Abstract

Glucanases provide an excellent option for pre-treatment of cellulose and improvement in properties of microfibrillated cellulose. In our research, we have used two different enzyme formulations, a purified β-1,4-endoglucanase, and an β-1,4-exoglucanase rich mixture and the focus of the study is on effect of high protein applications on PFI refined-microfibrillated cellulose (2,500 rev). At high protein applications, cellulose fibers showed improved fibrillation after endoglucanase treatment with 20.4% improvement over PFI-only refined fibers while the exoglucanase mix showed 6.8% improvement. At low protein applications, the purified endoglucanase treatment resulted in improved tensile, compression, Scott ply bond, extensional stiffness of microfibrillated cellulose compared with the exoglucanase mix or untreated refined fibers. Scott Ply Bond measurements are an indicator of hydroxyl groups on the fiber surface whose value increased with enzyme pre-treatment. Mechanical properties changed with enzyme treatment and suggest the bonding between fibers increases with endoglucanase treatment providing improved surface functionalization.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the current population reaching close to almost eight billion and the consequential depletion of readily available fossil fuels, humanity is forced to look into greener alternatives for sustainable materials (Zheng et al. 2019; Wigley et al. 1996). With almost 1011 tonnes being produced annually, cellulose is an obvious choice (Puranen et al. 2014) and improvements have been made to the strength (Boufi et al. 2017) and other functional properties (Jorfi and Foster 2015) to broaden the use of cellulose as biodegradable alternatives in many fields. Production of isolated forms of cellulose such as microfibrillated cellulose (MFC) consumes a very high amount of energy input in the range of 3000–20,000 kWh/ton fiber (Ang et al. 2019) to reverse all the low entropy that the cellulose structure has taken years to achieve in higher plants. A PFI (Papirindustriens Forskningsinstitutt) refiner applies shear forces on the surface of fibers thereby releasing microfibrils from long bundles of macrofibrils (Borjesson 2015). A beneficial by-product of this mechanical action is the production of secondary fines which enhances fiber–fiber bonding (Seth 2003).

To lower the amount of mechanical energy consumption, enzymatic pre-treatment is a much-needed method to assist refining for MFC production and since some of the early research conducted using enzymes to manufacture MFC (Kim et al. 2006; Henriksson et al. 2007) there has been limited research on glucanase assisted mechanical treatment which focuses on energy reduction measurements (Cui et al. 2015; Wu et al. 2020). There has been no research found on enzyme surface behaviour on cellulose at high protein applications and assessing the preferred enzyme formulations to deliver the best MFC properties.

The effect of β-1,4-glucanases to weaken different types of papermaking pulp fibers has been studied extensively (Gurnagul et al. 1992) and provided the necessary groundwork for how they break the recalcitrance of cellulose and assist in mechanical shearing to produce MFC (Tripathi et al. 2008; Wang et al. 2018; Yuan et al. 2019). Buzala et al. (2016) employed cellulases from Aspergillus sp. to show that there is a reduction in PFI refining energy by normalising the MFC to a drainage index at 30°SR. Cui et al. (2015) applied five different commercially available enzymes containing glucanases/xylanases/β-glucosidase activities on softwood kraft pulp and actioned different levels of PFI refining and several pH adjustments to observe the impact on MFC handsheet properties. In addition, a study has shown that commercial glucanases produced more sugar and aggressively lowered the degree of polymerisation compared to pure endoglucanase, which was also better at retaining fiber length post micro fluidization (Wang et al. 2015). Moreover, a different approach that combined PFI refining and enzymatic pre-treatment using mannanase, xylanase and glucanase enzymes was examined which resulted in the combined hemicellulases releasing the fibrils from the fiber surface and offered a different mechanism compared with the fiber cutting mechanism observed in glucanase action (Tian et al. 2017). To our knowledge, the differences between endoglucanases and other cellulases have not been examined from their effect on mechanical properties as a function of protein application.

Our study investigated the difference in MFC properties as a result of endoglucanase or exoglucanase pre-treatment on kraft fibers. Handsheet properties were assessed in addition to pulp properties to examine differences induced by different levels of pre-treatment.

Materials and methods

Enzymes and chemicals

Virgin never-dried unrefined bleached eucalypt kraft (BEK) pulp was provided by Australian Paper Maryvale. BEK fibers compose of 78.7% cellulose, 17.7% hemicellulose and 3.2% lignin. Solid content of BEK was measured by the oven drying method (Thermoline BTC-9090) at 105 °C for a minimum of 3 h whereby the mass of the wet sample was recorded before and after drying. A commercially available cellulase mixture originating from Trichoderma reesei was received from Opal Ltd. Dinitrosalicylic acid, phenol, sodium sulphite, Rochelle salt, sodium hydroxide, glucose, Bradford reagent, purified endoglucanase (Product number: C9748, source organism: Trichoderma longibrachiatum), Bovine Serum Albumin (BSA) and Sodium-carboxymethyl cellulose (CMC) were purchased from Sigma Aldrich, Australia. Sodium dodecyl sulphate–polyacrylamide gels were purchased from GenScript. SeeBlue™ Plus2 Pre-Stained Protein standard ladder was purchased from ThermoFisher Scientific.

Protein separation, detection, and enzyme activities

Sodium dodecyl sulphate–polyacrylamide gel electrophoresis (SDS-PAGE) was performed on both enzyme samples to separate protein bands by size and proteins were visualised in the gel by staining. A pre-stained protein ladder from 3 to 198 kDa was also entered in the wells to allow the estimation of cellulase molecular weight. Stained protein bands were cut from the gel and peptide mass sequencing was performed using a QExactive Plus 2 Mass Spectrometer (Thermo Scientific). All protein bands were digested with trypsin before sequencing was performed and mass sequencing scoring was conducted using the Mascot V2.4 search engine.

The protein concentration of each formulation was determined by performing the Bradford Protein quantification method using bovine serum albumin (BSA) as known standard (Bradford 1976). The protein concentration was performed on a Costar 96 flat bottom transparent polystyrene plate which was adapted for measurement on the Infinite 200 Pro multimode microplate reader (TECAN). The CMC activity assay of enzymes was performed as per (Wood and Bhat 1988). A 0.5 mL sample of CMC solution (2%) in sodium citrate buffer was heated to 50 °C and incubated with 0.5 mL enzyme solution (0.02% w/v) for 30 min. Several dilutions of protein stocks were made so that at least one dilution released more than 0.5 mg of glucose. The enzyme reaction was stopped via the addition of 3,5-dinitrosalicylic acid solution (DNS) and heating the mixture in boiling waterbath for 5 min, then cooled in an ice bath. Samples (200 μL) of enzyme reaction solution were measured at 540 nm (Tecan InfinitePro). Dilutions of samples were performed to ensure they measured within the detection range of the glucose standard calibration curve generated between 0 and 0.2 g/L.

Enzymatic pre-treatment of BEK pulp and reducing sugar measurement

BEK stocks were disintegrated in deionised water (2.4% w/v) at 15,000 revolutions using a pulp disintegrator 3 L Mavis Engineering (Model No. 8522). The effect of enzymatic pre-treatment on pulp properties was studied on 1 L batches of pulp containing 24 g oven dry fiber. After adding enzymes at varying protein applications, the solutions were incubated for 1 h at 50 °C in 2 L flasks stirred at 110 rpm in an Infors HT Ecotron incubator. Enzymes were applied to pulp at concentrations ranging from 0.3 µg protein/g substrate to 300 µg protein/g substrate. There was no pH adjustment of the solution. Post enzymatic treatment, a sample of reaction supernatant was collected for measurement of total reducing sugars measured via the DNS method (described above).

PFI Refining

Post enzymatic treatment and filtering of the pulp solution under vacuum, the filter cake was adjusted to contain 24 g oven dry pulp in 240 g DI water solution (10 wt% pulp consistency) as per the standard TAPPI T248 (TAPPI. 2001a) and the refined. A NORAM PFI Mill (Noram quality control & research equipment Limited, Quebec, Canada) with high shearing ability was used (Gharehkhani et al. 2015) and a light loading setting was employed for 2,500 revolutions per sample.

Handsheet preparation

The refined pulp was first disintegrated at 7250 revolutions and 120 gsm handsheets were made following the TAPPI T205 standard method (TAPPI 2002) using an Automatic British Handsheet Maker. Pulp solution was prepared in a stock divider and checked for grammage three times. Thirteen sheets were made per batch of fiber and each sheet was pressed twice by a manual sheet press system. Sheets were conditioned for 24 h at 23 °C and 50% Relative Humidity.

Characterisation

Fiber length distributions were obtained using a Valmet Fiber Image analyzer (Valmet FS5, Espoo, Finland). PFI-refined fiber solutions (0.02% solution w/v) were thoroughly mixed in the analyzer and measurements were conducted in triplicate per sample.

Gel point measurements were conducted via the sedimentation method using dilutions of MFC samples (0.1, 0.08, 0.06, 0.04, 0.03, 0.02, 0.01% w/v) and consistent volume (250 mL per cylinder) as described previously (Varanasi et al. 2013). Results were analysed as described previously by Ang et al. (2019) employing a MATLAB spline function. Briefly, the y-intercept of the first differential of concentration against sedimentation height over solution height provided the gel point, and aspect ratio was calculated from the Effective Medium Theory equation (Celzard et al. 2009).

Non-destructive tests for handsheet grammage (AS1301.405 s) and thickness (AS1301.426 s) were conducted to provide density. After specimens specific to each test were cut using dye cutters, destructive tests were actioned including Tear (AS1301.400 s), Tensile (AS1301.448 s), STFI Compression (AS1301.450rp), Scott ply Bond (ARTC-D4-200) and Paper Burst (AS1301.438 s).

Hydrogen Bond density was calculated using the method outlined for hydrogen bond dominated solids by (Nissan 1976). The equation was rearranged for hydrogen bond density for one-dimensional stretching in Eq. 1:

where NT = Hydrogen bond density (bonds/cm3). E = Young’s Modulus (dyn/cm2). k = constant for cellulose (8 × 103).

Statistical methodology

All Valmet Analysis and mechanical handsheet tests were conducted independently in a minimum of triplicates. A one-way analysis of variance (ANOVA) was performed in Microsoft Office Excel 365 on the control versus the enzyme-treated and refined samples for statistical significance at an alpha value of 0.05. Data is presented as means with standard deviations indicated by error bars.

Results and discussion

Enzyme characterisation

The result of de novo peptide sequencing using mass spectrometry on both enzyme formulations is shown in Table S1. The highest ranked proteins were mainly exoglucanases with the highest absolute log probabilities which is indicative of the p-value obtained for a peptide generated from an organism’s proteome. The protein sequence coverage, which is the number and sequence of the peptide sequence that were identified in the trypsin digested protein, were sufficient to identify the exoglucanases and endoglucanase from Trichoderma reesei and only the endoglucanase from Trichoderma longibrachiatum. Exoglucanases work in a processive nature from the reducing end of the cellulose chain (Vršanská and Biely 1992) whereas endoglucanases acts at random points on the cellulose surface to provide reducing ends (Jalak et al. 2012). Hence, an exo- and endo-glucanase mixture using two different modes of action on cellulose produces a different result to a pure endoglucanase. The protein concentrations of the pure endoglucanase and the exoglucanase mix were 17.52 mg/mL and 12.66 mg/mL respectively while the CMC activities were 6031 U/mL and 2096 mg/mL respectively. The pure endoglucanase was slightly more concentrated than the mix and had about three times more CMC activity.

The effect of exoglucanase rich mix can be seen in total reducing sugars released in Fig S1. At the lowest protein application, the sugar release is very similar between the exoglucanase mix and the endoglucanase. While the endoglucanase leads sugar production at the lower protein applications, at 300 µg/g substrate, the exocellulase mix produces three times more sugar. This result is in agreement with Jalak et al. (2012) where endoglucanases provide enough cleavages for exoglucanase to “escape blockages” and we see a synergy in endoglucanase and exoglucanase mode of action delivering a higher amount of reducing sugars.

MFC fiber characterisation

The aspect ratios of fibers estimated from gel point measurements are shown in Table 1. An important observation is that there is an initial reduction in gel point at the lowest enzyme treatment, then a steady increase from 3 µg/g substrate with both enzymes. This indicates that a continuous networks of fibers were formed at lower enzyme applications allowing an increase in aspect ratio. At 300 µg/g, the gel point is found at higher concentrations and results in lower aspect ratios. To explain the differences in aspect ratio, the effect fiber length must be taken into consideration.

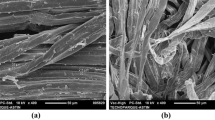

The fiber length distributions of enzyme treated, and refined fibers are shown in Fig. 1 and the kurtosis and skewness of those are displayed in Table 2. The fiber length distributions are largely asymmetrical with positive skewness values. Such unimodal distributions are characterised by a long right-tail-end. An analysis of kurtosis reveals that the length distributions are increasingly platykurtic (Kurtosis < 3) with increasing protein application. Percentages of length distribution peaks are lowered from 3.5 to 2.5% as can be seen in the protein applications of 30 and 300 µg/g substrate for the endoglucanase enzyme and at the 300 µg/g substrate protein application of the exoglucanase mix. At the 30 µg/g substrate protein addition, loss in fiber length accelerates for endoglucanase treated fibers with a loss of almost 27% but with the exoglucanase rich mix, length reductions are smaller at 7%. At low protein applications, the length distributions overlapped. Aspect ratio declines sharply at the highest protein applications (Table 1) in agreement with the length distributions in Fig. 1. Here, we can make some important conclusions about the behaviour of the two different enzymes on the cellulose surface. The exoglucanase-initiated processive cleavage of cellulose surface is less efficient in causing reduced aspect ratio since the decline in fiber length is slower, while the endoglucanase makes random scissions on the surface resulting in higher fibrillation but also more breakdown of fibers in the PFI mill. Therefore, the loss of length in endoglucanase treated fibers results in higher gel points and reduced aspect ratios.

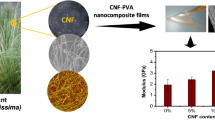

Fibrillation plays a role in the mechanical properties of handsheets by aiding the fiber network. Fibrillation% as detected by the solution-based fiber analyser is shown in Table 3. Fibrillation improves in fibers treated by both enzymes although the endoglucanase enzyme is more effective at each protein application.

The experiment was performed in triplicate and mean values and standard deviations were calculated. One way ANOVA analysis resulted in a p-value of < 0.05 making the differences created by enzyme pre-treatment significant.

A shorter fiber decreases the number of potential contact points available for improving fiber—fiber bonding. A second contributor to improving fiber—fiber bonding is fines shown in Fig. 2a, b which act as fillers in MFC (Taipale et al. 2010). Fines A are particles smaller than 0.2 mm in length (also known as primary fines from parenchyma cells of wood) and Fines B are small ribbon-like structures that result from a breakdown of fibrils by the shearing action of the refiner (also known as secondary fines) and results obtained here are in agreement with Seth (2003) where the fines occupy space between fibers during dewatering. Here, fines also contain a high density of surface hydroxyl groups due to glucanase action and therefore have enhanced capability to improve fiber–fiber bonding.

The experiment was performed in triplicate and mean values and standard deviations were calculated. One way ANOVA analysis resulted in a p-value of < 0.05 making the differences created by enzyme pre-treatment significant.

Impact of enzyme pre-treatment on MFC handsheet properties

The mechanical properties of handsheets are shown in Fig. 3a–d. Tensile Index increases by almost 2% for treatment with the exoglucanase mix over control but the improvement is increased with the endoglucanase by almost 9% at 0.3 µg/g substrate. At higher protein applications, the tensile index further improves by 3.5% and 13% for the exoglucanase mix and endoglucanase, respectively. Above this protein application, the tensile index starts declining below the control for the endoglucanase (− 3.7%) while the exoglucanase mix handsheet maintains strength until a 100-fold increase in protein application where it declines below the control (− 10.8%). Tensile Index is a test of paper failure and is strongly dependent on fiber length. These results are consistent with the length distribution results (Fig. 1) where the loss in fiber length dictates a reduction in Tensile Index. As the fiber length distribution changes between 30 and 300 µg/g substrate protein application for the pure endoglucanase, and the 300 µg/g substrate for the exoglucanase mix (Fig. 1), the Tensile Index reduces below that for the control refined fibers. The effect of length distribution and fibrillation can also be seen in sheet density and thickness (Fig S2 (a), (b)) where increase in protein application causes the handsheets to get denser with the pure endoglucanase providing enhanced improvements at every application over the exoglucanase mixture. Burst Index and Tear Index (Fig S3 (a), (b)) are also sensitive to fiber length and show a declining trend at mid-protein-level applications. There is an initial increase in Tear and Burst Index for enzyme treatments at 0.3 µg/g substrate, however, endoglucanase treatments above this concentration led to sharp reductions in Burst and Tear indices, steeper than is the case for exoglucanase mix which retains fiber length better. Longer fibers can make more bonds with neighbouring fibers and enhance connectivity, but shorter fibers are detrimental to Tear and Burst index benefits and these results are in agreement with earlier findings (Oksanen et al. 1997; Cui et al. 2015).

Handsheet properties (with std. dev as error bars) with untreated and refined to 2,500 revolutions handsheet used as control (dark pink) with each test a Tensile Index, b STFI Compression Index, c Scott Ply Bond, d Extensional Stiffness Index. Endoglucanase (black bars), Exoglucanase mix (grey bars). The x-axis shows protein application (µg protein/g substrate). The experiment was performed in triplicate and mean values and standard deviations were calculated. One way ANOVA analysis resulted in a p-value of < 0.05 making the differences created by enzyme pre-treatment significant in all handsheet properties

STFI compression index shows an improvement of almost 4% over the control with exoglucanase mix pretreatment and 8.5% with the endoglucanase at the lowest protein level of 0.3 µg/g substrate (Fig. 3b). With increasing protein concentration, compression index increases up to 15.3% for the exoglucanase rich fibers and 23.7% for the endoglucanase. STFI Compression is a test of compressive forces that a specimen can tolerate before failing. Compression is directly related to increase in fibrillation and density of contact points for bonding along with sheet density (Wink et al. 1984). Compression is therefore independent of fiber length and a direct measure of fiber–fiber bond improvement towards the geometric centre of the specimen. Compression index associates very well with fines production trends (Fig. 2).

The effect of enzymatic pretreatment on BEK is noteworthy for changes in Scott Ply Bond (Fig. 3c). Maximum detection limits of the test were observed for fibers treated at the lowest endoglucanase application while exoglucanases reached that limit at 300 μg/g substrate treatment. This result shows a minimum of 52.1% improvement in internal bond energy of fibers that have been endoglucanase treated while the exoglucanase reaches that improvement stepwise with increasing protein addition (13.8, 18.5, 47.3, 52.1%) which are similar improvements seen by Cui et al. (2015). Internal bond energy measures the number of bonds, average area per bond and their specific strength (Niskanen 2008). This result implies that endoglucanase has created a denser network of hydrophilic ends which are available to bond with the test binding tape and provide maximum resistance.

Extensional Stiffness Index is another property of interest that has been developed further in this study (Fig. 3d). Again, endoglucanase treatment results in a superior effect with an 8.6% increase at 0.3 μg/g substrate against a 3.6% increase with the exoglucanase mix. The increases in extensional stiffness improvements with increasing protein addition are shown to be independent of fiber length as there is no decline observed except for the exoglucanase mix at the highest protein addition while there is an improvement of up to 32.9% for the endoglucanase pretreated fibers at the highest protein treatment. Extensional stiffness is defined as the product of Young’s modulus of a specimen and its thickness (Tan 2001). As the enzyme dose is increased, the network improves, and the amount of force required to create a displacement in the test specimen is increased due to increased contact points per fiber by fibrillation. The same consistent improvement with dose is not seen by exoglucanase mix treatment.

Mechanical tests for handsheet properties and fiber image analysis have allowed comparison of the actions of two different cellulose-active enzymes. Tear index mostly decreased in handsheets made with enzyme pretreated BEK, and this effect worsened with increased enzyme application. The decrease in tear index is potentially due to the increased hydroxyl groups which are effectively now ruptured zones in the fiber chain, allowing tear at the sheet edge. Since Tear is administered on the cross-section of the specimen, the rupture zones created by enzyme action are high at this position. The fibers on the surface layer of the cross-section have no contact with another fibril/fiber to consolidate those existing hydroxyl groups and therefore are easier to tear. Hence Tear Index is shown to decline with increasing protein levels with increased rupture zones.

Paper burst is similarly dependent on fiber length and therefore neither the number of contact points via fibrillation nor fiber–fiber bonding provide an improvement. The results from burst and tear, therefore, agree with the length distributions in Fig. 1a, b) where the decline in fiber length is detrimental to these two properties. Surface hydroxyl groups promote inter-fiber bonding which provides strong network connectivity and therefore benefits compression tests.

Compression is the only measurement in this suite of mechanical tests that seems entirely dependent on the strength of the fiber network over small, concentrated parts of the specimen. Hydrogen Bond Density estimation derived from Young’s modulus measurements (Fig S4) suggests why some mechanical properties do not decrease with increased enzyme application. Based on this estimation, the hydroxyl groups on the cellulose surface increase through glucanase action, increasing hydrogen bond concentration which improves fiber–fiber bonding. This indicates that compression and Scott Ply Bond are dependent on local fiber–fiber forces. By studying the common mechanical properties that bear the highest potential for reinforcement like tensile, compression, Scott ply bond and extensional stiffness (Hellstrom 2014; Ang et al. 2020), with enzymatic pre-treatment and low level refining, we have been able to show from a mechanistic perspective, the different impacts of enzyme action by comparing pure endoglucanase and an exoglucanase mixture.

Conclusion

This study demonstrates that differences in MFC properties arise due to enzyme action on fibers where differing mechanisms affect properties; our approach and findings are distinct from previous investigations done in the field of cellulose processing with enzymes (Cui et al. 2015; Wang et al. 2018; Liu et al. 2019; Yuan et al. 2019). Enzyme action affects fiber length at mid-high protein applications; endoglucanase treatment results in shortened fibers at lower protein applications than the exoglucanase mix indicating an increased number of weak points created on the fiber surface with this enzyme. This is due to the processive surface-revealing action of exoglucanases as opposed to the endoglucanase which performs random scission. Primary and secondary fines production is more pronounced at protein levels of 30 and 300 µg/g substrate and their contribution to the strength of handsheets is significant except for properties like tensile, tear and burst index where fiber length is the key parameter. After evaluation of fiber characteristics and handsheet properties via pretreatment of fibers with two different glucanase formulations, the hypothesis of the study is accepted since it allows assessment of the difference between mechanisms of endoglucanases and exoglucanases. The study also highlights the importance of choosing the correct glucanase is crucial for desired outcomes. Further studies including enzyme cocktails could aid in providing further knowledge in improving MFC production.

References

Ang S, Haritos V, Batchelor W (2019) Effect of refining and homogenization on nanocellulose fiber development, sheet strength and energy consumption. Cellulose 26:4767–4786. https://doi.org/10.1007/s10570-019-02400-5

Ang S, Haritos V, Batchelor W (2020) Cellulose nanofibers from recycled and virgin wood pulp: a comparative study of fiber development. Carbohydr Polym 234:115900. https://doi.org/10.1016/j.carbpol.2020.115900

Borjesson MWG (2015) Crystalline nanocellulose - preparation,modification, and properties. In: Cellulose-fundamental aspects and current trends. pp 159–191

Boufi S, González I, Delgado-Aguilar M, et al (2017) Nanofibrillated cellulose as an additive in papermaking process. In: Cellulose-reinforced nanofibre composites: production, properties and applications. Elsevier Ltd, pp 153–173

Bradford M (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Buzala KP, Przybysz P, Kalinowska H, Derkowska M (2016) Effect of cellulases and xylanases on refining process and kraft pulp properties. PLoS ONE. https://doi.org/10.1371/journal.pone.0161575

Celzard A, Fierro V, Kerekes R (2009) Flocculation of cellulose fibres: new comparison of crowding factor with percolation and effective-medium theories. Cellulose 16:983–987. https://doi.org/10.1007/s10570-009-9314-0

Cui L, Meddeb-Mouelhi F, Laframboise F, Beauregard M (2015) Effect of commercial cellulases and refining on kraft pulp properties: correlations between treatment impacts and enzymatic activity components. Carbohydr Polym 115:193–199. https://doi.org/10.1016/j.carbpol.2014.08.076

Gharehkhani S, Sadeghinezhad E, Kazi SN et al (2015) Basic effects of pulp refining on fiber properties - a review. Carbohydr Polym 115:785–803. https://doi.org/10.1016/j.carbpol.2014.08.047

Gurnagul N, Page DH, Paice MG (1992) The effect of cellulose degradation on the strength of wood pulp fibres. Nord Pulp Pap Res J 7:152–154. https://doi.org/10.3183/npprj-1992-07-03-p152-154

Hellstrom, (2014) Fenton pre-treated microfibrillated cellulose evaluated as a strength enhancer in the middle ply of paperboard. Nord Pulp Pap Res J 29:732–740. https://doi.org/10.3183/npprj-2014-29-04-p732-740

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441. https://doi.org/10.1016/j.eurpolymj.2007.05.038

Jalak J, Kurašin M, Teugjas H, Väljamä P (2012) Endo-exo synergism in cellulose hydrolysis revisited. J Biol Chem 287:28802–28815. https://doi.org/10.1074/jbc.M112.381624

Jorfi M, Foster EJ (2015) Recent advances in nanocellulose for biomedical applications. J Appl Polym Sci 132:1–19. https://doi.org/10.1002/app.41719

Kim HJ, Jo BM, Lee SH (2006) Potential for energy saving in refining of cellulase-treated kraft pulp. J Ind Eng Chem 12:578–583

Liu X, Jiang Y, Song X et al (2019) A bio-mechanical process for cellulose nanofiber production – towards a greener and energy conservation solution. Carbohydr Polym 208:191–199. https://doi.org/10.1016/j.carbpol.2018.12.071

Niskanen K (2008) Paper physics, 2nd edn. Helsinki Paperi ja Puu Oy

Nissan AH (1976) H-Bond dissociation in hydrogen bond dominated solids. Macromolecules 9:840–850. https://doi.org/10.1021/ma60053a026

Oksanen T, Pere J, Buchert J, Viikari L (1997) The effect of Trichoderma reesei cellulases and hemicellulases on the paper technical properties of never-dried bleached kraft pulp. Cellulose 4:329–339. https://doi.org/10.1023/A:1018456411031

Puranen T, Alapuranen M, Vehmaanperä J (2014) Trichoderma enzymes for textile industries. In: Gupta VK, Schmoll M, Herrera-Estrella A et al (eds) Biotechnology and Biology of Trichoderma. Elsevier, pp 351–362

Seth RS (2003) The measurement and significance of fines. Pulp Pap Canada 104:41–44

Taipale T, Österberg M, Nykänen A et al (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020. https://doi.org/10.1007/s10570-010-9431-9

Tan Z (2001) Paper: Nondestructive Evaluation. In: Buschow KHJ, Cahn RW, Flemings MC, et al. (eds) Encyclopedia of Materials: Science and Technology. Elsevier, pp 1–5

TAPPI (2001a).T 248 sp-00 Laboratory beating of pulp (PFI Mill Method). Technology Park, Atlanta, GA, USA: technical Association of the pulp and paper industry (TAPPI) Press.

TAPPI (2002) Forming handsheets for physical tests of pulp. Test method TAPPI/ANSI T 205 sp-18. Tappi 1–9

Tian X, Lu P, Song X et al (2017) Enzyme-assisted mechanical production of microfibrillated cellulose from Northern Bleached Softwood Kraft pulp. Cellulose 24:3929–3942. https://doi.org/10.1007/s10570-017-1382-y

Tripathi S, Sharma N, Mishra OP et al (2008) Enzymatic refining of chemical pulp. IPPTA Q J Indian Pulp Pap Tech Assoc 20:129–132

Varanasi S, He R, Batchelor W (2013) Estimation of cellulose nanofibre aspect ratio from measurements of fibre suspension gel point. Cellulose 20:1885–1896. https://doi.org/10.1007/s10570-013-9972-9

Vršanská M, Biely P (1992) The cellobiohydrolase I from Trichoderma reesei QM 9414: action on cello-oligosaccharides. Carbohydr Res 227:19–27. https://doi.org/10.1016/0008-6215(92)85058-8

Wang S, Gao W, Chen K et al (2018) Deconstruction of cellulosic fibers to fibrils based on enzymatic pretreatment. Bioresour Technol 267:426–430. https://doi.org/10.1016/j.biortech.2018.07.067

Wang W, Mozuch MD, Sabo RC et al (2015) Production of cellulose nanofibrils from bleached eucalyptus fibers by hyperthermostable endoglucanase treatment and subsequent microfluidization. Cellulose 22:351–361. https://doi.org/10.1007/s10570-014-0465-2

Wigley MLT, Richels GR, Edmonds AJ (1996) Economic and environmental choices in the stabilization of atmospheric CO2 concentration. Nature 379:240–243

Wink WA, Watt JA, Whitsitt WJ, Baum GA (1984) Role of fiber axial modulus on compressive strength. Fibre Sci Technol 20:245–253. https://doi.org/10.1016/0015-0568(84)90045-9

Wood TM, Bhat KM (1988) Methods for measuring cellulase activities. Methods Enzymol 160:87–112. https://doi.org/10.1016/0076-6879(88)60109-1

Wu S, Ma X, Cao S et al (2020) Application of enzymes for the reduction of PFI revolutions in the secondary pulping process and characteristics of thermomechanical pulp. BioResources 15:7487–7502

Yuan Z, Wei W, Wen Y (2019) Improving the production of nanofibrillated cellulose from bamboo pulp by the combined cellulase and refining treatment. J Chem Technol Biotechnol 94:2178–2186. https://doi.org/10.1002/jctb.5998

Zheng X, Streimikiene D, Balezentis T et al (2019) A review of greenhouse gas emission profiles, dynamics, and climate change mitigation efforts across the key climate change players. J Clean Prod 234:1113–1133. https://doi.org/10.1016/j.jclepro.2019.06.140

Acknowledgments

Funding from the Australian Research Council-Industry Transformation Research Hub Processing Advanced Lignocellulosics (PALS) [grant number IH170100020] is gratefully acknowledged. Many thanks to Australian Paper Maryvale Mill for providing the Bleached Eucalypt Kraft pulp and especially to Opal Ltd. for the continuous support of the project. We thank Rafik Faltas and Thilina Gunawardhana for their assistance and for allowing access to the Opal R&D Centre.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. The research leading to these results received funding from the Australian Research Council under grant number IH170100020. The authors have no financial or proprietary interests in any material discussed in this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sharma, R., Garnier, G. & Haritos, V. A study of different actions of glucanases to modulate microfibrillated cellulose properties. Cellulose 29, 2323–2332 (2022). https://doi.org/10.1007/s10570-022-04451-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04451-7