Abstract

This study tested the hypothesis that post-harvest hot water blanching improves the chemical composition, mainly mineral and carbohydrate contents, and in vitro digestibility of two predominant brown macroalgae, Ascophyllum nodosum (AN) and Fucus vesiculosus (FV), as feed ingredients for monogastric and ruminant animals. Low-temperature water blanching (LTB; 40 °C for 5 min) had minor impacts on macroalgal chemical composition and in vitro digestibility. Conversely, high-temperature water blanching (HTB; 80 °C for 5 min) effectively reduced total ash and specific elements, including sodium, potassium, iodine, and arsenic, by ~ 25–73% compared to unblanched algal biomass (more prominently in FV). The HTB raised total sugar contents by ~ 25% in FV, markedly elevating uronic acids (~ 60%) and glucans (~ 33%). However, HTB reduced mannitol (> 50%) and enhanced total polyphenol extractability in both macroalgae. The HTB diminished ~ 8% of in vitro dry matter or organic matter digestibility and 26% of crude protein (CP) digestibility of both macroalgae for monogastric animals and of FV for ruminants (particularly of CP by ~ 42%). Those reduced digestibilities were associated with enriched fibre, uronic acids, total polyphenols, and declined mannitol in the HT-blanched macroalgal biomass. Our findings suggest that hot-water blanching can be an efficient technique to optimise the elemental composition of two fucoid algae, but the altered sugar and complex carbohydrate compositions may impair their digestibility. Future studies should identify appropriate post-harvest processing techniques for brown macroalgae that can optimise both nutritional composition and digestibility along with favourable impacts on feed utilisation and animal performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

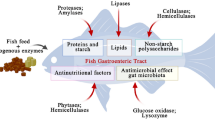

Macroalgae are important aquatic bioresources with enormous potential for diverse commercial applications. This sustainable biomass can grow in seawater and has a higher growth rate (Øverland et al. 2019) and greater carbon sequestering capacity than terrestrial plants (Krause-Jensen and Duarte 2016). Macroalgae possess promising macro and micronutrients, such as protein, carbohydrates, fatty acids, minerals, and vitamins, making them relevant as human food and animal feed (Mæhre et al. 2014; Rodrigues et al. 2015). Brown macroalgae, especially the kelps, have been of great interest in commercial applications, including animal feeding, due to their larger size and higher biomass yield potential than green and red species (Makkar et al. 2016; Stévant et al. 2017). They have high levels of carbohydrates and bioactive compounds, including complex polysaccharides, carotenoids, and polyphenols that can promote animal health (O’Sullivan et al. 2010; Holdt and Kraan 2011). For example, particular species from the Fucales, such as Ascophyllum nodosum (AN) and Fucus vesiculosus (FV), contain 42–70% of carbohydrates (dry matter, DM, basis) (Holdt and Kraan 2011; Hahn et al. 2012) and potentially the highest polyphenolic contents among macroalgae species (Ragan and Jensen 1978; Connan et al. 2004; Tibbetts et al. 2016). Dietary inclusion of brown algae or their bioactive compounds has been shown to reduce enteric methane emissions from ruminants (Pandey et al. 2021, 2022) and post-weaning intestinal disorders in pigs via their prebiotic and anti-microbial properties on selected harmful microorganisms (Dierick et al. 2010; Ford et al. 2020; Vigors et al. 2020). Hence, selected brown macroalgae may serve as a source of nutrients and health-promoting compounds for animals (Pandey et al. 2021) .

However, large-scale utilisation of brown macroalgae as animal feed is constrained by specific challenges. Firstly, they have a high level of ash (~ 20–40% of DM) dominated by minerals such as potassium, sodium, iron, and iodine, and heavy metals, including arsenic (Schiener et al. 2015). Some of these elements (e.g., Na, I, As) in macroalgae may exceed the recommended or maximum tolerable levels for animals (NRC 2005), posing risks of mineral toxicity if included at high levels in diets (Cabrita et al. 2016; Stévant et al. 2018). Secondly, brown macroalgae often have low organic matter (OM) digestibility due to less digestible complex carbohydrates (Orpin et al. 1985) and high polyphenols content, which impairs the degradation of fibre and protein (Wang et al. 2008; Vissers et al. 2018; Gülzari et al. 2019). Hence, polyphenol-rich brown macroalgae can suppress the feed degradability if included in large proportions (e.g., 20% DM) in the feed (Pandey et al. 2022). Thus, it is crucial to optimise the ash, minerals, and polyphenols contents of macroalgae to allow a higher inclusion level in the feed and to improve the safety and nutrient utilisation of macroalgae-based feed materials for production animals.

Post-harvest biomass processing such as washing, drying, or hydrothermal treatments, could help optimise the macroalgal chemical composition (Zhu et al. 2021). Water blanching or soaking of fresh biomass of the brown macroalga Saccharina latissima with warm water (32 °C for 1 h) lowered 49% of ash and 75–77% of Na and K in 22 h and > 87% of I, bringing it below the recommended maximum threshold value in food for humans (2000 mg kg−1 DM of food) (Stévant et al. 2018). For the same species, removal of I was more effective and rapid with blanching at a higher temperature (e.g., 45–80 °C for 2 s to 5 min) (Nielsen et al. 2020). On the other hand, depending upon the sensitivity of compounds towards temperature, water blanching (e.g., 85–95 °C for 15 min) could improve the extractability or bioactivities of sugars and phytochemicals such as polyphenols (Rajauria et al. 2010) and fucoxanthin (e.g., 60 °C for 12 min) (Nie et al. 2021). Hydrothermal treatments may also affect the digestibility of macroalgae. When fresh biomass of a brown macroalga, Alaria esculenta and a red macroalga, Palmaria palmata, was boiled for up to 1 h, the concentrations (86–109%) and bioavailability of amino acids (64–96%) and omega-3 fatty acids were raised in P. palmata after 15–30 min, but not in A. esculenta, potentially due to structural and compositional differences between these two algae (Maehre et al. 2016). Hence, besides the processing temperature and exposure time, macroalgae species-specific structural differences, such as the composition of complex carbohydrates, should be considered while aiming to optimise the chemical profile and nutritional values of various macroalgae using suitable hydrothermal treatments.

The impacts of mild hydrothermal processing on the composition of complex carbohydrates and sugars of brown macroalgae are poorly known. Moreover, the role of compositional changes by such treatments in the digestibility of macroalgae in livestock remains to be investigated. The objective of this study was to evaluate the impacts of hot water blanching at two different temperatures: low (40 °C; LTB: low-temperature blanching) and high (80 °C; HTB: high-temperature blanching) on chemical composition, carbohydrate profile, bioactive compounds, and in vitro digestibility (simulating both monogastric and ruminant animals) of two brown macroalgae AN and FV. These two species were chosen as they represent the most dominant macroalgae species in the wild populations along the North Atlantic Ocean (Catarino et al. 2017) and possess high commercial potential because of their promising biomass availability and bioactive composition. Specifically, the following hypotheses were tested: a) hot water blanching of fresh macroalgae leads to an improved nutritional profile of the biomass by reducing excess salts and polyphenolic compounds, b) HTB enhances the digestibility of nutrients such as carbohydrates and protein, and thus improves the overall digestibility of macroalgal biomass in livestock, and c) the concentration and activity of phytochemical constituents of macroalgae are elevated with LTB but are reduced with HTB.

Material and methods

Macroalgae harvesting and processing

Ascophyllum nodosum and Fucus vesiculosus were harvested manually from the coast of Hoøya, Steinkjer, Norway, during low tides in early spring of 2021 (March). About 3 kg of biomass was collected into nine separate plastic bags for each species and transported to the laboratory (Nord University, Steinkjer, Norway) within 30 min of sampling. In the laboratory, algal biomass from each bag was washed thrice with fresh water to remove any contaminants, soil, invertebrates, and epiphytes. After draining for ~ 15 min at room temperature, algal samples were exposed to two different blanching treatments or remained unblanched (UB). For blanching, ~ 700 g of fresh biomass was directly immersed in 10 L of water maintained at 40 °C (LTB) or 80 °C (HTB) for 5 min in a SousVide Supreme water bath (Eades Appliance Technology, USA). These low to medium–high blanching temperatures were selected based on their industrial relevance for macroalgae producers and to improve the nutritional value of the biomass without compromising the stability of heat-sensitive bioactive compounds. When the blanching was completed, biomass was allowed to drain and cool to room temperature. The samples were then frozen at -20 °C and freeze-dried at -50 °C under a vacuum pressure of ~ 0.13 mbar for 72 h. The freeze-dried samples were then ground via a 1 mm sieve (Cutting mill SM 100, Retsch GMBH, Germany) and stored in an airtight plastic bags at -20 °C until further analyses. All experimental procedures, including harvesting, processing, and further analyses of macroalgal biomass, were carried out in triplicates (n = 3).

Chemical composition analyses

Proximate composition

The dry matter content of the ground freeze-dried samples was determined by oven-drying at 103 ± 2 °C overnight (ISO 64961999) and ash by weighing the residue after combustion of samples at 550 °C overnight (ISO 59842002). Crude protein (CP) was calculated after determining the content of total N by the Kjeldahl method (KjeltecTM 8400, FOSS Denmark, Denmark) (AOAC 2001.11; 2001) using a nitrogen-to-protein conversion factor of 5, as previously suggested (Angell et al. 2016). Crude fibre (CF) content in the algal samples was determined via a Filter Bag Technique (ANKOM Technology 2021) with minor modifications. In brief, 1 g of each sample was weighed into F57 filter bags, previously defatted with acetone, and sequentially digested with 0.255 N H2SO4 and 0.313 N NaOH for 40 min each in a Fiber Analyzer (Ankom200 Fiber Analyzer, USA). After digestion, filter bags with residual samples were treated with acetone and incinerated (550 °C for 2 h) to determine CF content exclusive of residual ash. The neutral detergent fibre (NDF) and ash-corrected NDF (NDFom) were also determined via a filter bag technique of ANKOM Technology as previously described (Pandey et al. 2022). Crude fat was determined following extraction with 80% petroleum ether and 20% acetone in an Accelerated Solvent Extractor (ASE200; Dionex, USA) (European Commission 2009). The gross energy (GE) content of the samples was determined using a PARR 6400 Bomb Calorimeter (PARR Instruments, USA). Nitrogen-free extract (NFE) was calculated as follows:

Mineral elements

To quantify concentrations of different elements in the macroalgal powder, 0.2–0.3 g of each sample was digested in 5 mL of ultrapure concentrated nitric acid (HNO3) at 260 °C in an UltraClave microwave digestion system for 30 min (Milestone Srl, Sorisole BG, Italy). For I analysis, samples were extracted with tetramethylammonium hydroxide at 90 °C for 3 h. After extraction, samples were centrifuged at 1200 × g for 10 min and diluted to 50 mL of deionised water. Blank samples and standard/certified reference materials (apple leaves:1515, hay powder: BCR®-129, whole egg: 8415) were also treated in the same way at the same time. The concentration of macrominerals: Ca, K, Mg, Na, P) and S; microminerals: Br, Co, Cu, I, Fe, Mn, Ni, Se and Zn; and toxic elements: As, Cd and Pb were quantified by inductively-coupled plasma optical emission spectroscopy (ICP-OES) (Agilent 5110 ICP-OES, USA) or by inductively coupled plasma-mass spectrometry (ICP-MS) (Agilent 8800 ICP-MS, USA) depending upon the concentration.

Carbohydrate composition

Sample preparation and acid hydrolysis

Carbohydrate contents in the dried algal powder were analysed as reported previously (Hayes 2012) in the commercial laboratory of Celignis Limited, Ireland. In brief, samples were ground using a pestle and mortar and sieved in a Retsch AS200 Digital sieve shaker to homogenise the particle size to < 850 μm. The samples were subjected to a two-step acid hydrolysis to degrade the polysaccharides to monomeric units. In the first step, 300 mg of samples taken in the pressure tubes were treated with 3 mL of 72% H2SO4 and incubated in a water bath at 30 °C for 1 h with mixing every 10 min. Afterwards, 84 mL of water was added to each sample mixture to adjust acid concentration to 4%, and pressure tubes were sealed and autoclaved at 121 °C for secondary hydrolysis for 1 h. To determine any loss of the sugars during this hydrolysis step, three tubes containing 10 mL solution with known sugar composition plus 348 µL of 72% H2SO4 were also included.

Determination of monomeric sugars and sugar derivatives

The sugar composition in the acid hydrolysates was analysed using ion chromatography following a previously reported protocol (Hayes 2012). Hydrolysates were diluted 20 times with a solution containing a known concentration of the internal standard, melibiose, and filtered through 0.2 µm Teflon syringe filters. The samples were then transferred into vials, and sugars were separated in a Dionex ICS-3000 ion chromatography system equipped with an AS50 autosampler, an electrochemical detector attached with pulsed amperometric detection (PAD), a gradient pump, and a temperature-controlled column and UV–Vis Diode Array Spectrophotometer. Ten µL of the samples was injected by AS50 autosampler, and sugars were separated in the Carbo-Pac PA1 guard and analytical columns within 16 min using deionised water as an eluent at a flow rate of 1.1 mL min−1 and column/detector temperature of 18 °C. A standard Dionex ‘‘Carbohydrates’’ waveform was used to detect sugars. To maintain an alkaline condition for carbohydrate detection required by PAD, 300 mM NaOH was added to the post-column eluent stream using a Dionex GP40 pump at a 0.3 mL min−1 flow rate. Between samples, the column was regenerated and re-equilibrated with elution of 400 mM NaOH for 4 min, followed by elution with deionised water. The concentrations of arabinose, fucose, glucose, galactose, mannose, rhamnose, xylose, and sugar alcohol mannitol were determined using the corresponding sugar standards (Sigma-Aldrich, Germany). When the concentration of individual sugars was determined, polymeric sugars (pentosans: arabinan and xylan; hexosans: glucan, galactan, and mannan) were calculated by using corresponding anhydro correction factors (0.88 for pentoses: arabinose and xylose and 0.90 for hexoses: glucose, galactose, and mannose) (Sluiter et al. 2008).

The content of uronic acids (galacturonic acid, glucuronic acid, guluronic acid, and mannuronic acid) in the hydrolysates was also determined using ion chromatography (electrochemical detection) using the Carbo-Pac PA1 guard and analytical columns, melibiose as the internal standard, and a custom gradient program incorporating sodium hydroxide and sodium acetate.

Starch

Starch content in the algae samples was analysed by AACC Method 76–13-01: Total Starch Assay Procedure (Megazyme Amyloglucosidase/Alpha-Amylase Method), which corresponds to AOAC method 996.11- Starch (Total) in Cereal Products (AACC International) with prior treatment with 80% ethanol.

Fucoxanthin content analysis

The processing of algal samples and determination of fucoxanthin (pigment) was performed as described previously (Schweiger et al. 2018). The pulverised samples were ground with 80% acetone, centrifuged at 18,000 × g for 2 min, and the supernatant was collected. The pellet was re-extracted with 100% acetone and centrifuged under the same conditions as in the first extraction. The supernatants were pooled and filtered through a 0.45 μm nylon filter before a 20 µL sample was injected into the HPLC (Dionex) for the fucoxanthin measurement. The chromatography eluent gradients of acetonitrile: methanol:0.1 M pH 8.0 Tris buffer (8:1:1, v/v) (solvent A), and methanol: ethyl-acetate (68:32, v/v) (solvent B) were used following elution conditions as reported previously (Schweiger et al. 2018). The solvent flow rate was set at 2 mL min−1 and the elution involved a 12 min run of solvent A and a 4 min gradient from solvent A to B. Afterwards, solvent B was run for 2 min and accompanied by 1 min gradient from solvent B to A for achieving a column equilibrium. The fucoxanthin concentration was determined by UV detection (wavelength of 445 nm).

Total polyphenol contents determination

The total polyphenols from the dried algal powder (n = 3) were extracted by a two-step extraction method using 50% methanol (2 h) and 70% acetone (2 h) and quantified by the Folin-Ciocalteu method (Zhang et al. 2006). The extract solution was filtered via Whatman grade 597 standard filter paper to obtain the crude polyphenol extracts. The residual organic solvents in the crude polyphenol extracts were removed using a rotary evaporator (water bath temperature: 40 °C; vacuum pressure: 175 mbar). The concentrated extracts were lyophilised to dryness (24 h) and the weight of the dried polyphenolic extract was recorded. Ten mg of dried polyphenolic extracts were redissolved in 10 mL of deionised water (1000 μg mL−1), referred to as stock polyphenolic extract.

The total polyphenol content (TPC) in the stock polyphenolic extracts, standards, and blanks were determined in triplicate subsamples in a 96-well microplate (Thermo Fischer, Germany) as previously described (Pandey et al. 2022) using a spectrophotometric microplate reader (absorbance at λ750 nm; BIO-RAD, iMark Microplate Reader, USA). The mean TPC was expressed as milligram of phloroglucinol equivalents (mg PGE) per g DM of the sample.

DPPH (1,1-diphenyl-2-picrylhydrazyl) radical scavenging activities of polyphenol extracts

The DPPH radical scavenging capacity of the stock polyphenolic extract was determined, as reported earlier (Cox et al. 2010), with some modifications. One mL of polyphenol extract was added to an equal amount of 0.16 mM DPPH in a methanol solution and mixed well. Then the samples were incubated at room temperature for 30 min in the dark and read against a blank of methanol at 517 nm. A sample blank prepared by mixing 1 mL of polyphenol solution and 1 mL of methanol was included for each sample to correct the background absorbance given by the polyphenolic extract solution. Ascorbic acid and Trolox standards were used as positive controls.

The ability of the polyphenolic extract to scavenge the DPPH radicals was calculated using the following equation (Duan et al. 2006):

where: Abs. control is the absorbance of the control (DPPH solution without sample), Abs. sample is the absorbance of the test sample (DPPH solution plus polyphenol sample), and Abs. sample blank is the absorbance of the polyphenol sample only (sample without any DPPH solution).

In vitro digestibility in monogastric animals

A three-step enzymatic in vitro method simulating the conditions of the stomach, small intestine, and large intestine of the pig was used to determine in vitro digestibility of DM, OM, and CP of macroalgae for monogastric animals (Boisen and Fernández 1997). The macroalgae samples, two batches of soyhulls and oat (1 mm), and blanks were incubated in quadruplicate. In the first step, samples (500 mg) were placed in 100 mL flasks, and 25 mL of phosphate buffer (0.1 M, pH 6.0) and 10 mL of 0.2 M HCl were added. Using 1 M HCl or 1 M NaOH, the pH of the mixture was adjusted to 2.0. Afterwards, 1 mL of a freshly prepared pepsin solution containing 25 mg pepsin per mL (pepsin from porcine gastric mucosa, 2000 U g−1, Merck 1.07190.1000) was added. To prevent bacterial growth, 0.5 mL of chloramphenicol solution (0.5 g in 100 mL ethanol) was added. Capped flasks were incubated in a water bath at 39 °C for 2 h with agitation.

Once at room temperature, to initiate the second step, 10 mL of phosphate buffer (0.2 M, pH 6.8) and 5 mL of 0.6 M NaOH solution were added to the flask, and the pH was adjusted to 6.8. One mL of a freshly prepared pancreatin solution containing 100 mg of pancreatin per mL (porcine, grade IV, reference Sigma Aldrich P-1750) was added to the mixture and flasks were incubated in a water bath at 39 °C for 4 h with agitation. Flasks were then allowed to cool at room temperature.

In the third step, 10 mL of 0.2 M EDTA solution was added, the pH of the mixture adjusted to 4.8 with an acetic acid solution (30% v/v) and 0.5 mL of a mixed multi-enzymatic complex comprised of arabinase, cellulase, β-glucanase, hemicellulase, xylanase, and pectinase (Viscozyme L, Sigma-Aldrich V2010) was added. Flasks were incubated in a water bath at 39 °C for 18 h under agitation.

The undigested residue was transferred to crucibles (porosity 40–100 μm, P2) by filtration and rinsed with ethanol and acetone. Crucibles were dried at 103 ºC overnight and weighed for DM. Two crucibles from each sample were incinerated in a muffle furnace at 500 °C for 3 h and OM content was calculated. The CP content (N × 6.25) of the undigested residues of the two other crucibles for each sample was determined by a Leco nitrogen analyzer (Model FP-528, Leco Corporation, USA). The in vitro total tract digestibility of DM, OM, and CP was calculated by the difference between DM, OM, or CP of the initial samples and the undigested residue after correction for the blank.

In vitro digestibility in ruminant animals

The digestibility of macroalgae in ruminant animals was determined in vitro according to Tilley and Terry (1963) method modified by Goering and Van Soest (1970) using ruminal fluid from two non-lactating rumen-cannulated Holstein cows. Cows were maintained at the Vairão Agricultural Campus of the School of Medicine and Biomedical Sciences, University of Porto (ICBAS-UP, Vila do Conde, Portugal) following the good animal practices of the European Union (Directive 2010/63/EU). Animal procedures were approved by the Animal Ethics Committee of ICBAS-UP, licensed by the Portuguese Directorate-General of Food and Veterinary Medicine (permit #FT2014DGV 046412 ICB), and conducted by scientists with sufficient training (FELASA category C). The donor cows were fed a total mixed ration comprising, on a DM basis, 56% corn silage, 16% wheat straw, 11% haylage, and 17% compound feed (524 g kg−1 DM; 248 g kg−1 starch, 460 g kg−1 NDFom, and 91 g kg−1 CP) at 08:00 and 18:00 h and provided free access to fresh drinking water. Ruminal fluid was collected before the morning feeding, strained through four layers of cheesecloth, and kept at 39 °C under anaerobic conditions flushing with CO2. Then, 25 mL of buffered rumen fluid solution (1 rumen fluid:4 Kansas State Buffer) (Marten and Barnes 1979) was added to 250 mg of each macroalgal sample and laboratory references (corn silage and meadow hay, 1 mm ground), and blanks (0 mg) in 50 mL centrifuge tubes prepared in quadruplicate for each sample types. The centrifuge tubes were immediately flushed with O2-free CO2 and closed with rubber stoppers fitted to a Bunsen valve to control the pressure build-up of gases in the headspace from fermentation and were incubated at 39 °C for 48 h in a water bath.

The undigested residue was transferred to crucibles (porosity 40–100 μm, P2), extracted in boiling neutral detergent solution for 1 h (Robertson 1981), dried at 103 °C overnight, and weighed to calculate in vitro DM digestibility as the difference between the incubated DM and the non-digested DM that remained in the crucibles. Samples were corrected for bacterial and residual DM using blanks. Two crucibles from each sample were incinerated in a muffle furnace at 500 ºC for 3 h for OM digestibility calculation, and CP (N × 6.25) was determined using a Leco nitrogen analyzer (Model FP-528, Leco Corporation, USA) in the other two residues from each sample for calculation of CP digestibility. Rumen fluid blanks were used to correct the OM and CP digestibility of the samples.

Statistical analyses

Data were analysed using two-way ANOVA in R Foundation for Statistical Computing Platform, version 4.1.1 (R Core Team 2021). Statistical models included macroalgae species and blanching treatments as fixed effects as well as their interactions and the residual error. The homogeneity of variances was evaluated by residual plots, and the normality of residuals was tested by quantile–quantile plots and the Shapiro test. Any outliers and influential observations were tested by the outlier’s test and Cook’s index, respectively. Differences in the least square means (LS means) were compared by Tukey’s multiple comparison test. Finally, a Pearson correlation matrix was created to evaluate the relationship between the studied parameters (includes both species and all treatments) of chemical composition (ash, CP, crude fat, CF, NDFom, minerals, sugars, and sugar derivatives, fucoxanthin, and TPC) and in vitro digestibility (DM, OM and CP digestibility in monogastric and ruminant models) using Corrplot package. The level of significance for all statistical analyses was set at p < 0.05.

Results

Impacts of hot water blanching on the nutritional composition of macroalgae

Prior to hydrothermal treatments, both brown macroalgae, AN and FV, had similar ash (~ 21%), crude fat (~ 3%), and CF (~ 4.5–5%) contents, but significant species differences were observed for CP, NDFom, NFE, and energy contents (Table 1). Higher CP (p < 0.001) and energy (p = 0.019) levels were found in FV compared to AN, whereas the opposite trend was true for NDFom (p = 0.001) and NFE (p < 0.001).

Hot water blanching (LTB or HTB) did not influence the CP contents of the studied macroalgae species. The crude fat was affected by species and treatment interaction as it remained stable in AN with both water blanching treatments but declined by 33.8% in FV with HTB treatment (p = 0.037). On the other hand, HTB led to an increase in the levels of CF, NFE, and energy contents (p < 0.002, for both species), while both LTB and HTB (~ 19% and ~ 33% in AN and FV, respectively) increased NDFom (p < 0.001) as compared to their respective unblanched biomass. This increase in NDFom was 1.7 times higher in FV biomass than in AN. Effects of the interaction between species and water blanching were also observed for the ash content of macroalgae (p < 0.036). Ash was linearly reduced in both macroalgae when the blanching temperature was increased, but the reductions were more remarkable for FV (~ 8% and ~ 24% with LTB and HTB, respectively) than for AN (~ 5.5% and ~ 16% with LTB and HTB, respectively).

Impacts of hot water blanching on mineral composition of macroalgae

The fresh biomass of both AN and FV exhibited rich profiles of macro- (Fig. 1) and microminerals (Fig. 2). However, the composition of individual minerals varied considerably between the two species. Among the analysed six macrominerals, AN contained a higher level of Na, Mg, S, and Ca (p < 0.002, for all) and lower levels of P and K than FV (p < 0.001, for both). Three macrominerals: S, Na, and K accounted for 78–80% of the total minerals in both macroalgae. On the other hand, I, Br, Fe, and Mn were the dominant microminerals, irrespective of macroalgae species. Among the analysed nine microminerals, seven of those (Mn, Fe, Co, Ni, Cu, Zn, and Se) were found to be higher in FV (p < 0.018, for all) while AN had > twofold higher content of I than FV (p < 0.001).

Impacts of hot water blanching on contents of macroelements of A. nodosum (AN) and F. vesiculosus (FV). Two brown macroalgae were harvested from Hoøya, Steinkjer, Norway (coastal areas), in March 2021. UB, Unblanched algal biomass; LTB, Algal biomass exposed to low-temperature water blanching (40 °C for 5 min); HTB, Algal biomass exposed to high-temperature water blanching (80 °C for 5 min). Treatments not sharing the same letters over the bars within a species are significantly different from other treatments of the same species. Treatments with * sign over the bar are significantly different from the same treatment of another macroalgae species

Impacts of hot water blanching on contents of microelements of A. nodosum (AN) and F. vesiculosus (FV). UB, Unblanched algal biomass; LTB, Algal biomass exposed to low-temperature water blanching (40 °C for 5 min); HTB, Algal biomass exposed to high-temperature water blanching (80 °C for 5 min). Treatments not sharing the same letters over the bars within a species are significantly different from other treatments of the same species. Treatments with * sign over the bar are significantly different from the same treatment of another macroalgae species

The effects of hydrothermal treatments were highly evident in mineral compositions. Both LTB (~ 17% for both species) and HTB (~ 25% and ~ 38% for AN and FV, respectively) significantly diminished the content of Na (p < 0.001, for both species) (Fig. 1). Additionally, HTB resulted in a ~ 33% and ~ 40% reduction of K (p < 0.001) and ~ 43% and ~ 59% reduction of P (p < 0.002) in AN and FV, respectively, when compared to their UB counterparts. Magnesium, S, and Ca remained mostly unaltered or slightly raised in response to HTB in both species.

Like macrominerals, LTB had minor impacts on the micromineral composition of macroalgae (Fig. 2). LTB only lowered the concentration of Br in both macroalgae compared to their UB samples (p = 0.026). However, HTB not only profoundly decreased the level of Br (~ 40–44%, p < 0.001) but also of I (> 73% and 28% in AN and FV, respectively; p < 0.001, for species: treatment interaction) in macroalgal biomass. The loss of I with HTB was 2.6 times greater for AN than for FV; this trend contrasted with other species-specific effects of HTB. On the other hand, the Fe level was increased by HTB in FV biomass (p = 0.023). None of the blanching treatments affected the concentrations of Mn, Cu, Zn, and Se in macroalgae (p > 0.05).

Impacts of hot water blanching on the heavy metal contents of macroalgae

The contents of all three studied heavy or toxic metals: As, Cd, and Pb, were greater (> twofold) in FV than in AN (p < 0.001, for all) (Fig. 3). The contents of all three heavy metals remained unaffected by LTB. However, HTB caused a 38.2% and 62.7% decline in As content in AN and FV, respectively, compared to their UB samples (p < 0.001, for species: treatment interaction). In contrast, HTB led to an increase in the content of Cd in FV biomass relative to its UB biomass (p < 0.001).

Impacts of hot water blanching on contents of heavy metal elements of A. nodosum (AN) and F. vesiculosus (FV). A) Arsenic content; B) Cadmium content; C) Lead content. UB, Unblanched algal biomass; LTB, Algal biomass exposed to low-temperature water blanching (40 °C for 5 min); HTB, Algal biomass exposed to high-temperature water blanching (80 °C for 5 min). Treatments not sharing the same letters over the bars within a species are significantly different from other treatments of the same species. Treatments with * sign over the bar are significantly different from the same treatment of another macroalgae species

Impacts of hot water blanching on the carbohydrate profiles of macroalgae

Along with a higher total carbohydrate content, unblanched samples of AN had significantly higher TSC (sum of all sugars and sugar derivatives) than FV (48.7 vs. 34.4% DM) (p < 0.001) (Table 2). The most dominant sugar components in macroalgae were uronic acids, followed by hexose sugars such as fucose and glucose (glucan), and the sugar alcohol mannitol. The uronic acids alone represented ~ 45.8% and ~ 52.2% of TSC in FV and AN, respectively. Among three uronic acids detected: mannuronic acid (MA), guluronic acid (GA), and glucuronic acids, MA content was over twofold higher in AN than in FV (p < 0.001), while both macroalgae contained similar levels of GA and glucuronic acids. The levels of fucose (10 vs. 6.25% of DM) and xylan (> threefold) were higher in AN than in FV (p < 0.001). In contrast, mannitol (5.68 vs. 4.8% of DM) and galactans were found in higher amounts in FV than in AN (p < 0.007).

When macroalgae were exposed to blanching, the TSC of two macroalgae species were differentially affected (p = 0.001, for species and treatment interaction) (Table 2). The TSC got elevated with both LTB (p = 0.040) and HTB (p < 0.001) in FV, consequently increasing its level by 24.5% compared to its UB samples. However, the TSC of AN remained stable with both those blanching treatments. With HTB, there was a massive rise of both MA (67.5%) and GA (56.5%) in FV (p < 0.001), resulting in a ~ 60% increase in total uronic acids. Although HTB caused a modest increase in GA (21.5%) (p = 0.016), no significant change was observed in total uronic acids in AN. Glucans and mannitol were uninfluenced by LTB in both macroalgae, but they were oppositely affected by HTB. Glucans were significantly increased (~ 13 and 33% in AN and FV, respectively; p = 0.003), whereas mannitol was dramatically reduced (~ 50% and ~ 82% in AN and FV, respectively; p < 0.001) when compared to their UB samples (Table 2).

Impacts of hot water blanching on the total polyphenol and fucoxanthin contents of macroalgae

When compared between the unblanched samples, both the fucoxanthin (~ 6.25-fold) and TPC (~ 2.26-fold) levels were greater in FV than in AN (p < 0.001 for both) (Fig. 4). When exposed to blanching, both LTB and HTB significantly and similarly lowered the level of fucoxanthin (~ 67%) in AN compared to its unblanched samples (p < 0.007). However, fucoxanthin was increased in FV with exposure to HTB (p = 0.001 for species and treatment interaction). The levels of TPC in the polyphenolic extracts were increased for both AN (34%) and FV (19%) with HTB treatment (p = 0.017 for both species). However, species and blanching treatment did not affect the DPPH radical scavenging capacity of polyphenolic extracts (Fig. 4).

Impacts of hot water blanching on fucoxanthin, total polyphenols, and antioxidant activity of A. nodosum (AN) and F. vesiculosus (FV). A) Fucoxanthin content; B) Total polyphenol content (TPC); C) DPPH (1,1-Diphenyl-2-Picrylhydrazyl) radical scavenging activity. UB, Unblanched algal biomass; LTB, Algal biomass exposed to low-temperature water blanching (40 °C for 5 min); HTB, Algal biomass exposed to high-temperature water blanching (80 °C for 5 min). Treatments not sharing the same letters over the bars within a species are significantly different from other treatments of the same species. Treatments with * sign over the bar are significantly different from the same treatment of another macroalgae species

Impacts of hot water blanching on the in vitro digestibility of macroalgae for monogastric and ruminant animals

The three-step monogastric digestibility analysis revealed a higher in vitro total tract DM (76.9 vs. 69.3%) and OM (76.7 vs. 65.6%) digestibility of AN than FV (p < 0.002, for both), but both macroalgae had similar CP digestibility (Fig. 5). The DM and OM digestibilities of AN were higher than both standard feeds, oat, and soy hulls (p ≤ 0.001, for both), while those of FV were only higher than that of soy hulls (p < 0.001). However, both AN and FV had considerably lower CP digestibility than the standard feeds (p < 0.001).

Impacts of water blanching on in vitro digestibility of A. nodosum (AN) and F. vesiculosus (FV) for monogastric and ruminant animals. A) Dry matter digestibility in monogastric animals; B) Organic matter digestibility in monogastric animals; C) Crude protein digestibility in monogastric animals; D) Dry matter digestibility in ruminants; E) Organic matter digestibility in ruminants; F) Crude protein digestibility in ruminants. UB, Unblanched algal biomass; LTB, Algal biomass exposed to low-temperature water blanching (40 °C for 5 min); HTB, Algal biomass exposed to high-temperature water blanching (80 °C for 5 min); SF, Standard feeds; SoyH, Soy hulls; CS, Corn silage; MH, Meadow hay. Treatments not sharing the same letters over the bars within a species are significantly different from other treatments of the same species. Treatments with * sign over the bar are significantly different from the same treatment of another macroalgae species. Treatments with # sign are significantly different from oat (monogastric) or MH (ruminants), while treatments with ¤ sign are different from SoyH (monogastric) or CS (ruminants)

Ascophyllum nodosum also had a slightly higher in vitro OM digestibility than FV in the ruminant animal model (p = 0.015), whereas the latter had higher CP digestibility (p = 0.046). When compared with the standard feeds tested for the ruminant’s model: corn silage and meadow hay, both AN and FV had a lower DM, OM, and CP digestibility than corn silage (p < 0.001, for all), but both macroalgae had higher DM and OM digestibility than that of meadow hay (p < 0.001, for both).

The in vitro total tract digestibilities of DM, OM, and CP for monogastric animals were reduced by both LTB (p < 0.001) and HTB (p < 0.001) for AN (~ 6.8–26%), whereas only the HTB had adverse effects on those digestibility parameters (7.8–26.5%) of FV (p < 0.004, for all). The HTB treatment had the most severe reductions in CP digestibility (~ 26%) for both macroalgae. However, in ruminant animals, the in vitro ruminal DM, OM, and CP digestibility of two macroalgae were differentially affected by the hot water blanching (p < 0.001, species and treatment interactions for all). The digestibility of all three tested parameters mostly remained unaffected with blanching for AN, but HTB treatment reduced all three digestibility parameters (DM, OM, and CP) (p < 0.001, for all) for FV, notably reducing the CP digestibility by ~ 42.2% compared to its UB biomass.

Correlation between the chemical composition and in vitro digestibility of macroalgae

Pearson correlation analysis revealed that contents of CF (r = -0.53 to -0.71, p < 0.024) and GA (r = -0.53 to -0.86, p < 0.023) were negatively correlated with all three studied digestibility parameters (DM, OM, and CP) in both monogastric and ruminant models (Fig. 6). Similarly, glucuronic acid was inversely correlated to all digestibility parameters (-0.6 to -0.9, p < 0.009) in ruminants and with DM and OM digestibility in monogastric animals (r = -0.6 to -0.78, p < 0.001). Macroalgal TPC was also negatively associated with DM and OM digestibility in both monogastric and ruminant models (r = -0.66 to -0.86, p < 0.004). For both animal models, CP digestibility was inversely correlated with NDFom (r = -0.72 to -0.81, p < 0.001) and NFE (r = -0.62 to -0.78, p < 0.006) contents. On the other hand, mannitol was positively correlated with the DM and CP digestibility (r = 0.62 and 0.77, respectively, p < 0.006) in the monogastric model and with all three digestibility parameters in ruminant animals (r = 0.53–0.82, p < 0.022).

Correlation between chemical composition and digestibility parameters of A. nodosum and F. vesiculosus. A Pearson correlation analysis was performed, including all the chemical composition and in vitro digestibility parameters of both macroalgae. However, the correlations between selective chemical composition and digestibility parameters are shown in the figure. CP, Crude protein; cFat, Crude fat; cFibre, Crude fibre; NFE, Nitrogen free extract; NDFom, Ash free NDF; GulcU, Glucuronic acid; MA, Mannuronic acid; GA, Guluronic acid; TSC, Total sugar content; TPC, Total polyphenol content; DMD_M, Dry matter digestibility in monogastric animals; OMD_M, Organic matter digestibility in monogastric animals; CPD_M, CP digestibility in monogastric animals; DMD_R, Dry matter digestibility in ruminant animals; OMD_R, Organic matter digestibility in ruminant animals; CPD_R, CP digestibility in ruminant animals

Discussion

To the best of our knowledge, this is the first study to investigate the effects of post-harvest hydrothermal treatments (hot water blanching) on nutritional composition and in vitro digestibility of two economically important and predominantly available brown macroalgae, A. nodosum and F. vesiculosus, targeting both monogastric and ruminant animals. It was hypothesised that post-harvest hot water blanching could optimise the nutritional and bioactive composition of the brown macroalgal biomass to be utilised as animal feed ingredients. The results of this study reveal that hot water blanching induces remarkable changes in the chemical composition of brown macroalgae but in a species-specific and temperature-dependent manner. Notably, the HTB treatment was highly effective in optimising the mineral contents and potentially toxic elements, altered the composition of carbohydrates and monomeric sugars, and led to some undesirable changes in the in vitro digestibility of two fucoid algae species, more prominently of FV. The findings of this study suggest that both nutritional composition and digestibility should be considered while employing suitable post-harvest hydrothermal processing for brown macroalgal biomass.

Hot water blanching favourably affects the mineral composition of two fucoid macroalgae species

The brown macroalgae AN and FV are closely related species belonging to the same family (Fucaceae) and share a habitat in the intertidal zone (Catarino et al. 2017; Pereira et al. 2020). However, this study illustrated a diverse chemical composition, particularly in carbohydrates, CP, and mineral composition between them. The FV biomass seemed to be a better protein source with an acceptable level of CP (> 10%), while AN biomass was highly enriched with NDFom, and these results agree with previous studies on the same brown species (Tibbetts et al. 2016; Lorenzo et al. 2017; Garcia-Vaquero et al. 2021). Despite having similar ash contents (> 20% of DM), the algae illustrated discrepancies in macro- and micromineral composition as AN was more enriched with most of the studied macro elements (except K and P). In contrast, most microminerals studied (except Br and I) were found to be more abundant in FV. The concentrations of minerals observed in the present study are in the same range reported for these species in previous studies (Tibbetts et al. 2016), including those from Norway (Mæhre et al. 2014; Biancarosa et al. 2018). Assuming all minerals present in biomass are fully bio-accessible, and considering the mineral requirements of animals (% or mg kg−1 DM of diet): Na (0.1–0.4%), Mg (0.15–0.3% for ruminants, < 0.1% for non-ruminants), P (0.2–0.8%), S (0.18–0.24%), K (1500–3000 mg for chickens and swine, 10,000 mg for lactating cows), Ca (0.5–1%), Fe (50–100 mg), Mn (10–40 mg), Cu (4–20 mg for ruminants, 125–250 mg for swine and poultry), Se (0.1–0.38 mg) and I (0.1–2 mg) (NRC 2005), it appears that only a low to moderate level of these macroalgae can be included in the animal diet. To include these macroalgae in the feed, special considerations should be given for Na, K, and I as their concentrations may exceed not only the recommended but also the maximum tolerable levels (% or mg kg−1 DM of diet): NaCl (3–4.55% for cattle; 5% for pigs), K (10,000 and 20,000 mg for non-ruminants and ruminants, respectively), and I (50 mg for cattle and sheep; 300 mg for chicken and turkey and 400 mg for swine) for animals (NRC 2005). For example, the inclusion of just 2.7 and 6 g kg−1 DM feed, respectively, of AN and FV can fulfil the I requirements of cattle and sheep, while ~ 67 and 151 g kg−1 feed DM inclusion of AN and FV, respectively, would surpass the maximum tolerable limits for I for them. This suggests that removing low to high proportions of certain minerals, such as I, from the harvested macroalgal biomass would be necessary to minimise the risk of mineral toxicity and increase the level of inclusion of these two macroalgae in livestock feed. Hydrothermal treatments for removing minerals are even more relevant for macroalgal biomass harvested in spring (this study), as the ash and mineral contents generally higher in spring than in those harvested in the summer or autumn season (Schiener et al. 2015; Tayyab et al. 2016).

The present study demonstrates that the hot water blanching of fresh biomass can effectively reduce the contents of specific minerals from brown macroalgae lowering the risk of toxicity in animals. Although LTB seemed to provide limited benefits, HTB was highly influential in minimising up to 24% of ash and 25–73% of Na, K, I, and Br. On the other hand, several elements, including Mg, S, Ca, Fe, Zn, Mn, and Cu, remained mostly unaltered or raised with HTB, suggesting differential impacts of hot water blanching on specific minerals. Similar to the results of this study, water blanching of A. esculenta (70 °C for 5 min) effectively reduced Na (18.1%) and K (~ 35.6%) without affecting or slightly enriching Ca, Mg, and Zn (Zhu et al. 2022). A considerable loss of ash (49%), Na (> 72%), and I (85–93%), but an increase in chromium, Mn, Zn, and Ni was also reported for S. latissima with water blanching (45 °C or 80 °C for 2 min) (Trigo et al. 2023). Similarly, boiling (1–20 min) differentially affected the leaching of Na (0–61.1%), K (12.1–58.1%), and I (0–77.6%) (highest loss after 20 min of boiling) from rehydrated biomasses of four macroalgae (S. latissima, Laminaria digitata, Undaria pinnatifida, and Chondrus crispus) (Correia et al. 2021). These observations suggest that Na, K, and I are the principal macroalgal minerals targeted by low to medium–high-temperature hydrothermal processing, but the magnitude of the effect would vary with the leachability of minerals in hot water and the processed macroalgae species. Hence, the significant loss of Na, K, P, Br, and I from macroalgae compared to other elements, such as Ca and Mg, is most likely because of their higher solubility/leachability in hot water (Hou and Yan 1998). Certain elements, such as Na, are localised on the outer surface of the biomass, which could also facilitate the rapid removal during blanching (Correia et al. 2021). The considerable removal of the minerals by HTB that exceed the animal requirements or maximum tolerable levels suggests that this treatment effectively enhances the safety of macroalgal biomass, allowing a higher macroalgal inclusion level in the livestock feed. When we considered one of the most critical minerals, I, the HTB treatment contributed to increasing the optimal inclusion levels in cattle and sheep diets from 2.7 g to 10 g kg−1 DM (270% increase) for AN and 6 g to ~ 8.5 g kg−1 DM (44.2% increase) for FV. Moreover, the maximum tolerable dietary inclusion levels in cattle and sheep diets elevated to 249 g kg−1 DM (from ~ 67 g) and ~ 212 g kg−1 DM (from 151 g) for AN and FV, respectively. Hence, the HTB treatment used in this study could be a highly effective processing treatment to reduce the potential mineral toxicity and increase the inclusion levels of brown macroalgae in livestock feed.

In this study, more prominent effects of blanching on ash and mineral concentrations were observed in FV biomass, revealing higher susceptibility of this macroalgae towards hot water blanching than AN. Hot water exposure can affect the integrity or texture of macroalgal blades in a species-specific manner (Stévant et al. 2018). The variation in susceptibility of two fucoid species against hot water blanching in the present study could also be attributed to their differential ability to maintain the cellular integrity of their parts, such as blades. In contrast to other minerals, the loss of I was more effective in AN (2.6-fold) than in FV. In macroalgae, I can exist in inorganic (I−, IO3, I2) and organic (bound to macromolecules) forms, and their water solubility or leachability (inorganic I− having a higher water solubility) vary widely (Hou et al. 1997; Correia et al. 2021; Blikra et al. 2022). The predominant form of I in AN possibly was the inorganic I, resulting in higher solubilisation in hot water during blanching (Schiener et al. 2017).

Macroalgae can also accumulate non-essential and potentially harmful elements from seawater. In this study, FV biomass showed higher potential (> twofold) of accumulating As, Cd, and Pb than AN. Similar findings have been reported previously for these species collected from Northern Norway (Biancarosa et al. 2018). In both species, contents of Cd and Pb were below the maximum tolerable threshold for domestic animals (Cd: 10 mg kg−1 DM feed and Pb: 0.5, 25, and 250 mg kg−1 DM feed for chicken, pigs, and ruminants, respectively), but As contents, particularly in FV, exceeded the maximum tolerable threshold (30 mg kg−1 DM feed) (NRC 2005). Hence, FV may pose additional health risks, as As can have toxic and carcinogenic effects, depending upon its chemical form: organic or inorganic (more toxic) (Hughes 2002). In this study, the HTB treatment lowered the As levels in both macroalgae, particularly in FV (~ 63%), below the potentially toxic levels for domestic animals. Even though Cd and Pb were slightly up-concentrated in FV by HTB, both were still below the risk level. The effects observed on all three heavy metals in this study agree with results observed in a previous blanching study in S. latissima (Trigo et al. 2023). Although the inorganic or toxic form of As was earlier found at negligible levels (0.09–0.11 mg kg−1 DM) in both AN and FV (Biancarosa et al. 2018), our results indicate that HTB treatment can substantially eradicate the risk of As, even considering them as sole animal feed. Hence, HTB treatment, as employed in this study, seems highly beneficial to improve the safety of brown macroalgal biomass as an animal feed source.

It cannot be excluded that with the removal of ash and mineral elements, other valuable nutrients could have also been lost during the exposure of macroalgal biomass to hot water. However, this study suggests no such apparent loss of major nutrients, such as CP and carbohydrates from the brown macroalgae during the water blanching, although HTB reduced crude fat in FV biomass. With the hot water blanching, the proportion of carbohydrates was enriched since NFE, CF, and NDFom levels were linearly raised in macroalgae biomass with the increasing blanching temperature, and these increments were more profound in FV. Similar effects of hot water blanching on CP, crude fat, and total carbohydrates have also been reported in S. latissima (Nielsen et al. 2020). This suggests that major nutrients in brown macroalgae generally remain unaffected with hot water blanching.

Hot water blanching differentially alters carbohydrate compositions of brown macroalgae

Brown macroalgae contain unique structural carbohydrates such as alginate, fucoidan, and cellulose, and storage carbohydrates including laminarin and mannitol (Rioux and Turgeon 2015). The contents and composition of these carbohydrates will have important implications for the cellular integrity of macroalgal biomass and the digestibility/utilisation of macroalgal nutrients (Rioux and Turgeon 2015; Maehre et al. 2016). This study demonstrates that AN is a superior source of sugars, evidenced by ~ 49% TSC DM, compared to only ~ 34.4% in FV. This trend is consistent with a previous study on the same two brown species (Rioux et al. 2007). The TSC of AN observed in this study is even higher than that reported for sugar-rich kelp species, such as A. esculenta and S. latissima (Stévant et al. 2018), indicating a potential for commercial applications. When exposed to hot water blanching, the TSC of two brown macroalgae were differentially influenced, as both blanching treatments led to an enrichment of TSC in FV, upgrading it by 24.5% with HTB, which did not happen in AN. This again suggests the macroalgal species-specific effect of hot water blanching as reported by a previous study which noted 1.9, 2.7, and 4.3-fold increases in TSCs, respectively, in Laminaria saccharina (S. latissima), L. digitata and Himanthalia elongata, with hydrothermal treatments (maximum at 85 °C for 15 min) (Rajauria et al. 2010). The elevation of TSC, specifically in FV, could be partly attributed to its greater increase in carbohydrate fraction in the biomass with HTB. This difference between the two brown algae could be associated with the differential modification of cell wall polysaccharides by hydrothermal treatments that can affect carbohydrate hydrolysis and the release of sugars from biomass (Rajauria et al. 2010).

In both algae, major sugar components were uronic acids > fucose > glucose (glucan) or mannitol, uronic acids accounting for approximately half of the TSC. However, as anticipated, these two brown algae differed in the concentrations of individual sugars: uronic acids, fucose, xylan, and mannitol, the first three being greater in AN. Notably, the content of MA was over twofold higher in AN than in FV, while both species had similar concentrations of GA. This led to a higher MA/GA ratio in AN (2.4) than in FV (~ 0.95). The two uronic acids, MA and GA, are building blocks of alginate (joined by 1,4-glycosidic linkages) and occur in varied proportions (MA/GA ratio) and arrangements in the alginate chain: MA-MA or GA-GA or MA-GA blocks depending on macroalgae species (Rioux et al. 2007; Manns et al. 2014). Alginate with higher GA blocks or a low MA/GA ratio leads to a more brittle or less elastic gel and vice versa (Draget et al. 2000; Khajouei et al. 2021). Hence, the relative concentrations of these two uronic acids and their total sum (rough estimation of alginate) would be critical for the susceptibility or resistance of macroalgal biomass towards hydrothermal treatments. This study illustrates that a short low-temperature hydrothermal exposure is insufficient for changing brown algal carbohydrate composition, as LTB did not affect any of the sugar components measured. Conversely, HTB seemed to affect several sugar components, namely the uronic acids, glucans, and mannitol, but with marked species differences. With HTB, FV biomass demonstrated a remarkable enrichment in MA, GA, and glucan concentrations, and in agreement with this study, a considerable increase in uronic acids or alginate was recorded in S. latissima after 2 min water blanching at 80 °C (Trigo et al. 2023). However, there were only minor changes in all those three sugars in AN, even after HTB. It has been reported that macroalgae with high uronic acids or alginate need more robust conditions to decompose their biomass or carbohydrates (Manns et al. 2014). In this study, a higher level of uronic acids in AN compared to FV (25.4% for AN vs. 15.7% for FV) suggests that more robust physicochemical treatments may be required to disintegrate the AN biomass and influence its carbohydrate composition.

The HTB treatment used in the present study seemed to adversely affect the mannitol concentrations in brown macroalgal biomass, leading to a 50–82% loss relative to the unblanched biomass (more prominently from FV). As reported previously, the loss of mannitol from both algae could be due to its high solubility in hot water (Soetaert et al. 1999). Mannitol is a high-value product with various pharmacological and functional food-related applications (Manns et al. 2014; Dai et al. 2017) and has been found to improve feed efficiency and animal productivity when included in animal feed (Hanieh and Sakaguchi 2009). The HTB treatment hence could lower the commercial potential of brown algae as a source of mannitol.

Hot water blanching improves the extractability of total polyphenols and fucoxanthin

Phytochemical constituents, such as fucoxanthin and polyphenols, play critical roles in the bioactive properties of macroalgae. Greater contents of both fucoxanthin and TPC in FV suggest that FV can have higher bioactive potential than AN, as previously reported (Shannon and Abu-Ghannam 2017). However, fucoxanthin concentrations herein observed are slightly lower than in the previous study. Fucoxanthin content varies within the parts of the thallus in an individual alga; fronds, or blades containing higher fucoxanthin than stipe and holdfasts (Schmid and Stengel 2015; Shannon and Abu-Ghannam 2017). Thus, the lower fucoxanthin observed in both species in this study might be due to the use of whole macroalgal biomass for fucoxanthin extraction. The species difference in TPC observed in this study agrees with our earlier study (Pandey et al. 2022). However, other studies have reported a similar level of polyphenols in AN and FV (Ragan and Jensen 1978; Connan et al. 2004; Tibbetts et al. 2016). The contents of polyphenols or phlorotannin in brown macroalgae are linked to their growth stage and seasonal conditions, and lower concentration has been reported during the active growth stage (Parys et al. 2009). Among the two fucoid species, AN has a slower growth rate than FV (Choi and Norton 2005). Therefore, the potential difference in the growth stage of AN and FV might have contributed to species difference in TPC in this study, although both algae were harvested in the same period (spring/March) of the year.

Hydrothermal treatments can also affect the concentration, extractability, and activity of macroalgal phytochemicals, including fucoxanthin and polyphenols. Fucoxanthin is present in the chloroplast, inside the membrane-bound compartment called thylakoids (Shannon and Abu-Ghannam 2017) and generally remains as complex of fucoxanthin-chlorophyll a/c-binding proteins (FCPs) (Di Valentin et al. 2013). Similarly, polyphenols (phlorotannins) are synthesised in membrane-bound cytoplasmic vesicles of macroalgae called physodes (Lüder and Clayton 2004; Bartsch et al. 2008), and most of the polyphenols exist in a bound state with sugars, proteins, or fatty acids (Rajauria et al. 2010). Heat exposure to a certain level (e.g., 60–95 °C) may improve the recovery of fucoxanthin and polyphenols by facilitating the diffusion of solvents through the cell membrane and detaching the phytochemicals from the complexes, whereas a too-high temperature can lead to the degradation and loss of those compounds (Rajauria et al. 2010; Nie et al. 2021). In this study, HTB treatment improved the extractability of polyphenols, as evidenced by higher TPC in the extracts of both macroalgae compared to the unblanched biomass. The HTB also enhanced the extractability of fucoxanthin from FV, although it adversely affected that of AN. This indicates that short-term and medium-high temperature water-blanching do not cause a loss of polyphenols from brown macroalgae, and their extractability could be improved. However, effects on pigments can vary with macroalgae species.

Hot water blanching does not result in desirable impacts on in vitro digestibility of brown macroalgae

Since the hot water blanching improved the nutritional profile of macroalgal biomass by lowering ash and the extractability of certain compounds, such as sugars, an improvement was also expected in the digestibility of blanched biomass. Contrary to this, the in vitro digestibility studies with monogastric and ruminant models did not indicate such improvements for both brown macroalgae. Although LTB had minimal impacts on macroalgal digestibility in both animal models, HTB seemed detrimental, reducing up to 8% of in vitro DM or OM and ~ 26% of CP digestibility of both algae for monogastric animals. In the ruminant digestibility model, hot water blanching had less impact, as it only impaired the digestibility of FV with HTB. However, its CP digestibility was more severely reduced (~ 42%) with HTB in ruminants than in monogastric animals. To the best of our knowledge, no other studies that evaluated the effects of water blanching on the digestibility of macroalgae in animals exist to compare with our findings. Nevertheless, this study indicates that CP digestibility could be the most adversely affected parameter of brown macroalgae with HTB. Hence, the reduced DM and OM digestibilities seem to be mainly attributed to poor CP digestibility.

As suggested by the correlation analysis, the reductions in DM, OM, and CP digestibilities with blanching in the present study seem to be associated with increased carbohydrates or fibre levels and uronic acids, particularly the GA in the macroalgal biomass. A negative correlation between fibre contents and in vitro digestibility of macroalgae has also been reported previously (Bikker et al. 2020). Macroalgal carbohydrates or sugars: the alginate, uronic acids, and fucoidan have restrictive digestibility in ruminants (Orpin et al. 1985; Williams et al. 2013) and are primarily undigestible in monogastric animals (Chen et al. 2018; Di et al. 2018). Additionally, the reduction in the digestibility might be contributed by increased TPC, along with reduced digestible fraction (mannitol) in the algal biomass, because TPC was negatively correlated with digestibility parameters. High polyphenols in feed can minimise fermentation efficiency and degradation of fibre and protein in ruminants (Wang et al. 2008; Vissers et al. 2018), whereas mannitol was found to be positively associated with caecal acid detergent fibre digestibility, feed efficiency, and daily weight gain in rabbits (Hanieh and Sakaguchi 2009). The more severe effects of HTB in the CP digestibility of FV could be associated with its more significant enrichment of TPC and NDFom, as protein molecules can form complexes with polyphenols (Vissers et al. 2018) and NDF (Shayo and Udén 1999).

Recent studies have reported that hot water blanching can lead to a loss of macroalgal biomass (Nielsen et al. 2020; Trigo et al. 2023). Hence, it cannot be excluded that certain readily digestible nutrients, such as soluble carbohydrates and free amino acids, had been lost during the biomass processing contributing to the poor digestibility of macroalgae in this study (Maehre et al. 2016; Stokvis et al. 2021). Considering the differential effects of LTB and HTB on macroalgal composition and in vitro digestibility observed in this study, future in vivo feeding trials may provide a better insight into the impacts of blanching-derived macroalgal compositional changes on nutrient utilisation and animal performance. In the context of the altered composition of complex carbohydrates and phytochemicals, it would be interesting to investigate whether and how the health-promoting properties, such as prebiotic and anti-microbial activities of brown macroalgae, are affected by hot water blanching. Although practically simple, hot water blanching is an energy-consuming process and can lead to an increased production cost of macroalgae in commercial-scale production. However, the present study highlights the ability of hot water blanching, particularly the HTB, to optimise nutritional compositions and reveals that there are species-specific impacts of water blanching on the sugar or carbohydrate composition of two fucoid brown macroalgae, AN and FV.

Conclusions

The present study investigated the impact of post-harvest hot water blanching on diverse chemical composition parameters and in vitro digestibility of two commercially important brown macroalgae, A. nodosum and F. vesiculosus, for monogastric and ruminant animals. The exposure of fresh biomass to a medium–high temperature water blanching (e.g., HTB) efficiently minimises the levels of ash, excess minerals (Na, K, P, Br, I), and heavy metals (e.g., As) in brown macroalgae. On the other hand, HTB treatment enriches the carbohydrate content in macroalgal biomass, mainly fibre fractions, and alters sugar composition, increasing the level of uronic acids and glucans but reducing mannitol content. The FV biomass was found to be more sensitive to high-temperature exposure than AN, as the changes in the chemical composition were more prominent, which could be associated with their different carbohydrate profiles. Consequently, HTB appeared detrimental to the digestibility of FV biomass for both monogastric and ruminant animals, notably impairing the CP digestibility. The digestibility of AN was maintained with blanching for ruminants, but both LTB and HTB negatively affected its digestibility for monogastric species. Future studies are needed to identify appropriate macroalgal post-harvest processing techniques to improve both nutritional composition and digestibility and evaluate their impacts on animal health, production, and performance.

Data availability

Data generated during this study are available from the corresponding author upon reasonable request.

References

AACC International Approved Methods of Analysis, 11th Ed. Method 76–13.01. Total Starch Assay Procedure (Megazyme Amyloglucosidase/alpha-Amylase Method). AACC International, St. Paul, MN, U.S.A. https://www.cerealsgrains.org/resources/Methods/Pages/76Starch.aspx

Angell AR, Mata L, de Nys R, Paul NA (2016) The protein content of seaweeds: a universal nitrogen-to-protein conversion factor of five. J Appl Phycol 28:511–524

ANKOM Technology (2021) Crude Fiber Analysis. https://www.ankom.com/analytical-methods-support/fiber-analyzer-a200. Accessed 29 Jun 2021

AOAC 2001.11 (2001) Protein (Crude) in Animal Feed, Forage (Plant Tissue), Grain, and Oilseeds. Block digestion method using copper catalyst and steam distillation into boric acid. AOAC Official Method 2001.11–2005

Bartsch I, Wiencke C, Bischof K, Buchholz CM, Buck BH, Eggert A, Feuerpfeil P, Hanelt D, Jacobsen S, Karez R (2008) The genus Laminaria sensu lato: recent insights and developments. Eur J Phycol 43:1–86

Biancarosa I, Belghit I, Bruckner CG, Liland NS, Waagbø R, Amlund H, Heesch S, Lock EJ (2018) Chemical characterisation of 21 species of marine macroalgae common in Norwegian waters: benefits of and limitations to their potential use in food and feed. J Sci Food Agric 98:2035–2042

Bikker P, Stokvis L, van Krimpen M, van Wikselaar P, Cone J (2020) Evaluation of seaweeds from marine waters in Northwestern Europe for application in animal nutrition. Anim Feed Sci Technol 263:114460

Blikra MJ, Henjum S, Aakre I (2022) Iodine from brown algae in human nutrition, with an emphasis on bioaccessibility, bioavailability, chemistry, and effects of processing: A systematic review. Compr Rev Food Sci Food Saf 21:1517–1536

Boisen S, Fernández J (1997) Prediction of the total tract digestibility of energy in feedstuffs and pig diets by in vitro analyses. Anim Feed Sci Technol 68:277–286

Cabrita AR, Maia MR, Oliveira HM, Sousa-Pinto I, Almeida AA, Pinto E, Fonseca AJ (2016) Tracing seaweeds as mineral sources for farm-animals. J Appl Phycol 28:3135–3150

Catarino MD, Silva A, Cardoso SM (2017) Fucaceae: A source of bioactive phlorotannins. Int J Mol Sci 18:1327

Chen L, Xu W, Chen D, Chen G, Liu J, Zeng X, Shao R, Zhu H (2018) Digestibility of sulfated polysaccharide from the brown seaweed Ascophyllum nodosum and its effect on the human gut microbiota in vitro. Int J Biol Macromol 112:1055–1061

Choi HG, Norton TA (2005) Competition and facilitation between germlings of Ascophyllum nodosum and Fucus vesiculosus. Mar Biol 147:525–532

Connan S, Goulard F, Stiger V, Deslandes E, Ar Gall E (2004) Interspecific and temporal variation in phlorotannin levels in an assemblage of brown algae. Bot Mar 47:410–416

Correia H, Soares C, Morais S, Pinto E, Marques A, Nunes ML, Almeida A, Delerue-Matos C (2021) Seaweeds rehydration and boiling: Impact on iodine, sodium, potassium, selenium, and total arsenic contents and health benefits for consumption. Food and Chem Toxicol 155:112385

Cox S, Abu-Ghannam N, Gupta S (2010) An assessment of the antioxidant and anti-microbial activity of six species of edible Irish seaweeds. Int Food Res J 17:205–220

Dai Y, Meng Q, Mu W, Zhang T (2017) Recent advances in the applications and biotechnological production of mannitol. J Funct Foods 36:404–409

Di T, Chen G, Sun Y, Ou S, Zeng X, Ye H (2018) In vitro digestion by saliva, simulated gastric and small intestinal juices and fermentation by human fecal microbiota of sulfated polysaccharides from Gracilaria rubra. J Funct Foods 40:18–27

Di Valentin M, Meneghin E, Orian L, Polimeno A, Büchel C, Salvadori E, Kay CW, Carbonera D (2013) Triplet–triplet energy transfer in fucoxanthin-chlorophyll protein from diatom Cyclotella meneghiniana: Insights into the structure of the complex. Biochim Biophys Acta Bioenerg 1827:1226-1234

Dierick N, Ovyn A, De Smet S (2010) In vitro assessment of the effect of intact marine brown macro-algae Ascophyllum nodosum on the gut flora of piglets. Livest Sci 133:154–156

Draget KI, Strand B, Hartmann M, Valla S, Smidsrød O, Skjåk-Bræk G (2000) Ionic and acid gel formation of epimerised alginates; the effect of AlgE4. Int J Biol Macromol 27:117–122

Duan X-J, Zhang W-W, Li X-M, Wang B-G (2006) Evaluation of antioxidant property of extract and fractions obtained from a red alga, Polysiphonia urceolata. Food Chem 95:37–43

European Commission (2009) Commission Regulation (EC) No 152/2009 of 27 January 2009 laying down the methods of sampling and analysis for the official control of feed. Off J Eur Union 54:1-130

Ford L, Stratakos AC, Theodoridou K, Dick JT, Sheldrake GN, Linton M, Corcionivoschi N, Walsh PJ (2020) Polyphenols from brown seaweeds as a potential anti-microbial agent in animal feeds. ACS Omega 5:9093–9103

Garcia-Vaquero M, Rajauria G, Miranda M, Sweeney T, Lopez-Alonso M, O’Doherty J (2021) Seasonal variation of the proximate composition, mineral content, fatty acid profiles and other phytochemical constituents of selected brown macroalgae. Mar Drugs 19:204

Goering HK, Van Soest PJ (1970) Forage fiber analyses (apparatus, reagents, procedures, and some applications). U.S.D.A. Agricultural Research Service, Agriculture Handbook No 379, p 20

Gülzari ŞÖ, Lind V, Aasen IM, Steinshamn H (2019) Effect of supplementing sheep diets with macroalgae species on in vivo nutrient digestibility, rumen fermentation and blood amino acid profile. Animal 13:2792–2801

Hahn T, Lang S, Ulber R, Muffler K (2012) Novel procedures for the extraction of fucoidan from brown algae. Process Biochem 47:1691–1698

Hanieh H, Sakaguchi E (2009) Effect of d-mannitol on feed digestion and cecotrophic system in rabbits. Anim Sci J 80:157–162

Hayes DJ (2012) Development of near infrared spectroscopy models for the quantitative prediction of the lignocellulosic components of wet Miscanthus samples. Bioresour Technol 119:393–405

Holdt SL, Kraan S (2011) Bioactive compounds in seaweed: functional food applications and legislation. J Appl Phycol 23:543–597

Hou X, Chai C, Qian Q, Yan X, Fan X (1997) Determination of chemical species of iodine in some seaweeds (I). Sci Total Environ 204:215–221

Hou X, Yan X (1998) Study on the concentration and seasonal variation of inorganic elements in 35 species of marine algae. Sci Total Environ 222:141–156

Hughes MF (2002) Arsenic toxicity and potential mechanisms of action. Toxicol Lett 133:1–16

ISO 5984 (2002) ISO 5984:2002, Animal feeding stuffs – Determination of crude ash. International Organization for Standardization, Geneva

ISO 6496 (1999) ISO 6496:1999 Animal feeding stuffs — Determination of moisture and other volatile matter content. International Organization for Standardization, Geneva

Khajouei RA, Keramat J, Hamdami N, Ursu A-V, Delattre C, Gardarin C, Lecerf D, Desbrières J, Djelveh G, Michaud P (2021) Effect of high voltage electrode discharge on the physicochemical characteristics of alginate extracted from an Iranian brown seaweed (Nizimuddinia zanardini). Algal Res 56:102326

Krause-Jensen D, Duarte CM (2016) Substantial role of macroalgae in marine carbon sequestration. Nat Geosci 9:737–742

Lorenzo JM, Agregán R, Munekata PE, Franco D, Carballo J, Şahin S, Lacomba R, Barba FJ (2017) Proximate composition and nutritional value of three macroalgae: Ascophyllum nodosum, Fucus vesiculosus and Bifurcaria bifurcata. Mar Drugs 15:360

Lüder UH, Clayton MN (2004) Induction of phlorotannins in the brown macroalga Ecklonia radiata (Laminariales, Phaeophyta) in response to simulated herbivory—the first microscopic study. Planta 218:928–937

Mæhre HK, Malde MK, Eilertsen KE, Elvevoll EO (2014) Characterisation of protein, lipid and mineral contents in common Norwegian seaweeds and evaluation of their potential as food and feed. J Sci Food Agric 94:3281–3290

Maehre HK, Edvinsen GK, Eilertsen K-E, Elvevoll EO (2016) Heat treatment increases the protein bioaccessibility in the red seaweed dulse (Palmaria palmata), but not in the brown seaweed winged kelp (Alaria esculenta). J Appl Phycol 28:581–590

Makkar HP, Tran G, Heuzé V, Giger-Reverdin S, Lessire M, Lebas F, Ankers P (2016) Seaweeds for livestock diets: A review. Anim Feed Sci Technol 212:1–17

Manns D, Deutschle AL, Saake B, Meyer AS (2014) Methodology for quantitative determination of the carbohydrate composition of brown seaweeds (Laminariaceae). RSC Adv 4:25736–25746

Marten GC, Barnes RF (1979) Prediction of energy digestibility of forages with in vitro rumen fermentation and fungal enzyme systems. In: Pidgeon WJ, Batch CC, Graham M (eds) Workshop on Standardisation of analytical methodology for feeds. IDRC, Ottawa, Canada pp 61–71

Nie J, Chen D, Lu Y, Dai Z (2021) Effects of various blanching methods on fucoxanthin degradation kinetics, antioxidant activity, pigment composition, and sensory quality of Sargassum fusiforme. LWT 143:111179

Nielsen CW, Holdt SL, Sloth JJ, Marinho GS, Sæther M, Funderud J, Rustad T (2020) Reducing the high iodine content of Saccharina latissima and improving the profile of other valuable compounds by water blanching. Foods 9:569

NRC (2005) Mineral tolerance of animals:Second Revised Edition 2005, The National Academies Press Washington DC, USA, p 510

O’Sullivan L, Murphy B, McLoughlin P, Duggan P, Lawlor PG, Hughes H, Gardiner GE (2010) Prebiotics from marine macroalgae for human and animal health applications. Mar Drugs 8:2038–2064

Orpin C, Greenwood Y, Hall F, Paterson I (1985) The rumen microbiology of seaweed digestion in Orkney sheep. J Appl Bacteriol 58:585–596

Øverland M, Mydland LT, Skrede A (2019) Marine macroalgae as sources of protein and bioactive compounds in feed for monogastric animals. J Sci Food Agric 99:13–24

Pandey D, Mansouryar M, Novoa-Garrido M, Næss G, Kiron V, Hansen HH, Nielsen MO, Khanal P (2021) Nutritional and anti-methanogenic potentials of macroalgae for ruminants. In: Lei XG (ed) Seaweed and microalgae as alternative sources of protein. Burleigh Dodds Science Publishing, Cambridge, pp 1–33

Pandey D, Hansen HH, Dhakal R, Aryal N, Rai SP, Sapkota R, Nielsen MO, Novoa-Garrido M, Khanal P (2022) Interspecies and seasonal variations in macroalgae from the Nordic region: Chemical composition and impacts on rumen fermentation and microbiome assembly. J Clean Prod 363:132456

Parys S, Kehraus S, Pete R, Küpper FC, Glombitza K-W, König GM (2009) Seasonal variation of polyphenolics in Ascophyllum nodosum (Phaeophyceae). Eur J Phycol 44:331–338

Pereira L, Morrison L, Shukla PS, Critchley AT (2020) A concise review of the brown macroalga Ascophyllum nodosum (Linnaeus) Le Jolis. J Appl Phycol 32:3561–3584

Ragan MA, Jensen A (1978) Quantitative studies on brown algal phenols. II. Seasonal variation in polyphenol content of Ascophyllum nodosum (L.) Le Jol. and Fucus vesiculosus (L.). J Exp Mar Biol Ecol 34:245–258

Rajauria G, Jaiswal AK, Abu-Ghannam N, Gupta S (2010) Effect of hydrothermal processing on colour, antioxidant and free radical scavenging capacities of edible Irish brown seaweeds. Int J Food Sci Technol 45:2485–2493

Rioux L-E, Turgeon SL, Beaulieu M (2007) Characterisation of polysaccharides extracted from brown seaweeds. Carbohydr Polym 69:530–537

Rioux L-E, Turgeon SL (2015) Seaweed carbohydrates. In: Tiwari BK, Troy DJ (eds) Seaweed sustainability. Elsevier, Amsterdam, pp 141–192

Robertson J (1981) The detergent system of analysis and its application to human foods. In: James WP, Theander O (eds) The Analysis of Dietary Fibre in Food. Marcel Dekker, New York, pp 123–158

Rodrigues D, Freitas AC, Pereira L, Rocha-Santos TA, Vasconcelos MW, Roriz M, Rodríguez-Alcalá LM, Gomes AM, Duarte AC (2015) Chemical composition of red, brown and green macroalgae from Buarcos bay in Central West Coast of Portugal. Food Chem 183:197–207

Schiener P, Black KD, Stanley MS, Green DH (2015) The seasonal variation in the chemical composition of the kelp species Laminaria digitata, Laminaria hyperborea, Saccharina latissima and Alaria esculenta. J Appl Phycol 27:363–373

Schiener P, Zhao S, Theodoridou K, Carey M, Mooney-McAuley K, Greenwell C (2017) The nutritional aspects of biorefined Saccharina latissima, Ascophyllum nodosum and Palmaria palmata. Biomass Convers Biorefin 7:221–235

Schmid M, Stengel DB (2015) Intra-thallus differentiation of fatty acid and pigment profiles in some temperate Fucales and Laminariales. J Phycol 51:25–36

Schweiger AK, Cavender-Bares J, Townsend PA, Hobbie SE, Madritch MD, Wang R, Tilman D, Gamon JA (2018) Plant spectral diversity integrates functional and phylogenetic components of biodiversity and predicts ecosystem function. Nat Ecol Evol 2:976–982

Shannon E, Abu-Ghannam N (2017) Optimisation of fucoxanthin extraction from Irish seaweeds by response surface methodology. J Appl Phycol 29:1027–1036

Shayo C, Udén P (1999) Nutritional uniformity of crude protein fractions in some tropical browse plants estimated by two in vitro methods. Anim Feed Sci Techno 78:141–151

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedure, 1617:1-16

Soetaert W, Vanhooren PT, Vandamme EJ (1999) The production of mannitol by fermentation. In: Bucke C (ed) Carbohydrate Biotechnology Protocols. Humana Press, Totowa, pp 261–275

Stévant P, Rebours C, Chapman A (2017) Seaweed aquaculture in Norway: recent industrial developments and future perspectives. Aquacult Int 25:1373–1390

Stévant P, Marfaing H, Duinker A, Fleurence J, Rustad T, Sandbakken I, Chapman A (2018) Biomass soaking treatments to reduce potentially undesirable compounds in the edible seaweeds sugar kelp (Saccharina latissima) and winged kelp (Alaria esculenta) and health risk estimation for human consumption. J Appl Phycol 30:2047–2060

Stokvis L, van Krimpen M, Kwakkel R, Bikker P (2021) Evaluation of the nutritional value of seaweed products for broiler chickens’ nutrition. Anim Feed Sci Technol 280:115061