see Fig. 2c), similar to CNF, but with ‘juncture’ points between the fibrils. Again, the reader is referred to a previous review of BC, and the other forms of CNFs, for more details [15].

Copyright American Chemical Society, 2005), Figure 2b from [2] with permission from Springer-Nature (Copyright Springer-Nature, 2010) and Figure 2c from [11] (CC-BY Open Access, 2019)

Example electron microscope images of cellulose nanomaterials (CNMs); TEM images of a cellulose nanocrystals (CNCs) obtained via acid hydrolysis of microcrystalline cellulose [11] b cellulose nanofibrils (CNFs) [2] and c a scanning electron microscope image of bacterial cellulose (BC) [12]. Figure 2a reproduced from [11] with permission from the American Chemical Society (

Cellulose is the world’s most used material, and it has been exploited for many centuries as wood for fuel and construction, as fibers to produce paper, and textile materials for clothing, ropes, sails and other applications. Our most intimate connection with the material is with wood, and in fact the very word ‘material’ derives from an old Latin word māteria for ‘trunk of a tree’, which itself derives from the word māter which means ‘mother’; many other languages include similar words such as Moeder (Dutch), Maman (French), Māṁ (ਮ) (Punjabi), Mama (Swahili), Maa (媽) (Cantonese), and Mutter (German). The use of this word provides further connection to ‘mother earth’ a concept that is contained in many indigenous languages and belief systems. Perhaps this connection ought to be regained since we are seeking to protect our planet collectively through sustainability, and through the use of mother nature’s material—cellulose.

A review in this journal published in 2010 [2] quoted the English poet Chaucer. It seems apposite to now recall the words of the Japanese Haiku author Matsuo Bashō (1644 – 1694)

“butt of the tree

see in it the cut end

today’s moon”

highlighting the mysteries of wood, or perhaps the old Kenyan proverb that ‘Sticks in a bundle are unbreakable.’ This proverb might both suggest collaboration is a good thing and that we have had a long history of understanding the mechanical properties of wood. Certainly, our relationships with wood are ancient, and intimately associated with our languages, as already described. Wood itself is also probably the oldest composite, and it is well known that it possesses a hierarchical structure, which has been well-documented in the literature [16]. The review we present to you contains work that both deconstructs the woody and plant materials into nanomaterials, but also addresses the use and modification of wood itself, making use of its own inherent nanostructure. We therefore present to you a collection of international research on nanocellulose and its application in a variety of fields. It is truly staggering how this material has grown in interest, with publications on ‘nanocellulose’, and citations to them, growing dramatically over the last decade.

Perhaps it is true to say that many real applications are still yet to materialize. Charreau et al. [17] have, however, recently published data on the numbers of published patents, and their growth since 2010, when the last review in this series was published [2]. This growth in the patent literature is truly dramatic, and nanocellulose is certain to make an impact into many application areas. This review aims to cover research that is a prelude to, and underpins, applications of nanocellulose. Several target areas are covered in the review, namely healthcare, water security, composites, and energy. Recent research in these target areas is discussed, focusing on applications, but also the fundamental research itself that is, and needs to be undertaken to underpin this translation to real products. Each section in this review highlights some work being undertaken by a selected number of international groups, but also contexts this with current work in the field.

Cellulose nanomaterial terminology

Since ‘nanocellulose’ emerged onto the scene as a material there has been a proliferation of the terminology used to describe these materials. We will aim to be consistent in our description of nanocellulose and thereby conform to standards that have been recently laid out in another comprehensive review of techniques to analyze what should collectively be called cellulose nanomaterials (CNMs) [18]. This is the acronym we will use to refer to the different forms of ‘nanocellulose’. We will use the terms cellulose nanocrystals (CNCs) and cellulose nanofibrils (CNFs) to refer to the rod-like and fibrillar cellulosic materials. Confusingly CNCs have also been called whiskers, needles and nanocrystalline cellulose (NCC), and we will avoid such terms. Bacterial cellulose (BC) will also be used as a term, referring to the fibrillar material produced by the gram-negative bacteria Glucanobacter xylinum. We will conform to the international organization for standardization (ISO) on the terminology used for CNMs [19] where possible and to otherwise revert to commonly used terms.

Introduction to nanocellulose in healthcare

Nanocellulose has found suitability in various healthcare applications, for example, tissue engineering and drug delivery, as well as diagnostic devices, wound healing, coatings, drug screening and biosensing [20, 21]. Some key enablers allowing nanocellulose to be used in healthcare applications are its biocompatibility and relatively low cost, as well as its versatility with respect to both the variety of forms available and its ability to be chemically modified. While purity and uniformity of different nanocellulose types (CNFs, CNCs, BC) are dependent on the starting source and production method, they generally offer a reliable, chemically defined, and robust nanomaterial. Plant-based biomaterials can solve some issues present with animal-derived biomaterials where poorly defined, complex mixtures, and high variability from batch to batch suggest advantages of using exogenous components in biomedical applications.

All types of nanocellulose have been evaluated extensively in tissue engineering and drug delivery applications and this section aims to summarize some of the newest advances and trends in the area. For applications in healthcare, BC stands out for its purity (no hemicelluloses, lignin, etc.) and its ability to be manipulated following biotechnological production pathways; in some product development areas like implants, wound healing and cell cultivation/encapsulation, BC has surpassed CNFs and CNCs as reviewed elsewhere [22]. Additionally, we highlight how different architectures like micelles, spheres, patterned surfaces, and 3D-printed shapes, that are based on nanocellulose building blocks, offer advantages such as large surface area, high porosity and enhanced interactions with drugs and cells. While nanocellulose has been shown to have low toxicity [23], there are key variables that have been reported to affect toxicity including size, morphology, crystallinity, surface chemistry and stability [24]. Despite the broad consensus on the low toxicity of the different types of nanocellulose, further studies are recommended to evaluate this property specific to each targeted application, as well as long-term bioaccumulation in the body.

Other important aspects of nanocellulose for healthcare applications are its in vivo biodegradability and bioactivity [23, 25, 26]. High crystallinity celluloses possess low biodegradability and, thus, may limit their use in some bio-applications. Significant efforts have been made to improve biodegradability through chemical modification [27,28,29] or through higher-order arrangement where the structure degrades but not the nanocellulose itself [30]. It is also known that pure nanocellulose lacks bioactivity [25]. Consequently, many efforts have focused on chemical and physical surface modification routes to provide CNF, CNC, and BC scaffolds with improved bioactivity [25, 26]. Their effect on cell culture parameters has been studied and compared to non-modified nanocellulose forms, demonstrating significant progress.

Owing to the rich chemical, structural, and morphological diversity of nanocellulose, a vast amount of research and commercial translation toward medical applications has been reported. In this section, up-to-date information on the use of nanocellulose for tissue engineering and drug delivery applications is presented. Specifically, the use of CNFs, CNCs and BC as tissue engineering scaffolds for in vitro cell culture and the effect of surface modification to render nanocellulose bioactive are summarized. This includes the introduction of chemical moieties at the surface of nanocellulose to provide negative or positive surface charges, and the use of amino acids, proteins, and growth factors, to enhance cell uptake/adsorption at the scaffold surface and promote cell adhesion, growth, proliferation, and specific cell morphologies. Additionally, the effect of nano- and microscale anisotropy within nanocellulose scaffolds on cell response and aligned growth is discussed. Nanocellulose offers multiscale control in both 2D and 3D environments, creating new opportunities within tissue engineering. As for drug delivery, the role of nanocellulose as a drug carrier, co-stabilizer, or release modulator in various forms including sheets/films, nanoparticles, and micelles is reported. The use of various types of nanocellulose-based drug delivery systems is presented including examples with hydrophilic and hydrophobic drugs as well as various administration routes such as oral, transdermal, local and triggered-release.

Franck Quero (University of Chile, Chile): tailoring surface chemistry of nanocellulose scaffolds for in vitro cell culture

Cells modify their behavior dependent on the cues that they perceive from their microenvironment [31,32,33]. One strategy to render the surfaces of several types of nanocellulose more biocompatible and bioactive is through surface modification [25, 26]. Chemical moieties, biomolecules, bio-oligomers and biomacromolecules can be introduced physically or chemically at the surface of nanocellulose to provide cell signals. These include positive or negative surface charges as well as cell receptors such as the amino acid sequence arginine-glycine-aspartic acid. These signals aim at favoring cell uptake/adsorption at the surface of nanocellulose scaffolds, and their effect on cell adhesion, growth, proliferation, and morphology is typically studied.

Research involving the use of BC and CNCs for tissue engineering applications was reviewed by Dugan et al. in 2013 [34]. The surface modification of BC with bioactive peptide sequences using cellulose-binding domains was discussed as a strategy to enhance its bioactivity. The surface charge of CNCs has also been mentioned as a critical factor to provide their surface with biocompatibility and bioactivity. It is known that mammalian cells possess a net negative charge. As a result, materials with positively charged surfaces could potentially favor cell uptake by electrostatic attraction. On the other hand, materials with negatively charged surfaces would minimize cell uptake due to electrostatic repulsion. The first in vitro study of CNCs with living cells was by Roman et al., where the potential of CNCs as carriers in targeted drug delivery applications was demonstrated [35]. Mahmoud et al. then modified the surface of CNCs with fluorescein isothiocyanate or alternatively rhodamine B isothiocyanate, providing them with negative and positive surface charges, respectively [36]. CNCs modified with positive surface charges were found to be uptaken by human embryonic kidney 293 cells, whereas those modified with negative surface charges were not significantly taken up by both cell types at a physiological pH. The results were explained in terms of cell/material surface electrostatic interactions [36]. Cell uptake mechanisms are, however, more complex, and other scaffold features need to be considered including local nanofiber alignment among others, which are discussed in detail below.

The research group led by Ferraz at Uppsala University explored the effect of nanocellulose surface charge on human dermal fibroblast (HDF) cell culture 2D film scaffolds. In their first work, cationic CNFs and Cladophora nanocellulose were obtained by glycidyltrimethylammonium chloride condensation, whereas anionic CNFs and Cladophora nanocellulose were obtained by carboxymethylation and TEMPO-oxidation, respectively [37]. The results revealed that anionic CNF films possessed greater cytocompatibility than non-modified and cationic CNF films. On the other hand, anionic Cladophora films better promoted cell adhesion and viability compared to non-modified and cationic Cladophora films. The improved cell adhesion of HDF onto anionic Cladophora films was attributed to local nanofiber alignment.

In a subsequent study, non-modified, anionic, and cationic CNF films were evaluated as 2D scaffolds to direct monocyte/macrophage (MM) responses in the absence or presence of lipopolysaccharide [38]. The results suggested that MM cultured onto anionic CNF films experienced activation toward a proinflammatory phenotype. Non-modified CNF films, however, promoted a mild activation of THP-1 monocyte cells, whereas cationic CNF films behaved as a bioinert material. None of the materials were able to directly activate the MM toward an anti-inflammatory response.

In a third study by the same group, the effect of the negative surface charge density of TEMPO-oxidized Cladophora nanocellulose on the response of HDF and human osteoblastic cells was investigated [39]. From a carboxyl group amount ≥ 260 μmol g−1, equivalent to a threshold ζ-potential value of -36 mV, TEMPO-oxidized Cladophora nanocellulose was found to be cytocompatible, demonstrating that bioinert nanomaterials can be turned bioactive by adjusting the magnitude of their surface charge density.

More recently, three primary works have studied the effect of surface charge on cell culture. Films composed of non-modified, anionic, and cationic CNFs were obtained by an evaporation-induced droplet-casting method [40]. Non-modified and cationic CNFs resulted in 2D surfaces with higher degrees of local nanofiber orientation compared to anionic CNFs. With respect to cell viability and proliferation, anionic and cationic CNF surfaces were found to perform similarly compared to a positive control surface. Although the use of fibronectin coating slightly enhanced cell response for all 2D surfaces, uncoated anionic and cationic CNF surfaces were found to support cell growth. Cationic CNF surfaces, along with the presence of CNF alignment, were found to guide cell growth toward a specific orientation direction [40]. In a subsequent study by Pajorova et al. [41], cellulose mesh 3D scaffolds were coated with either cationic, anionic or a 1:1 mixture of cationic and anionic CNFs. Cell adhesion, proliferation, spreading, and morphology were studied by seeding the 3D scaffolds with either HDF or adipose-derived stem cells (ADSC). Anionic CNFs promoted the proliferation of both HDF and ADSC, whereas cationic CNFs enhanced the adhesion of ADSC. The cationic and anionic CNF mixture resulted in promoting combined benefits arising from each CNF type [41]. Lastly, CNFs, CNCs and TEMPO-CNFs with variations in total surface charge were investigated as coatings for cell culture [42]. TEMPO-CNFs with a total surface charge of 1.14 mmol g−1 were found to provide the highest cell viability and adhesion compared to the mechanically isolated CNFs without chemical pre-treatment, and CNCs, from which HDF cells were unable to adhere, leading to low viability [42].

Another strategy to render nanocellulose bioactive is by binding either amino acids, peptides, or proteins onto its surface. A first study covalently bound amino acids to the surface of commercial cellulose filter membranes [43]. Cationic amino acids including lysine and arginine were found to enhance cell adhesion, whereas anionic as well as small amino acids significantly reduced cell adhesion. In subsequent work, the surface of α-cellulose fibrous networks was modified by covalent grafting of hydrophilic, aliphatic and aromatic amino acids onto their surface by esterification [44]. Aromatic amino acids, and in particular tryptophan, resulted in enhanced fibroblast cell spreading. Immobilization of collagen peptides onto the surface of dialdehyde BC was proposed by Wen et al. [45] and found to promote enhanced fibroblast cell adhesion and attachment compared to non-modified BC. Another investigation by Barud et al. [46] used silk fibroin proteins to modify the surface of BC, forming a sponge-like scaffold. This was found to facilitate the attachment and growth of L-929 cells, where proteins acted as cell receptors [46].

The research group led by Franck Quero at the University of Chile have produced protein-functionalized cellulose fibrils from the tunic of Pyura chilensis by a top-down approach [47]. As illustrated in Fig. 3, the CNFs were used to produce films, which were subsequently evaluated as 2D scaffolds to culture mouse skeletal C2C12 myoblast cells [47]. Membranes having ~ 3.1% residual proteins at their surface were found to promote higher cell density and spreading as well as a more orientated shape cell morphology compared to membranes constituted of bleached CNFs. In another work by Zhang et al. [48], the real-time cell adsorption of cells onto non-modified and modified CNF films was monitored by multi-parametric surface plasmon resonance. The presence of either human recombinant laminin-L521 (natural protein of the extracellular matrix) or poly-L-lysine at the surface of the CNF films resulted in enhanced attachment of human hepatocellular carcinoma cells compared to non-modified CNF films.

Tunic of Pyura chilensis from which CNFs were extracted and used to produce protein functionalized and bleached cellulose membranes (H1 and B, respectively). Fluorescence microscopy images show the differentiation of myoblasts that adhered and grew onto the surface of H1 and B membranes. Reproduced and adapted with permission from [50] (

Another method to render the surface of CNFs bioactive has been to modify their surface by polyion complex formation between negatively charged TEMPO-oxidized CNFs and positively charged basic fibroblast growth factors (bFGFS) [49]. In this way, Liu et al. mimicked the interactions that naturally exist between bFGFS and heparin sulfate in the extracellular matrix. The scaffold was found to release controlled amount of bFGFS, which was regulated by both CNF surface chemistry and enzymatic deconstruction of the scaffolds. This resulted in significantly enhanced fibroblast cell proliferation [49].

Instead of tailoring the surface chemistry of nanocellulose, other features have been reported to control cell response including multiscale topographical and multicomponent approaches.

These aspects and their specifics are presented in the next subsection and could potentially be translated toward new commercial products in the near future.

Marcus Johns and Emily Cranston (University of British Columbia, Canada): nanocellulose for directional multiscale tissue engineering

Three-dimensional biophysical and biochemical interactions between cells and scaffolds modulate the cell response in terms of proliferation, migration, differentiation, deposition of extracellular matrix proteins, and—ultimately—cell survival. These interactions are dependent on cell surface receptors and, when cell attachment occurs, are regulated by integrin pairs that have a defined nanometric spacing between them [51]. The control of cell alignment via topographical features has been known since the late 1980s/early 1990s [52,53,54]. Microscale features with step changes > 10 µm and spacings > 2 µm inhibit cell migration and spreading [55], whilst nanoscale features with dimensions < 70 nm and spacings between 70 and 300 nm disrupt focal adhesions [56]. Thus, modification of the tissue engineering scaffold over multiple length scales is significant in defining the response of the cells.

This subsection briefly reviews one particularly promising and emerging area of nanocellulose tissue engineering, namely the design of scaffolds with topographical anisotropy at one, or more, length scales. There are, however, numerous examples in the literature of nanocellulose scaffolds that do not exhibit anisotropy that are well suited to biomedical applications (and tested explicitly in vitro or in vivo) as reviewed elsewhere [20, 25, 57,58,59,60,61,62,63,64,65,66] with many newer reports focusing on 3D printing specifically [67,68,69,71,71]. Some highlights in the general area of nanocellulose tissue engineering include: 3D scaffolds with controlled bioabsorbability [30, 72]; self-healing hydrogels for cell delivery [73]; scaffolds that maintain stem cell pluripotency [74], or guide cell differentiation [75,76,77,78,79]; hydrogels that support organoid growth [80,81,82,83]; and bioinks that enable 3D cell printing [84,85,86,87,88,89,90,91,92].

Since all nanocellulose types are anisotropic, being fiber or filament-like with diameters at the nanoscale (e.g., BC and CNF), or spindle-like nanoparticles with all dimensions at the nanoscale (e.g., CNCs), the design of tissue scaffolds with, at least, short-range directionality and nano/micro features becomes possible. Furthermore, long-range directionality and mechanical anisotropy to direct cell response can be achieved via topographical patterning of the scaffold (e.g., soft lithography, 3D printing, templating, electrospinning) or through directed assembly to induce nanoparticle alignment.

In 2010, Dugan et al. [93] were the first to report that the nanoscale structure of CNCs could align myoblast muscle cells (Fig. 4a&b), despite being orders of magnitude smaller than the cells themselves. Straightforward 2D surfaces with spin-coated (radially oriented) CNCs and no other components were sufficient to demonstrate this effect [93]. Similarly, the anisotropic deposition of CNCs onto titanium surfaces guided fibroblast proliferation, offering new opportunities for integrating implants [94]. Although these features appear too small to enable cell attachment according to earlier literature, it has been recently demonstrated that integrin clusters can form across nanofeatures so long as the feature spacing is < 110 nm [95]. It is reasonable to expect that these integrin clusters arrange themselves in line with the features, enabling cell alignment. This work in simple 2D nanocellulose films set the stage for more complex 2D scaffolds and higher dimensionality structures with optimized physicochemical properties and a variety of topographies.

(Copyright American Chemical Society, 2010). c, d Reprinted (adapted) with permission from [97] (Copyright American Chemical Society, 2015). e, f Reprinted (adapted) with permission from [109] (Copyright Elsevier, 2021). S.E. = Standard Error

a Myotubes stained for myosin one week after induction of differentiation on aligned CNC surface. Arrow: approx. degree of CNC alignment, scale bar: 250 µm; b histogram of myoblast orientation relative to approx. radial axis of CNCs; c representative confocal image of human dermal fibroblast adhering to BC substrate with grating microtopography. Orientation of grating reported in top left corner; d histogram reporting the cell alignment distribution relative to grating. Error bar: ± S.E.; e myoblast cell adhesion on uniaxially microscale wrinkled POEGMA-CNC hydrogel sheets with nanoscale parallel-orientated fibers. Scale bar: 50 µm; f histogram of cell orientation angle relative to wrinkles. a, b Reprinted (adapted) with permission from [93]

Soft lithographical techniques have been utilized in tissue engineering for almost 20 years [96], however, the first reported use with nanocellulose was demonstrated on BC by Bottan et al. [97] in 2015 (Fig. 4c&d). Since then, the patterning of BC is typically achieved using polydimethylsiloxane with designed structural features > 1 µm [97,98,99,100]. Spacings of 10 µm between features have been used to direct growth of fibroblasts [97, 99], neuronal cells [98, 100] and muscle cells [100], whilst having a more limited impact on keratinocytes [97, 99]. Importantly, structural control of fibroblast growth via BC scaffolds can influence scar formation in vivo [101]. Jin et al. demonstrated that structured pure BC scaffolds with 10 µm stripes reduced fibroblast proliferation, which limited collagen accumulation. The reduction in collagen, in turn, reduced scar contraction and limited hypertrophic scar formation [101]. Likewise, Boni et al. [99] produced similarly structured BC scaffolds impregnated with silk sericin. The structural features enabled alignment of fibroblasts whilst the silk sericin enhanced fibroblast and keratinocyte proliferation in vitro. However, the structural features limited collagen deposition compared to structurally unmodified BC, which they suggested enhanced the potential to limit fibrosis and scar formation [99]. Thus, soft lithographical modification of BC offers opportunities to produce inexpensive scaffolds and wound dressings with improved healing properties.

Despite previous publications describing increased cell alignment with decreased feature spacing of BC-based materials [97], reports of directly controlling BC ‘ribbon’ alignment are limited. Wang et al. [102] have recently demonstrated that alignment could be achieved via wet-drawn stretching of the BC film. The gelatin impregnated, aligned films exhibited enhanced mechanical properties and significantly improved fibroblast alignment in vitro, with further enhancement achieved via electric field stimulation [102].

Alternatively, one may produce aligned fibers via electrospinning. He et al. produced aligned regenerated cellulose fibers (with ca. 200 nm diameters) loaded with CNCs and spun from lithium chloride/dimethyl acetamide solution [103]. This composition and processing led to improved tensile properties of the fibers and enabled aligned growth of dental follicle cells [103]. The same scaffolds impregnated with bone morphogenic protein-2 promoted osteogenic differentiation of mesenchymal stem cells in vitro, while anisotropic fiber orientation promoted cell alignment, no significant differences in biomarkers (alkaline phosphatase activity, calcium content) were observed between aligned and unaligned fibers [104]. However, in vivo, the aligned fibers enabled aligned collagen deposition and new cortical bone growth on the external face of the implant. These responses were not observed in the unaligned scaffolds, nor in a similar study using aligned poly(L-lactic acid) nanofibers. As such, the enhanced response in the CNC loaded sample was attributed to the improved mechanical properties observed by the incorporation (and alignment) of CNCs in the scaffold [104].

The improvement of mechanical properties and development of nanoscale anisotropy in multicomponent electrospun and 3D-printed scaffolds via CNC/CNF inclusion has only recently begun to be explored [105,106,107,108,109,110,111]. For example, De France et al. reported on the facile production of ‘2.5D’ poly(oligoethylene glycol methacrylate) (POEGMA)/CNC scaffolds that enabled microscale control of ‘wrinkled’ features, similar to those produced using soft lithography, via controlled thermal shrinkage while independently controlling the alignment of the nanoscale features via electrospinning [109]. Uniaxially (micro) wrinkled features with parallel-orientated (nano) fibers resulted in aligned myoblast growth (Fig. 4e&f), whereby CNC content was used to control the compressive modulus and protein uptake [109]. Similarly, Huang et al. [110] demonstrated that they could align oxidized BC along the direction of extrusion in simple printed structures, which influenced the orientation of lung epithelial stem cells. While research into the nanoscale alignment of nanocellulose in 3D-printed architectures through control of shear is still in the initial stages [112,113,114], it offers opportunities for the development of scaffolds that exhibit photoresponsive mechanical properties [115], or change shape depending on the degree of hydration [116].

Nanocellulosic 3D structures with directed cell growth due to anisotropic microscale topographies have been achieved via directional freezing to produce aligned pores within cryogels [117, 118] (as opposed to the anisotropy resulting from aligned nanocellulose itself). The effect of pore morphology on cell response is less well defined than that of 2D ridges/grooves. For example, Karageorgiou and Kaplan reported that the optimal pore size to promote osteogenesis was > 300 µm [119], while the optimal pore diameter for neuronal cells has often been reported to be < 100 µm [120,121,122]. However, strategies to control pore size and morphology in nanocellulosic cryogels are known, including regulation of the gel composition [123,124,125]; freeze-casting temperature and/or rate [123, 126]; sol pH [127]; and nanocellulose morphology [126]. Furthermore, Tetik et al. [128] have recently incorporated directional freezing with 3D printing, which enabled the production of controlled 3D geometries with aligned micropores.

Nanoscale anisotropy via alignment of nanocellulose is readily achieved via various techniques [129]. These include shear forces [112, 113, 130,131,132,133]; magnetic fields [134,135,136,137]; electric fields [138,139,140,141,142]; and material stretching [143,144,145,146]. With regard to magnetic alignment in 3D scaffolds, De France et al. [147] showed that anisotropy could be induced in POEGMA-CNC hydrogels with weak magnetic fields capable of aligning CNCs quickly, even within a polymer gel [136]. This enabled alignment of myoblasts in a 3D culture. Echave et al. [137] took this concept further to produce biphasic gelatin hydrogels that mimicked the tendon-bone interface with magnetically aligned CNCs in one section and hydroxyapatite in the other. Adipose-derived stem cells preferentially aligned and expressed tenascin-C (TNC), a tendon tissue-related biomarker, in the CNC section, while cells remained disordered and preferentially expressed osteopontin (OPN), an osteogenic differentiation-related biomarker, in the section containing hydroxyapatite [137].

Unfortunately, there are limited comparative studies investigating cell responses to different nanocellulose morphologies. Kummala et al. [42] have recently examined the response of dermal fibroblasts on different nanocellulose types (i.e., CNCs, a predominantly microfibrillated CNF, and two predominantly nanofibrillated CNFs). While true ‘nano’-CNFs supported cell attachment and proliferation, limited cell response was observed on the microfibrillated CNF and CNC surfaces. However, as the authors note, one must consider all the variables involved—including topographical features, surface chemical group type and degree of modification, fibril dimensions, tensile properties, and cell type—to be able to draw conclusions as to the cell response. This requires modeling to isolate cell response to specific parameters, such as the regression modeling performed by Johns et al. [148], and must also take the growth media into consideration as selective molecular adsorption will mediate cell-surface interactions [41, 118].

We conclude that topographically anisotropic nanocellulose scaffolds are promising biobased biomaterials for enabling cell alignment in both 2D and 3D, impacting—for example—wound healing in vitro and stem cell differentiation in vivo. Control of the topographic features at both the microscale and nanoscale through patterning and nanocellulose alignment offers new opportunities in regulating cellular response. Combining these structures with stimuli-dependent chemistry may present future opportunities in dynamic/bio-responsive tissue engineering.

Mudrika Khandelwal (IIT Hyderabad, India) and Anu Sebastian (CIPET: IPT-Kochi, India): nanocellulose-based drug delivery systems

Cellulose has a long history of application in pharmaceutics owing to ease of availability and a good compaction property, primarily as an excipient in oral formulations. Nanocellulose has been shown to play a variety of roles and offer several advantages in drug delivery applications, for example, for its release modulation, as a drug carrier, its improved mechanical properties, better compaction, and appropriate rheological modification [20, 23, 149,150,151]. It has been shown that the addition of nanocellulose can control the release of incorporated drugs to significantly reduce consumption [152,153,154,155,156]. Nanofibers offer an additional advantage in terms of mechanical support and improvement of shelf life by improving oxidative stability [29]. Novel drug delivery systems such as triggered and targeted forms have emerged using different types of nanocellulose [157, 158]. Most interestingly, nanocellulose allows easy incorporation of multiscale therapeutic agents such as nanoparticles, drug molecules, supramolecular organization and as a template for the production of other drug carriers [159,160,161,162].

In this subsection, the most up-to-date and relevant findings in the literature are summarized in Table 1, describing the nanocellulose type and source, composition or formulation, mode of drug delivery, and key outcomes. The ability of nanocellulose to act as a drug delivery modulator may be attributed to various reasons: aggregation of nanocellulose, interactions between drug molecules and cellulose hydroxyl groups, as well as cellulose’s ability to modulate the microstructure and morphology of composite materials. It has been shown that nanocellulose can be successfully used for both water-soluble as well as poorly water-soluble drugs [24, 151, 163]. Nanocellulose can be modified, and in the case of BC, to hasten as well as delay the release of a drug and offer a combination of release profiles [164,165,166,167]. Nanocellulose has been utilized for various routes of drug delivery—oral, transdermal, local. There are a few recent reviews on nanocellulose in drug delivery [24, 151, 163, 168]; however, an important emerging concept of triggered or actuated drug delivery remains less discussed [24, 151, 163, 168].

Suitability of nanocellulose for drug delivery

Given the wide variety of nanocellulose types, it can be used in various ways in different drug delivery systems. For example, nanocellulose can be the carrier for the drug or act as a delivery modulating agent. Furthermore, it is important to recognize that nanocellulose can be obtained or processed in the form of nanoparticles, microparticles, tablets, aerogels, hydrogels, and membranes, enabling varied modes of drug delivery [169]. The large surface area and high density of surface hydroxyl groups on nanocellulose make it conducive for hydrophilic drug delivery specifically. For hydrophobic drug delivery, functionalization or the production of composites or hybrid materials has been shown to be useful [152, 170, 171].

Despite many advantages, nanocellulose also has some limitations—namely, moisture sensitivity and low thermal stability [172]. Significant progress has been made to improve these properties through pre-treatments and surface modifications. Aggregation can be a challenge and may be overcome by deploying electrostatic effects and steric stabilization mechanisms [163]. To summarize, surface modification pathways have emerged as an important step to optimizing nanocellulose in drug delivery to 1) carry the drug; 2) make it suitable for delivering hydrophobic drugs; 3) prevent aggregation; 4) improve processability (i.e., by enhancing thermal stability); and 5) improve shelf life by decreasing moisture sensitivity [162].

Nanocellulose for various routes of drug delivery

Delivery systems must be developed to administer drugs using the most suitable route. Different types of nanocellulose have been used to deliver various classes of drugs including anticancer, anti-inflammatory, analgesics and antibiotics following oral, transdermal, implantable, and local delivery routes, as summarized in Table 1. While oral drug delivery is the most common mode of drug administration, it suffers from challenges such as the need for high and frequent doses, and side effects, which need to be addressed. Nanocellulose has been used for the delivery of, for example, indomethacin, salbutamol sulfate, diclofenac, ampicillin, and ranitidine. It has also been demonstrated that the addition of nanocellulose to these formulations offers several benefits such as an increase in the dissolution rate and oral bioavailability, high drug entrapment efficacy, enabling sustained and controlled drug release, prolonged drug release in fasted state-simulated stomach fluid, and good mechanical and viscoelastic properties [154, 173,174,175,176].

Nanocellulose has shown great potential in transdermal as well as topical drug delivery systems where the drugs are administered through the skin to achieve therapeutic concentrations. Thus, it allows the drug to by-pass the gastrointestinal tract and liver metabolism and enables an effect at lower doses. Nanocellulose has enabled release modulation, high drug entrapment, good permeation rates with drugs such as berberine compounds, diclofenac, providone-iodine, hydroquinone, ceftriaxone, and crocin [177,178,179,180,181]. It is important to note that transdermal delivery works better for small molecule drugs.

Another popular approach is implantable systems or local drug delivery systems that release the drug at or near the target site, increasing the effectiveness and lowering the required dose. Nanocellulose has been particularly beneficial with local delivery of diclofenac, doxorubicin, and methotrexate [165, 182]. Another local delivery route explored with nanocellulose is ocular drug delivery, which takes advantage of nanocellulose gel properties [153].

Nanocellulose has also been explored to produce stimuli-responsive materials for smart/triggered drug delivery systems. These materials are sensitive to specific stimuli which can be a change in humidity, pH, and light, or the application of an electric or a magnetic field. For example, multi pH/near-infrared responsive polydopamine/CNF composites with calcium ions as crosslinkers have been developed for drug delivery and wound healing applications [183]. The drug tetracycline hydrochloride could be released in a controlled fashion on exposure to Near Infrared (NIR) radiation or lower pH conditions. Such a system also offers a synergetic effect on wound healing and is advantageous as it is easy to fabricate while providing multi-response and sustained release of the drug. CNF-sodium alginate-based gel macrospheres were developed for intestinal targeted delivery of probiotics, thereby protecting them from the acidic conditions of the stomach [184]. A novel dual stimuli responsive drug delivery system of aminated nanodextran and carboxylated nanocellulose deposited on the surface of modified graphene oxide was prepared by layer-by-layer assembly [158]. It showed that curcumin can destroy HCT116 cells upon exposure to NIR radiation. In this case, the drug was loaded into the nanocomposite based on hydrogen bonding or π-π stacking and was released faster in an acidic environment than at an intestinal pH [158].

A dual responsive hydrogel based on BC and sodium alginate which reacts to changes in pH and electric stimuli has been developed [157]. The model drug, ibuprofen, showed an enhanced release in a neutral or alkaline medium and in the presence of an electric stimulus [157]. Another BC-based drug delivery system was fabricated by chemical oxidative polymerization of BC and polyaniline [185]. This resulted in a pH-electro sensitive hydrogel that showed a slower release of the drug berberine hydrochloride in acidic conditions thereby protecting the drug before it is released into the small intestine for drug absorption, and it also showed accelerated release on application of an electric potential [185].

Commercialization of healthcare products incorporating nanocellulose

Several companies have been commercializing medical grade products based on BC (e.g., Membracel® by Vuelopharma, Epi Nouvelle+® naturelle by JeNaCell GmbH) and CNFs derived from tunicates (e.g., Ocean TuniCell®) and wood pulp (e.g., UPM Biomedicals). Most of these products are based on non-surface-modified nanocellulose but UPM Biomedicals now sells a cell culture media product named GrowDex®-A that consists of surface-modified CNFs with proteins or peptides. UPM Biomedicals also produces FibDex®, an advanced CNF wound care dressing that has proven to provide efficient wound healing in skin graft donor sites [209]. CELLINK have also developed a series of bioinks based on CNFs and alginate for the 3D printing of tissue engineering cell scaffolds. As such, commercial opportunities exist to move forward with the use of surface-modified nanocellulose toward new commercial products.

Surrounding wound dressings with transdermal drug delivery, application, product development and commercialization of nanocellulose continues to advance significantly. Some commercial products include Biofill®, Bioprocess®, Suprasorb X + PHMB® and Xcell®. Nanocellulose-based drug delivery products such as Gengiflex® membranes for dental implants exist; however, there is a need to push clinical trials and commercialization of nanocellulose further [23, 149]. For widespread acceptance of nanocellulose in drug delivery, a better understanding of the influence and regulation of drug release, interactions between drug molecules and nanocellulose, as well as possible reduction or destruction of drug activity and structure is required. In addition, toxicity needs to be further assessed, likely on a case-by-case basis [210].

Introduction to nanocellulose and water purification

Although water is a basic need for all 7.9 billion of us, access to clean portable water remains a significant challenge globally. The UN estimates that over one million people in developing countries do not have access to clean drinking water and that up to 159 million people around the world consume untreated water from surface water sources [211]. Yet this water is often contaminated by toxic levels of heavy metals, dyes, and hydrocarbons.

This section presents advances in the application of cellulose in water treatment. We classify the use of cellulose for water treatment applications into the following three categories: (i) as the active agent i.e., adsorbent, (ii) as a support for adsorbents or catalysts, and (iii) for the enhancement of photocatalyst performance through reduction of the band gap energy.

As the active agent, negatively charged (-COO¯) cellulose materials such as those generated by TEMPO (2,2,6,6-tetramethylpiperidine-1-oxyl radical)-mediated-oxidation or sulfuric acid hydrolysis (-SO32−) can serve as adsorbents for cationic contaminants (e.g., metal ions [212,213,214]). The surfaces of cellulose fibers may also be functionalized by amine (-NH2¯), thiol (-SH¯), phosphoryl (-PO32−), or sulfate (-SO32−) groups to increase the specificity for specific elements [215, 216]. In similar fashion, cationically modified cellulose may be applied as an adsorbent for anionic pollutants (e.g., As(V), As(III), Cr(VI), pesticides, and dyes [217, 218]. These approaches have the advantage of involving relatively simple modifications to the cellulose fibers [217, 218].

The use of cellulose as an adsorbent support takes advantage of the physical properties of cellulose, in particular, its porosity [219]. Pores within and between fibers can act as nucleation and deposition sites for adsorbents, reducing their attrition/ loss, thus increasing the performance and lifespan. Iron oxides, for instance, are excellent adsorbents for arsenic, whose contamination of groundwater poses serious health effects to over 40 million people worldwide [220]. However, recovery from treated water poses a significant challenge to the use of iron oxides for this purpose. Recent work has shown that iron-oxide-cellulose composites can overcome this challenge, increasing both the performance and lifespan of the adsorbent [221]. A similar rationale has been employed in the design of catalysts for advanced oxidative processes, to allow for reuse/recycling of catalysts [222]. Further, it has also been suggested that cellulose increases catalyst performance by providing settling sites for radicals and pollutants thus increasing their interaction, and the subsequent degradation of the latter [223], in addition to preventing catalyst aggregation of the catalyst, increasing access to active sites on the catalyst surface [224].

A third way by which cellulose has been applied in water treatment has been for the enhancement of the performance of photocatalysts. In the presence of graphitic structures (e.g., cellulose char), electron–hole recombination after exposure of the catalyst to irradiation is hindered, as electrons are instead quickly captured by the cellulose char [225]. Holes created in the conduction band (CB) because of this electron capture result in a higher probability of the formation of •OH radicals, while electrons in the biochar combine with oxygen in solution to form superoxide radicals (•O2 ¯). Cellulose therefore acts as a sustainable and renewable graphitic source, improving catalyst performance. Indeed, Fu et al. [226] found that for the oxidative degradation of orange II by peroxymonosulfate, the graphitization degree had a greater influence than surface area and pore volume of a MnFe2O4-based catalyst.

Anita Etale (University of Bristol, UK): nanocellulose for water purification

Using locally available agricultural waste biomass including hemp, and corn stover, various approaches for the preparation of heavy metal adsorbents have been explored. In one study, cellulose-supported iron oxides were prepared and applied for the removal of As(III), As(V) and Cr(VI) ions. Notwithstanding that arsenic is considered carcinogenic even at very low concentrations, over 200 million people in 40 countries around the world are exposed to drinking water with As levels above World Health Organisation guidelines (10 µg L−1) [227]. Although As(V) predominates (as H2AsO4− and HAsO42−) in oxidizing conditions, in regions of previous gold mining activity which are often characterized by reducing conditions and high sulfate concentrations, arsenic exists predominantly in the more toxic As(III), as H3AsO30 and H2AsO3−. Nevertheless, because of slow redox transformations, both forms often occur in either redox environment [228].

Anita Etale’s group has explored two strategies for the use of cellulose in water treatment applications. The first involves using cellulose as a support material for iron oxides which are excellent adsorbents for arsenic [229]. Preliminary work, however, showed them to be prone to dissolution so that the prepared iron oxides ‘leached’ into treated water compromising both the treatment process and adsorbent lifespan. To address this challenge, iron oxides were deposited on CNF extracted from hemp fibers. Importantly, the CNF are thought to be porous [219]. CNF porosity may be the result of dissolution of lignin and hemicellulose between the lamellae by the chemical pulping process, or mechanical treatments e.g., blending and sonication applied to increase fibril separation. CNF with average pore sizes of ~ 6 nm have recently been reported [219]. Manninen et al. [230] also reported a cumulative pore volume of 1.7 mL g−1 from pore sizes that ranged from < 1 – 3 nm in kraft pulp fibers, and from 3 nm to an undefined maximum between the CNF fibers.

The approach to adsorbent synthesis has, therefore, involved exploiting these pore spaces as embedment sites for contaminant adsorbents. In one study, a cellulose-ferrihydrite composite (Fig. 5a) was synthesized by the deposition of iron oxide onto TEMPO-oxidized fibrils at pH 10.5. Iron oxides, including poorly crystalline ones such as ferrihydrite, have a strong affinity for both As(III) and As(V). Adsorption occurred primarily by ligand exchange with surface OH2 and / or OH− resulting in bidentate binuclear inner-sphere complexes [229, 231]. This adsorbent displayed efficiencies of > 99% for the removal of As in mine drainage contaminated water (Fig. 5b). Further, column experiments showed that 1 g of the adsorbent was needed to treat 1L of contaminated water. The reduction in absorbance intensity from the OH region (1000 cm−1) on FTIR spectra (Fig. 5c) suggests that adsorption of both arsenic species involved some loss of OH as suggested by Jain et al. [229].

(Copyright Elsevier, 2013); e and f are reproduced under the terms of a CC-BY license from [218]. a–c are unpublished data

a Scanning electron micrograph of CNF-Fe adsorbent. b Removal efficiency of the CNF-Fe adsorbent when exposed to mine-drainage contaminated water c FTIR spectra of CNF-Fe before adsorption, and after uptake of As(III) and As(V). The box highlights changes in the surface -OH absorption region before and after adsorption. d Scanning electron micrograph of succinic anhydride-modified CNF [215]. e CP-MAS 13C NMR spectra of unmodified and cationized cellulose with the additional peak at ~ 52 ppm from (CH3)3 N+- groups of the quaternary amines highlighted fr(VI) removal efficiency of cationized cellulose. (d) is reproduced from [215] with permission from Elsevier

A similar approach was employed in Sillanpää’s group for the removal of Ni, Cd, Cu, as well as PO43− and NO3− [232]. Removal of these ions by CNF-calcium hydroxyapatite composites was rapid with > 95% of metal ions adsorbed in the first five minutes of exposure. Removal efficiencies were also high for phosphate ions (> 85%) and nitrates (> 80%). Exposure of the same adsorbent to Cr(VI) contaminated water also revealed similarly high efficiencies between pH 5 and 7: 94% of Cr(VI) ions were removed from solution in the first 5 min [233]. In a separate study, succinic anhydride was deposited onto CNF, and the composite investigated for adsorption of a range of metals (Fig. 5d) [215]. The results showed maximum metal uptakes ranging from 0.72 to 1.95 mmol g−1 and following the order Cd > Cu > Zn > Co > Ni. Adsorption was constant between pH 3 and 7 for Zn, Cu, and Cd (> 95%), and above 75% for Co and Ni at pH 7. Importantly, 96 -100% of the adsorption efficiency could be regenerated by sonicating the used composite in 1 M HNO3 for 15 s.

A second approach has been through surface modification of cellulose e.g., via amination [216], thiolation [234], and cationization. This latter approach uses two quaternary ammonium salts: 3-chloro-2-hydroxypropyl trimethyl ammonium chloride (CHPTAC) and glycidyltrimethylammonium chloride (GTMAC), and has been explored (Fig. 5e) and the resulting materials examined for Cr(VI) removal (Fig. 5f), and antibacterial activity. The results showed that at pH 4, 0.1 g of CHPTAC-modified cellulose removed up to 47% of Cr (VI) ions, while 72% was adsorbed by GTMAC-cationized cellulose. GTMAC-cationized also displayed considerable antibacterial effects, reducing the viability of Escherichia coli by up to 45% after just 3 h of exposure. However, Cr(VI) uptake in contaminated water (pH 2.7) was diminished to 22% likely due to competition from sulfate and selenate ions [235] which are abundant in mine drainage. Nevertheless, together, these results suggest that cationized cellulose can be applied in the treatment of Cr(VI)-contaminated mine water particularly if pre-treatments to reduce concentrations of other anions are applied.

Supree Pinitsoontorn (Khon Kaen University, Thailand): carbonized bacterial cellulose aerogel as an efficient sorbent for oil-polluted water

Bacterial cellulose (BC) is a class of nanocellulose with a unique structure and properties, such as a three-dimensional network of intertwined cellulose nanofibers, remarkable mechanical properties, high porosity, and low density [236, 237]. In its original state, BC is a hydrogel with a significant water uptake volume (~99%) [237]. Freeze-drying removes the water content but still preserves the BC 3D nanofibrous network and transforms a hydrogel into an aerogel. Moreover, pyrolysis of the BC aerogel in an inert gas atmosphere leads to the carbonization of the BC nanofibers, thereby forming a carbon nanofiber aerogel. The carbonized BC (c-BC) aerogel inherits the BC precursor's merits, so it still preserves the 3D continuous architecture, the interconnected nanofibrous network, and an extremely high porosity. The surface area of the carbon nanofibers can reach > 400 m2 g−1, with a sizeable porous volume (ca. 3.00 cm3 g−1) and an ultra-light weight (4–6 mg cm−3) [238]. Furthermore, high-temperature pyrolysis can induce the hydrophobic/oleophilic properties of the c-BC aerogel, which makes it an ideal material for oil sorption.

Oil pollutants are one of the leading global environmental problems. Every year, the annual spillage of petroleum compounds to the marine environment is over 1.4 million tonnes which has caused catastrophic effects on ecological systems [239, 240]. Therefore, a remedy for oil-spills is urgently needed. Although there are several approaches for treating oil-spills, the most effective approach is via physical adsorption, i.e., the use of oil sorbents, which has been proven to be energy-efficient, highly selective, environmentally friendly, fast, and recyclable [241, 242]. Research over the last decade has reported several types of oil sorbent materials. Carbon aerogels have received considerable attention as one of the most effective materials for adsorption, separation, and recovery of spilled oil [243, 244]. The carbon aerogels can be fabricated from various biomass-based products, such as cotton, bamboo, winter melon, or waste paper [241]. These aerogels have been applied for remedying oil-spills and have successfully demonstrated a large oil sorption capacity of up to 100 times of their weight. However, the preparation processes for such aerogels may involve severe mechanical and chemical pre-treatments, which are high in energy consumption, and subject to environmental concerns. Moreover, high-temperature pyrolysis may cause frangibility and brittleness to those biomass-based carbon aerogels [245], which hinders their practical use for oil recovery. On the other hand, carbon aerogels from carbonized BC (c-BC) have advantages over other biomass-derived materials. The fabrication of c-BC is simple and cheap without any use of harsh chemicals or complicated processes. Also, the natural 3D continuous nanofibrous architectures of BC make the c-BC material mechanically robust and flexible. The c-BC aerogel is typically obtained in a bulky macroscopic form, which is desirable for easy handling and recycling after oil sorption. Plus, the shapes and sizes of the c-BC aerogel are controllable via the bacteria cultivation process and scalable for industrial production.

The application of the c-BC aerogel for oil sorption was firstly reported by pioneering work done by Wu et al. [246]. They showed that pyrolyzing the BC aerogel under an argon atmosphere at 700–1300 °C led to a c-BC aerogel with a density of only 4–6 mg cm−3 and a high porosity up to ca. 99.7%. The c-BC aerogel exhibits hydrophobicity and can adsorb a wide range of oils and organic solvents with excellent recyclability by direct combustion. The sorption capacity reached up to 310 times the weight of the c-BC aerogel. Moreover, it was highly flexible and mechanically robust. It could also be compressed to a more than 90% volume reduction and almost recover to its original shape after release, making a ‘squeezing’ process to recover oil possible [246]. In a recent study, a c-BC aerogel pyrolyzed at 1200 °C was compressed to 99.5% strain, and it was able to be restored elastically to almost its original shape after release [247]. A detailed surface area and pore-size study showed that micropores and mesopores (2–100 nm) occupied a large portion of the pore-size distribution, providing huge spaces for oil sorption and leading to high oil sorption capacity. Furthermore, this c-BC aerogel was an excellent thermal insulator with extremely low thermal conductivity (0.025 W m−1 K−1) comparable to air [247].

Several efforts have been reported to increase the oil sorption capacity of c-BC aerogels by using a composite approach. c-BC was combined with carbon nanofibers derived from polyimide (PI) by freezing the mixture of BC and PI precursor suspension before imidization and pyrolysis [248]. The resultant carbon aerogel consisted of a 3D carbon skeleton with a cellular architecture from carbonized PI, decorated with 1D c-BC nanofibers. This hierarchical structure was advantageous for enhancing the compressive modulus leading to an improved shape-retention ability due to the effective crosslinking between the PI carbon skeleton and the c-BC nanofibers. The aerogel was so stiff that it supported a weight of 200 g without any noticeable deformation. Moreover, the combined 3D carbon skeleton and 1D c-BC nanofibers resulted in a reduced pore size and a narrow pore size distribution, which could be beneficial for oil sorption [248].

Wan et al. fabricated a c-BC aerogel nanocomposite with graphene [249]. To facilitate the uniform distribution of graphene in the BC network, an in situ biosynthesis route under agitated cultivation using a graphene-dispersed culture medium was employed. The spherical BC/graphene hydrogel was carbonized at 800 °C to form a sphere-like c-BC/graphene aerogel. The nanocomposite aerogel exhibited an open honeycomb-like surface pattern consisting of numerous ridges and large cavities, which increased the aerogel's specific surface area and porosity. The unique nanostructure of the sphere-like c-BC/graphene aerogel is the key to enhance the sorption capacity (up to 457 times of its weight) for a wide range of oils and organic solvents [249].

Reduced graphene oxide (rGO) has also been composited in a c-BC aerogel [250]. This was done by freeze-casting and freeze-drying of the GO and BC mixed suspension. The GO nanosheets and BC nanofibers were uniformly assembled into a porous and interconnected 3D network. Subsequent pyrolysis transformed it into rGO/c-BC aerogel with the preserved 3D nanostructure where the c-BC nanofibers were still coated on the rGO sheets. The aerogel density was easily controlled by varying the concentration of the precursor in the suspension and the ratio of GO/BC. The lowest density was found for a GO/BC ratio of 1:1. The oil sorption capacities of the rGO/c-BC aerogel ranged from ~ 300 to 1000 times of its weight, much higher than most carbon sorbents [250]. The ultrahigh sorption capacity was attributed to its low density and high porosity.

Luo et al. devised a new method of preparing c-BC aerogels containing rGO by a novel BC culturing process [251]. A thin BC pellicle was used as a substrate in the static culture. The solution containing a 2D few-layer rGO (FrGO) suspension was sprayed onto the BC substrate to form a thin layer, onto which BC was grown to consume the sprayed FrGO layer completely. The process was repeated to form a thick BC/FrGO layered structure, which was then freeze-dried and pyrolyzed. The c-BC/FrGO aerogel from the process exhibited an entangled nanostructure between the FrGO sheets and c-BC nanofibers, creating a multi-scaled porous structure and large specific area. As a result, the c-BC/FrGO aerogel exhibited mechanical robustness and an extremely high sorption capacity of 245–598 times its weight for a range of oils and organic solvents [251]. It also showed excellent reusability by both squeezing and combustion, with nearly the same sorption retention.

To assist the collection of a c-BC aerogel for reuse, regeneration, or recycling after oil sorption, functionalizing the aerogel with magnetic properties is a very useful and practical approach. A magnetic functionalized c-BC aerogel can be collected easily in large quantities with the aid of an applied magnetic field. Supree Pinitsoontorn and his team at the Institute of Nanomaterials Research and Innovation for Energy (IN-RIE), Khon Kaen University, have explored that concept by using in situ co-precipitation of magnetic Fe3O4 nanoparticles in the BC pellicle before converting it into a magnetic c-BC aerogel [252]. Interestingly, by controlling the concentration of the initial Fe3O4 precursors, the c-BC nanofibers were decorated with well-dispersed magnetic nanoparticles with a Fe/Fe3O4 core–shell structure (Fig. 6a&b). The core–shell structure increased the magnetization of the NPs due to the large magnetization of the Fe core. This, in turn, improved the magnetic attraction ability when subjected to external magnetic forces. Although magnetic NPs were impregnated in the c-BC structure, the outstanding mechanical properties of the c-BC aerogel were still maintained. The magnetic c-BC aerogel was able to be compressed up to 90% strain and return to its original shape after release. This process was repeated up to 100 successive cycles, and the shape of the aerogel was nearly unchanged from the original state. Moreover, even with the addition of magnetic NPs, the magnetic c-BC aerogels had an ultralightweight property with a density of only 7.4 mg cm−3, which is lighter than other magnetic carbon aerogels from several carbon sources [253, 254]. The oil sorption capacity of the magnetic c-BC aerogel was still very high (37–87 times of its weight), which is comparable to other carbon aerogels from various sources [254,255,256]. Also, it can be rendered recyclable several times by dissolution. The highlight of the magnetic c-BC aerogel is its ability for magnetic retrieval from the liquid after sorption. As shown in Figs. 6c&d, the motion of the magnetic c-BC aerogel in a liquid can be controlled by an external magnet. The magnetic force can also lift it out of the liquid after use. This functionality is beneficial for manipulating the sorbents in a large area of polluted water, in a practical application of this technology.

a, b TEM micrographs of the magnetic c-BC aerogel showing the magnetic Fe/Fe3O4 core–shell nanoparticles anchoring on carbon nanofibers. c The sorption experiment and magnetic retrieval after oil sorption. d The sorption of oil floating on water, with magnetic manipulation and retraction of the c-BC aerogel. [252]. Image reproduced from [252] with permission from the ACS (

The magnetic c-BC aerogel could not just be used for the remediation of an oil-spill but also be applied to other contaminant adsorption situations. Figure 7 shows a series of images demonstrating the dye (indigo carmine) sorption capability of the magnetic c-BC aerogel [257]. The vivid blue color gradually faded, and the water became clear just like before the dye was added, indicating the complete dye removal, as confirmed by UV–Vis analysis. After the process, the aerogel was magnetically removed from water by a permanent magnet. The dye-adsorbed c-BC aerogel can be regenerated by dissolution followed by oven-drying before reuse. In addition, the magnetic c-BC aerogel can still be utilized in water treatment applications for other contaminants such as bisphenol A and Cr(VI) [258, 259].

Yixiao Cai (Donghua University, China): using cellulose for wastewater treatment for dyes, heavy metals and desalination

In recent years, various semiconductor/cellulose composite materials have been widely used in the degradation of organic dyes in printing and dyeing wastewater, such as metal oxides (TiO2, ZnO, WO3), metal sulfides (CdS, ZnS), bismuth-based semiconductors (BiOCl, BiOBr, BiOI, Bi4O5Br2), silver-based semiconductors (AgBr, AgI, Ag3PO4, AgVO4 and AgCrO4) and non-metallic semiconductors (graphite, carbon nitride).

Some studies combine photocatalysis with other oxidation methods to further strengthen wastewater treatment. Rajagopal et al. [260] prepared microcellulose (MC) and TiO2 composite materials, combined with hydrogen peroxide photocatalytic degradation (TiO2 + MC + H2O2), to decolorized wastewater containing multiple dyes under sunlight. They showed that 99% of high-concentration methylene blue (MB) dye wastewater (200 mg/L) can be degraded within 150 min, and the removal efficiency of Chemical Oxygen Demand (COD) can reach 72%. It was highlighted that the synergy index of H2O2 assisted photocatalytic degradation is 3.54, which shows that the above process coupling has a positive synergistic effect. Other research that is being developed by Cai et al. [261] takes advantage of a nanocomposite strategy, rendering stable cellulose-based hybrid materials with diverse functionalities for micropollutant removal. Through synergistic oxidation, e.g., persulfate activation, photocatalytic water treatment has been proven to obtain practical value and can be further developed industrially [261].

As already discussed, heavy metal ions in water can be removed by adsorption. However, single physical adsorption can only enrich and transfer heavy metals but cannot completely remove them. Semiconductor photocatalysts have redox capabilities, which can change the chemical properties of heavy metal ions to reduce their toxicity. Taking TiO2 as an example, the mechanism of photocatalysis to remove heavy metal ions is roughly as follows:1) nano-TiO2 adsorbs heavy metal ions on its surface, 2) an ultraviolet lamp is excited to generate photogenerated electron–hole pairs, and the electrons transition to the conduction band and transfer to the TiO2 surface, 3) photogenerated electrons reduce the adsorbed heavy metal ions to low valence states (such as chromium, mercury, lead) or elemental forms (such as silver), the metal ions in the lower valence state further generate compounds and precipitate (such as chromium) or further obtain electrons as elemental substances (such as lead, mercury) and deposit on the surface of TiO2 particles. However, supporting TiO2 (or other semiconductor photocatalyst) on the surface of cellulose can improve the removal efficiency of heavy metal ions. Although the adsorption of heavy metal ions by the hydroxyl groups in cellulose contributes to the removal of metal ions, the adsorption effect is weak. For this, researchers usually take advantage of chemical modification or graft copolymerization to introduce effective adsorption active sites on the surface of cellulose [262] such as carboxyl groups, amino groups, and sulfonic acid groups. These groups can selectively recognize and capture various heavy metal ions through electrostatic attraction or complexation and chelation coordination effects [263], thereby improving the photocatalytic removal efficiency.

Interfacial solar evaporation, which utilizes the abundant sunlight to evaporate saltwater, has gained significant attention as an environmentally benign and sustainable approach. Significant efforts have been made in realizing supporting substrates that provide optimal thermal management and unimpeded water transport to foster high-performance interfacial solar evaporation. The high degree of crystallinity of CNMs provides excellent mechanical stability, and their highly dense surface functional groups enable direct deposition or adsorption of various photothermal materials [264, 265]. After subjecting MoS2/BC bilayered aerogels to vigorous mechanical agitation, no detachment of photothermal materials from a BC matrix was observed, and the bilayered structure remained intact [266]. Besides, CNMs can be easily processed into nanomicroporous structures, and this interconnected porous structure can enhance the light absorption of the photothermal materials loaded onto these structures because of the increased light reflection and scattering within the pores. Jiang et al. prepared carbon nanotube/cellulose composite aerogels as photothermal materials. Owing to the strong hydrogen bonding between the ample hydroxyl groups of CNFs and carboxylic groups of CNTs, these materials were found to be robust. The ultrahigh porosity of the CNF aerogel and high light absorption of CNTs led to a 97.5% light absorbance within the light range from 300 to 1200 nm [267]. In addition, owing to a low thermal conductivity they provide excellent thermal insulation. The thermal conductivity of a sophisticated solar evaporator designed by Li et al. was as low as 0.06 W m−1 K−1. This solar evaporator achieved high evaporation efficiency, up to 85.6% under 1 sun illumination [267].

Introduction to polymer matrix biocomposites from well-dispersed cellulose nanofibers

Cellulose-based plant fibers can be readily used by themselves to form paper, packaging board materials and recently molded fibers [268]. Polymer matrix composites based on the same fibers offer possibilities to improve processing (improved geometrical complexity, rate of processing etc.), extend the range of physical properties, and improve the chemical stability, where the improved moisture stability is particularly important for engineering applications. The use of CNFs as a reinforcement is then of obvious importance: wherein the intrinsic ‘fiber’ properties should be better than for the plant fibers, specific nanoscale phenomena may occur such as structural improvements to the polymer matrix (crystallinity, orientation, reduced molecular mobility etc.) and it may become easier to fabricate small-scale geometries.

The first effort to make cellulose nanocomposites with a polymer matrix appears to have been the investigation by Boldizar et al. [269]. Poly(vinylacetate) nanocomposite films were prepared from hydrolyzed and homogenized cellulose pulp, with strongly improved mechanical properties. Also, hydrolyzed cellulose pulp was compounded with thermoplastics, injection molded into specimens for mechanical property measurements. The reinforcement effect was better than for pulp fiber reinforcement, possibly due to the higher aspect ratios obtained from the disintegration of the pulp fibers into nanofibers. The cellulose nanocomposites field, however, did not really take off until researchers in Grenoble investigated hydrolyzed CNCs (then called ‘cellulose whiskers’) as a reinforcement [270, 271], followed by numerous studies, e.g., using nanocelluloses from parenchyma cells (potato tubers etc.), which are covered in a thorough review of the background to the whole field [272]. Yano and coworkers then investigated wood-based CNFs combined with poly(phenol formaldehyde) resins [273] and transparent nanocellulose films with an acrylate polymer matrix [274]. High optical transmittance and high mechanical performance is a highly interesting combination for biocomposites, which provides unique application opportunities, and will be reviewed in more detail in subsequent sections. Another important category of composites for engineering applications is ‘cellulose biocomposites’ based on thermosets. These are suitable for large-scale production, with nanopaper reinforcement in the form of prefabricated CNF mats. Epoxy and polyester resins typically used for glass fiber composites have been reinforced with a high content of wood CNFs [275, 276], and mechanical properties were competitive with molded glass fiber composites [277]. A large collection of mechanical property data for cellulose nanocomposites have previously been analyzed [278]. The strongest and stiffest nanocomposites were those based on a high content of prefabricated nanopaper reinforcement, and properties scaled with nanopaper properties and volume fraction.

Key research and technical goals for the promotion of nanocellulose applications include scalable processing concepts and processing technologies for cellulose nanocomposites. Numerous technical studies are disappointing in that the mechanical performance does not meet requirements. Properties are simply not good enough to justify substitution of a petroleum-based polymer composite reinforced with glass fibers or mineral fillers. The most common reason for this first problem is that the CNFs are agglomerated in the composite, often into microscale aggregates. Although such a material is based on nanofibers, it is not nanostructured in a true sense. The modulus usually still shows improvement, although the reinforcement can be even lower than for comparable plant fiber composites. Strength is often reduced by the presence of aggregates, since they form stress concentrations which tend to initiate failure at low strain. A second problem is that cellulose nanocomposites are expected to contribute to sustainable development, but energy demand and carbon dioxide emissions related to CNF and nanocomposites fabrication tend to be high [279], which needs to be addressed. Holocellulose-based native CNF is one interesting possibility with low fibrillation energy, despite the lack of chemical modification [280]. Finally, the cost of the nanocomposite material needs to be competitive with alternative materials for a given application. The two last points (sustainability and cost) mean that the possibilities for chemical modification of nanofibers are not endless, contrary to many optimistic statements.